Connection device for a plastic tube

A connection device, plastic pipe technology, applied in the direction of hose connection device, pipe connection arrangement, pipe/pipe joint/pipe fitting, etc., can no longer ensure the holding claw pressing force, damage the elastic function of the support ring, installation cost and other problems, to achieve the effect of eliminating wrong installation, reducing clamping tendency, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

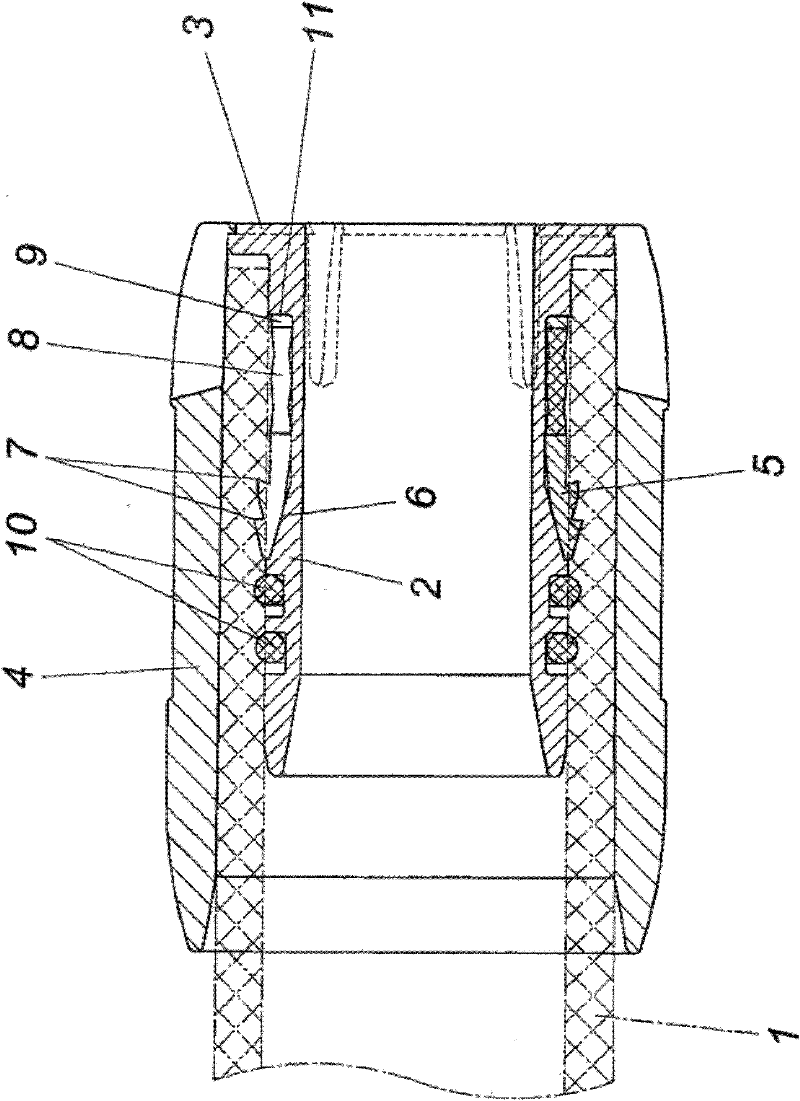

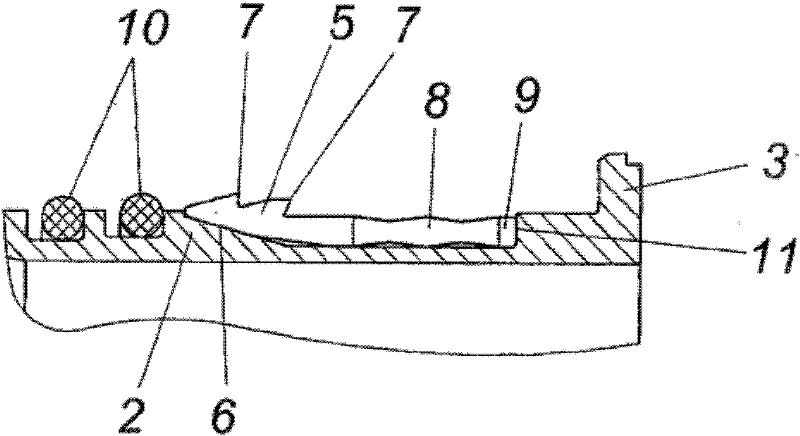

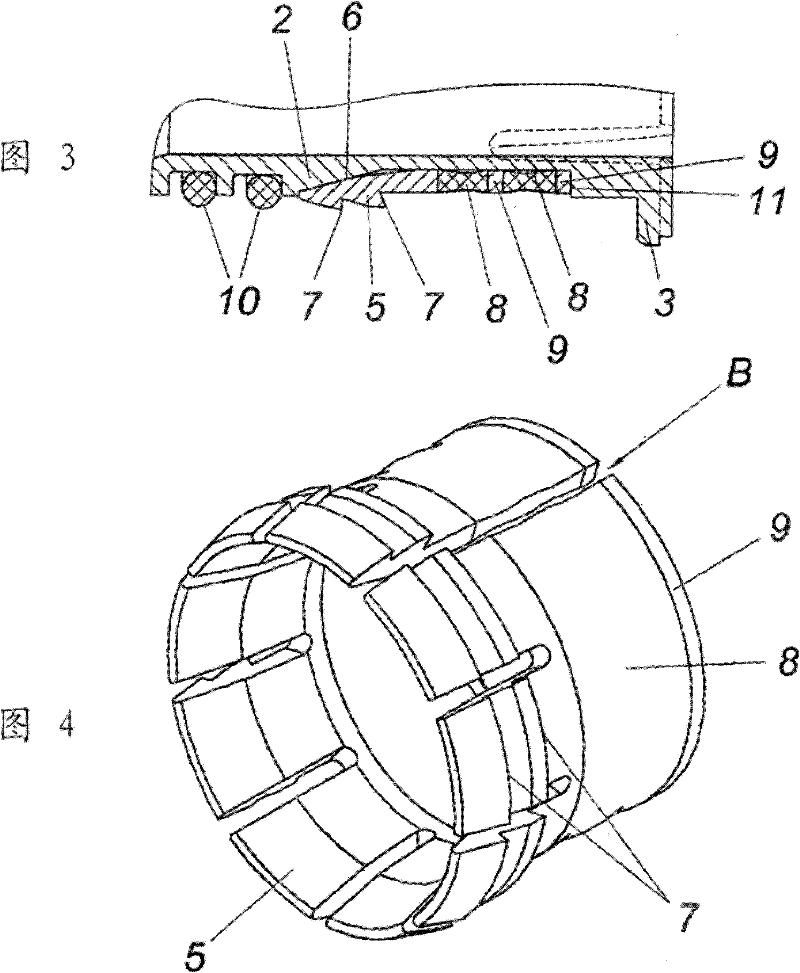

[0016] according to figure 1 , The connecting device for the plastic pipe 1 shown in dashed lines has a connecting joint 2 for receiving the plastic pipe 1 with a stop flange 3, and a sleeve 4 surrounding the plastic pipe 1 acts on the stop in a shear-resistant manner. Stop the flange.

[0017] In order to clamp the plastic tube 1 between the connection joint 2 and the sleeve 4, an expansion ring 5 is supported on the connection joint 2, and the expansion ring interacts with the outer cone 6 of the connection joint 2. The device is designed in such a way that the expansion ring 5 formed on the retaining pawl 7 protruding radially toward the outside of the plastic tube 1 is elastically supported on the stop 11 of the connection joint 2 via the elastic spring washer 8 and the support ring 9. The expansion ring 5, the spring washer 8 and the support ring 9 form a structural unit composed of several individual parts combined in a shear-resistant manner.

[0018] If the plastic tube 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com