Patents

Literature

158results about How to "Increase sliding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

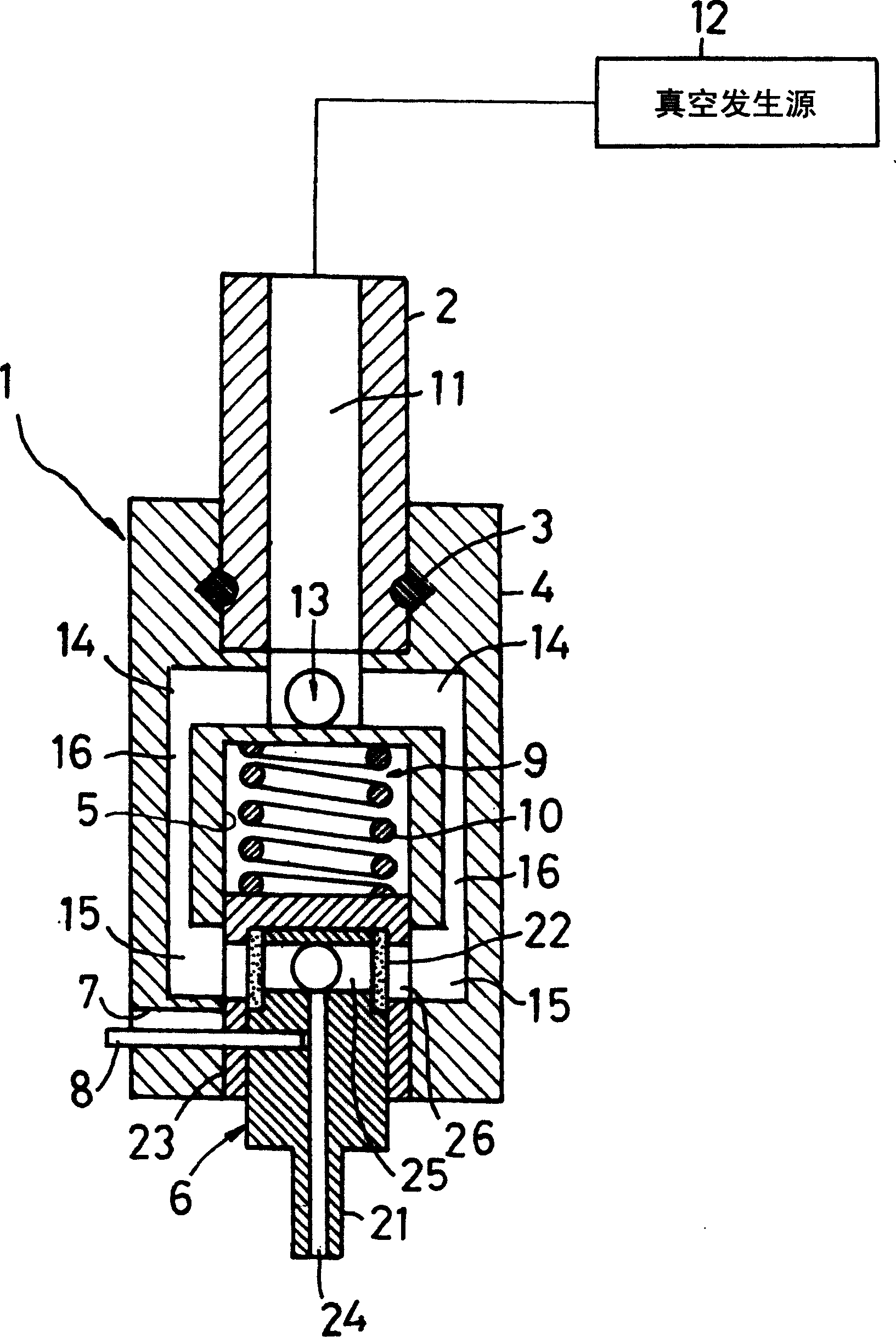

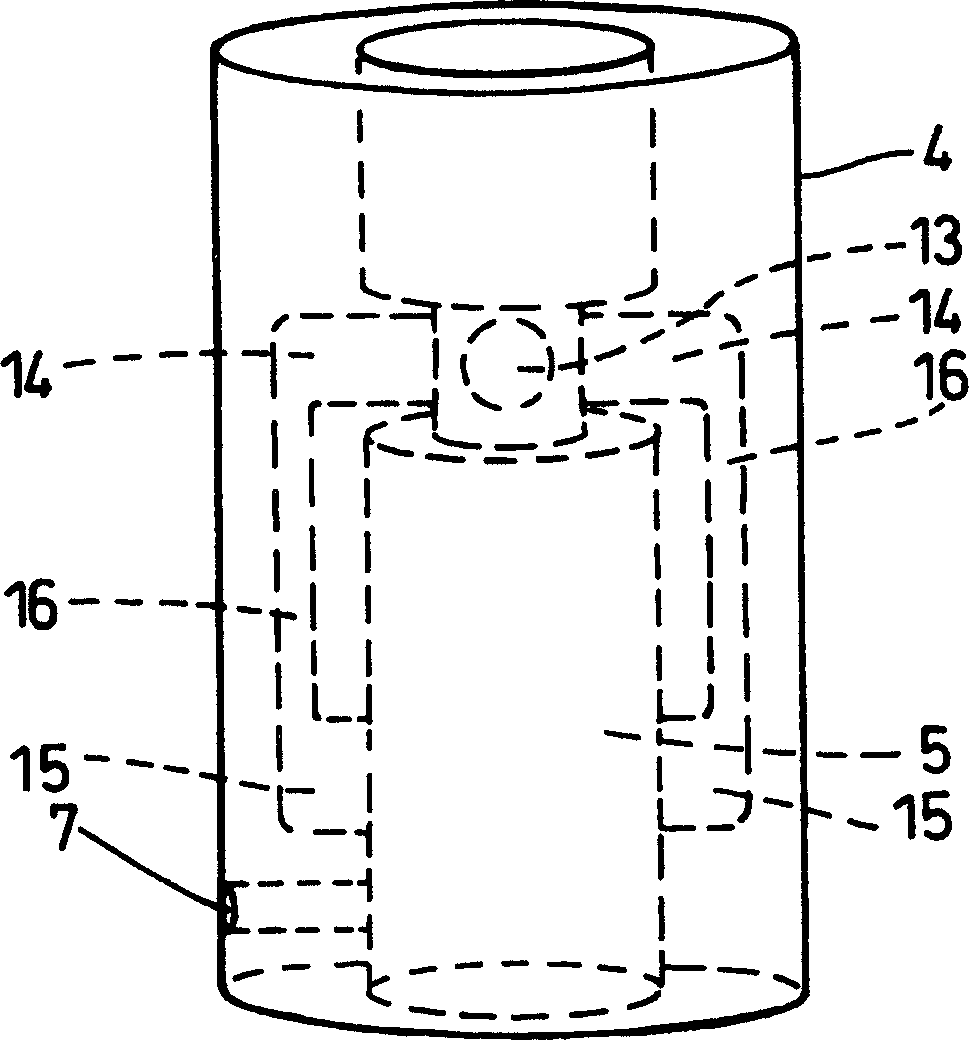

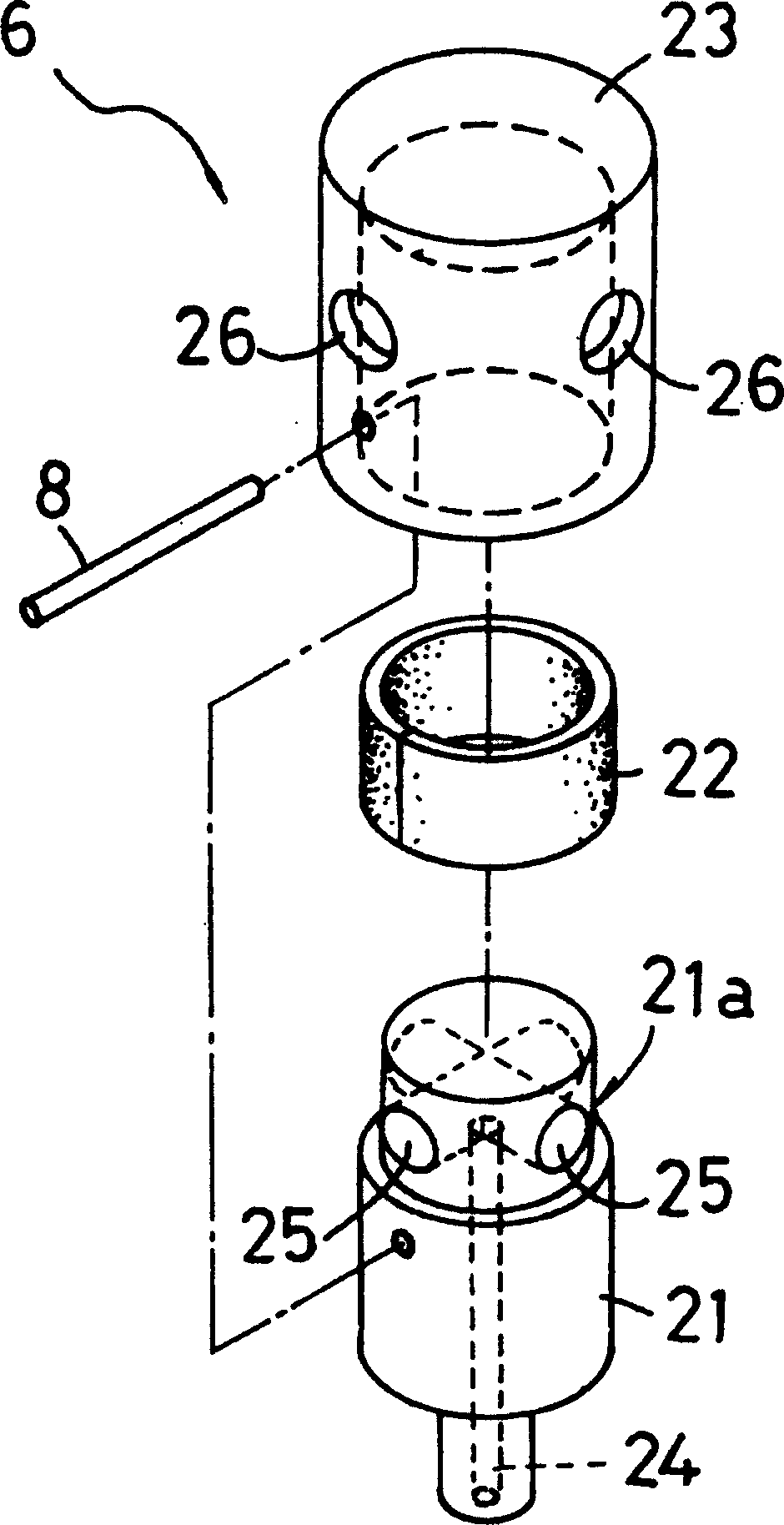

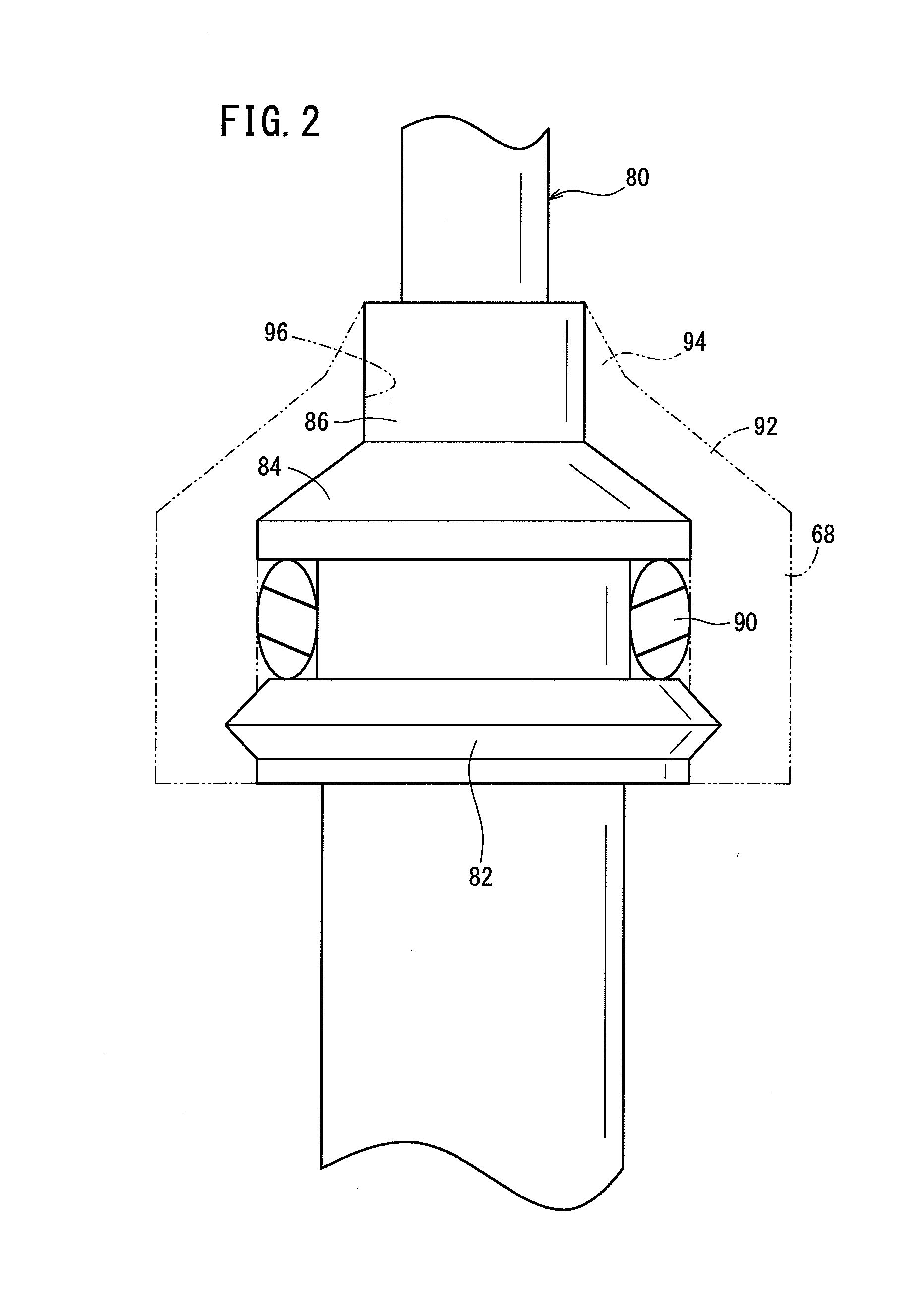

Adsorbing nozzle and mounting device of part using the same

InactiveCN1533968AIncrease sliding resistanceReduced bufferingElectrical componentsConveyor partsEngineeringNozzle

An adsorption mouth and its installation mechanism are disclosed. A front mouth is inserted in the hole formed on lower end of mouth sleeve. A spring is installed in said hole behind said front mouth to allow the front mouth to move downward. The adsorption hole formed on front mouth is communicated to vacuum source via air channel. A filter of external air is arranged behind said front mouth. It can perform adsorption operation while removing dust.

Owner:MURATA MFG CO LTD

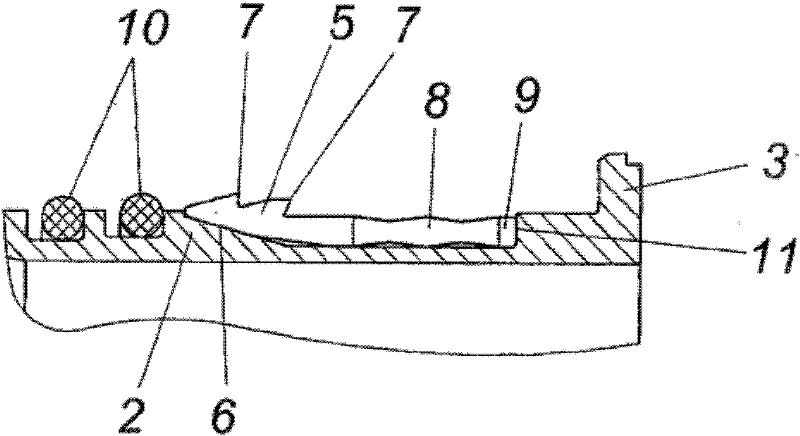

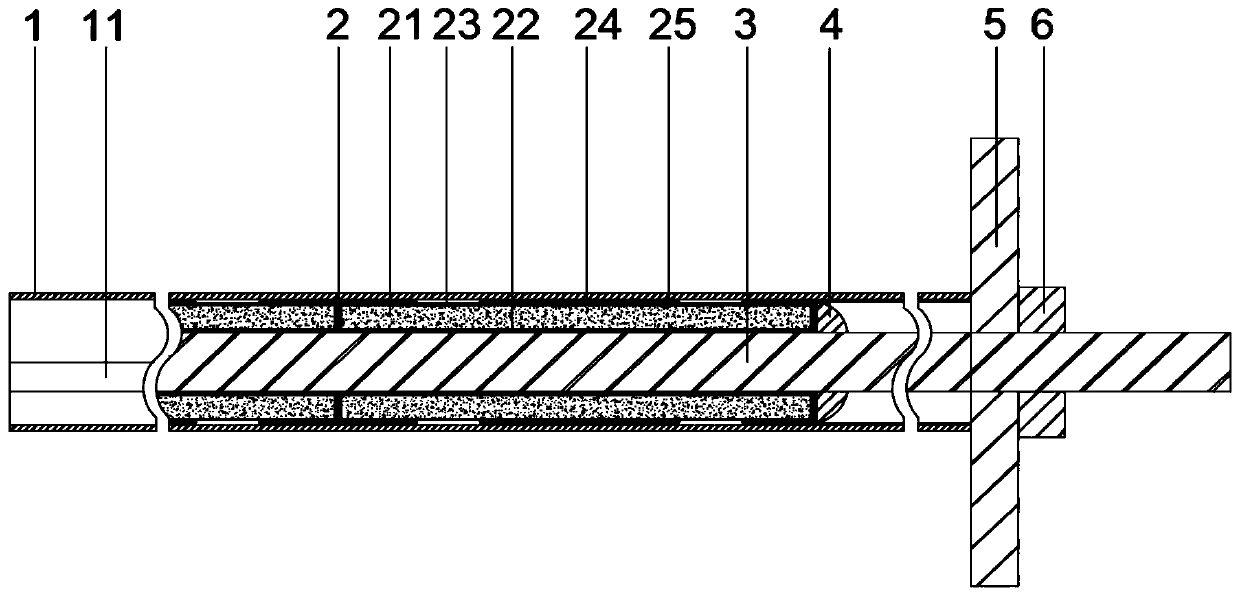

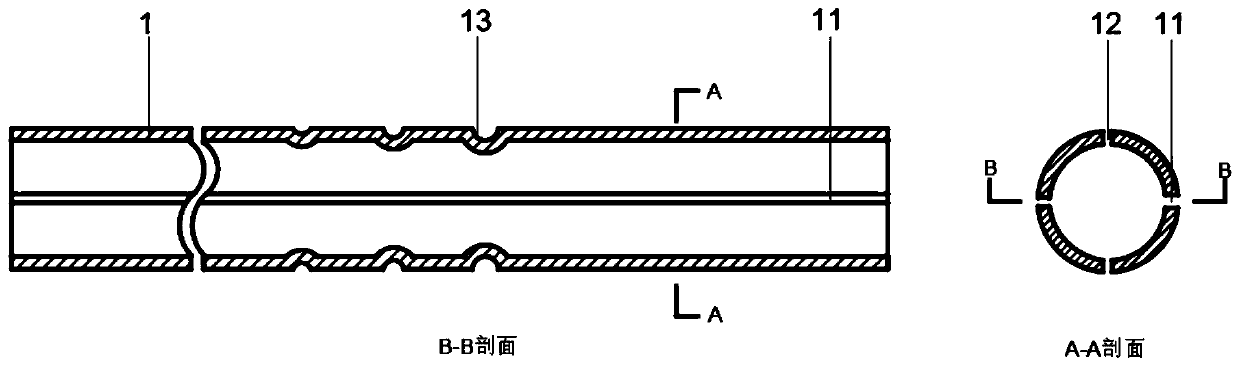

Connection device for a plastic tube

ActiveCN102472422AReduced clamping tendencyEasy to installCouplingsHose connectionsEngineeringAbutment

The invention relates to a connection device for a plastic tube (1), comprising a connection nipple (2) that receives the plastic tube (1) and forms an outer cone (6) widening towards the free nipple end. An expansion ring (5) that can be slid over the outer cone (6) and comprises outwardly protruding retaining claws (7) is provided between the outer cone and an axial abutment (11), said expansion ring being supported on the axial abutment (11) of the connection nipple (2) by means of a supporting ring (9). Said device also comprises a sleeve (4) surrounding the plastic tube (1) that has been pushed onto the connection nipple (3) and gripping in a traction-resistant manner onto an abutment flange (3) of the connection nipple. In order to create advantageous assembly conditions, a rubber-elastic spring ring (8) is arranged between the expansion ring (5) and the supporting ring (9). The expansion ring (5), the supporting ring (10) and the spring ring (8) are interconnected in a shear-resistant manner.

