Device and method for measuring gas phase temperature of a cigarette combustion cone

A gas-phase temperature, measuring device technology, applied in measuring devices, measuring heat, thermometers, etc., can solve the problems of small number of channels, increased operation steps and workload, inconvenient operation, etc., to improve the level of automation, reduce operation steps and The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

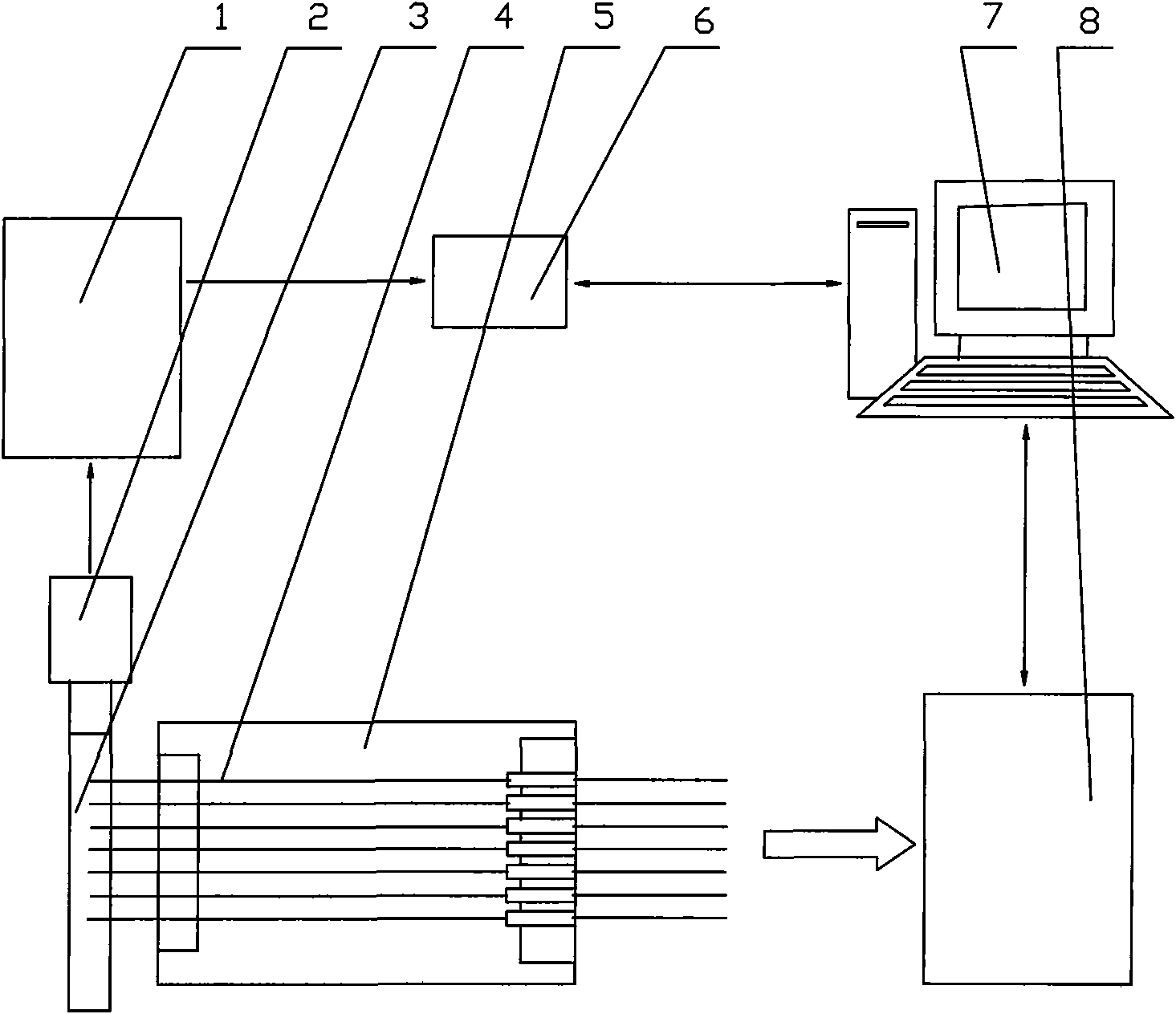

