Semiconductor device and producing method thereof

A technology of electronic devices and electronic components, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., to achieve the effects of enhancing heat radiation characteristics, shortening the distance, and preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

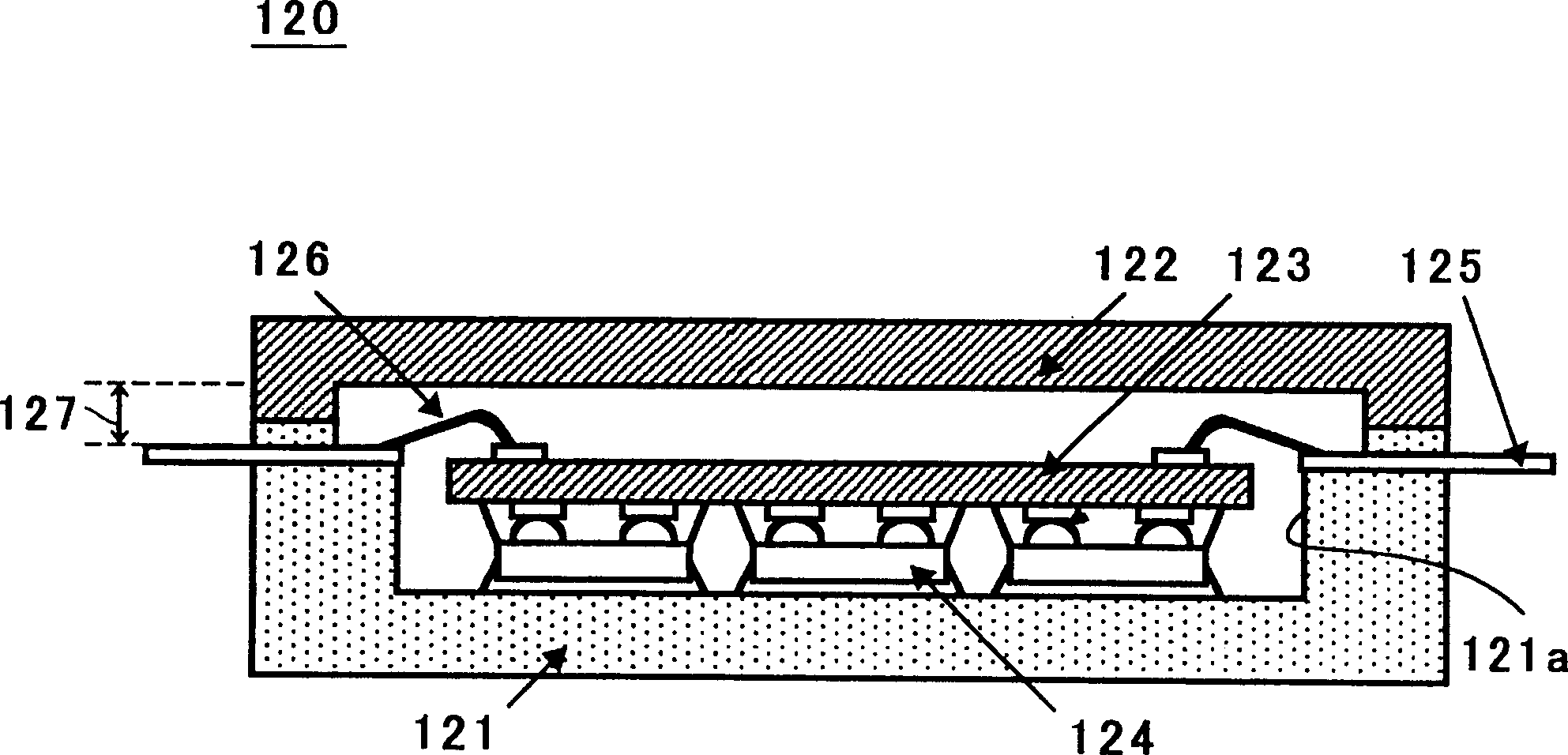

[0082] Figure 5 is a cross-sectional view of the electronic device 20 according to the second embodiment.

[0083] In the electronic device 10 according to the first embodiment, the high-frequency IC 14 is electrically connected to the electrode 12c through the bonding wire 17. In contrast, in the second embodiment, the high frequency IC 14 is electrically connected to the cover type wiring substrate 12 in a contact chip connection manner.

[0084] The structure of the electronic device 20 according to the second embodiment is the same as that of the electronic device 10 according to the first embodiment except that the high-frequency IC 14 is electrically connected to the cover type wiring substrate 12 by contact chip connection.

[0085] In the electronic device 20, on the upper surface of the high-frequency IC 14, it is electrically connected to the cover type wiring substrate 12 in the form of a contact chip. Thus, if Figure 5 As shown, the high frequency IC 14 can be...

no. 1 example

[0095] Similar to the first embodiment, by directly coupling the lead frame 11 and the cover type wiring substrate 12 together, the length of the wire can be shortened as a result.