Owner:KE KELIT KUNSTSTOFFWERK GMBH

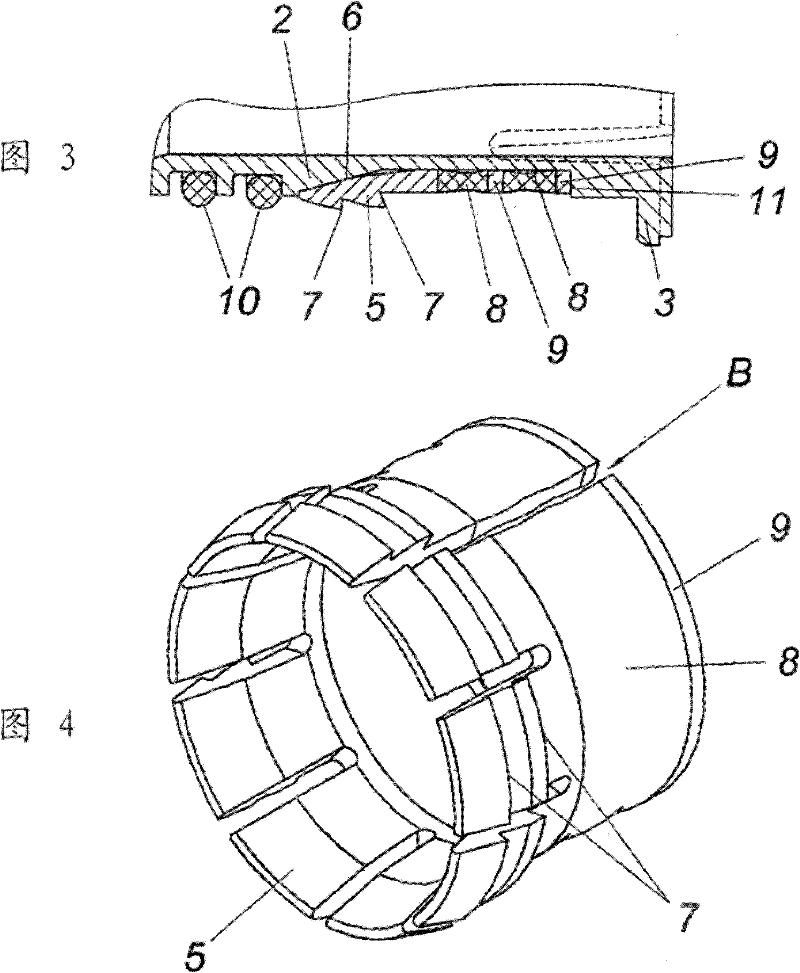

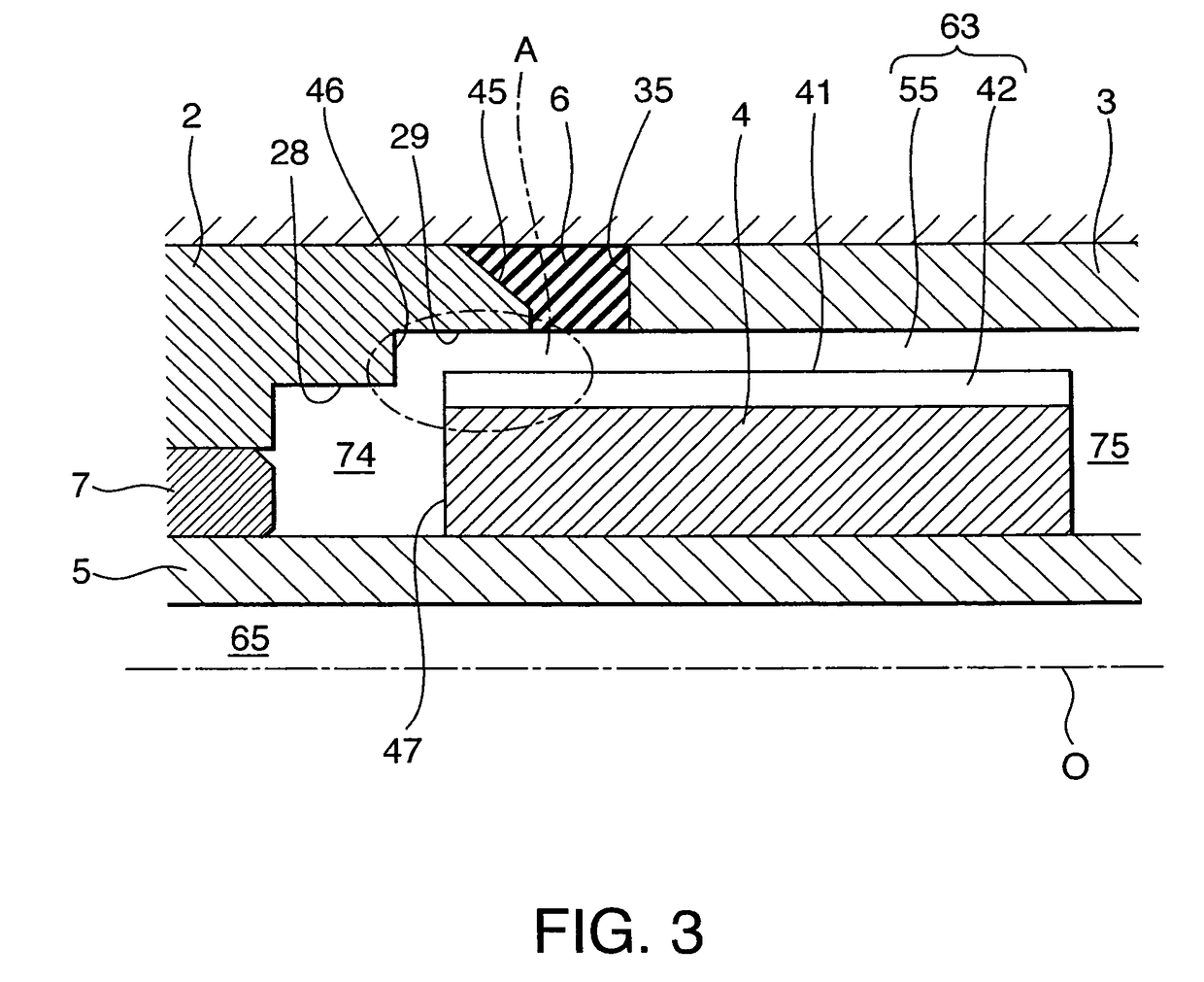

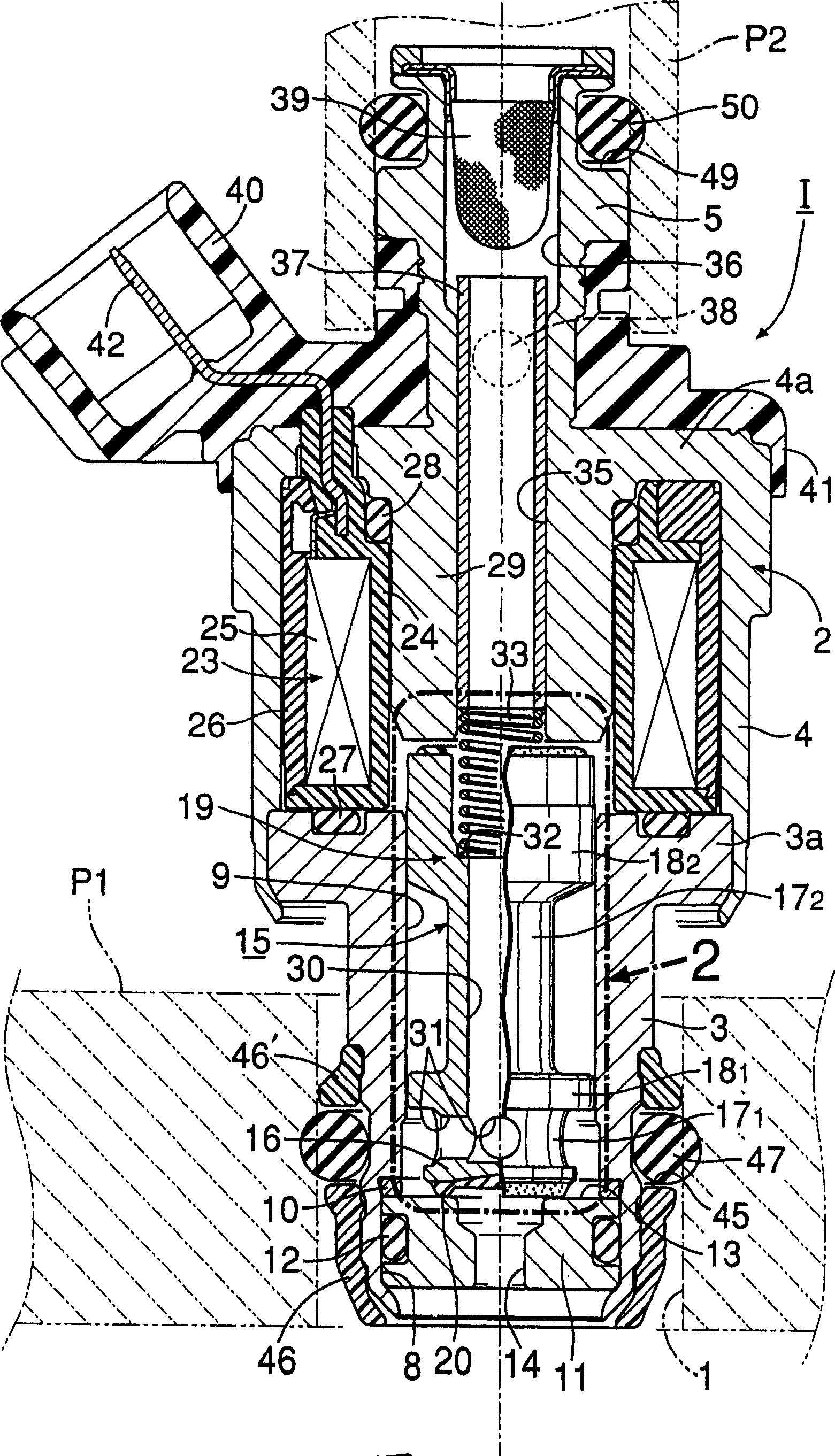

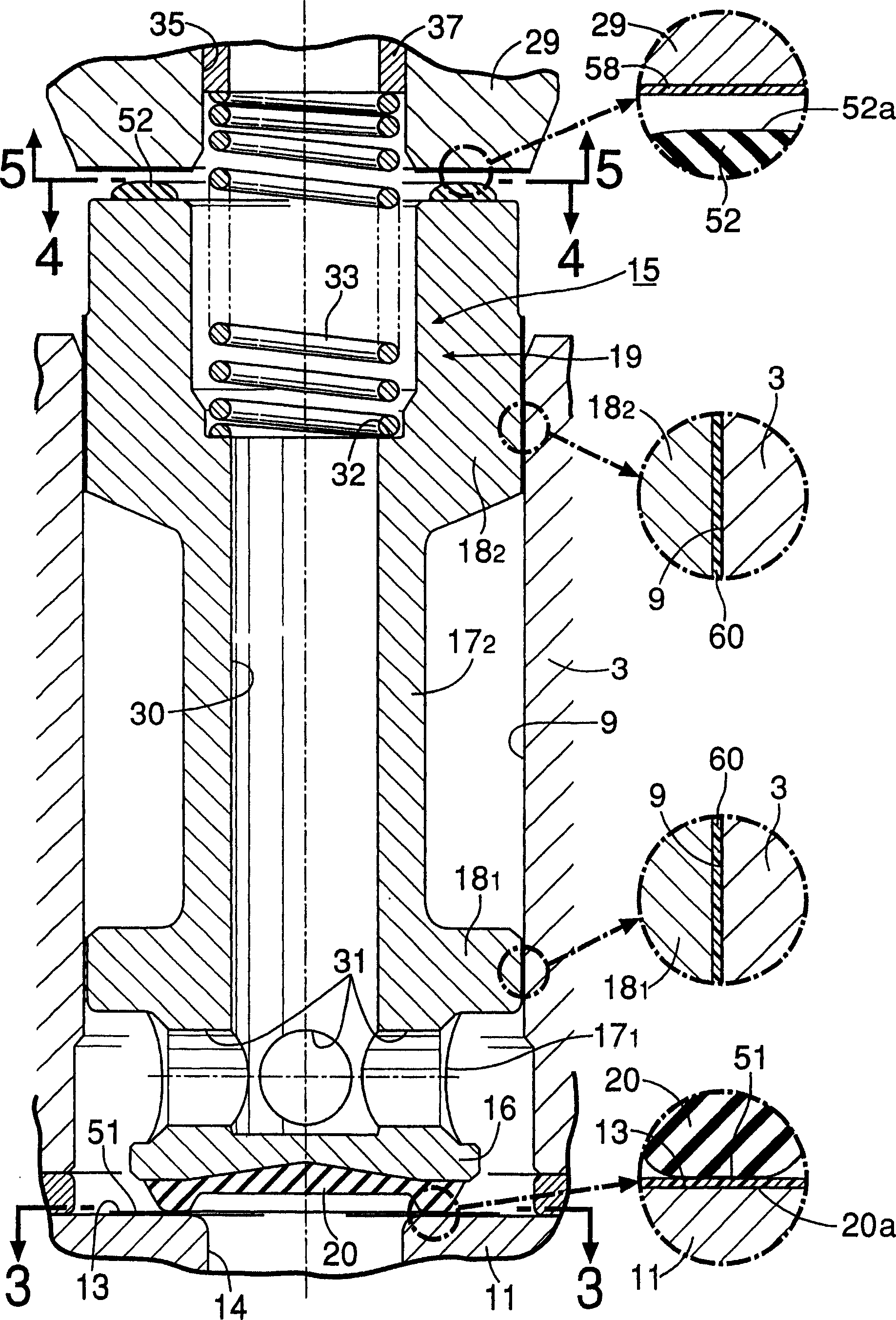

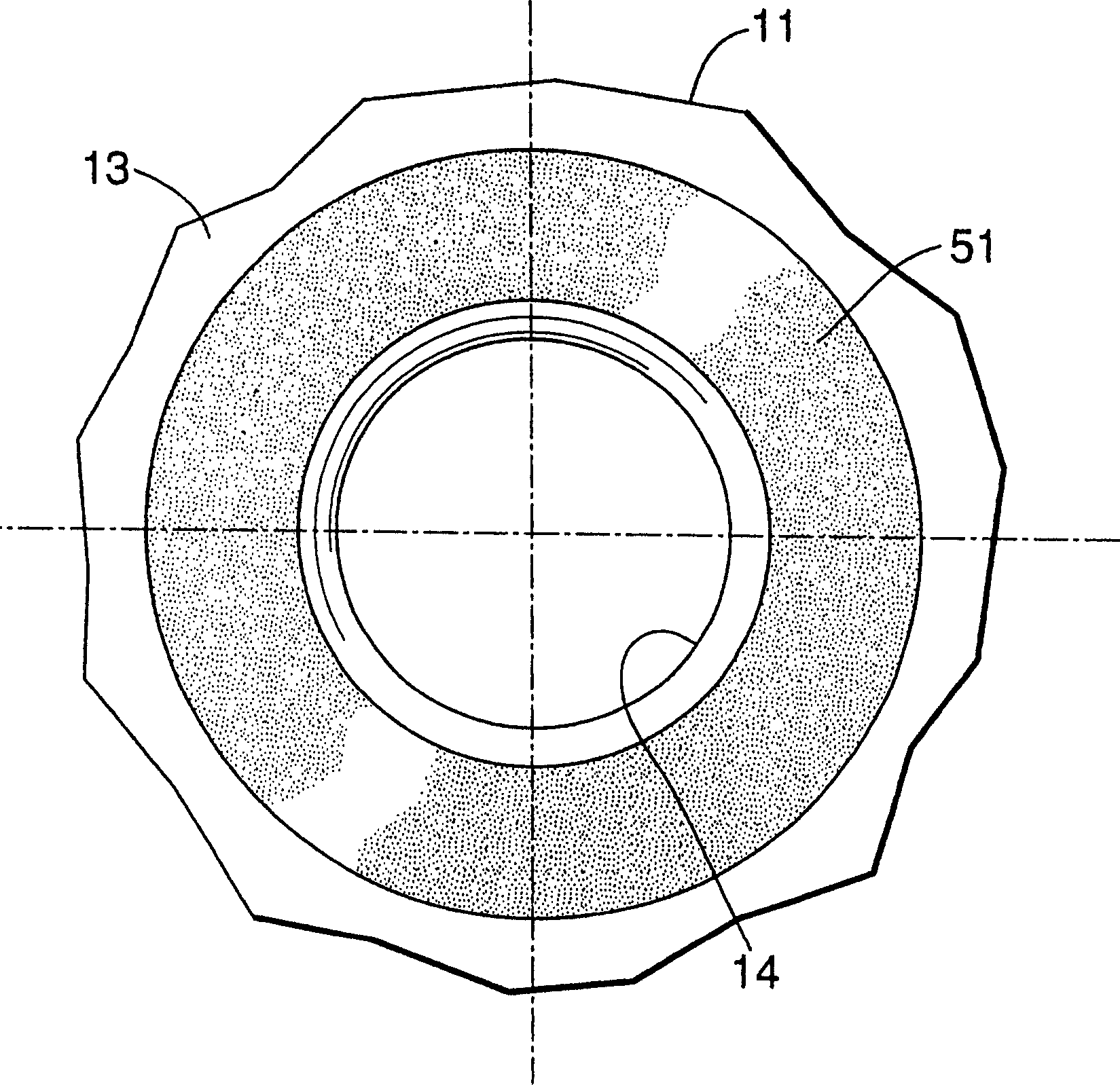

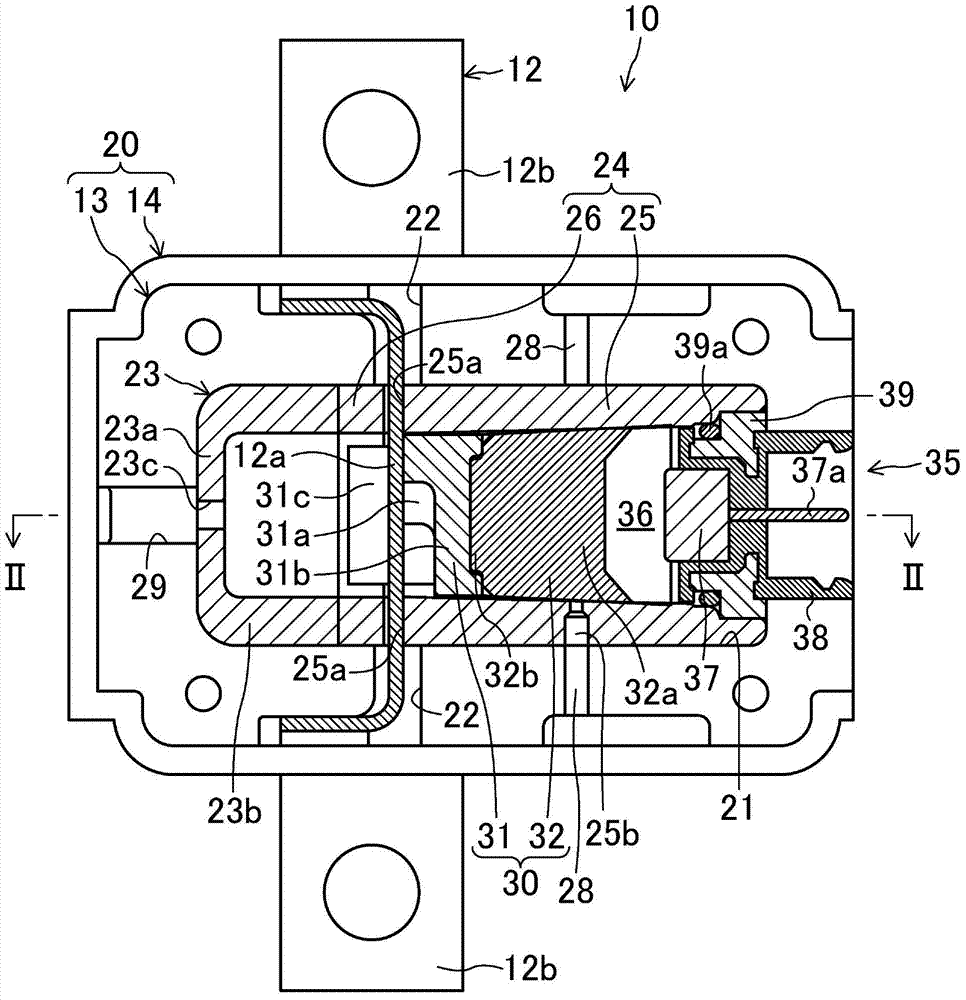

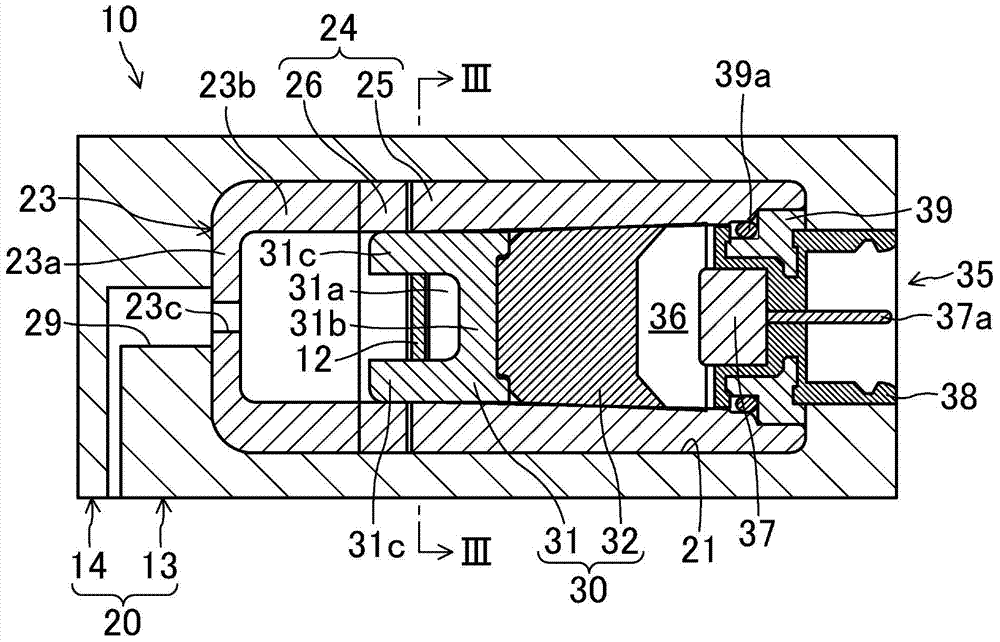

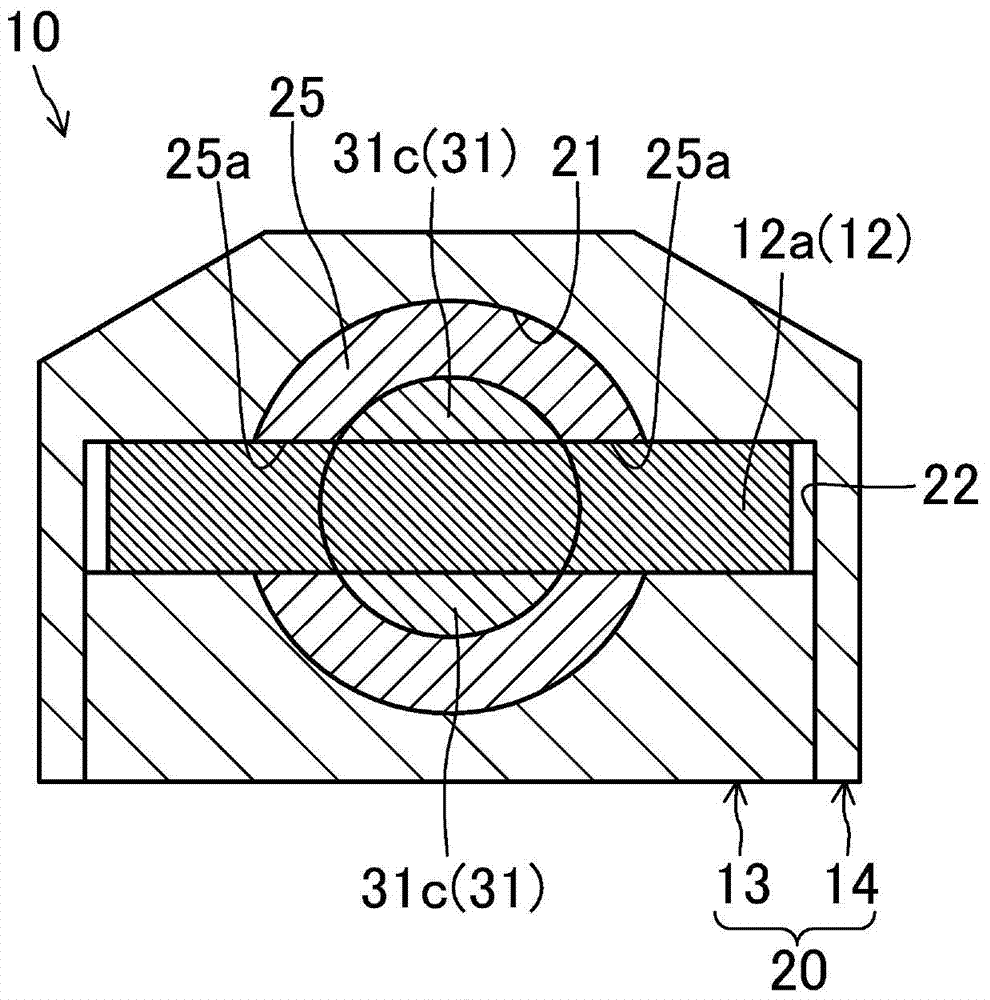

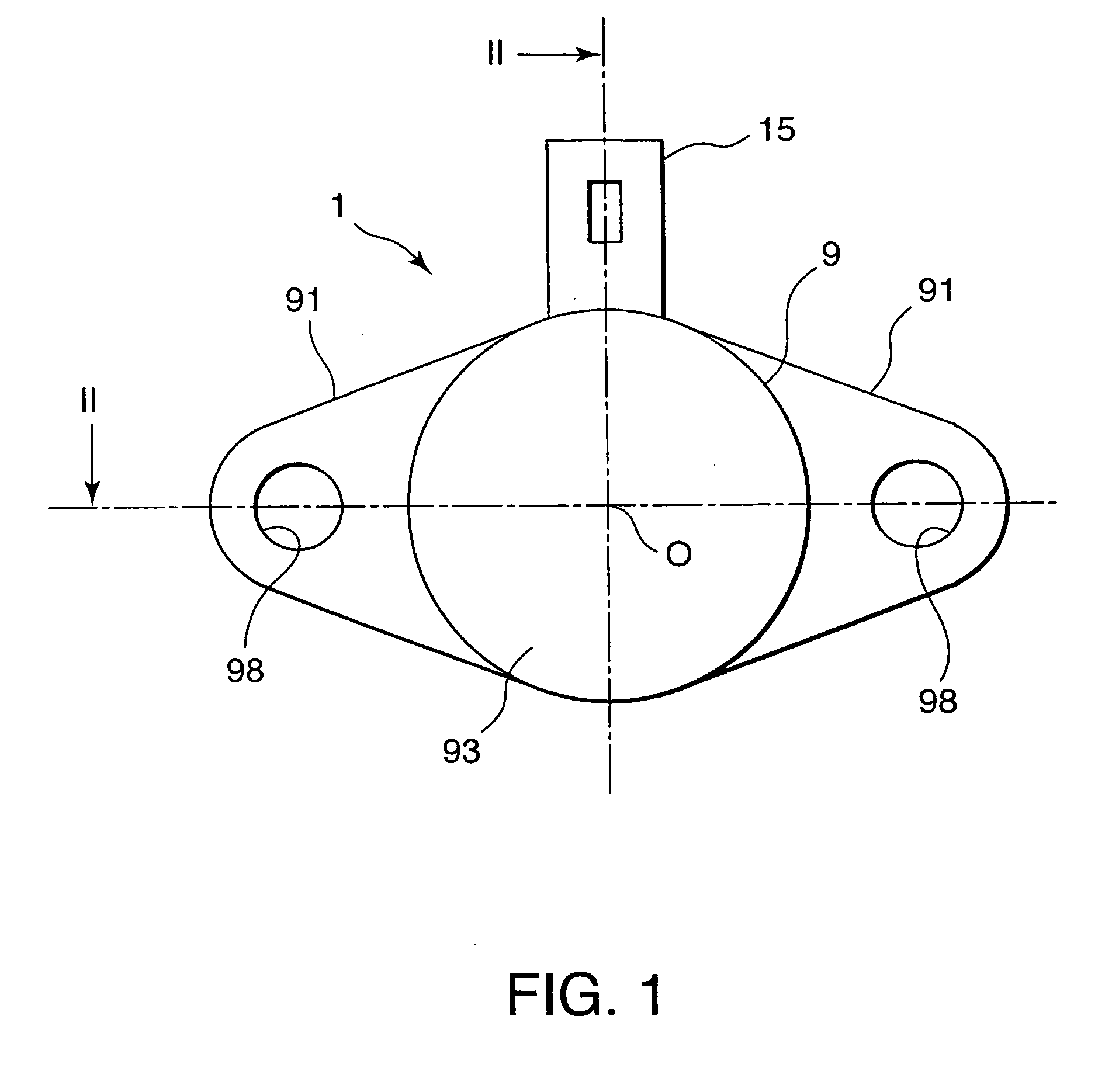

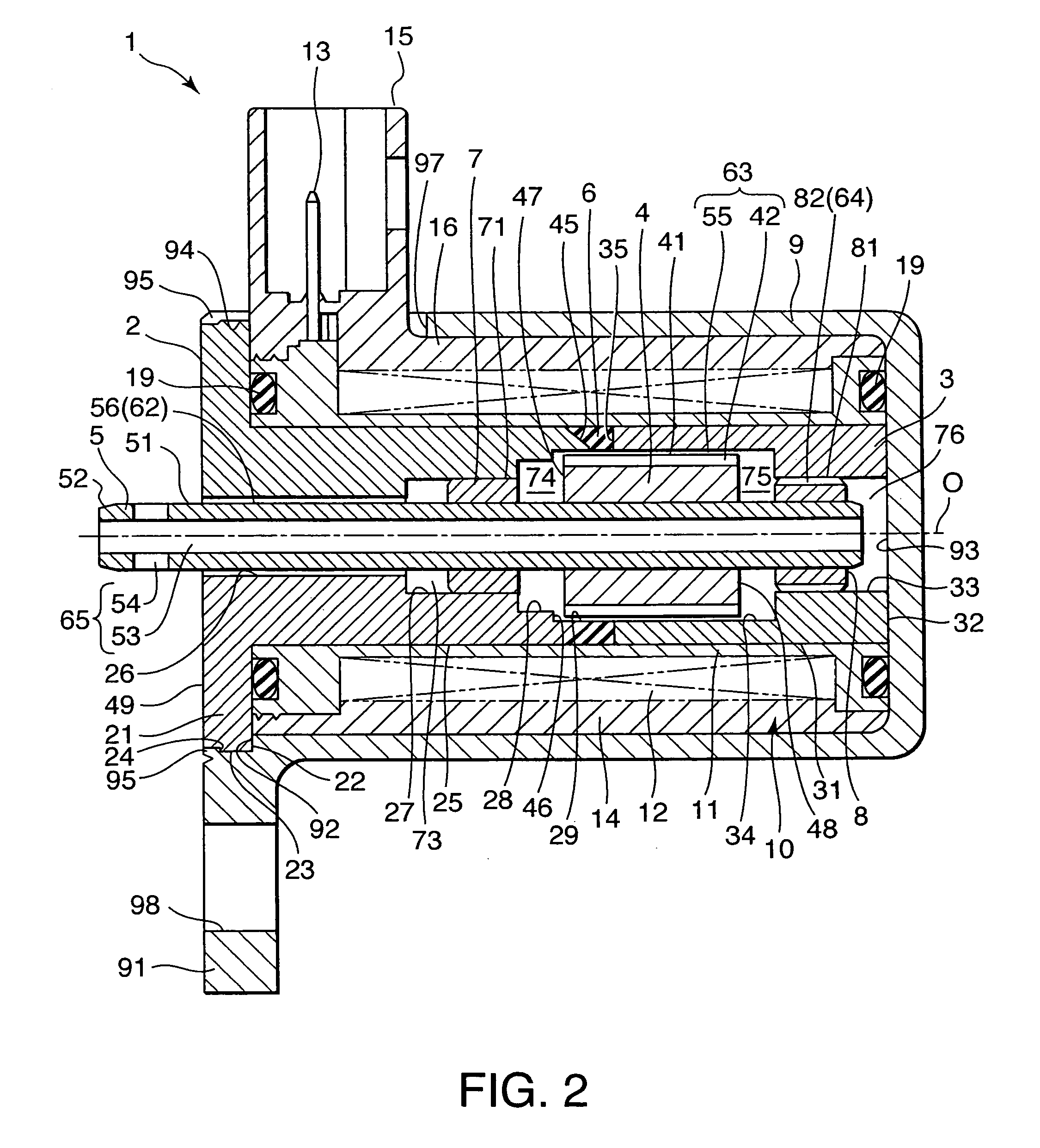

Solenoid actuator

InactiveUS8469334B2Increase sliding resistanceOperating means/releasing devices for valvesPiston pumpsEngineeringHydraulic equipment

A solenoid actuator (1) attached to hydraulic equipment comprises a shaft (5) connected to the hydraulic equipment, a plunger (4) fixed to the shaft (5), a coil (12) which magnetically drives the plunger (4), and a first bearing (7) and a second bearing (8) supporting the shaft (5) on either sides of the plunger (4). A plunger front chamber (74) is formed between the first bearing (7) and the plunger (4), and a plunger rear chamber (75) is formed between the plunger (4) and the second bearing (8). By providing a plunger exterior oil passage (63) on the outside of the plunger (4) to connect the plunger front chamber (74) to the plunger rear chamber (75), working oil flows through the plunger exterior oil passage (63) every time the plunger (4) strokes, thereby preventing a deposit of contaminant on the plunger (4) without increasing a stroke resistance of the plunger (4).

