Vacuum packaging structure, packaging method thereof, and vacuum packaging device

A vacuum packaging and vacuum cavity technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of large size, uneven temperature distribution of chip substrates, affecting performance, etc., to achieve good temperature uniformity and ensure performance. , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation of the vacuum packaging structure, packaging method, and vacuum packaging device provided by the present invention will be described in detail below with reference to the accompanying drawings.

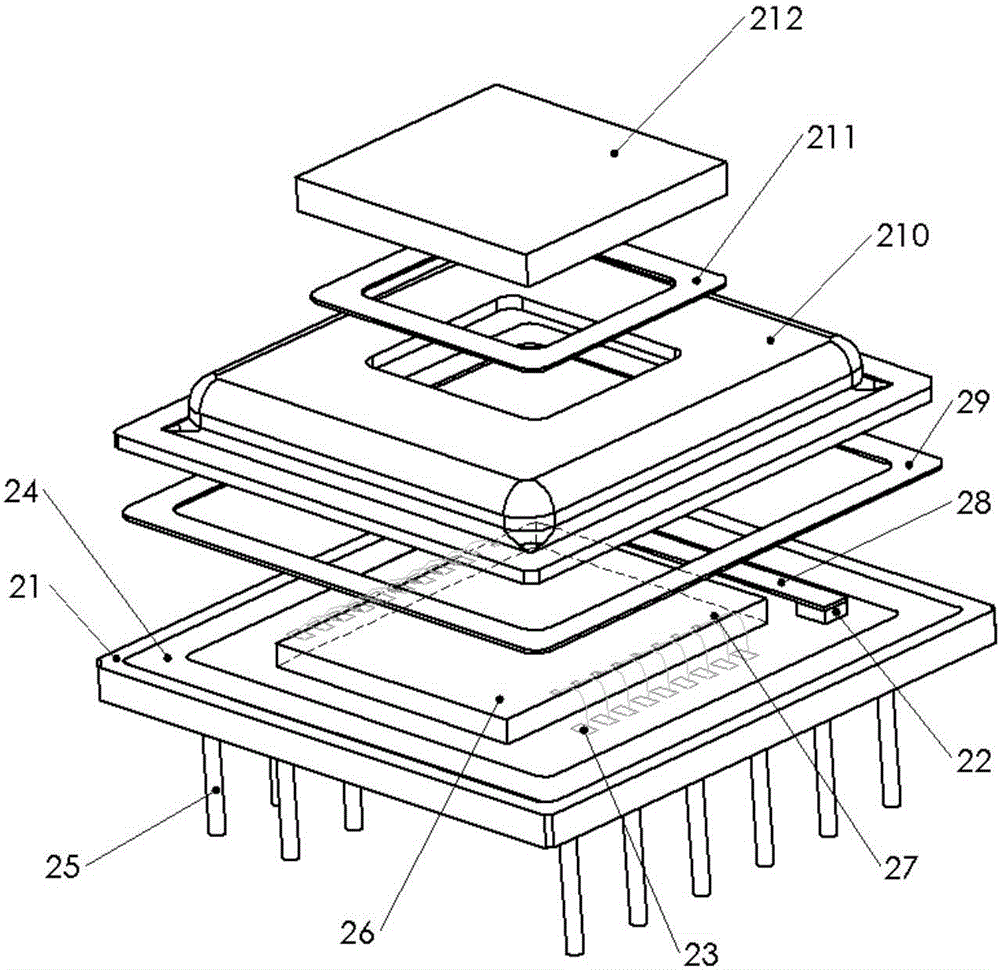

[0043] Please refer to figure 2 , the vacuum packaging structure is a vacuum packaging structure of an infrared detector chip, specifically comprising: a base 21 , a cap 210 , an infrared filter 212 , an infrared detector chip 26 and a getter layer 28 .

[0044] The material of the base 21 is ceramic, and the bottom of the base 21 may also be welded with metal pins 25 as electrical connection pins. The welding area 24 on the surface of the base 21 is plated with gold to form a firm weld with the cap 210 , and the thickness of the gold plating is greater than or equal to 0.8 microns.

[0045] The material of the cap 210 is Kovar. In other specific embodiments of the present invention, the material of the cap 210 can also be other metal materials wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com