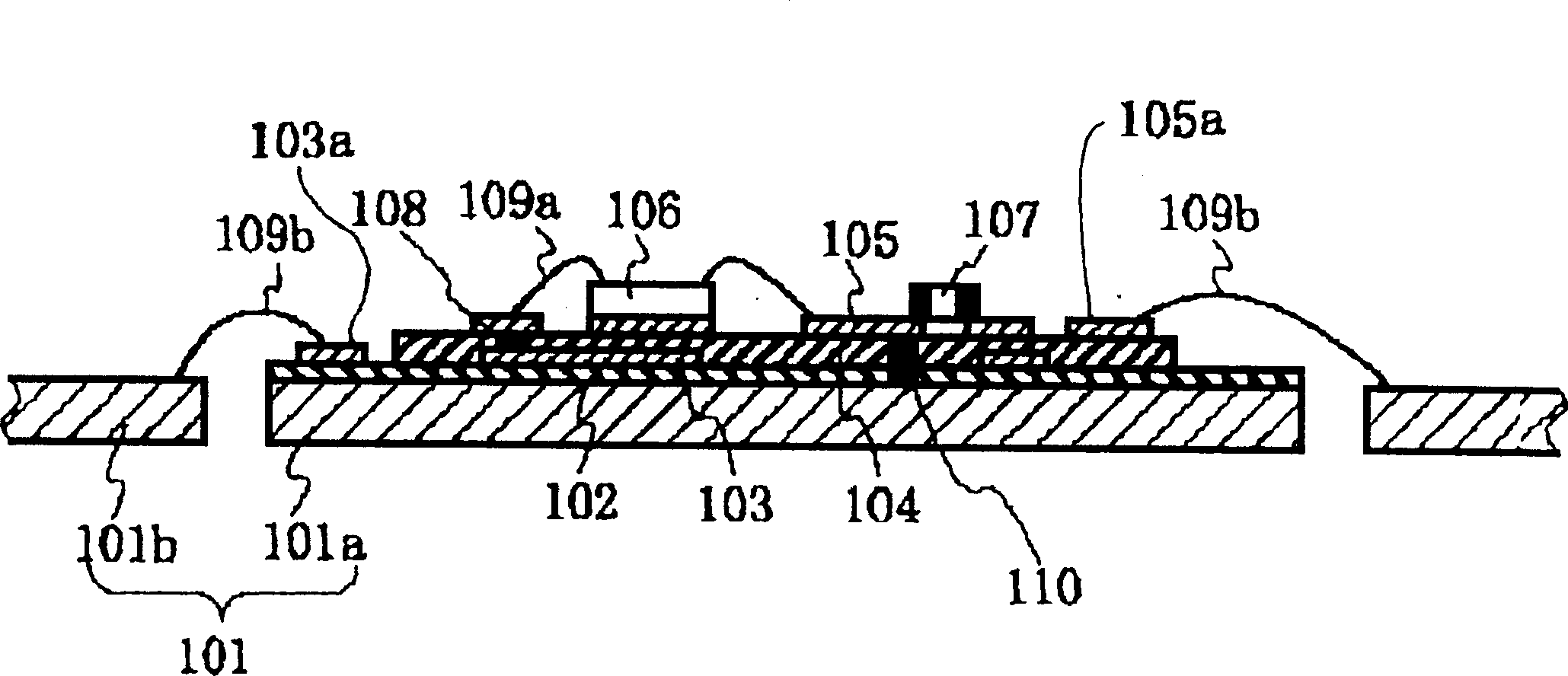

[0096] Such as image 3 As shown, in the electronic device 10 according to the first embodiment, the high-frequency IC 14 is electrically connected to the cover type wiring substrate 12 through the bonding wire 17 . In contrast, in the electronic device 20 according to the second embodiment, the high frequency IC 14 is electrically connected to the cover type wiring substrate 12 in a contact chip connection manner. Therefore, compared with the electronic device 10 according to the first embodiment, it is possible to further shorten the length of the wire, and suppress delay of signals and electromagnetic noise, both of which are proportional to the length of the wire.

[0097] A fifth advantage is that it is possible to enhance the heat radiation characteristics of the electronic device 20 .

[0...

no. 3 example

[0100] Image 6 is a cross-sectional view of the electronic device 30 according to the third embodiment.

[0101] In the electronic device 30 according to the third embodiment, three high-frequency ICs 14 are mounted on a cover type wiring substrate 12, and a lead frame 11 is formed on one surface on which three high-frequency ICs 14 are arranged, etc. Three grooves 15 are formed. Each groove 15 is associated with a high frequency IC 14 .

[0102] The electronic device 30 according to the third embodiment has the same structure as the electronic device 20 according to the second embodiment except that the electronic device 30 includes three high-frequency ICs 14 and three grooves 15 .

[0103] In addition to including the steps of simultaneously coupling three high-frequency ICs 14 with the covering type wiring substrate 12 in the form of contact chips in the method of manufacturing the electronic device 30, and simultaneously generating three depressions on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com