Owner:KYB CORP

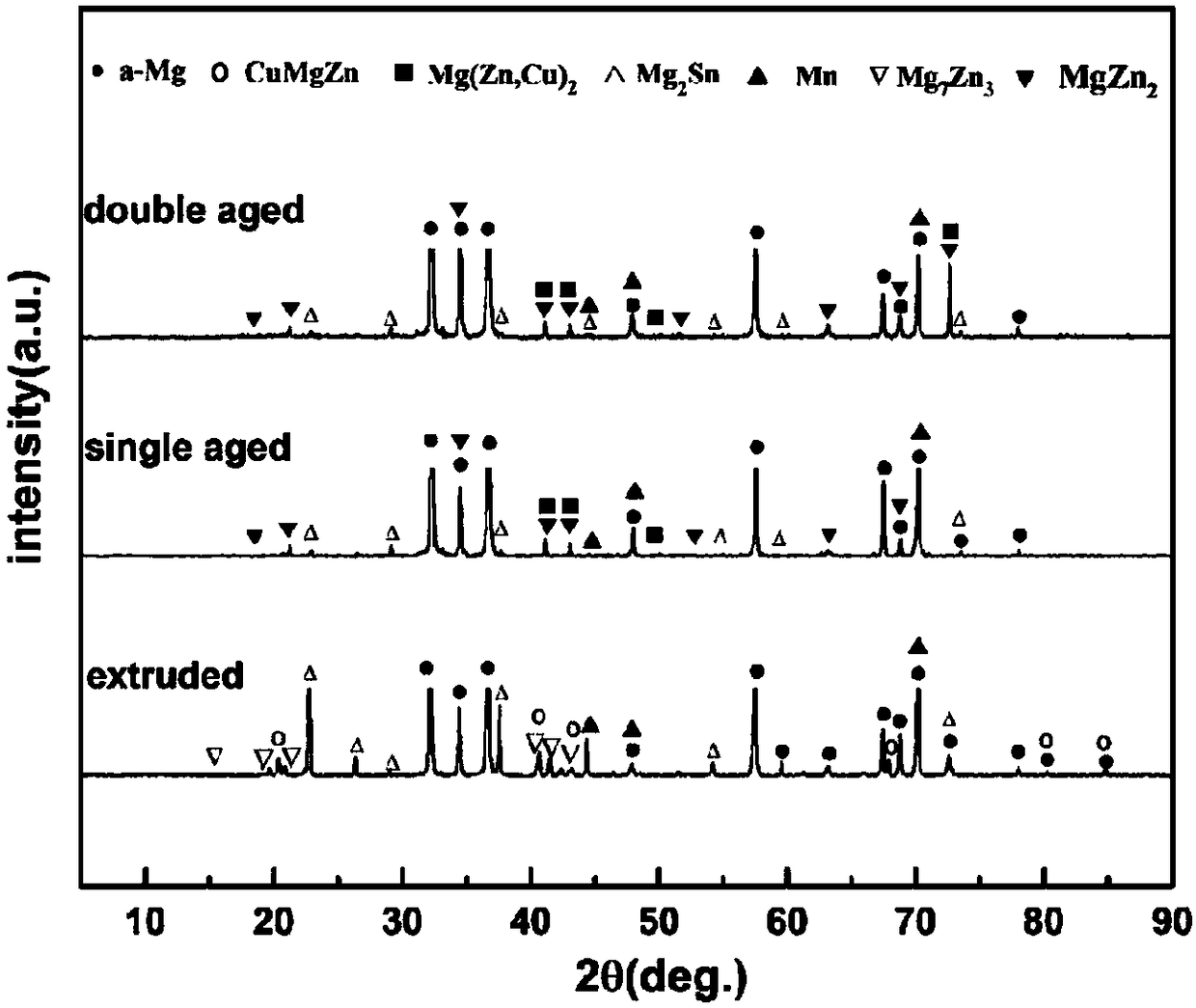

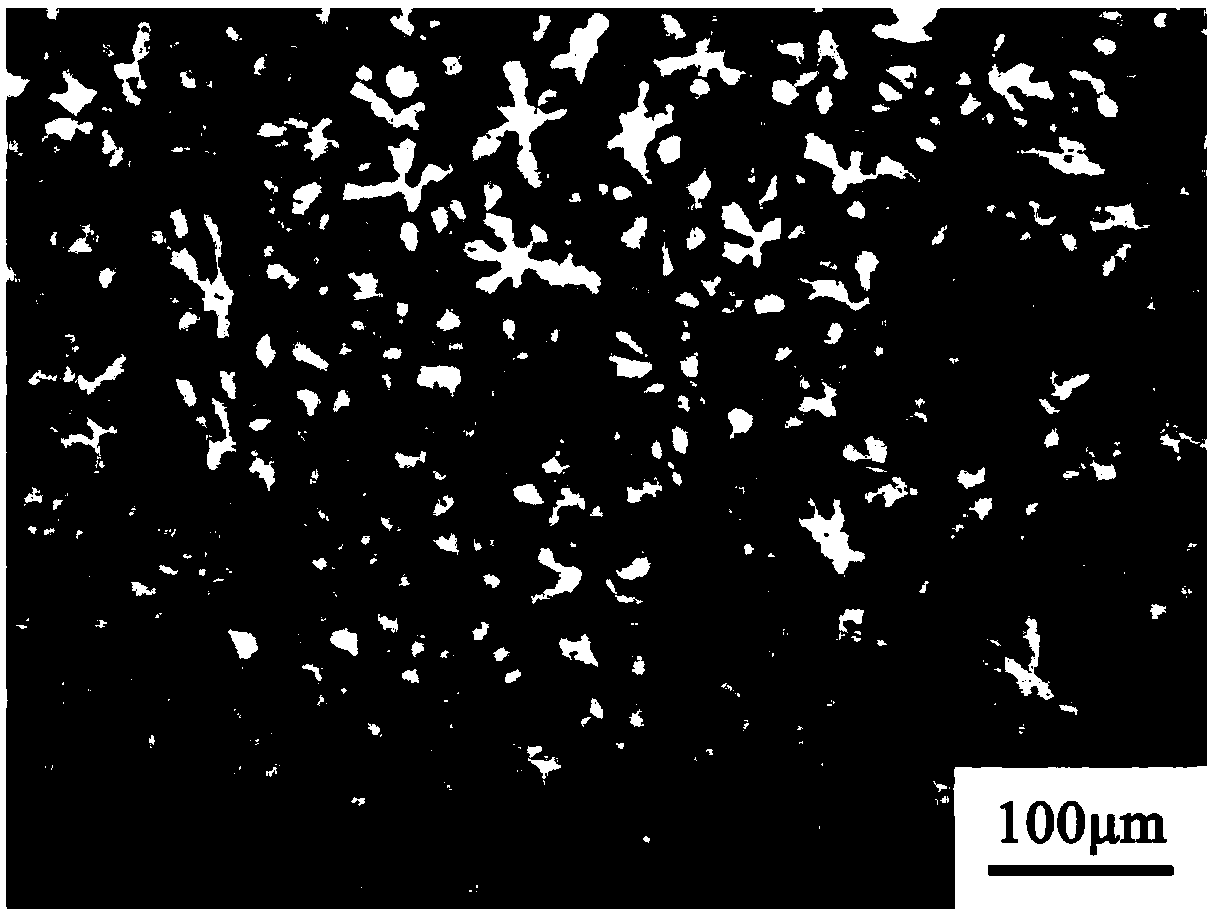

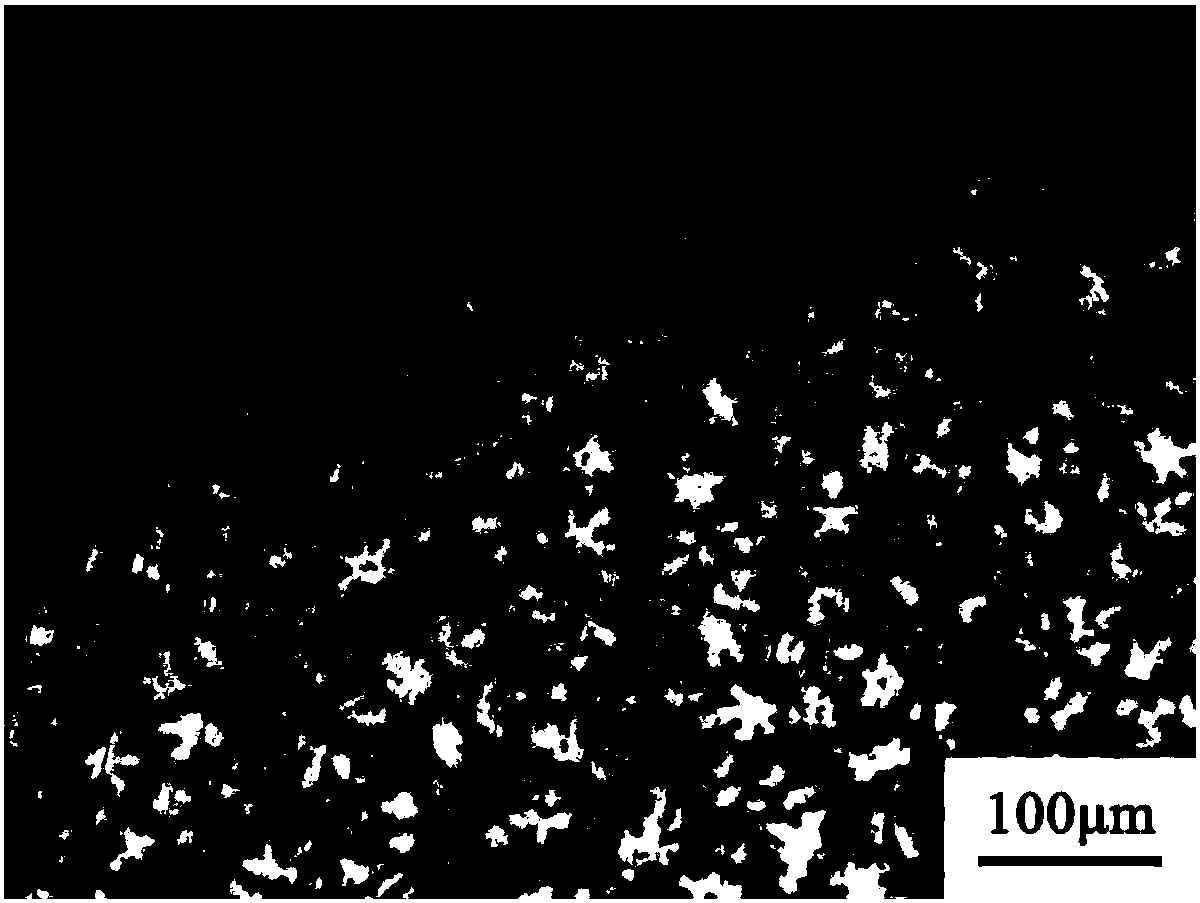

Wrought magnesium alloy material with low cost, high performance and heat resistance, and preparation method thereof

InactiveCN108385007AHigh strengthImprove mechanical propertiesRare-earth elementChemical composition

The invention provides a wrought magnesium alloy material with low cost, a high performance and heat resistance, and a preparation method thereof. The wrought magnesium alloy material is prepared fromthe chemical components in percentage by weight: 4.0 to 9.0 percent of Zn, 0.5 to 8 percent of Sn, 0.1 to 5 percent of Cu, 0.5 to 2 percent of Mn, and the balance magnesium and inevitable impurities.According to the wrought magnesium alloy material with the low cost, the high performance and the heat resistance, and the preparation method thereof provided by the invention, the problems that an existing high-strength heat-resistant wrought magnesium alloy material uses a rare earth element and a high-price alloy material, so that complicated processes such as large plastic deformation (rapidsolidification, powder metallurgy and the like) are higher in cost and the like are solved; and the element components of the alloy are reasonably blended, a conventional smelting and casting processis adopted, and reasonable heat treatment process conditions are selected after conventional plastic deformation and forming, so that the wrought magnesium alloy material with an excellent mechanicalproperty and a performance being remarkably superior to a high-strength ZK60 wrought magnesium alloy can be obtained. The wrought magnesium alloy material provided by the invention has the characteristics of low cost, high performance, no rare earth, and excellent high temperature and room temperature properties, and has a great application prospect.

Owner:XIANGTAN UNIV

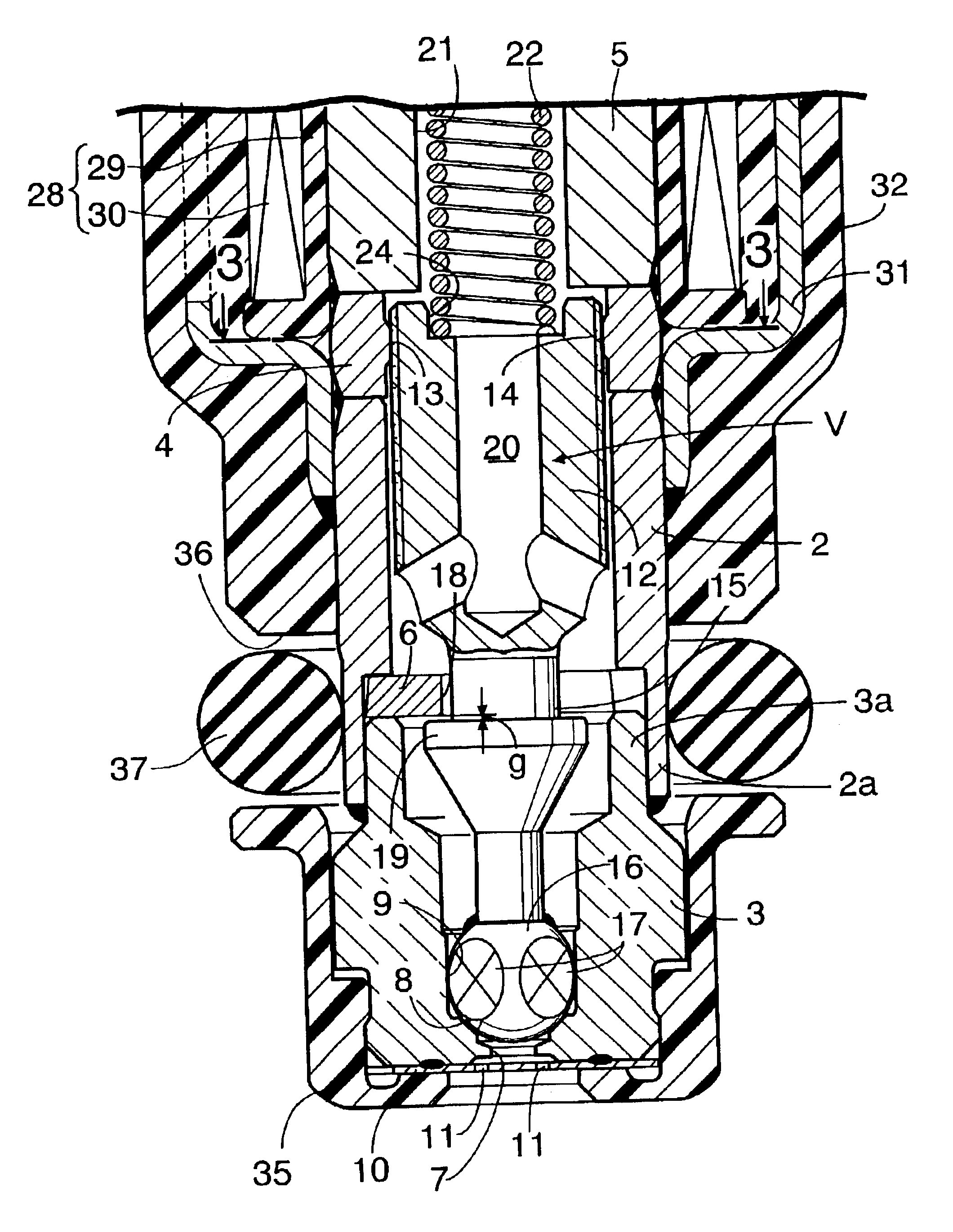

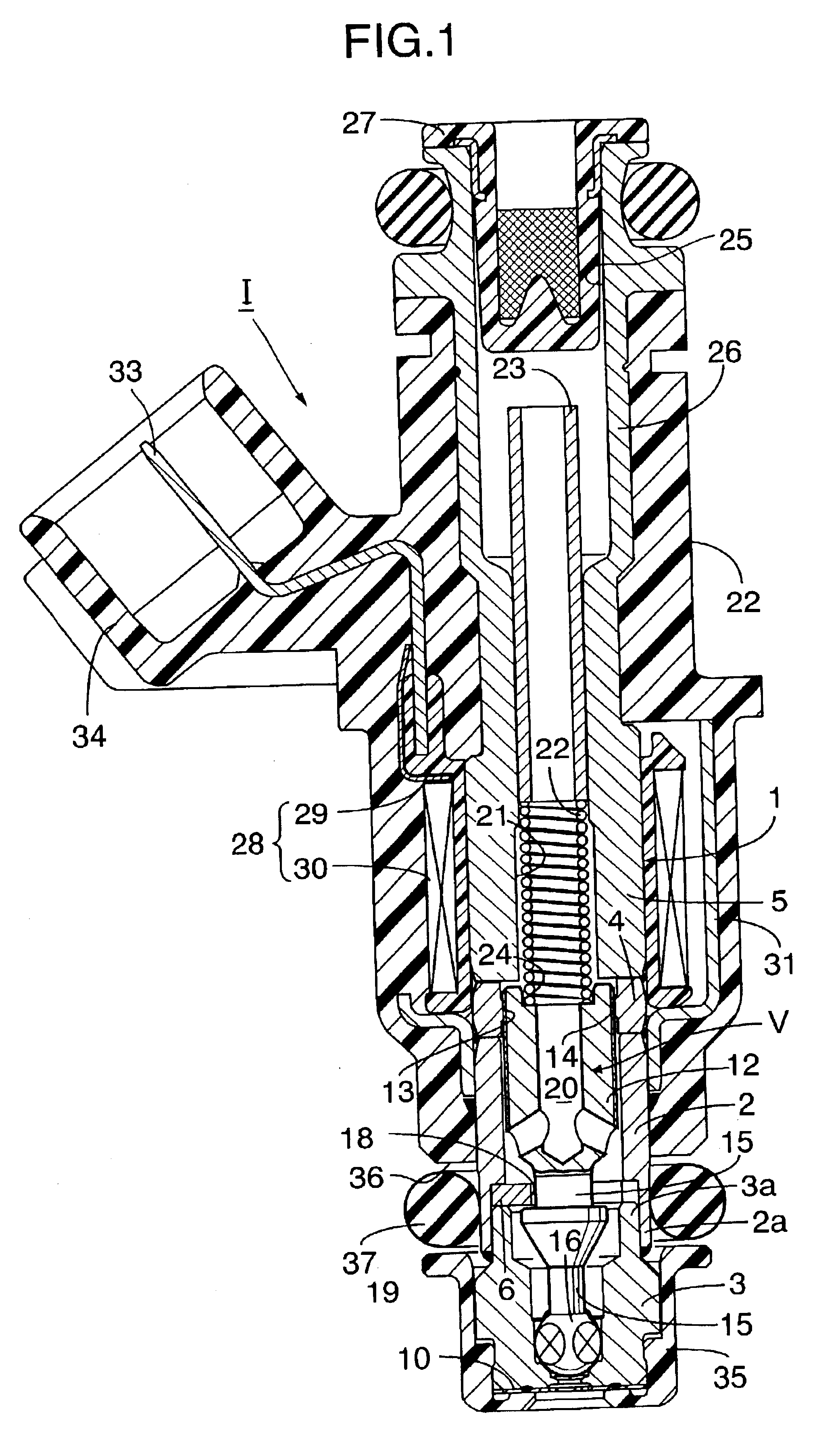

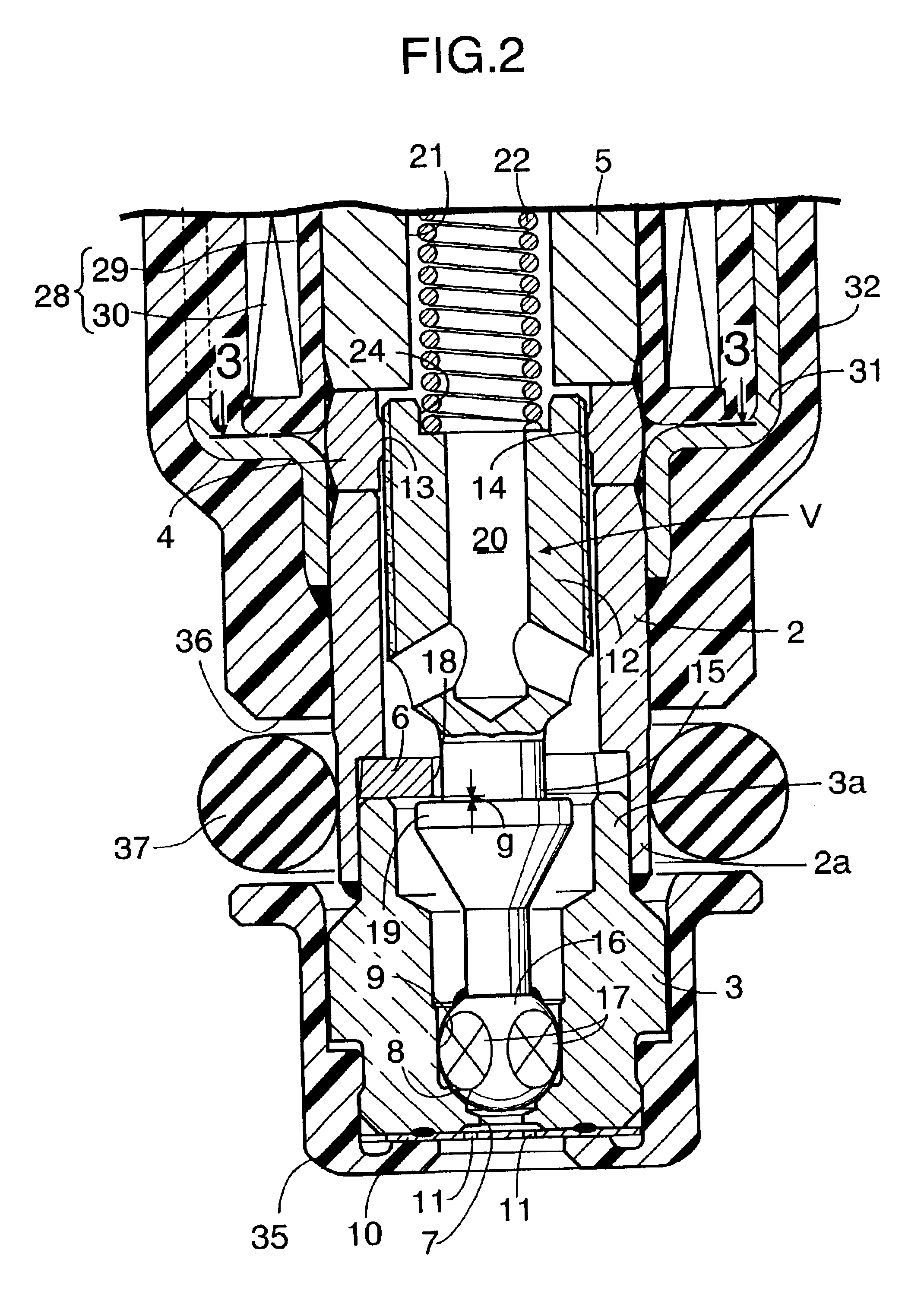

Electromagnetic fuel injection valve

InactiveUS6851630B2Increase sliding resistanceExcellent in stabilization of opened and closed attitudeWear reducing fuel injectionSpray nozzlesDiamond-like carbonSurface roughness

An electromagnetic fuel injection valve includes a valve housing coupled to at one end thereof to a valve seat member; a stationary core coupled to the other end of the valve housing; and a valve assembly comprised of a movable core slidably accommodated in the valve housing, and a valve member connected to the movable core through a rod portion and adapted to cooperate with the valve seat. In the electromagnetic fuel injection valve, the valve housing is provided with a guide portion on which the valve assembly is axially slidably carried, and a high-hardness coating of diamond-like carbon including silicon is formed on an outer peripheral surface of the valve assembly contacting with the guide portion. The surface roughness Rmax of the high-hardness coating is set in a range of 0.05 to 0.2 μm. Thus, it is possible to achieve the stabilization of opened and closed attitudes of the valve assembly and the responsiveness of the valve assembly, thereby contributing an improvement in low fuel consumption in an engine.

Owner:KEIHIN CORP

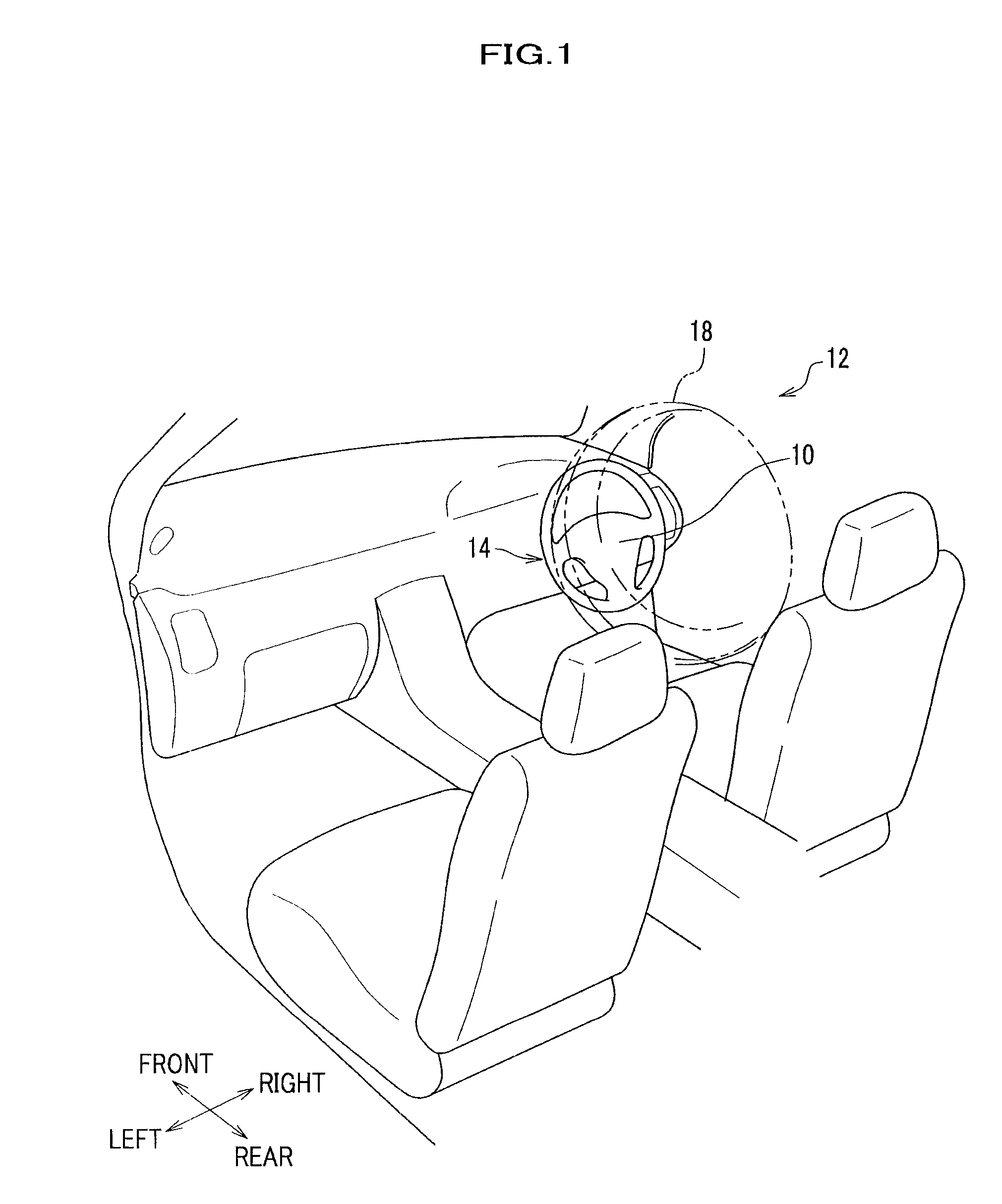

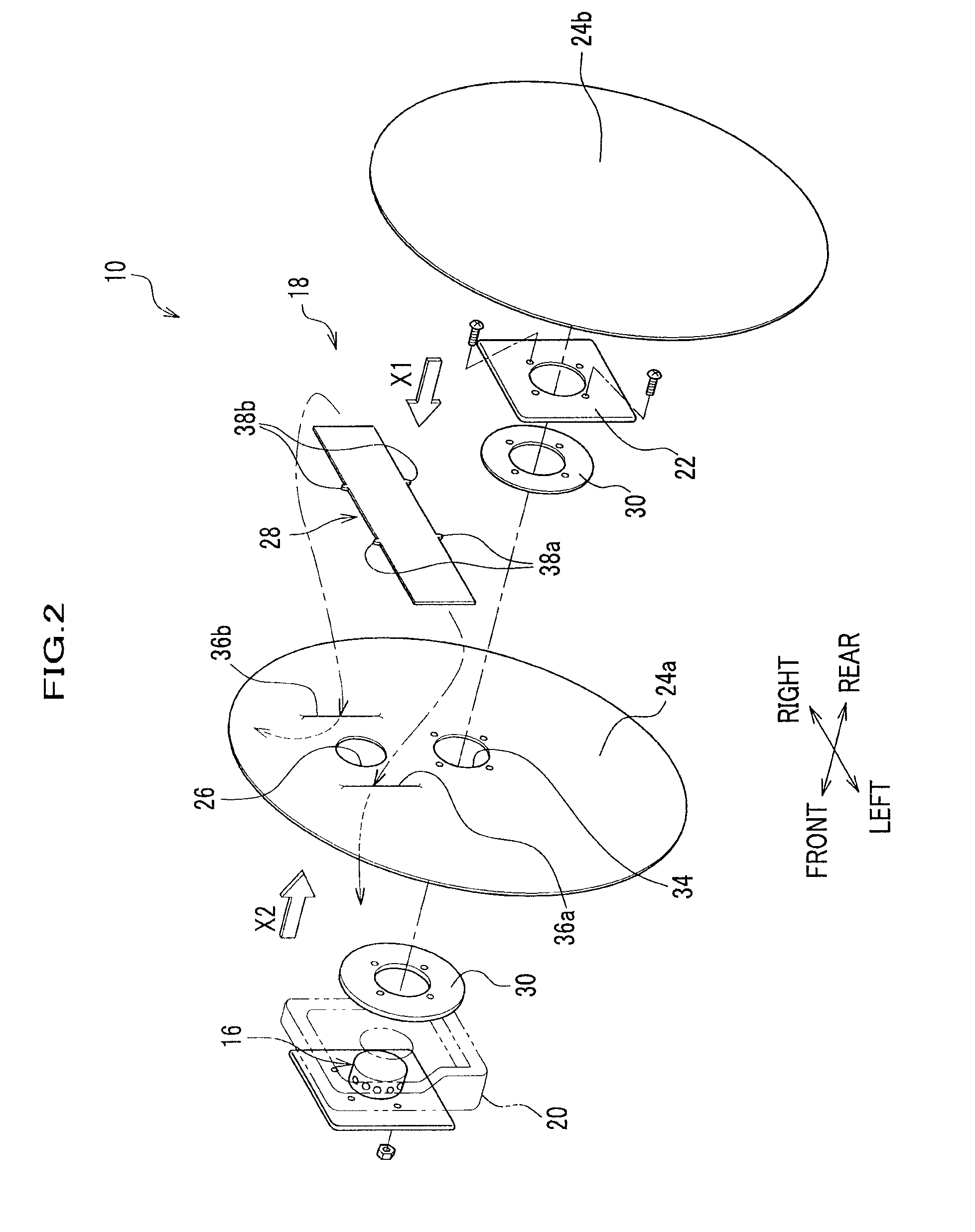

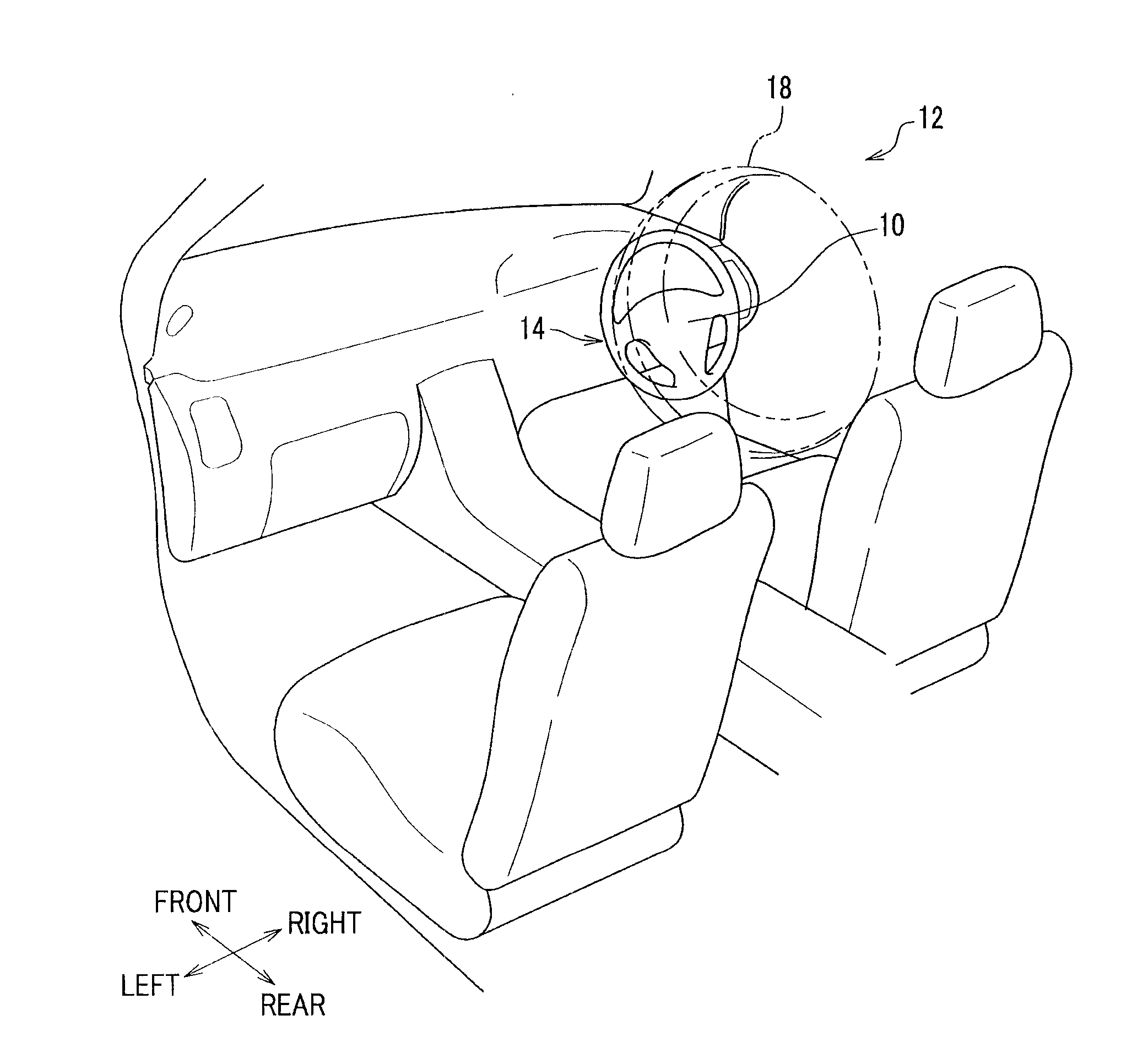

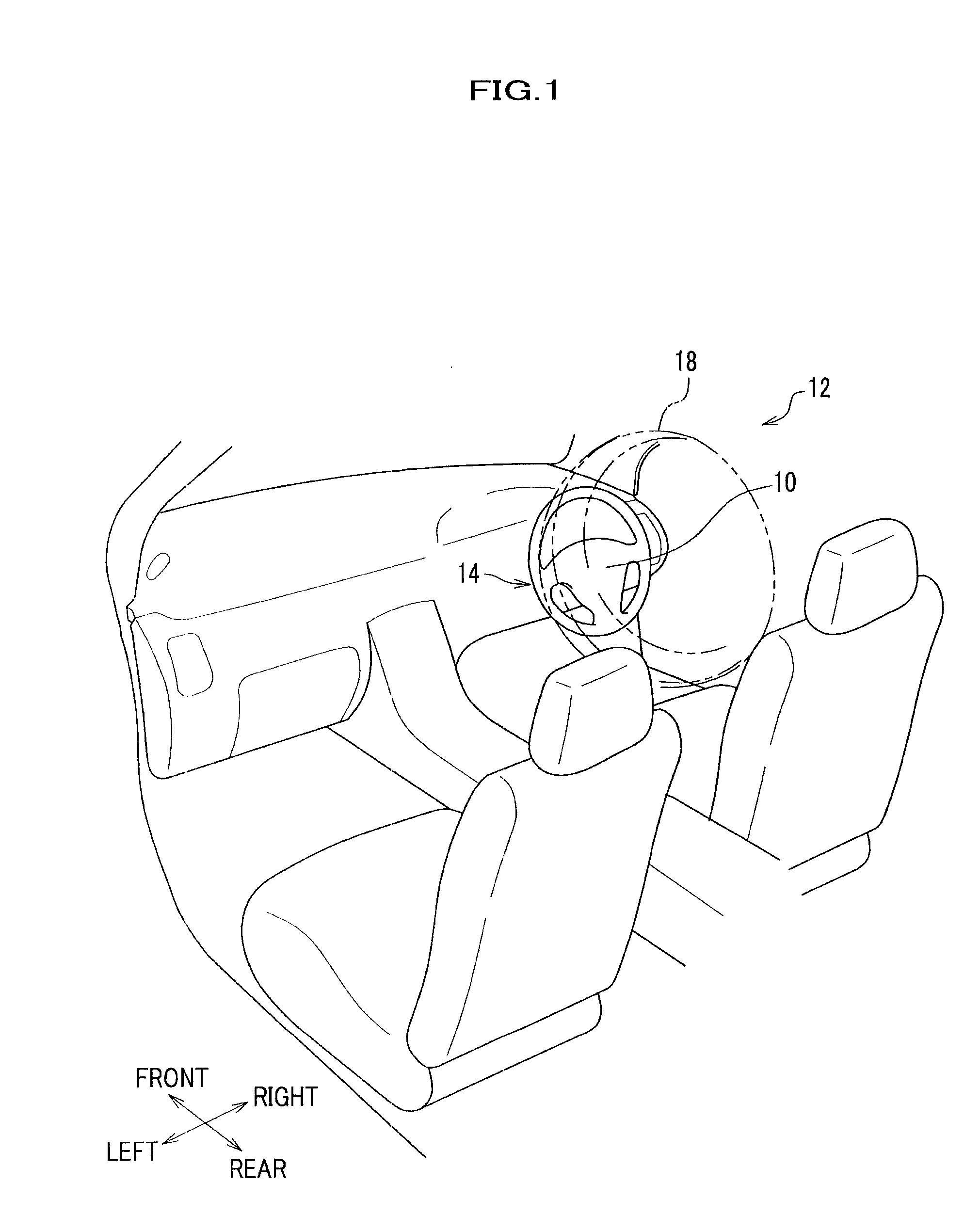

Air bag system for vehicle

InactiveUS8267425B2Improve the immunityIncrease sliding resistancePedestrian/occupant safety arrangementEngineeringElectrical and Electronics engineering

