Bearing assembling tool for mounting bearing in shaft sleeve part

A bearing assembly and shaft sleeve technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as easy collapse and flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

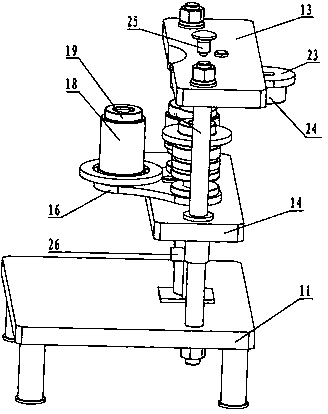

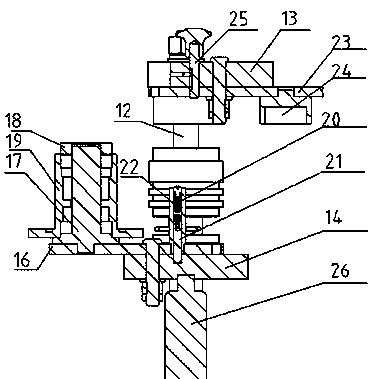

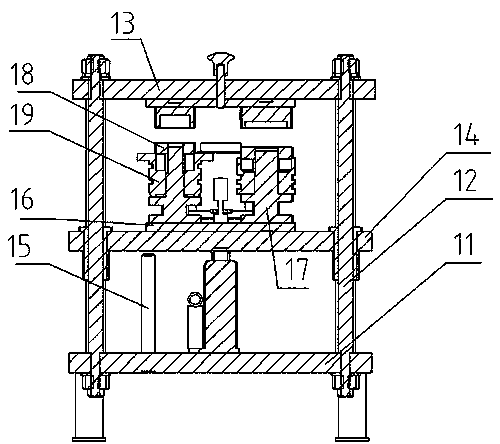

[0025] Embodiments of bearing assembly tooling for installing bearings into bushing parts, such as Figure 1-5 As shown, the bearing assembly tool for installing bearings in the sleeve parts includes a mounting frame 11, a guide column 12, an anvil plate 13 and a pressure plate 14 arranged at intervals up and down. In this embodiment, the mounting frame 11 includes a base, and guides Column 12 is vertically installed on the base, anvil 13 is positioned at pressing plate 14 and is fixedly assembled on the upper end of guide column 12, and pressing plate 14 is guided and assembled on guide column 12 by guide sleeve.

[0026] The base is provided with a telescopic pushing device and a limit post 15. In this embodiment, what the pushing device adopts is a hydraulic jack 26, and the pressing plate 14 can be pressed upwards by the pushing device, and the stop post 15 is used to limit The lowest position of the pressing plate 14, so that there is enough space to place the pushing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com