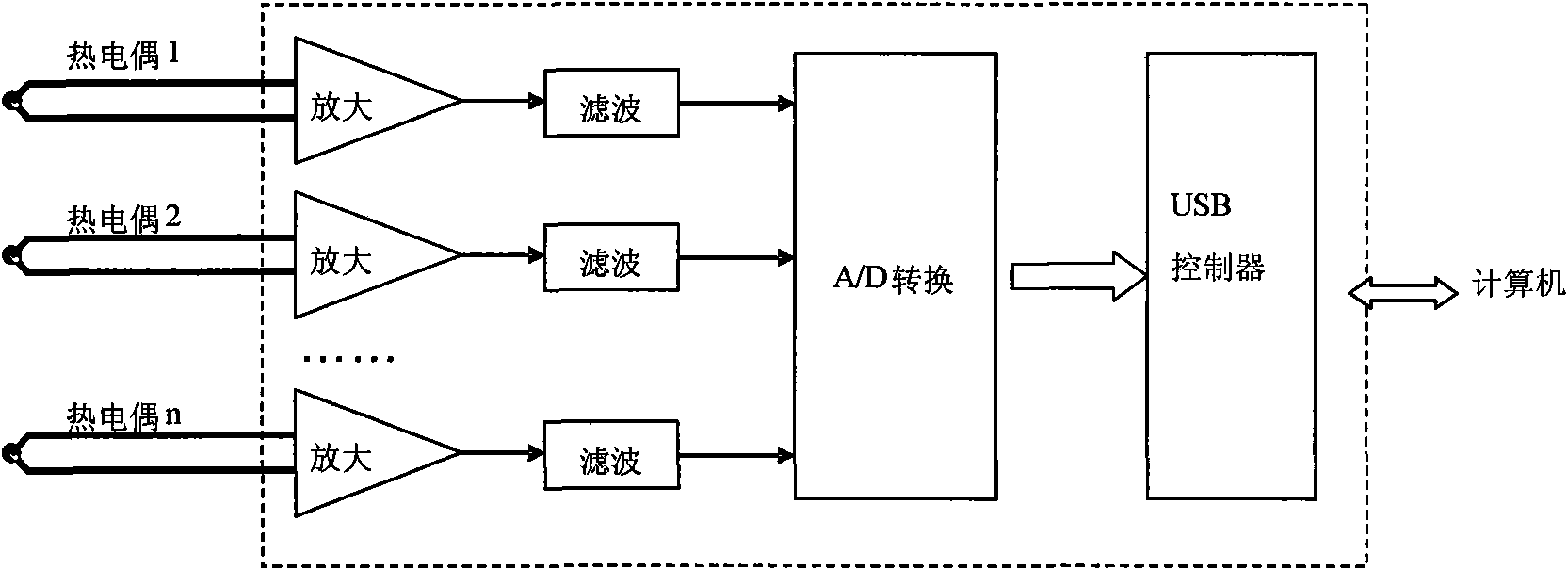

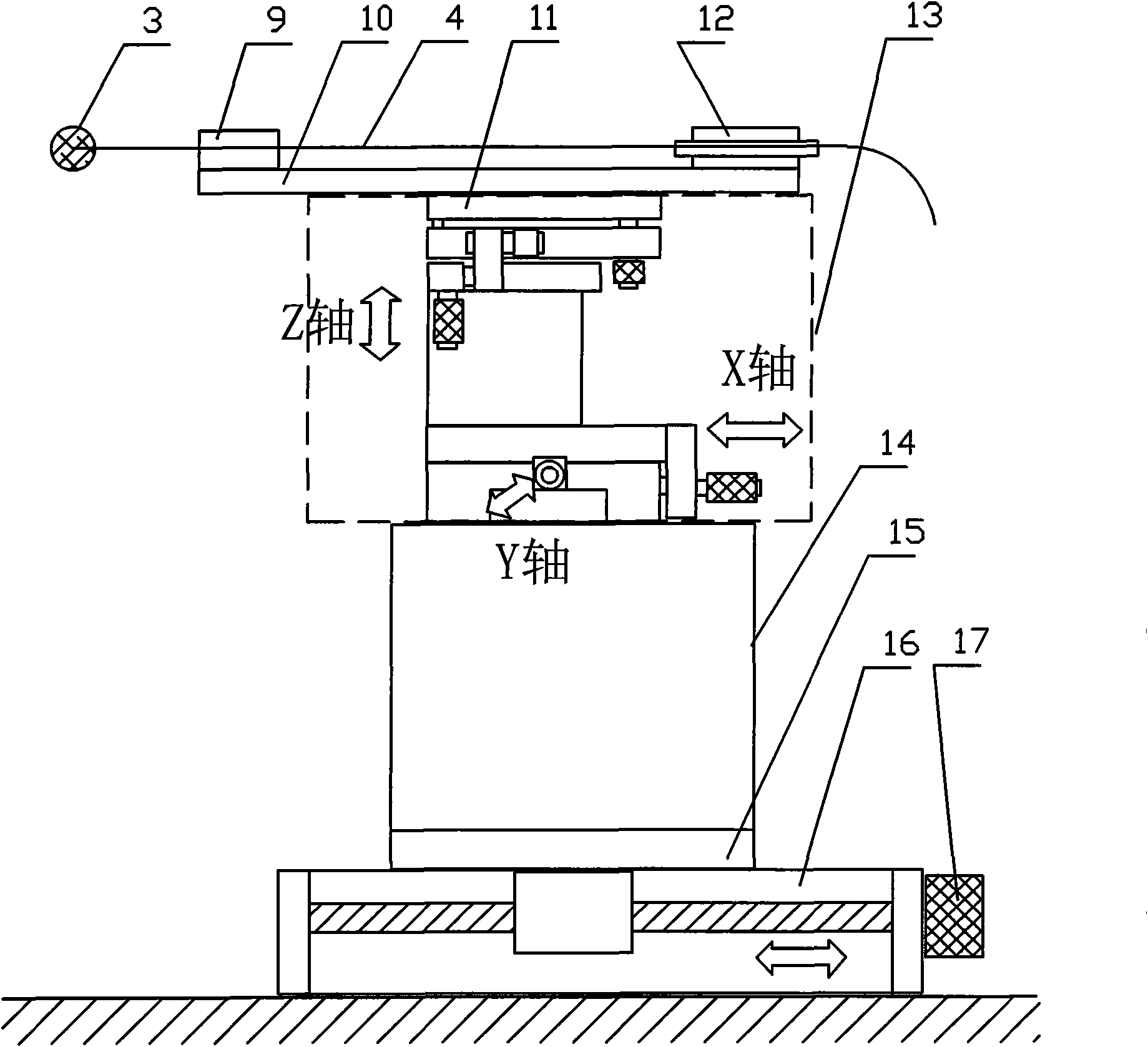

[0044] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 Shown is a general structural schematic diagram of a cigarette combustion cone gas phase temperature testing device. The device consists of a smoking machine 1, a thermocouple temperature measurement system 5, a synchronous trigger device 6, a data acquisition card 8 and a computer control system 7. The filter end of the cigarette 3 is plugged into the joint 2 of the smoking machine 1 , the output end of the smoking machine 1 is connected to the input end of the synchronous trigger device 6 , and the output end of the synchronous trigger device 6 is connected to the computer control system 7 . A group of N thermocouples 4 are inserted in parallel to the shredded tobacco part of the cigarette 3, the output end of the thermocouple temperature measuring system 5 is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com