Owner:HONDA MOTOR CO LTD

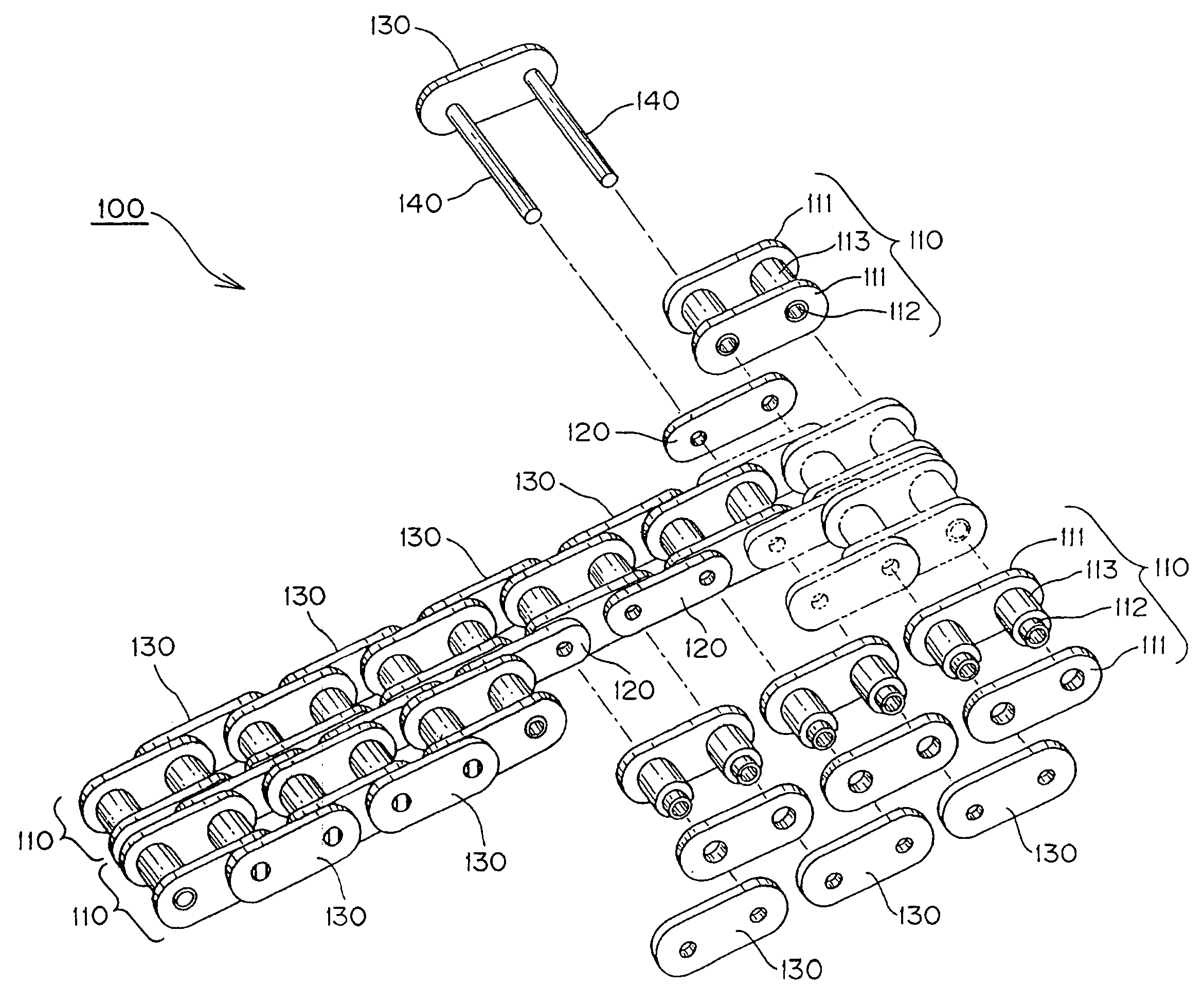

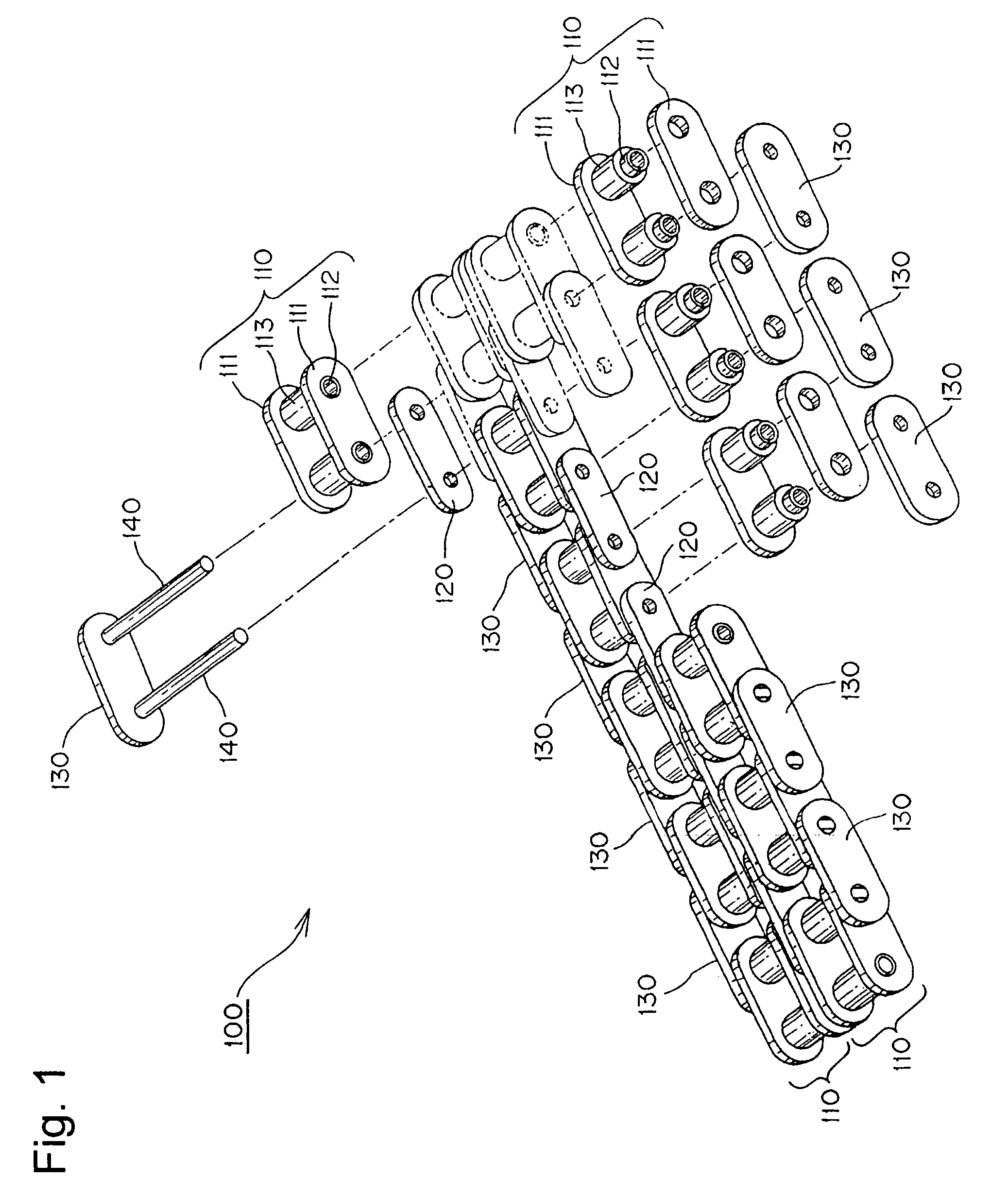

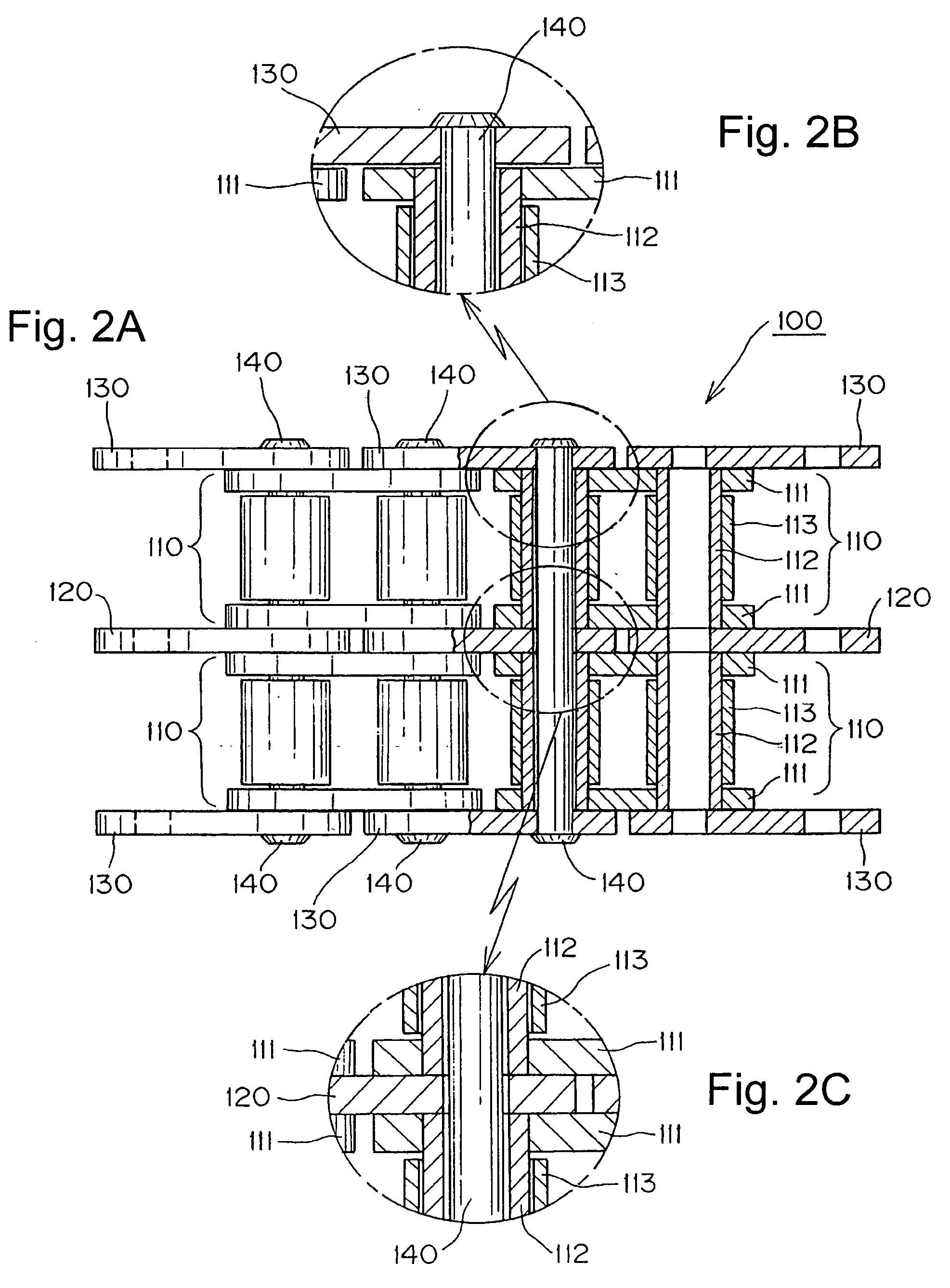

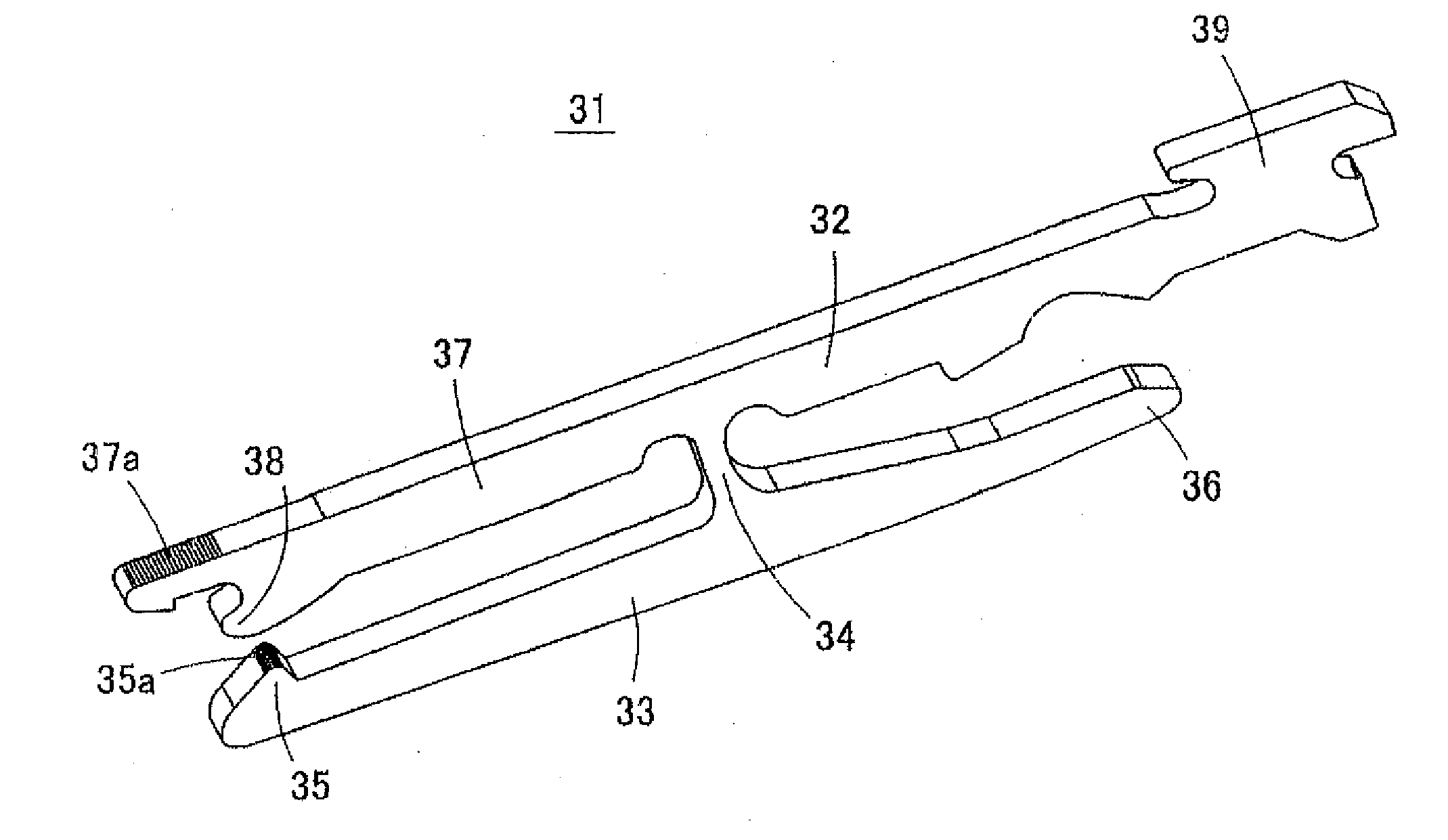

Transmitting multi-row chain

InactiveUS20070254759A1Improve accuracyDisconnection of likeMachine supportsDriving chainsEngineeringMechanical engineering

A transmitting multi-row chain in which the chain strength is high, the chain is lightweight, and the disassembly and assembly operation of the chain such as disconnecting and connecting of the chain and the like is simple. A transmitting multi-row chain has inner link units, each comprising a pair of right and left inner plates into which a pair of front and rear bushes is press-fitted. The inner link units are connected in rows to each other in large numbers in the longitudinal direction of the chain by connecting pins and the rows are disposed in parallel with each other through intermediate plates in a width direction of the chain. The connecting pins are press-fitted into outer plates disposed on the outermost sides in the width direction of the chain and are loosely fitted into pin holes of the intermediate plates. The intermediate plates are each formed in a plate height dimension smaller than the plate height dimension of each of the inner plate and the outer plate. The ends of the intermediate links are semi-circular with a bulge in the plate-shearing direction.

Owner:TAMIYA ATSUHIRO

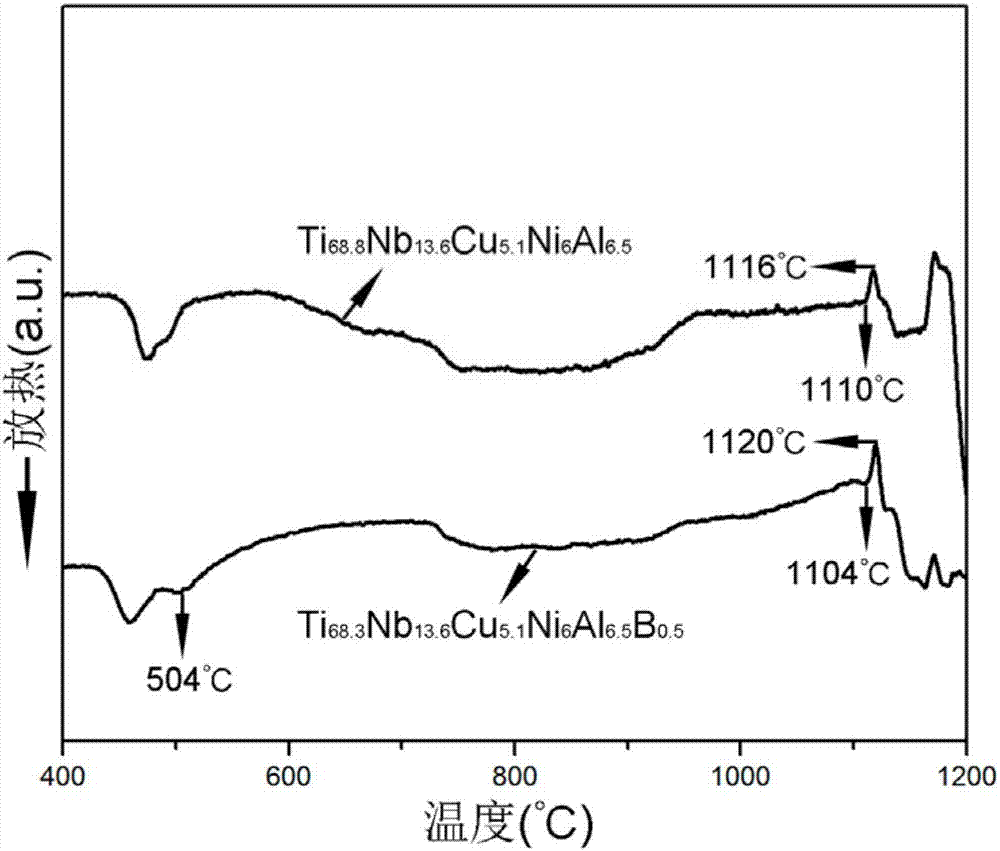

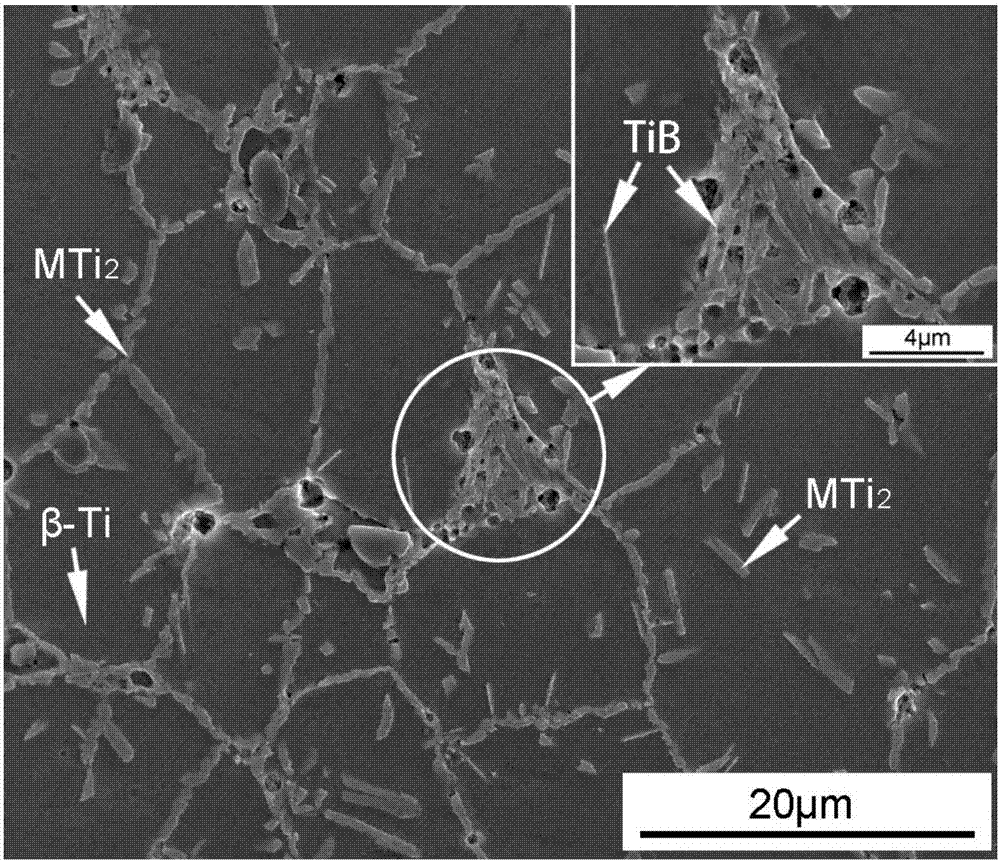

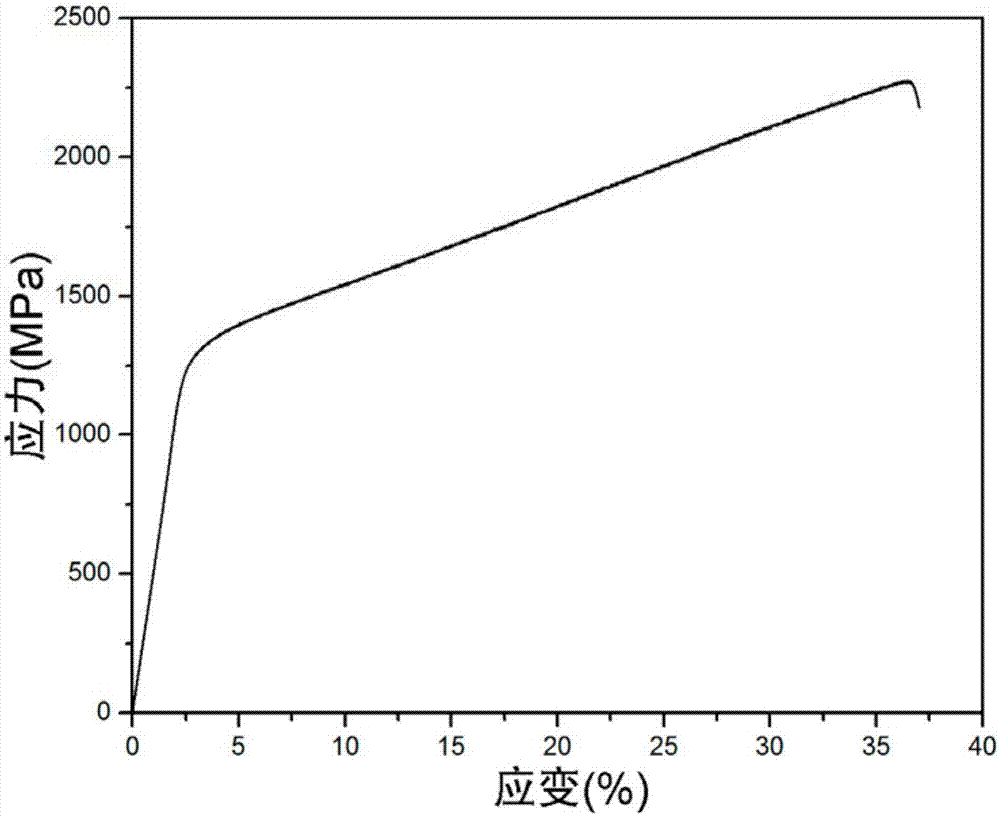

Double-scale structure titanium alloy based on in-situ whisker strengthening and toughening, preparation and application

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Gaseous fuel injection valve

ActiveCN1908413APrevent adhesionAvoid stickingInternal combustion piston enginesFuel supply apparatusEngineeringVALVE PORT

A gaseous fuel injection valve includes: a valve housing; a metallic nozzle member having a flat valve seat and a nozzle bore passing through a central portion of the valve seat; a valve body provided at one end face with a rubber seating member which is operated in cooperation with the valve seat; a coil; and a return spring for urging the valve body toward the valve seat. A stationary core attracts the valve body to move the seating member away form the valve seat, when the coil is excited. In this injection valve, a flourine resin valve seat coating is formed on the valve seat so that the seating members brought into close contact with the valve seat coating. Thus, an oil-repellent property of the valve seat coating is provided to the valve seat to prevent adherence of oil to the valve seat, leading to an improvement in valve-opening response of the valve body upon the excitation of the coil.

Owner:HITACHI ASTEMO LTD

High manganese steel containing tungsten

The invention discloses a high manganese steel which contains tungsten, and the high manganese steel contains chemical constituents in the following mass percent: C: 1.05%-1.35%, Si: 0.3%-0.9%, Mn: 11%-19%, W: 0.5%-1.5%, P<=0.070% and S<=0.045%, and the rest is Fe, furthermore, the high manganese steel also can contain a rare earth element RE, and the content of the RE is 0.01%-0.3%. The high manganese steel also can contain Cr and the content of the Cr is 1.2-2.5%. The high manganese steel which contains the tungsten of the invention is added with the elements of tungsten, rare earth element RE and chrome in particular when the content of the Mn is 16%-19%, which enables the whole high manganese steel to have the advantages of good toughness, high yield strength, high work hardening degree, better abrasive resistance and the like compared with the existing steel, and thereby the application range of the high manganese steel is enlarged. The high manganese steel of the invention is suitable for preparing fitting parts which are used in the working condition of abrasion and in particular to impact abrasion.

Owner:JINAN UNIVERSITY

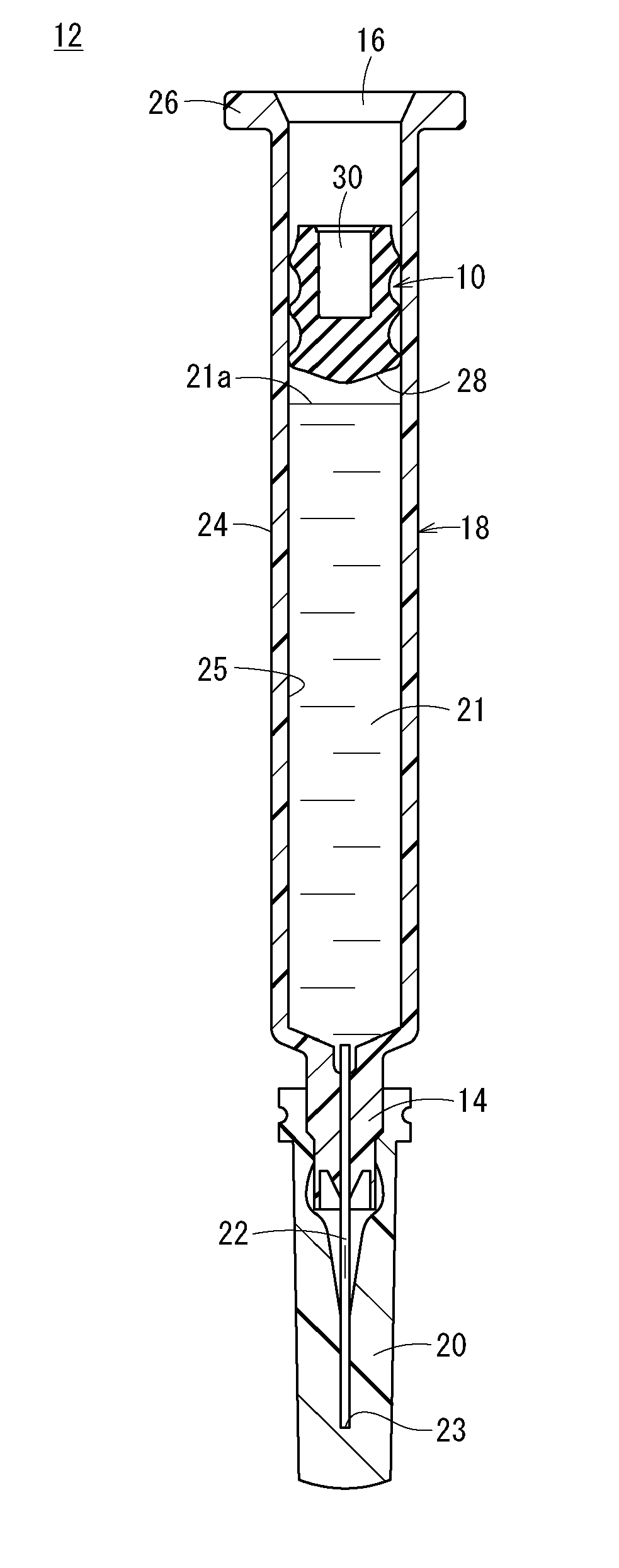

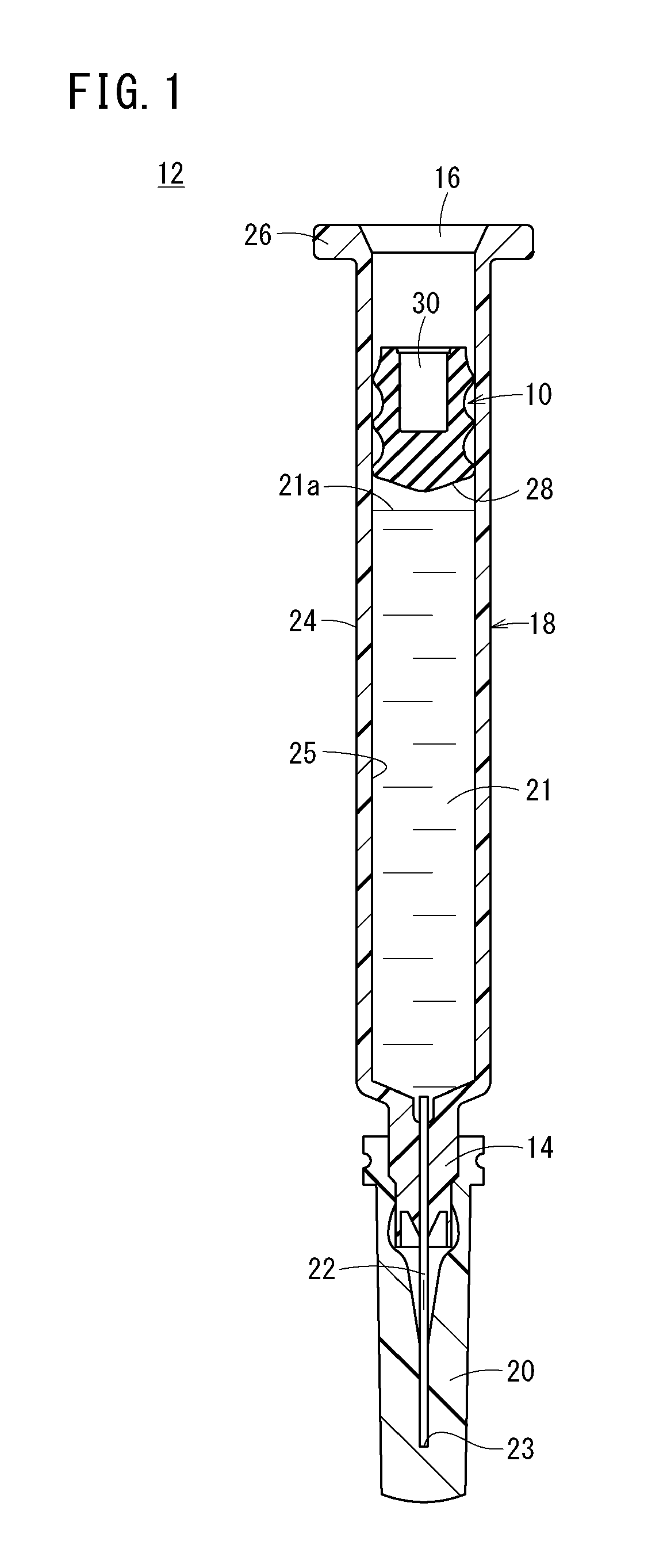

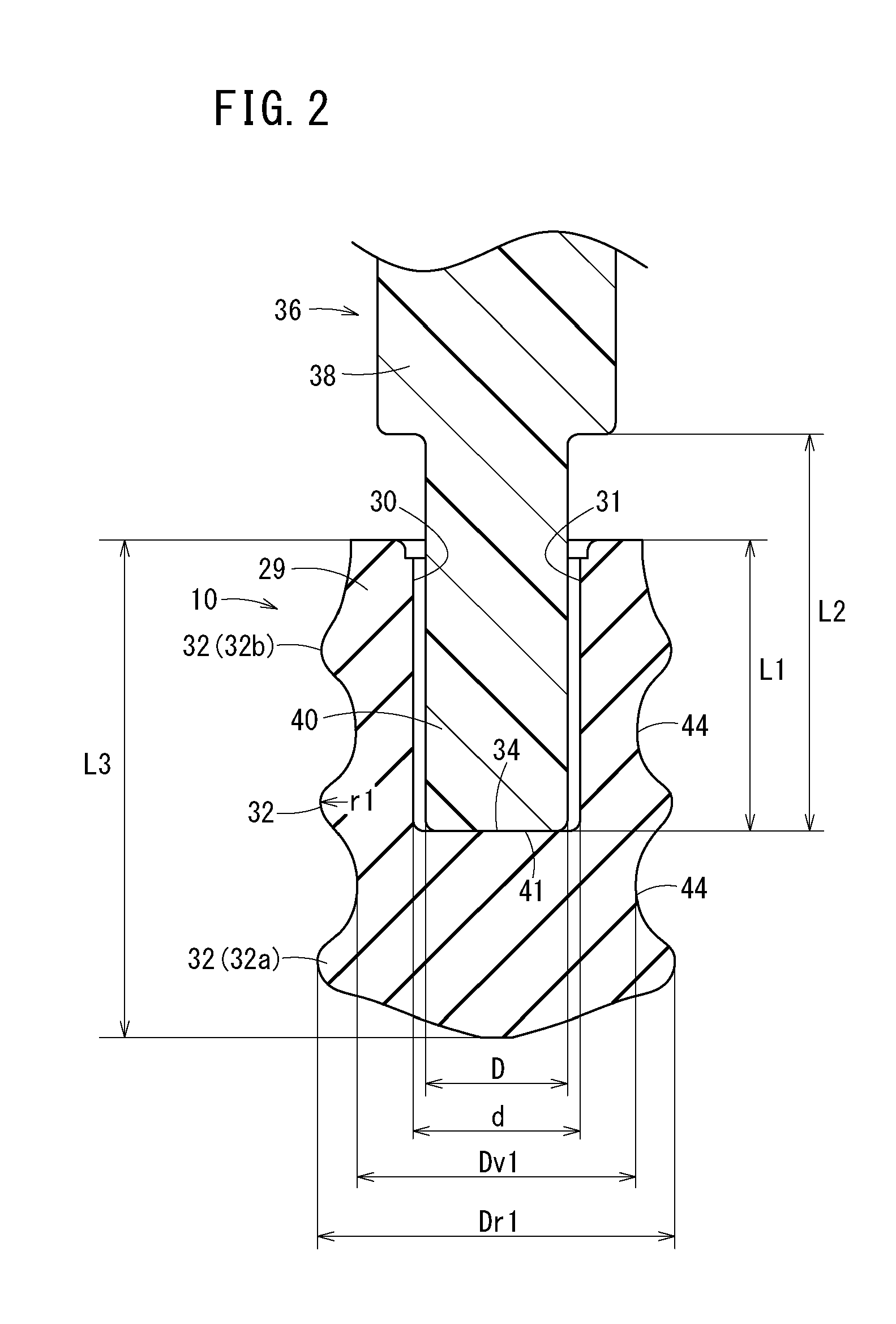

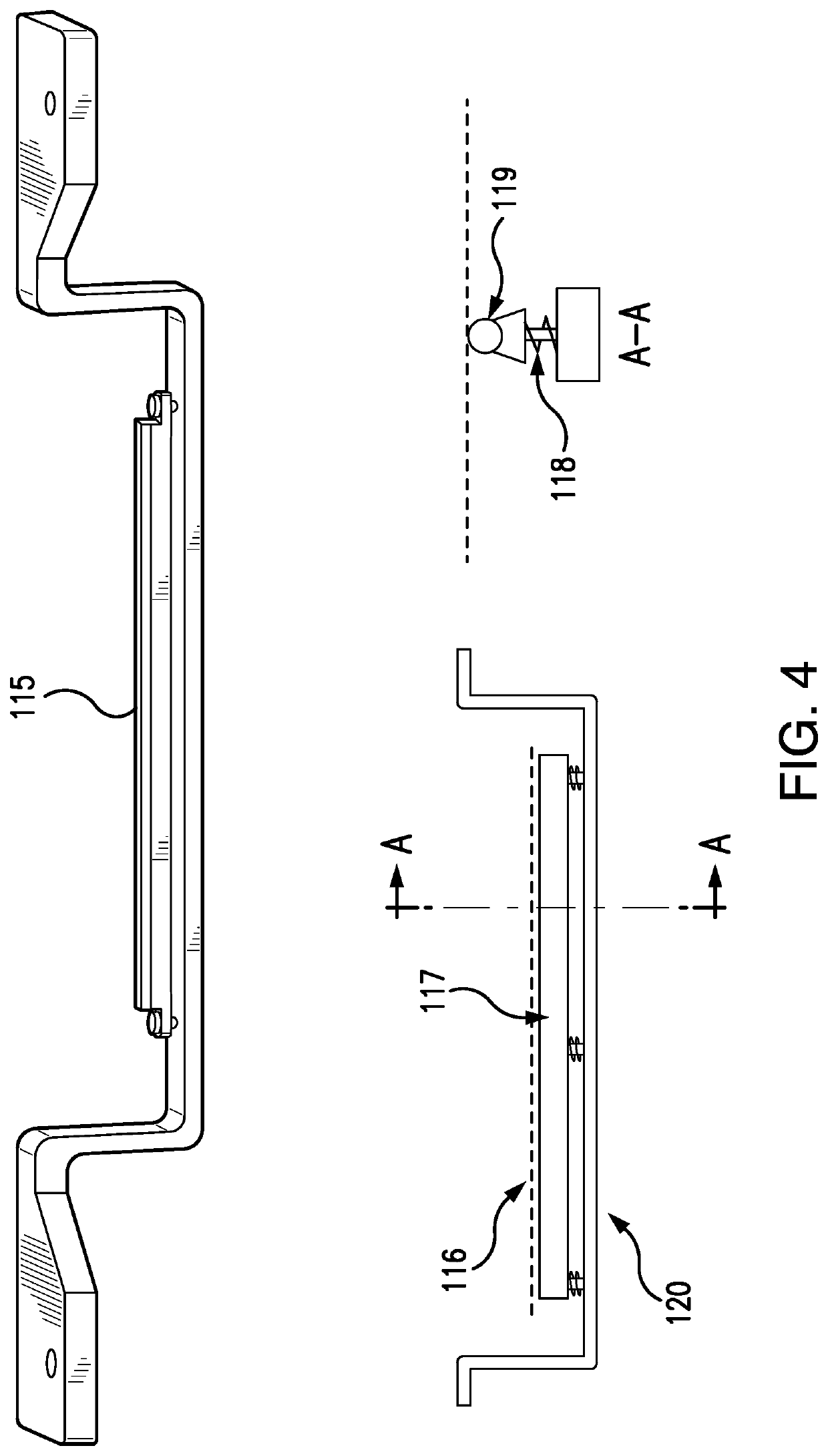

Gasket insertion method for mounting gasket inside outer cylinder of syringe, and gasket for mounting

ActiveUS20160146346A1Increase sliding resistanceLow maneuverabilityPiston ringsBraking action transmissionEngineeringSyringe

A gasket insertion method for inserting a gasket into an outer cylinder includes providing an outer cylinder having a base end opening section; providing a gasket having a recessed section that is open at a base end of the gasket and that includes a flat bottom surface; pushing the gasket into a sleeve configured to be inserted into the outer cylinder, by relatively moving an inserter in a tip end direction with respect to the sleeve while a flat tip end surface of a tip end section of the inserter abuts the bottom surface of the recessed section; inserting the sleeve into the outer cylinder through the base end opening section; and arranging the gasket inside the outer cylinder by relatively moving the sleeve in a base end direction with respect to the outer cylinder while maintaining relative axial positions of the outer cylinder, the gasket, and the inserter.

Owner:TERUMO KK

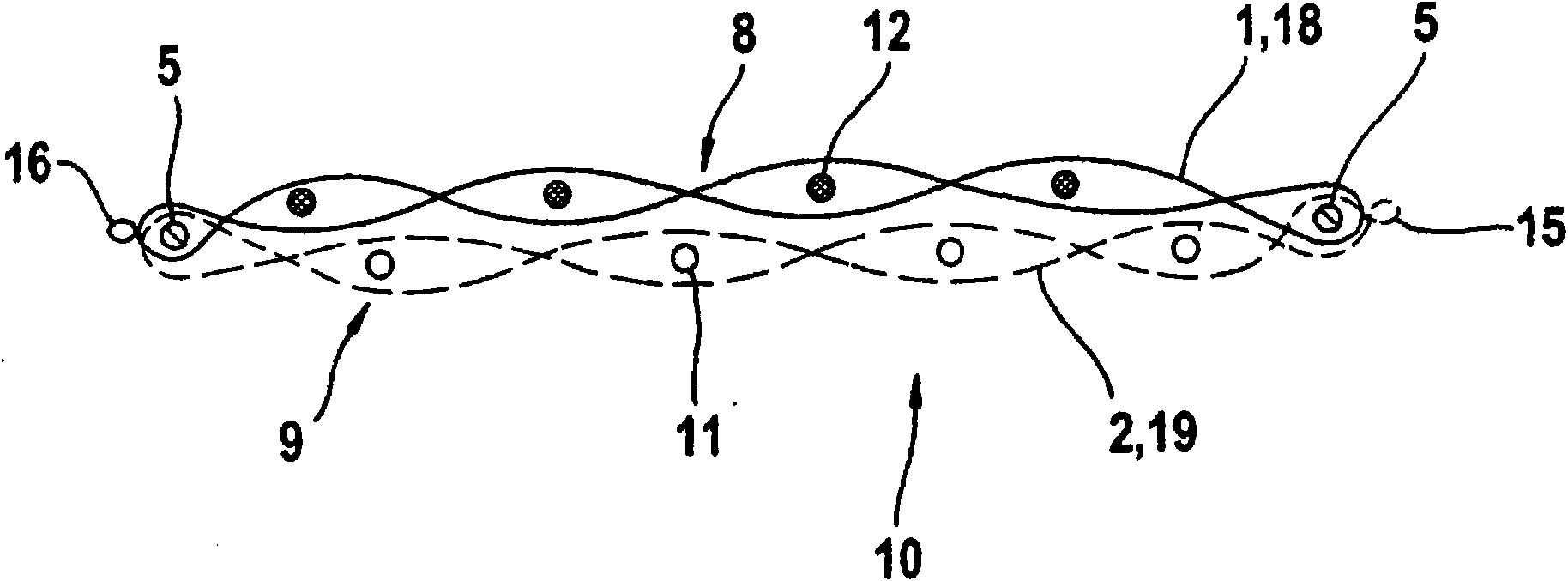

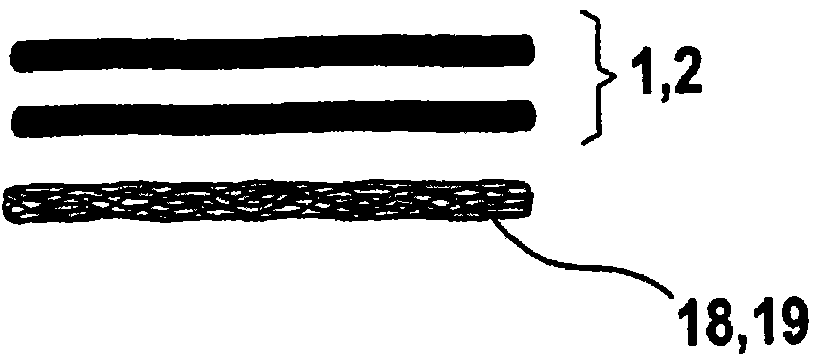

Method for producing a woven fabric and woven fabric produced thereby

ActiveCN101772599AImprove lateral stabilityEliminate separate feedMulti-ply fabricsEngineeringLow shrinkage

The invention relates to a method for producing a woven fabric (8, 9), the woven fabric (8, 9) comprising at least one monofil or monofil-like weft thread made of highly shrinkable material and warp threads made of low-shrinkage material, characterized in that at least one multifil weft thread (18, 19) running in the same shed is woven together with the at least one monofil or monofil-like weft thread (1, 2) during the weaving process.

Owner:IPROTEX

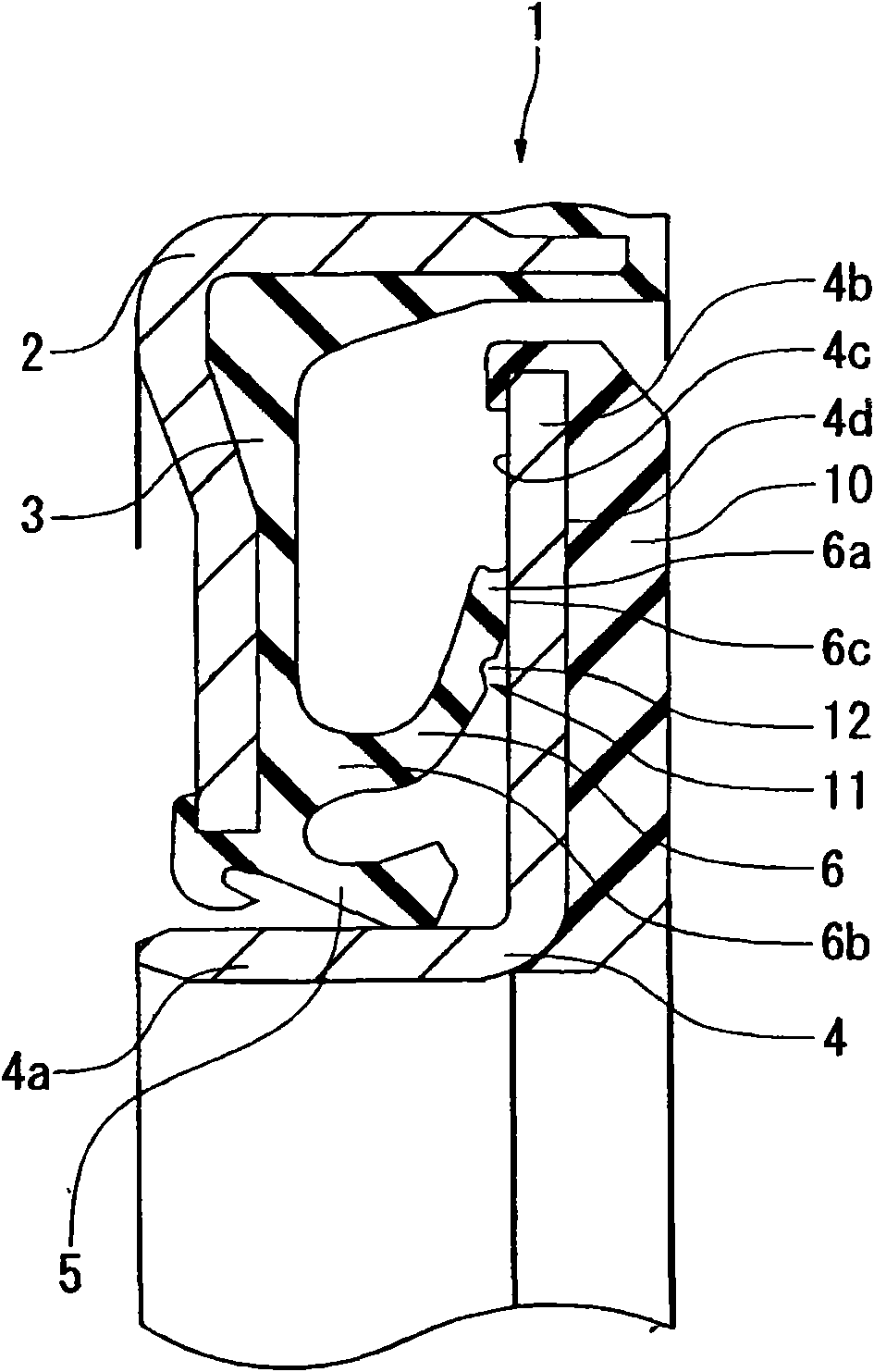

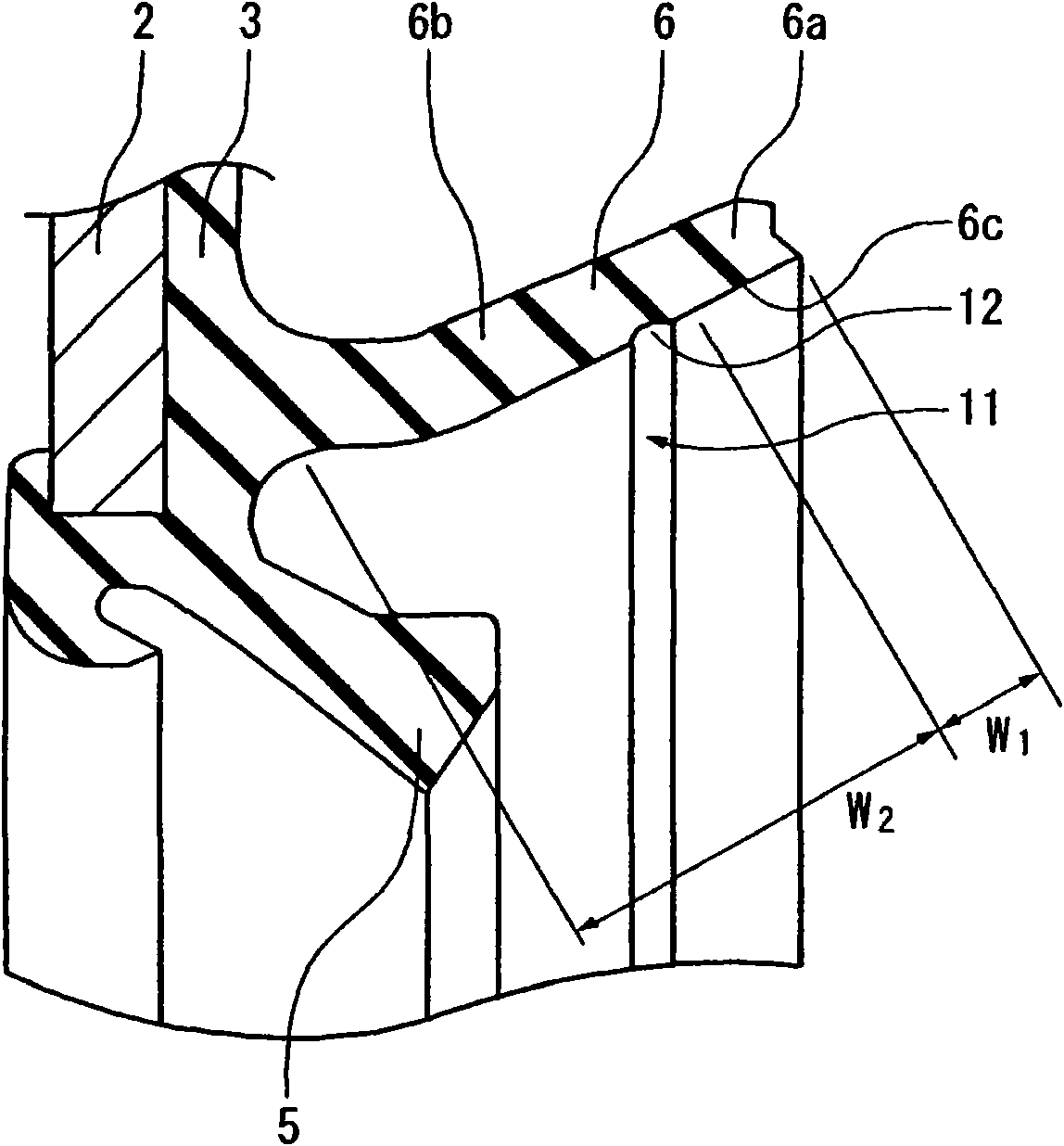

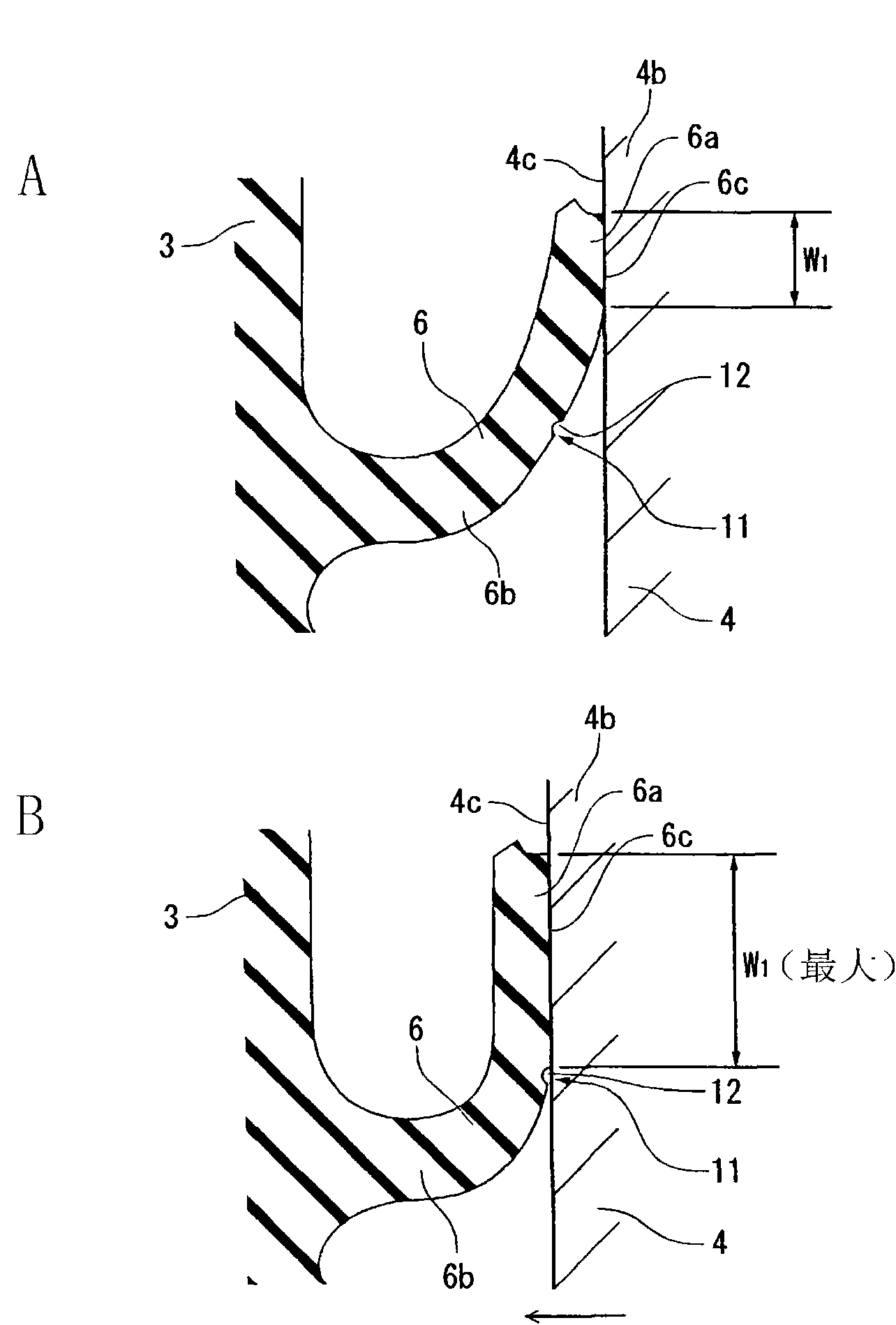

Hermetic sealing device

InactiveCN101600896AStable sealing performanceSuppresses sliding frictionEngine sealsEngineeringHermetic seal

A hermetic sealing device having a side lip coming into slidable tight contact with a partner member such as a slinger in which contact state of the side lip can be stabilized and sliding resistance of the side lip can be reduced when lip tightening margin becomes maximum. The contact surface (6c) at the contact part (6a) of the side lip (6) has a cross-section of a straight shape in a free state. The noncontact part (6b) of the side lip (6) is provided with a grease holding portion (11) for holding grease being supplied to the contact part (6a). The grease holding portion (11) provided at the noncontact part (6b) of the side lip (6) is arranged at a position becoming the boundary between the contact part (6a) and the noncontact part (6b) when the width (W 1 ) of the contact part (6a) and lip tightening margin become maximum. The grease holding portion (11) consists of an annular groove (12) or a radial groove.

Owner:NOK CORP

Self-expanding pipe seam anchor rod for surrounding rock large deformation and preparation and using methods of self-expanding pipe seam anchor rod

PendingCN110030025AReduce installation difficultyImprove installation efficiencyAnchoring boltsHydration reactionEngineering

The invention discloses a self-expanding pipe seam anchor rod for surrounding rock large deformation and preparation and using methods of the self-expanding pipe seam anchor rod. An anchor rod comprises a rod body internally provided with self-expanding explosive columns and a tray, resistance increasing seams are formed in the pipe wall, making contact with the self-expanding explosive columns, of the rod body, ring-shaped resistance increasing grooves are formed in the pipe wall of the rod body on the rear parts of the self-expanding explosive columns, the rear end of a threaded rod of the series-wound self-expanding explosive columns penetrates through the tray and is connected with a fastening nut, and the tray is not fixedly connected with the rod body. During using, the self-expanding explosive columns are soaked in water first, then the anchor rod is inserted into a drilling hole, the fastening nut is screwed, thus the tray and surrounding rock wall get close; radial expansion pressure is generated by using size expanding of a hydration reaction of a self-expanding anchoring agent, and the anchoring effect is performed; when lager deformation of surrounding rocks occurs, rock body deformation force is applied to the self-expanding explosive columns through the tray, a fastening bolt and the threaded rod, fiction slippage occurs between the self-expanding explosive columns and the rod body when stress exceeds design resistance, in the process of slippage, constant resistance and yielding can be maintained by the resistance increasing seams and resistance increasing grooves, and the anchoring function can be continuously performed after displacement.

Owner:NORTHEASTERN UNIV

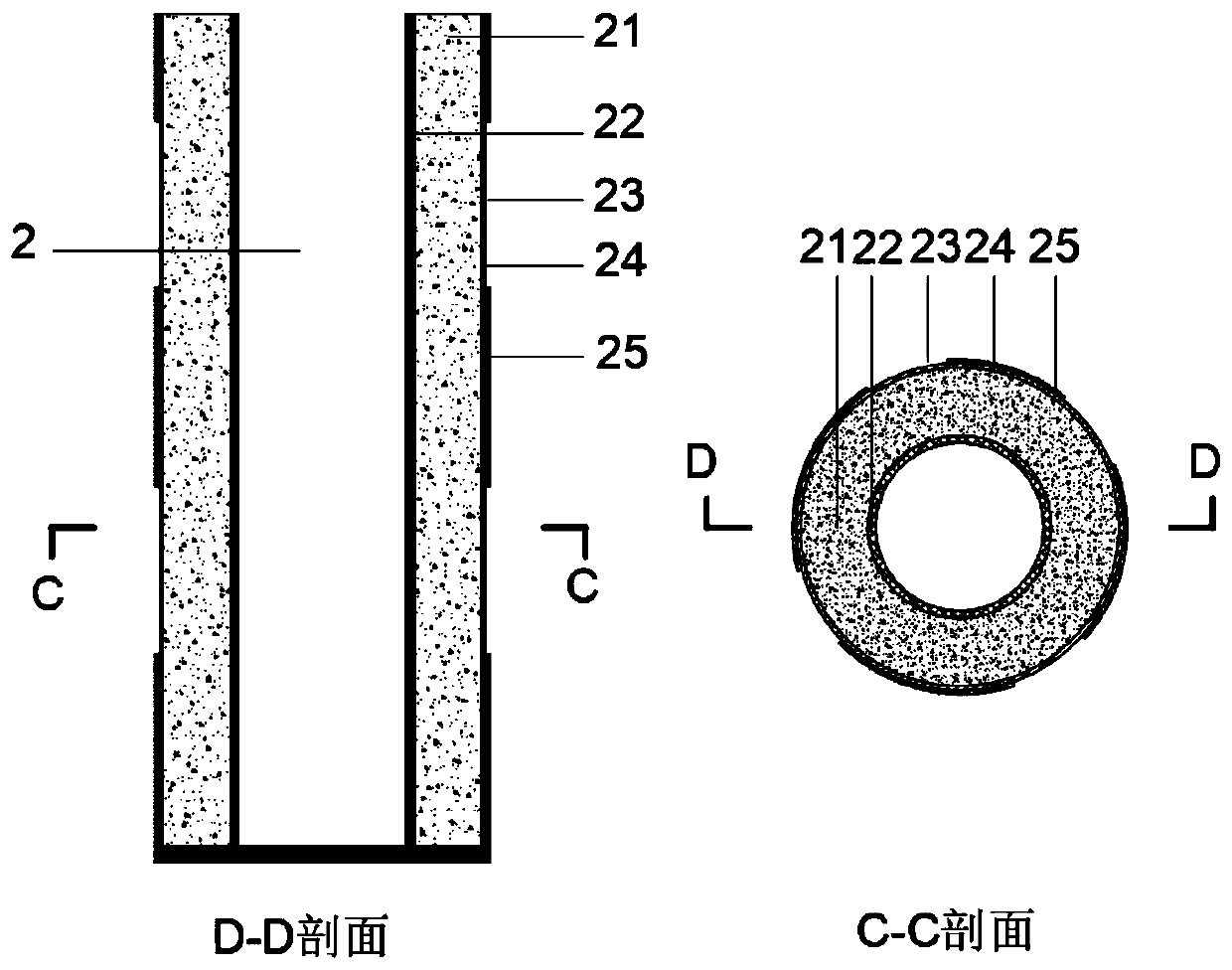

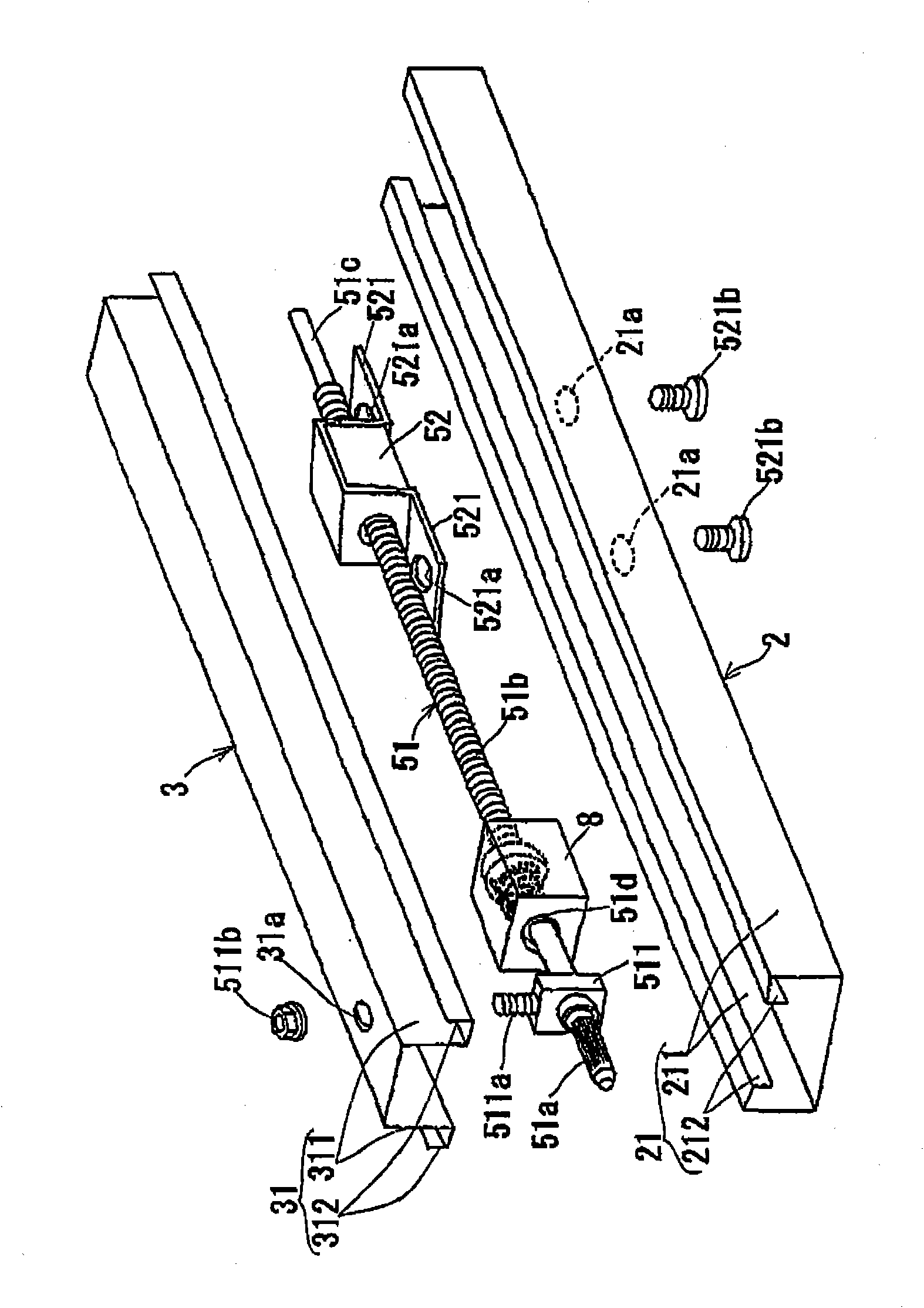

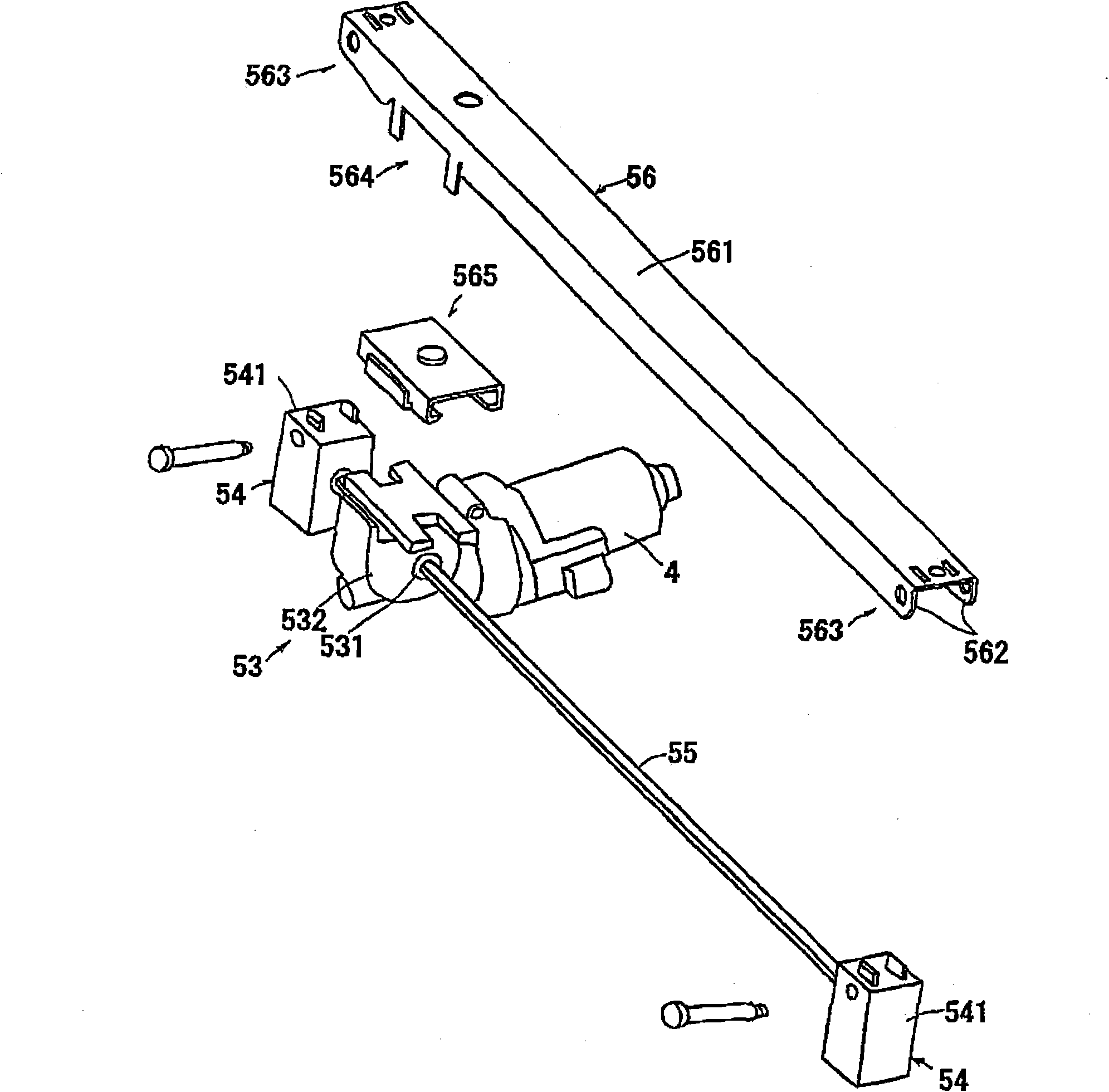

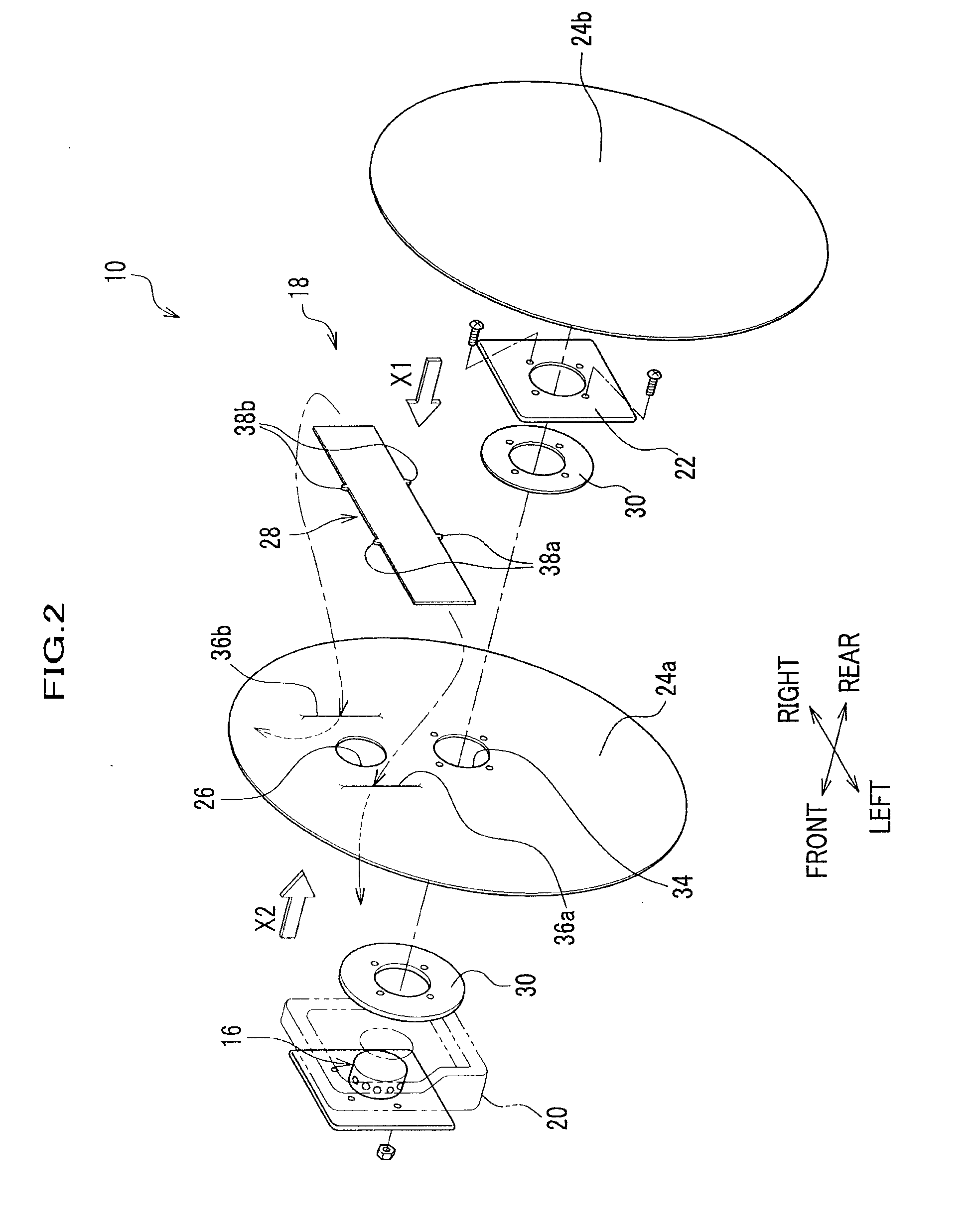

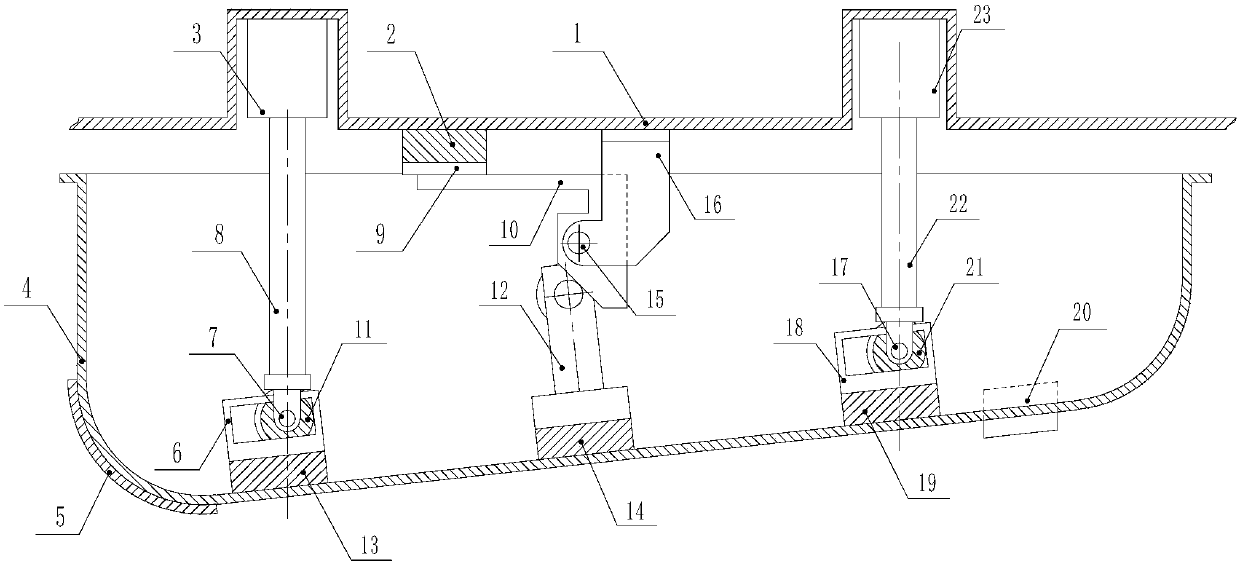

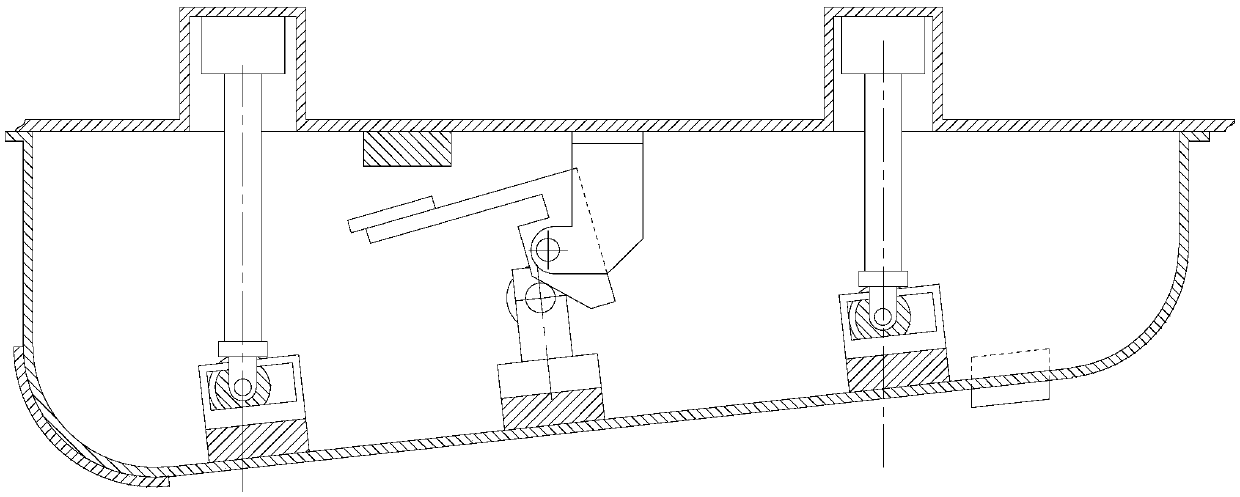

Seat slide apparatus for vehicle

InactiveCN101987584ALow sliding resistanceIncreased press fitMovable seatsEngineeringMechanical engineering

Owner:AISIN SEIKI KK

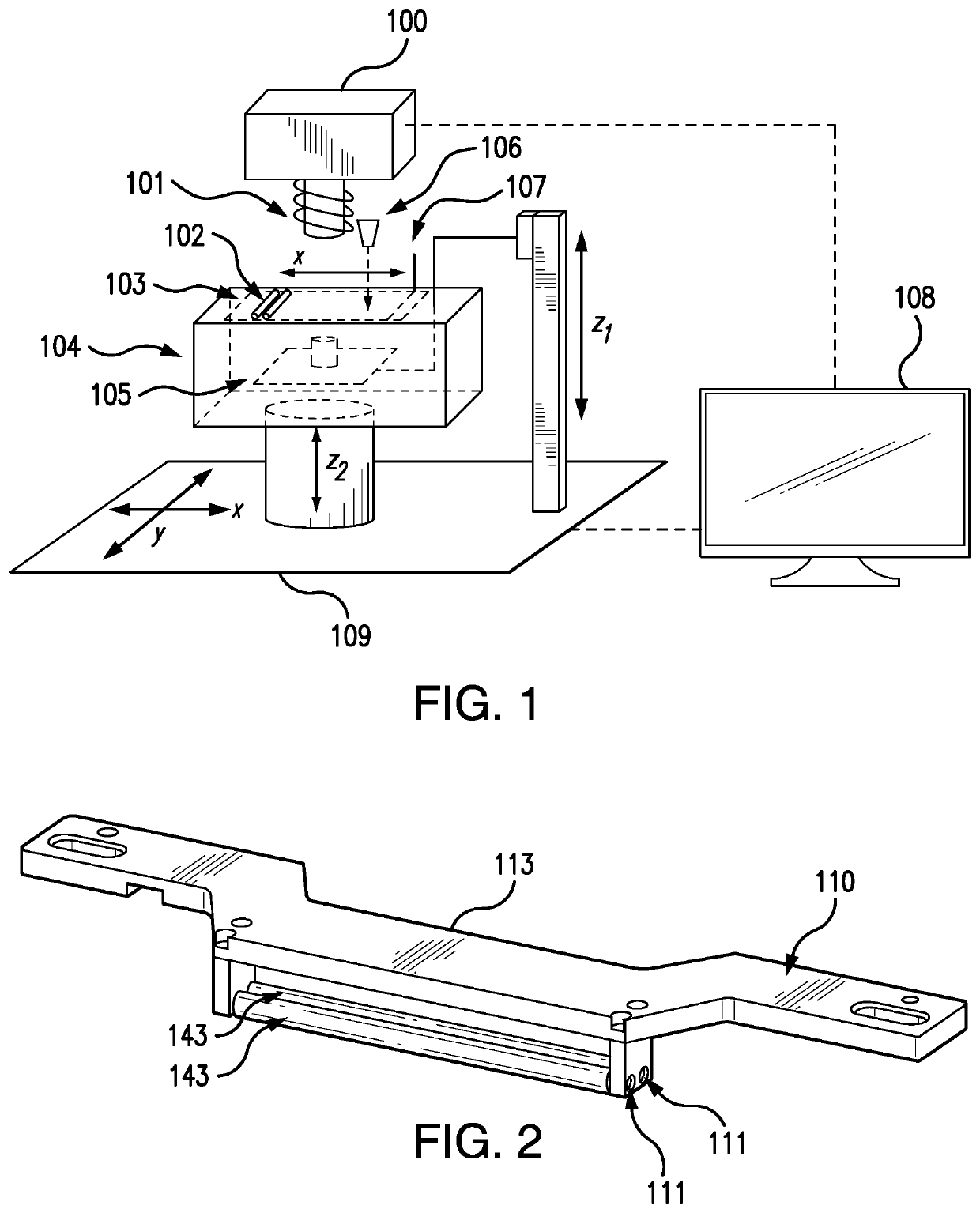

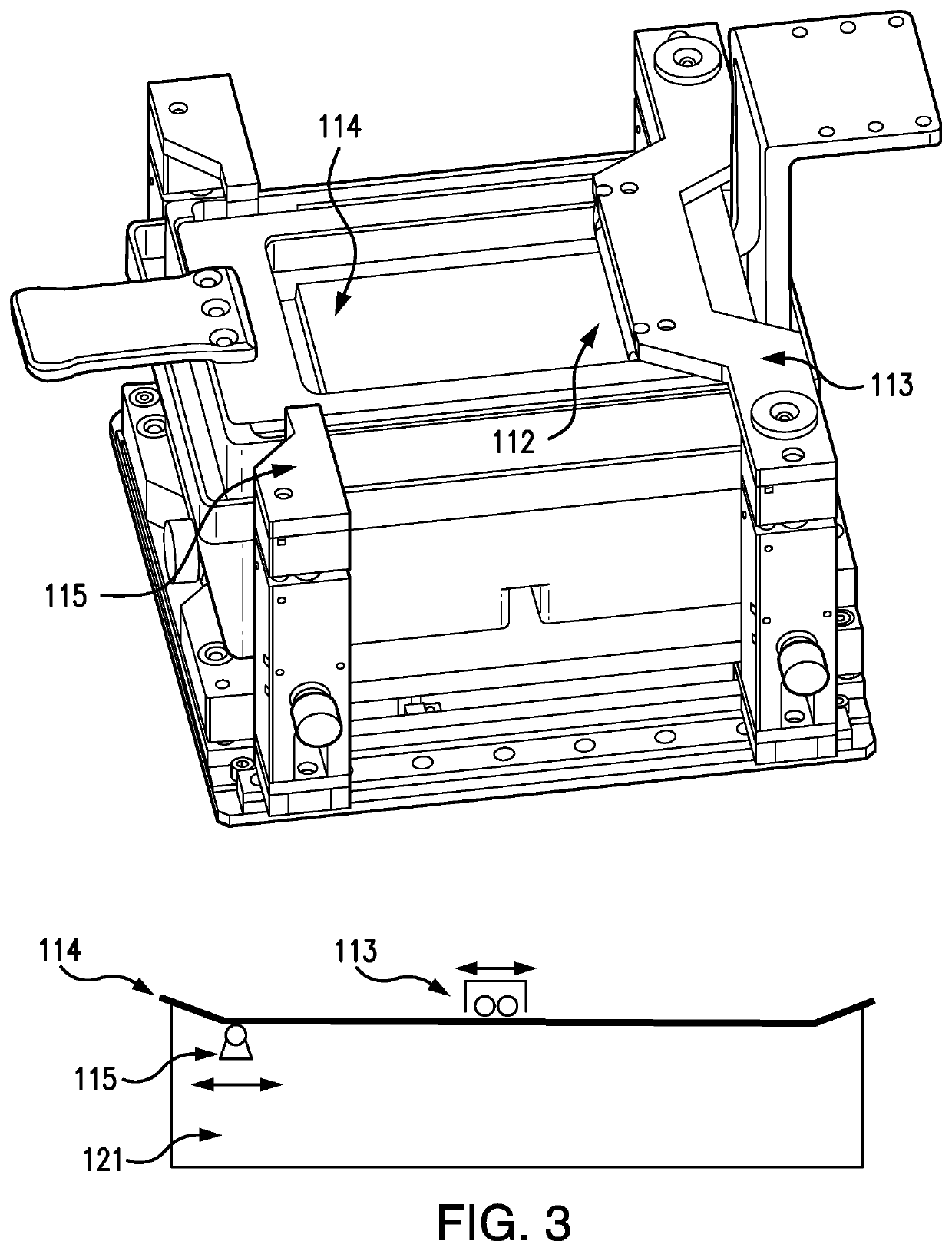

Roller-membrane layering micro stereolithography

PendingUS20210299952A1Improve accuracyIncrease speedManufacturing platforms/substrates3D object support structuresStereolithographiesEngineering

The speed and control over layer thickness in multi-layer 3-D printing is enhanced when producing a sample layer by projecting an image of the layer from light engine onto an optically clear membrane in contact with a printing material to prepare a sample layer in contact with the membrane, followed by moving the sample away from the membrane to separate the two, then moving the sample back toward the membrane to a point where the distance between the membrane and sample, as measured by a laser displacement sensor, is equal to the thickness of the next layer. While the sample moves back toward the membrane a dual-roller spreader or rotary roller spreader oscillates on the membrane to simultaneously to drive away printing material and flatten the membrane. A bubble scrapper is employed to remove bubbles from the printing material as they form.

Owner:BMF NANO MATERIAL TECH CO LTD

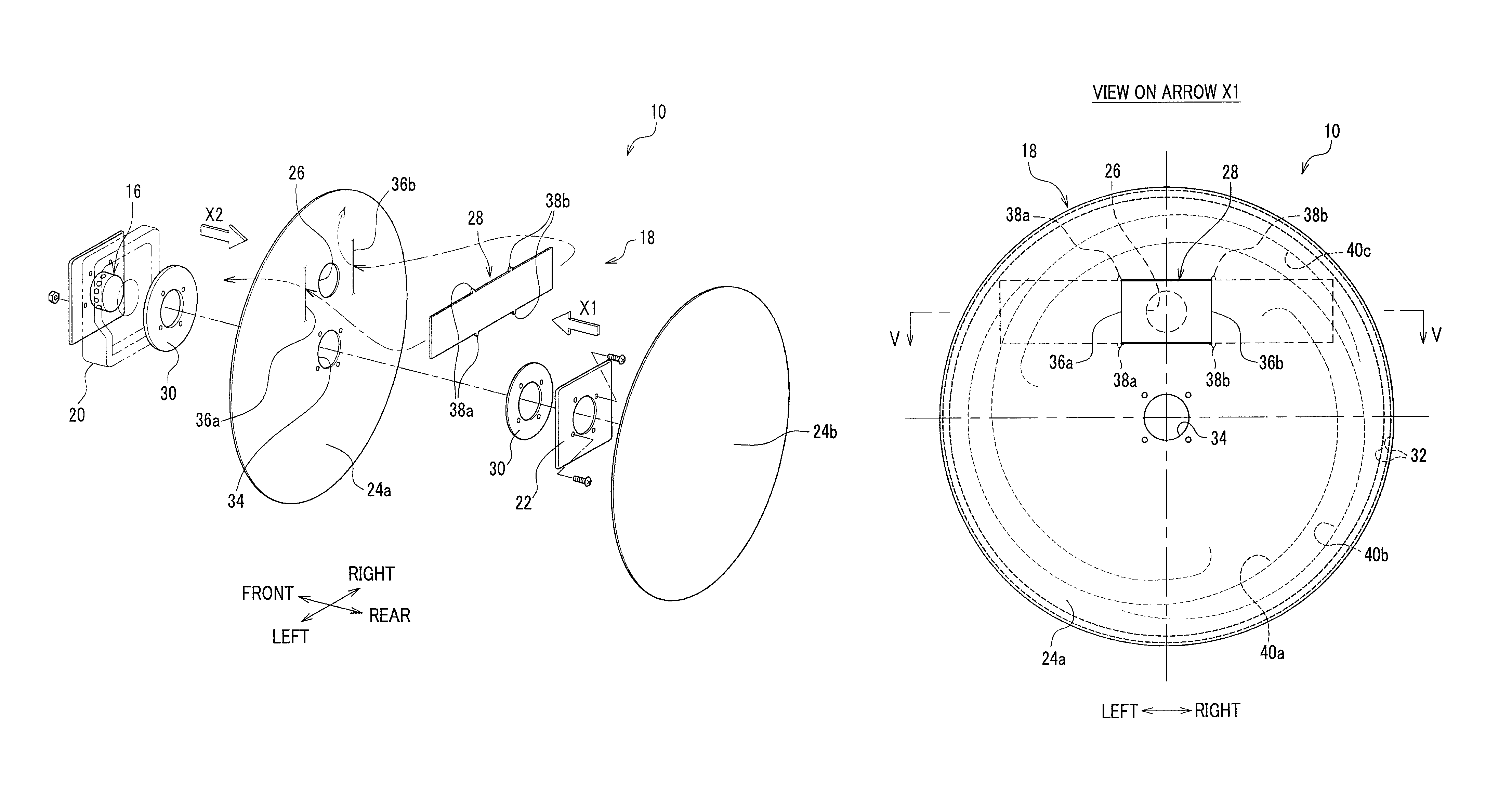

Cutting device

InactiveCN103946947APrevent movementCut off smoothlyConductor severing switchesShearing machinesMechanical engineeringEngineering

A cutting device (10) prevents movement of a harness during cutting. The cutting device (10) is provided with: a first tubular member (25) and a second tubular member facing each other with a specified interval between the axial-direction end face (25c, 26c) of each, said tubular members having a harness (12) inserted therebetween in the axial direction; and a blade (30) stored in the first tubular member (25) so as to slide freely in the axial direction, and having a front-side cutting portion (31) and a rear-side pusher (32). In the first tubular member (25), a rear-side tapering portion (25d) and a front-side tapering portion (25e) are formed, in which the inner circumference gradually narrows from rear to front in the plane in which the pusher (32) slides.

Owner:DAIKIN IND LTD

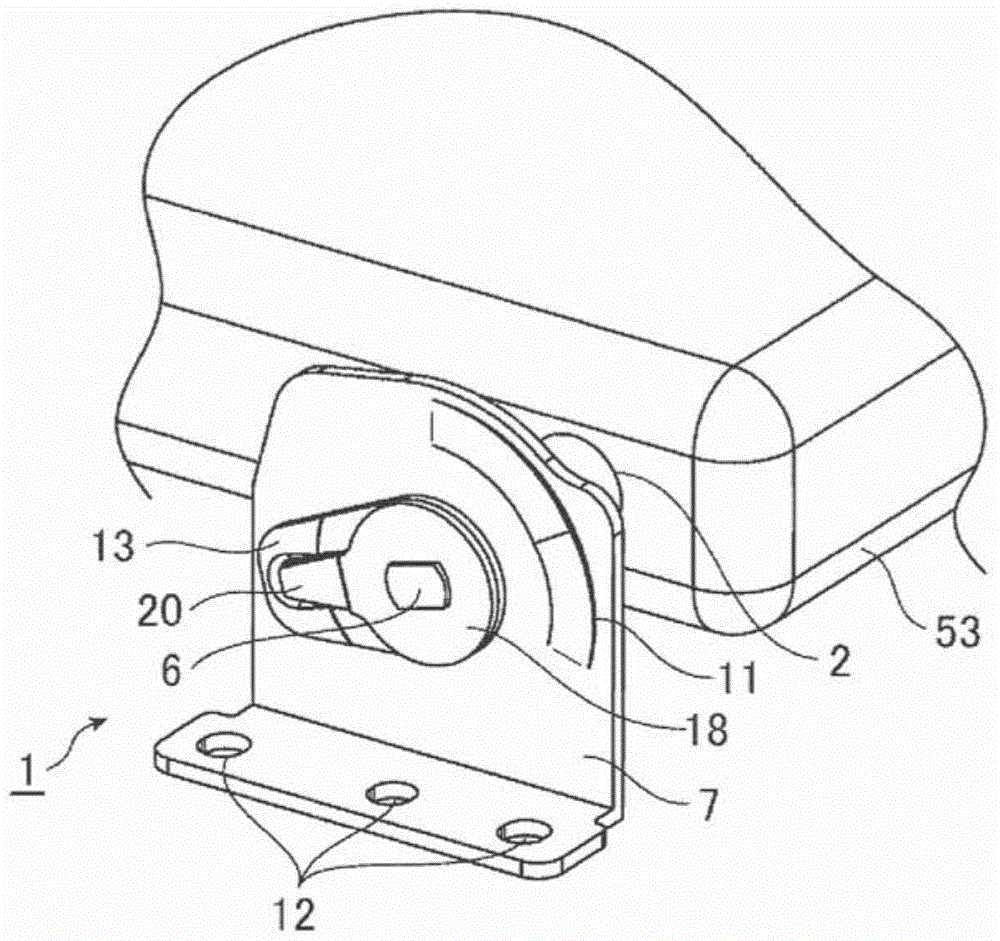

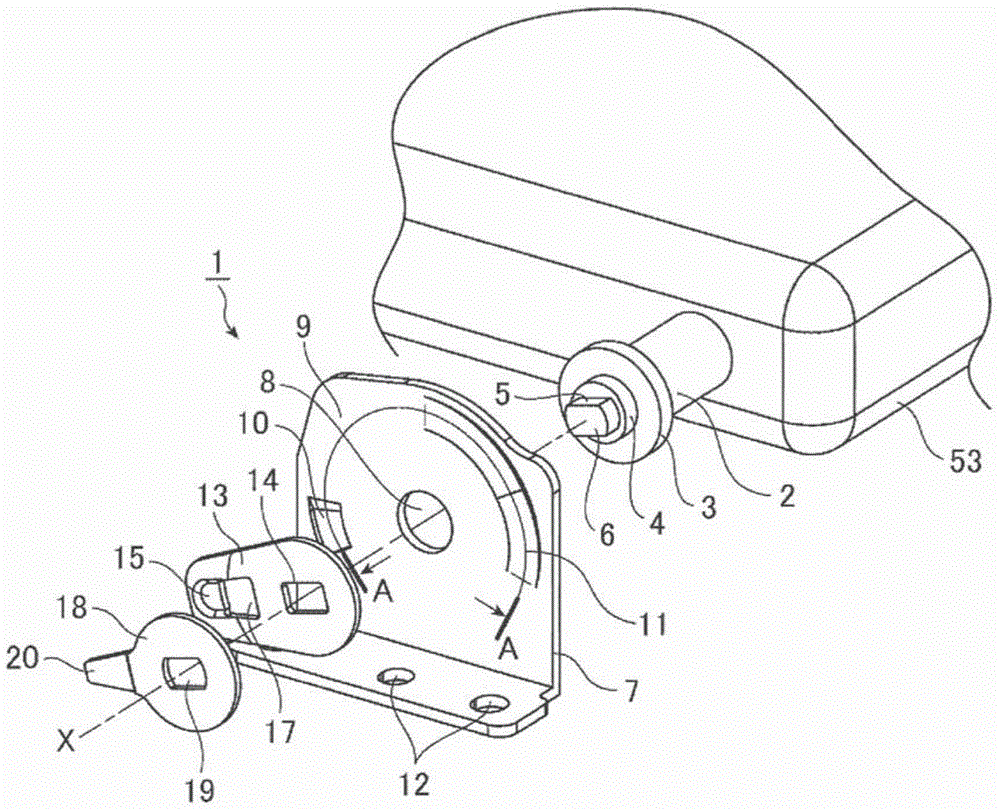

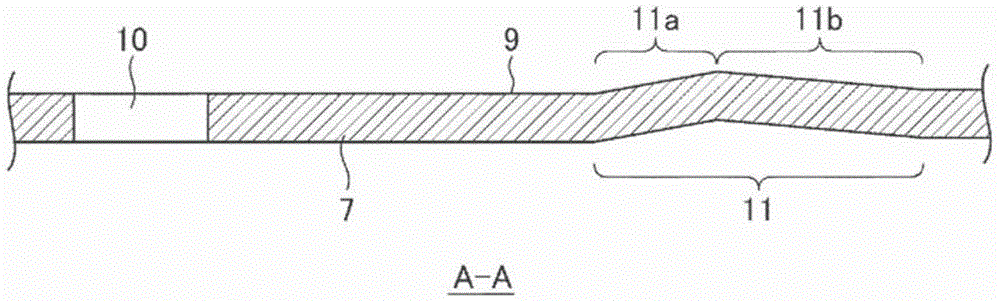

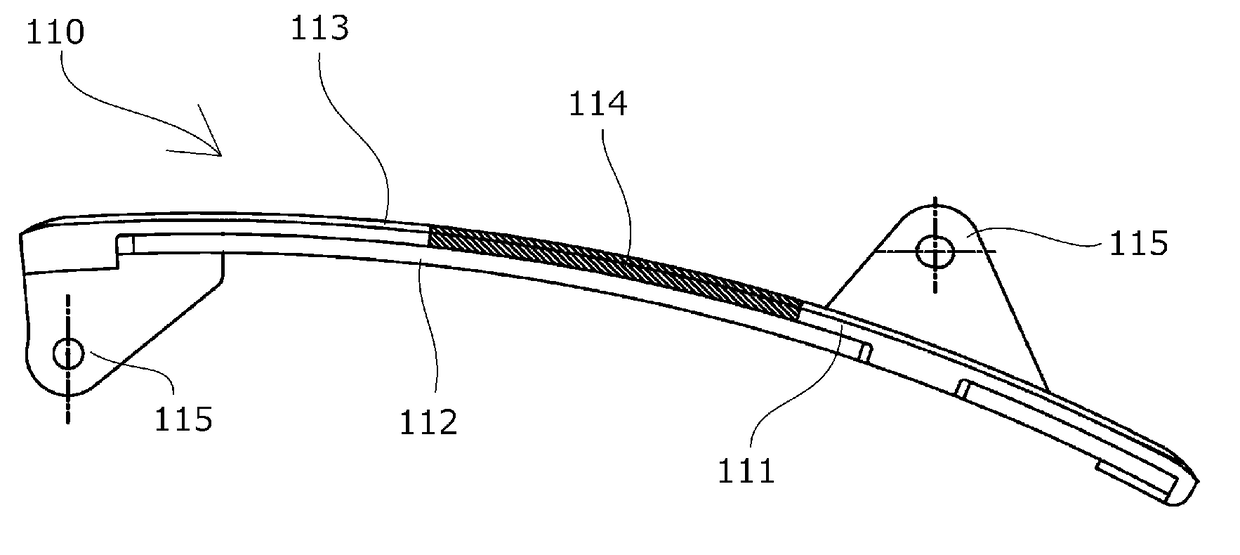

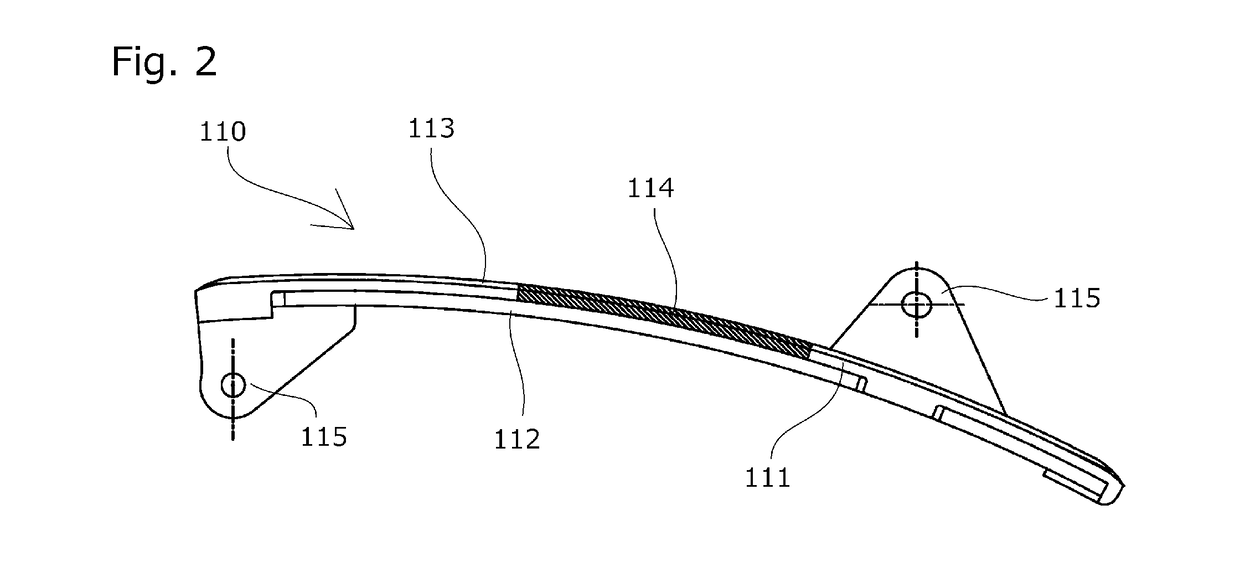

Hinge mechanism and panel apparatus

ActiveCN104838154ALow sliding resistanceIncrease sliding resistanceVehicle arrangementsCasings with display/control unitsEngineeringSurface plate

Owner:MITSUBISHI ELECTRIC CORP

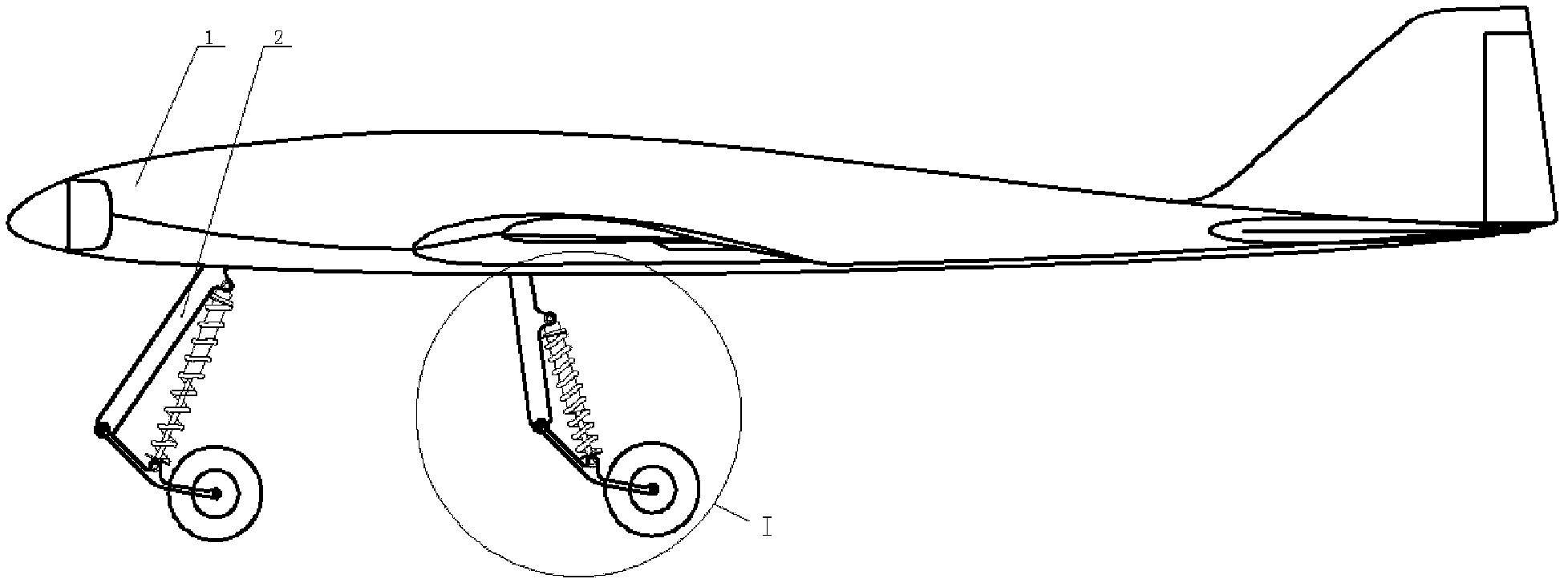

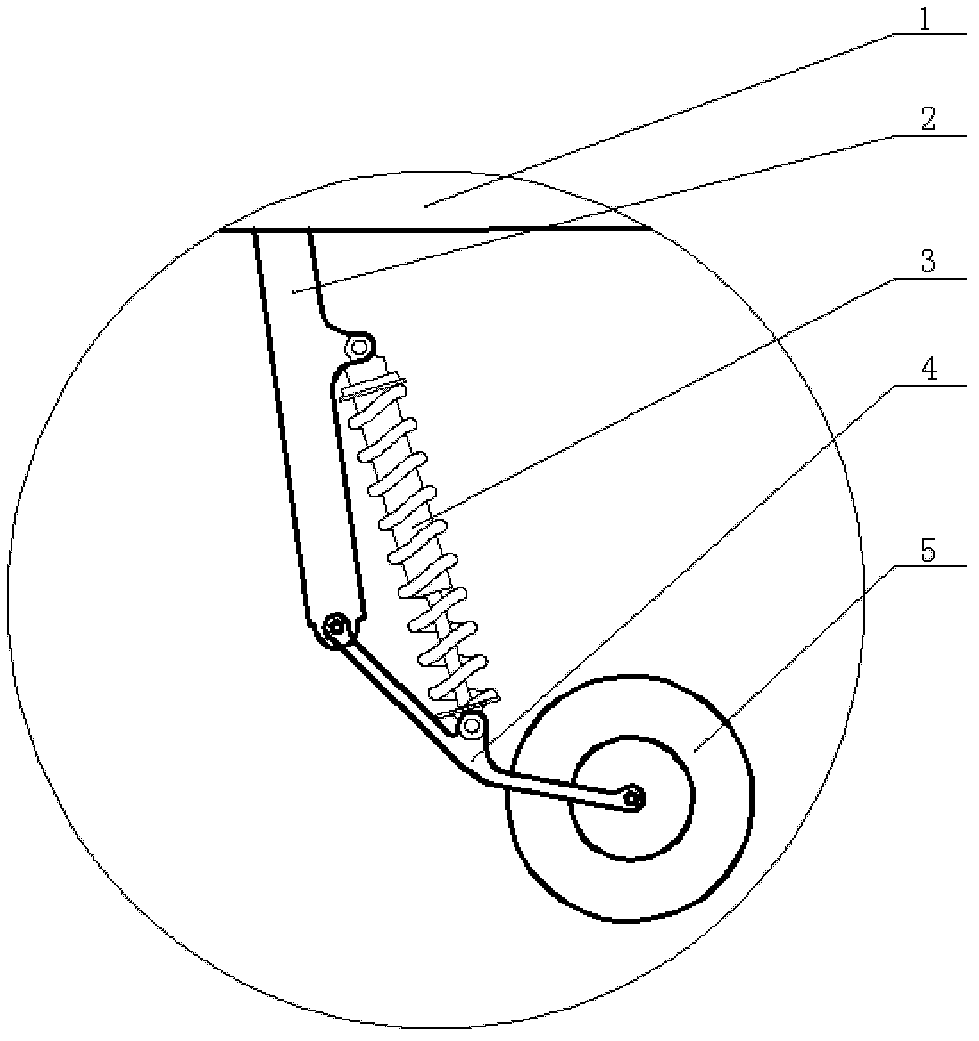

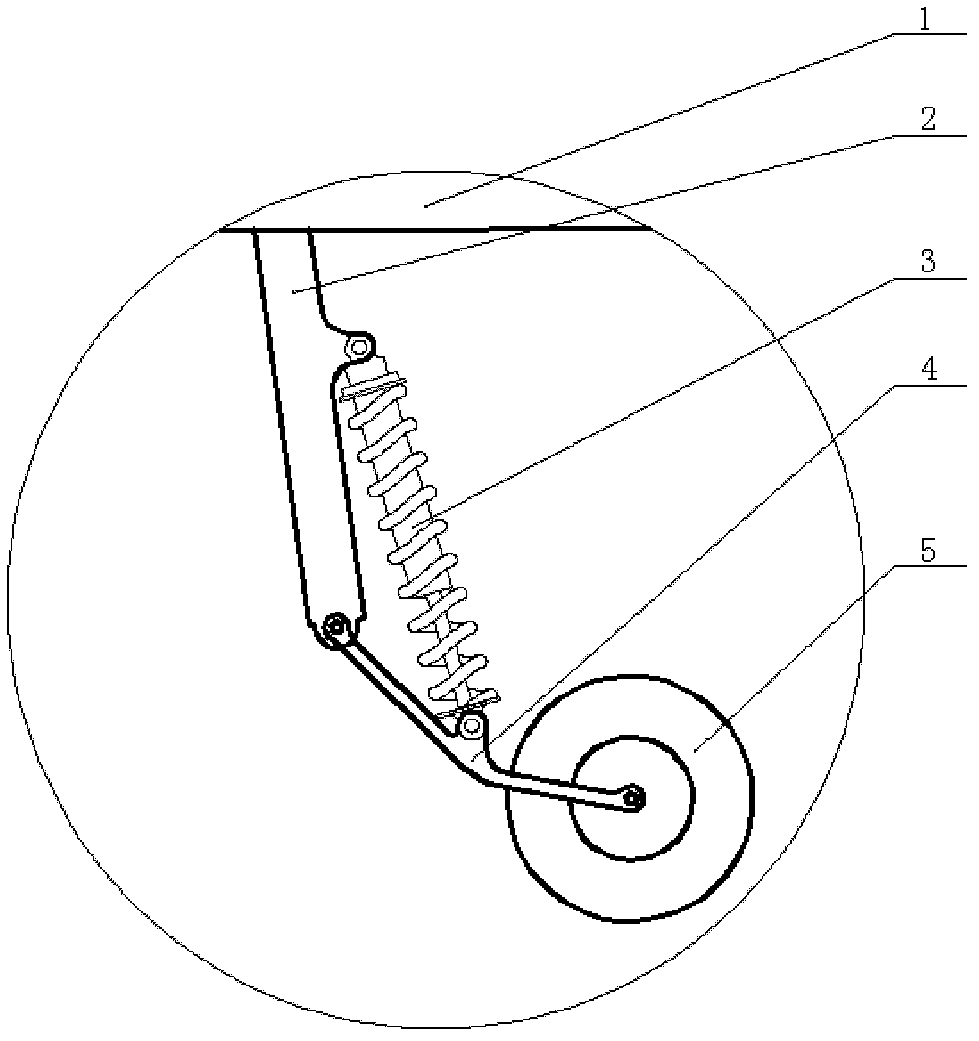

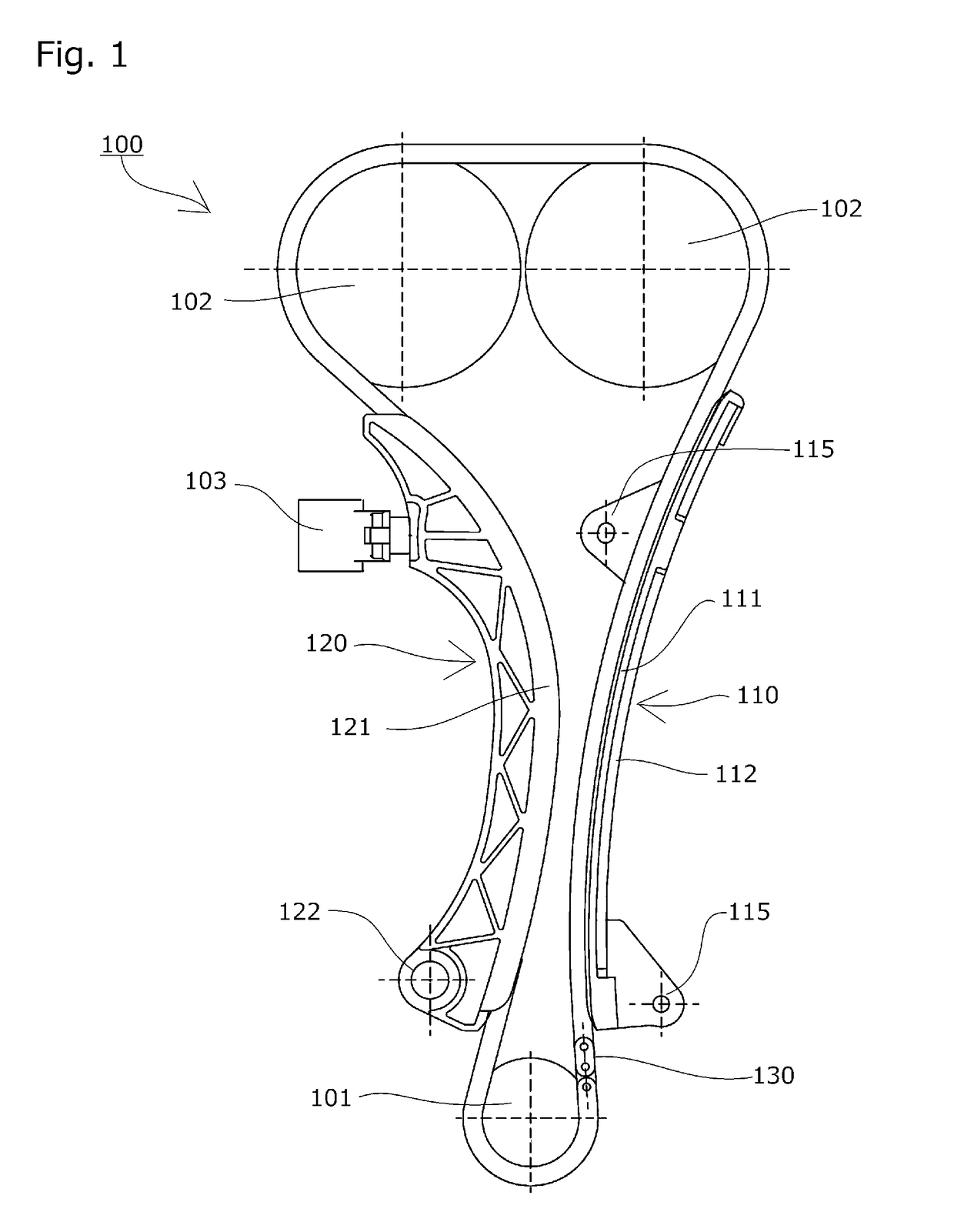

Sledge and wheel integrated landing gear for unmanned aircraft

InactiveCN102602532ASmooth landingImprove securityWheel arrangementsUndercarriagesTerrainJet aeroplane

The invention relates to a sledge and wheel integrated landing gear for an unmanned aircraft. The sledge and wheel integrated landing gear comprises a supporting arm and an aircraft wheel, wherein the upper end of the supporting arm is arranged at the bottom of the unmanned aircraft body; the aircraft wheel is arranged at the lower end of the supporting arm; a sledge is arranged between the aircraft wheel and the supporting arm; the upper end of the sledge is hinged to the lower end of the supporting arm of the landing gear; and the aircraft wheel is arranged at the lower end of the sledge. The sledge and wheel integrated landing gear is scientific in design and relatively low in cost and has a simple structure and a wide application range; due to a simple mechanical structure, the landing safety of the unmanned aircraft during landing is improved effectively, the shock absorption effect is good, and the sledge and wheel integrated landing gear is suitable for various environments with complicated terrains; the unmanned aircraft can be landed steadily in a flat flying place, a rugged land and a soft grass land, and obstacles with relatively large volumes can be kept away from the aircraft during landing; and furthermore, the sledge and wheel integrated landing gear occupies a small area and has a small volume, light mass, high reliability and long service life.

Owner:天津全华时代航天科技发展有限公司

Air bag system for vehicle

InactiveUS20100253054A1Reduce air pressureEasy to slidePedestrian/occupant safety arrangementEngineeringMechanical engineering

An air bag system for a vehicle including an air bag in a folded state and installed in a vehicle. The air bag is inflated and expanded by gas from an inflator, which introduces gas into the air bag. A vent hole is formed in at least one base fabric piece of the air bag so as to establish a communication path between an inside and an outside of the air bag through which gas may be discharged from the inside toward the outside of the air bag. A blocking member is supported on the base fabric piece to block up the vent hole. A guide portion is provided to slidably support the blocking member and to restrict the position of the blocking member relative to the vent hole. A sliding resistance increasing portion is provided on at least either one of the guide portion and the blocking member, so as to increase a sliding resistance between the guide portion and the blocking member when the blocking member slides.

Owner:HONDA MOTOR CO LTD

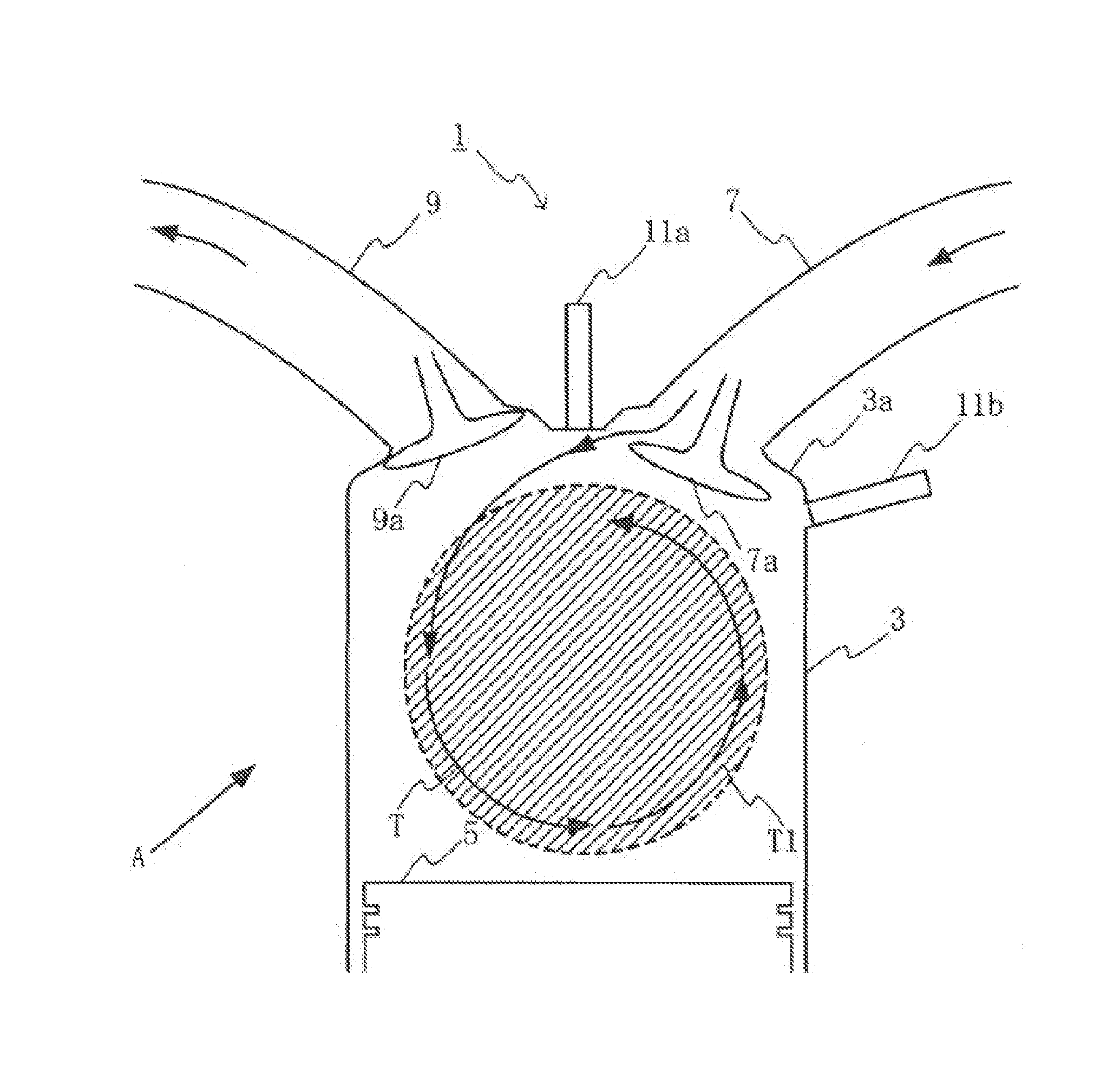

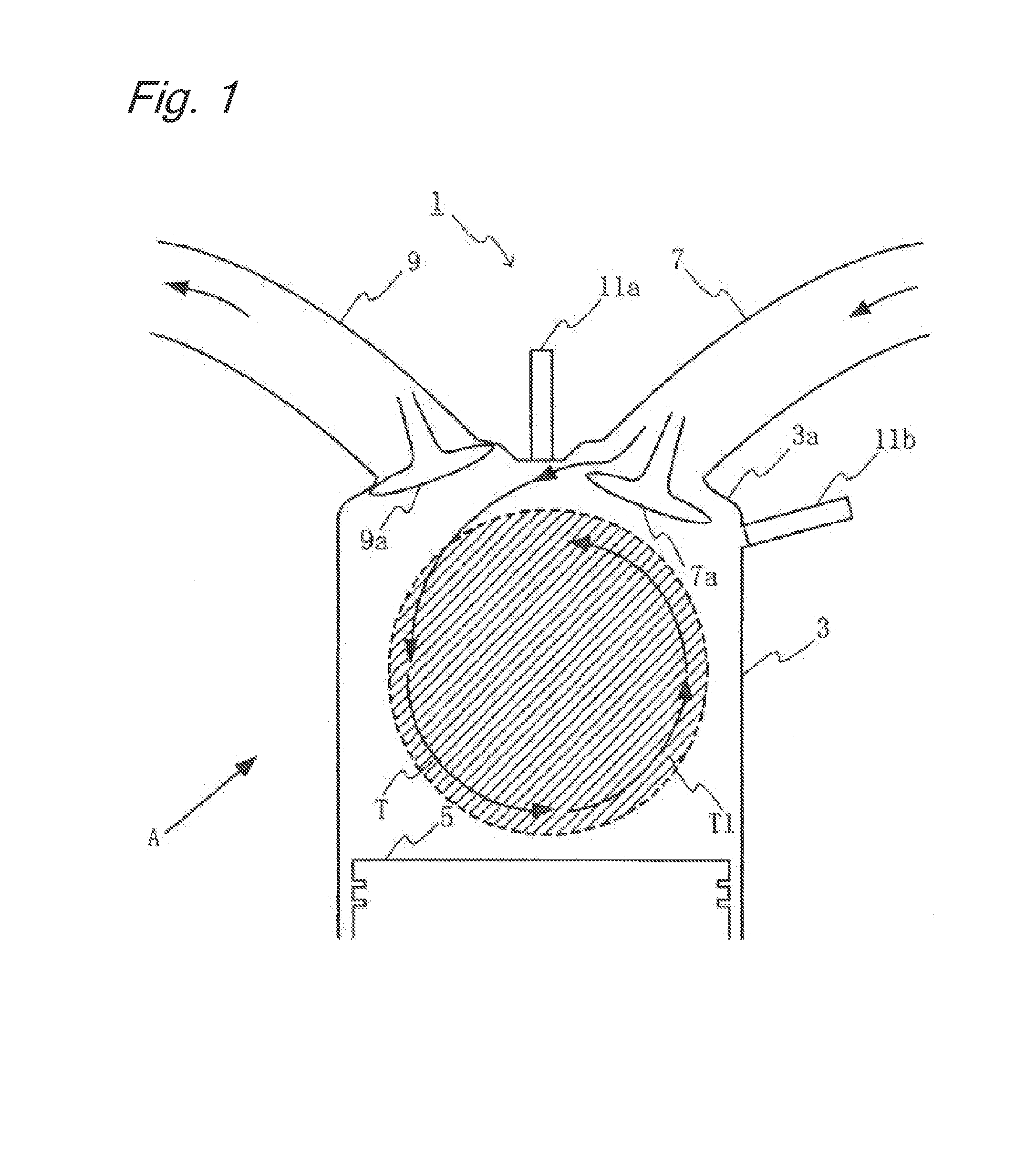

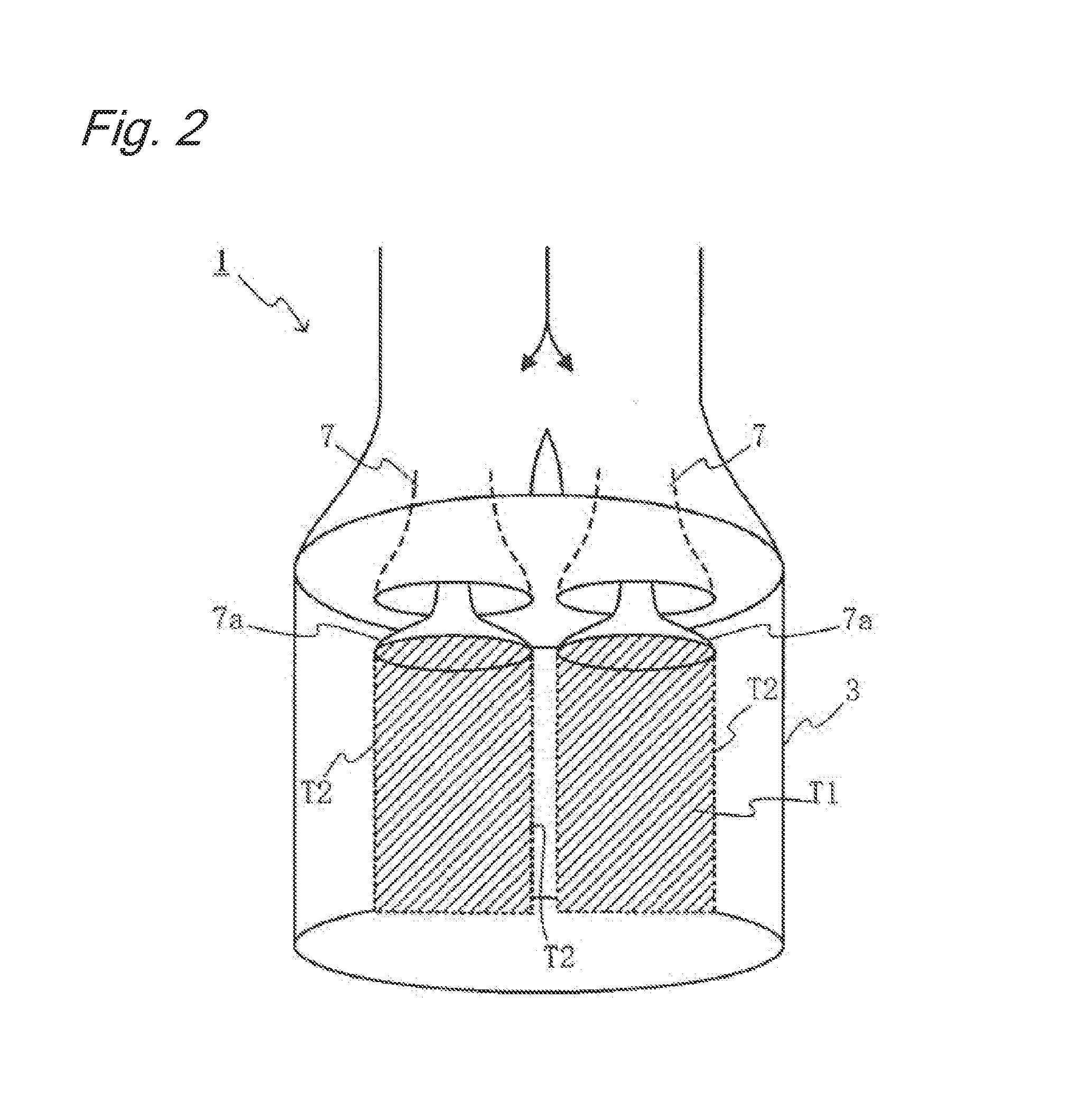

Fuel injection valve, internal combustion engine and fuel injection method

ActiveUS20140130772A1Reduce oil dilutionReduce adhesionInternal combustion piston enginesFuel injection apparatusPenetration forceInternal combustion engine

It is an object of the present invention to reduce the penetration of a fuel spray directed toward a certain area in a cylinder, thereby reducing oil dilution that increases sliding resistance in the engine, reducing fuel adhesion or the like onto the cylinder liner, and also reducing the adverse effect of a fuel spray having an increased penetration.A fuel injection valve that has a plurality of injection holes and injects fuel into a cylinder 3 of an internal combustion engine includes: injection holes a2 and a6 having a larger diameter for injecting fuel toward a ring-shaped space T1 including areas A2 and A6 of strong tumble flow T formed in the cylinder; and injection holes al, a4, a3 and a5 having a smaller diameter for injecting fuel toward a space including areas A1, A4, A3 and A5 of weak tumble flow formed in the cylinder 3. A fuel spray from an injection hole having the larger diameter has a penetration force to the tumble flow larger than the penetration force of a fuel spray from an injection hole having the smaller diameter.

Owner:BOSCH CORP

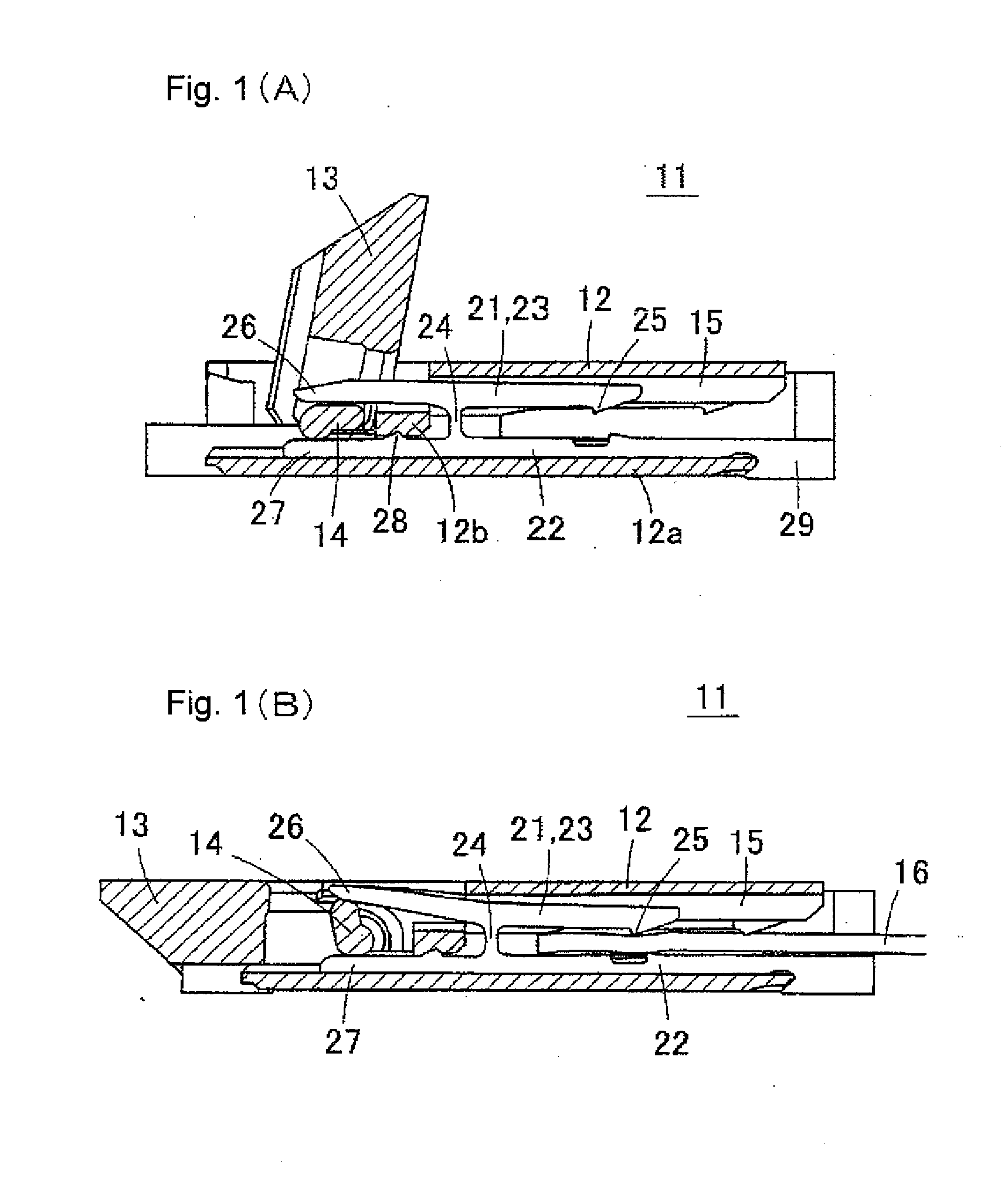

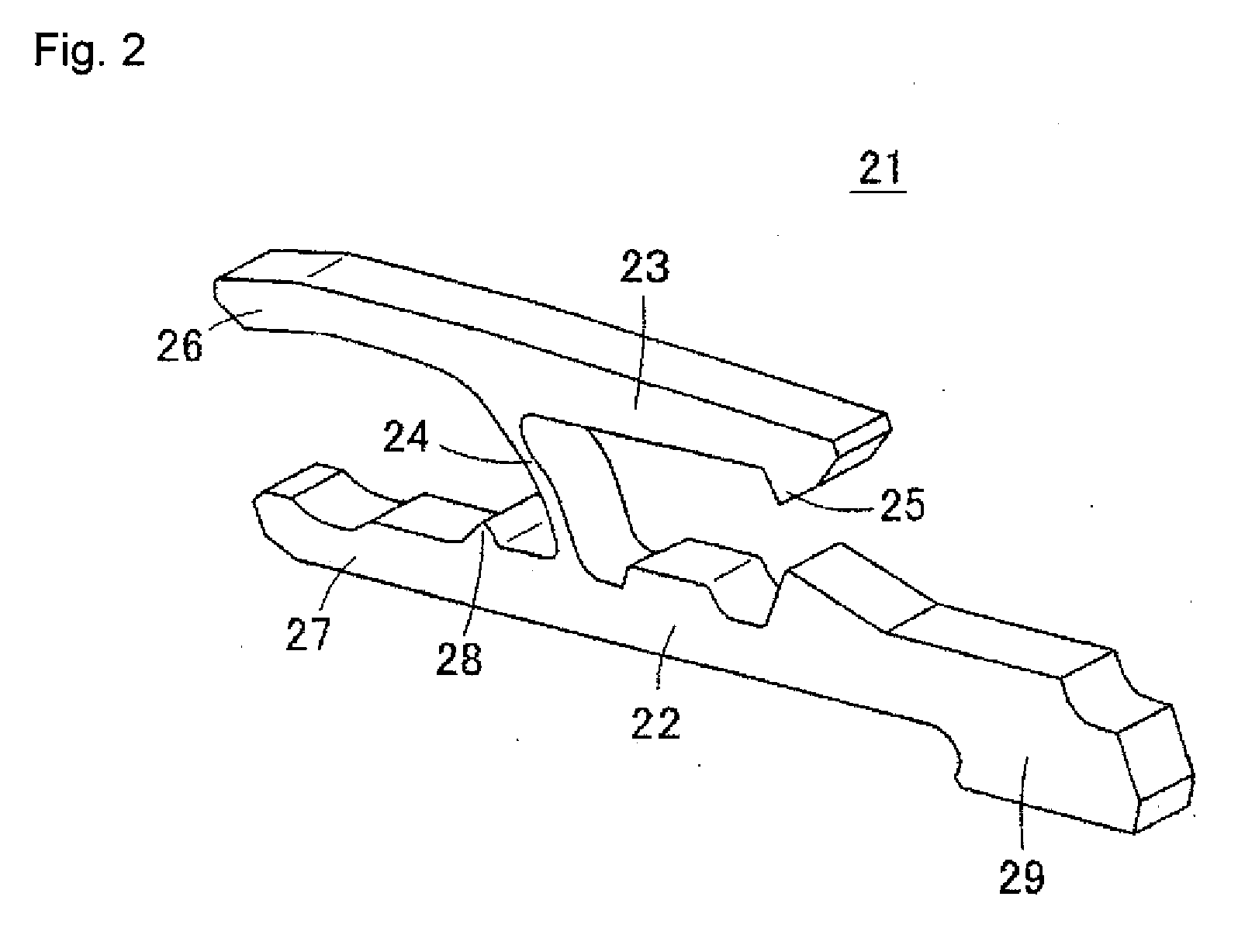

Yarn carrier of weft knitting device

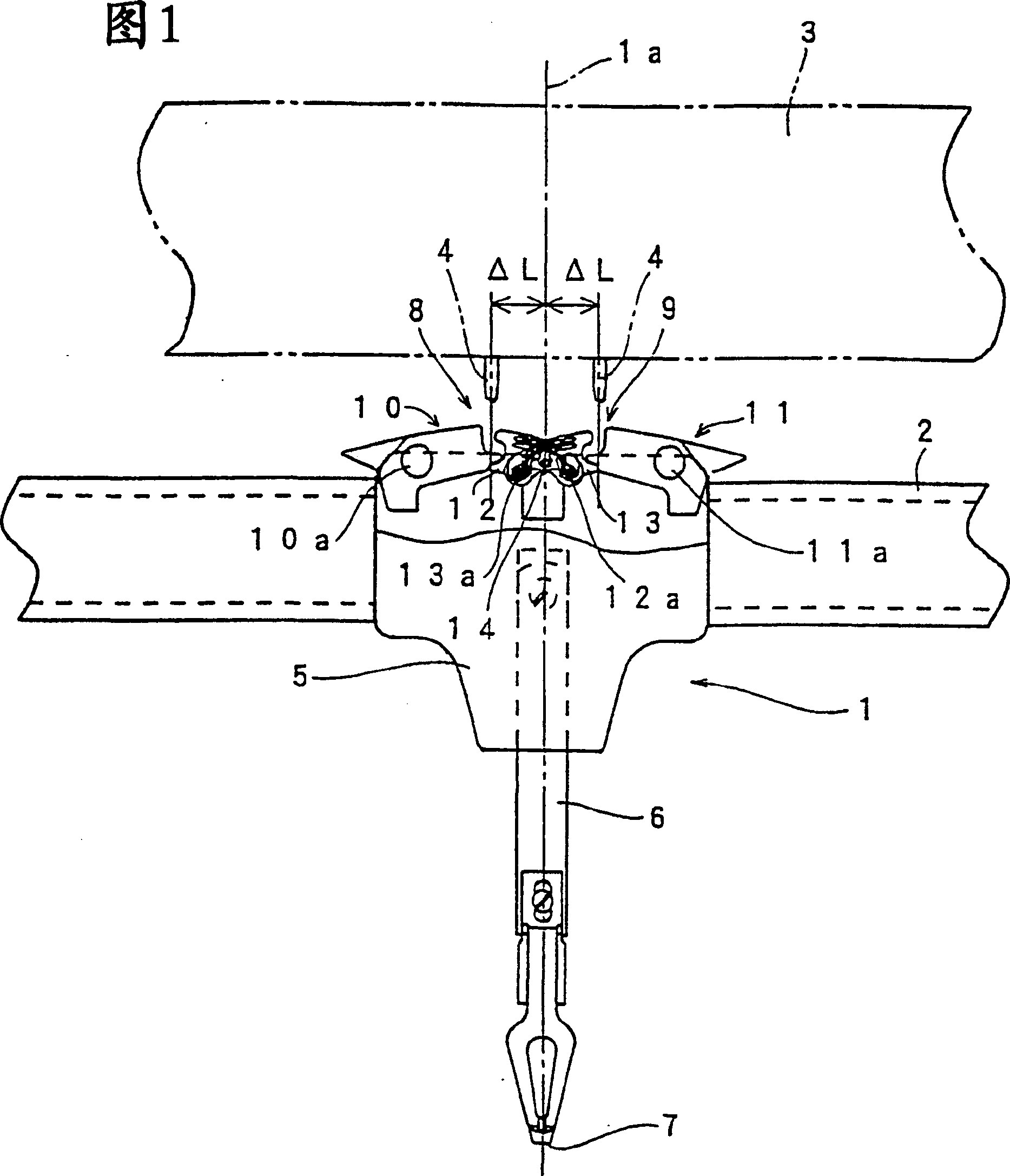

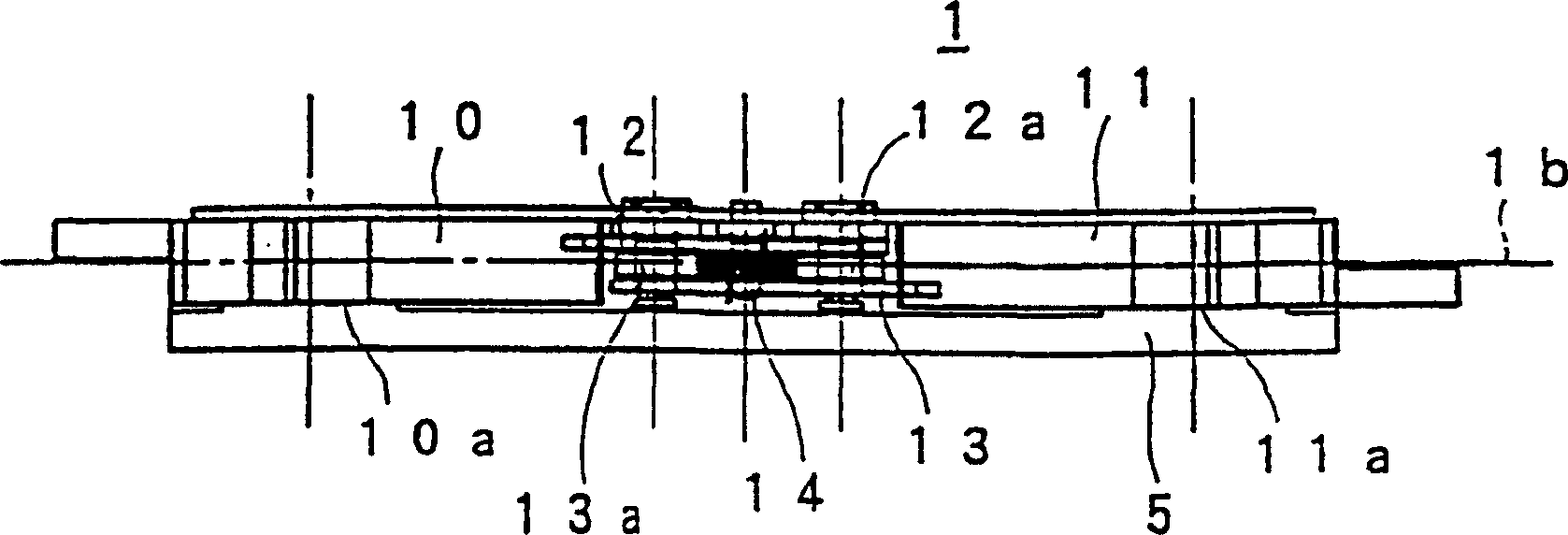

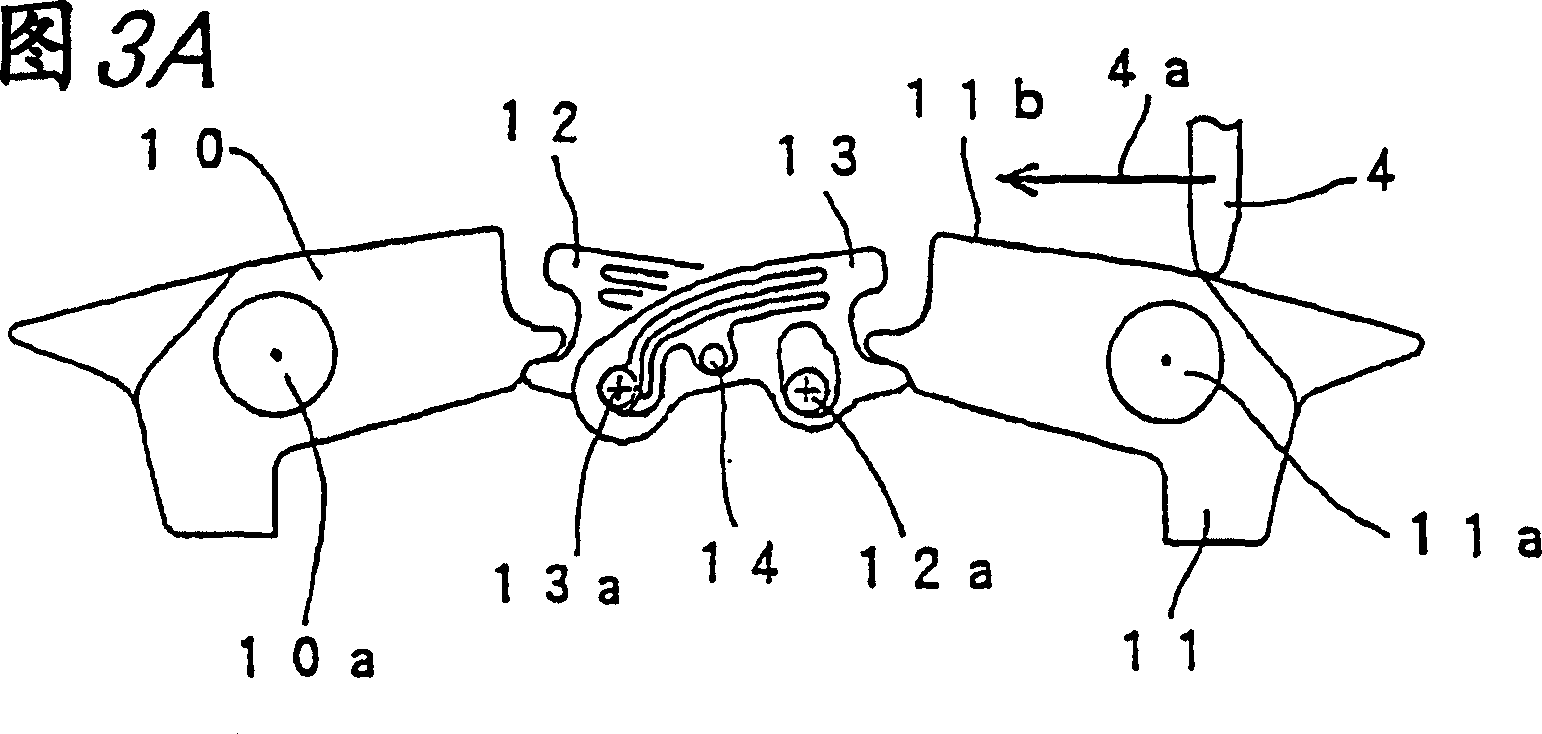

InactiveCN1500165AIncrease sliding resistanceEasy to break awayWeft knittingYarnBiomedical engineering

A yarn carrier 1 is capable of being engaged with a pin 4 protruding from a carriage 3 at two engagement points 8, 9 separated by a delay amount DeltaL with respect to a center 1a, respectively. Assuming that the carriage 3 approaches from the right with the pin 4 protruding in order to select and haul the yarn carrier 1 stationary on a yarn guide rail 2, the tip of the pin 4 is guided on a guide portion 11b of an oscillating piece 11, and a tip portion 11c prevents engagement with the engagement point 9 by making oscillation displacement about a shaft 11a. The pin 4 is guided to the engagement point 8 by guide portions 13a, 12a of oscillating plates 13, 12, and abuts on a tip portion 10c of an oscillating piece 10, which is engaged with the front side of the pin 4. The oscillating plate 12 also departs from the pin 4, and a tip portion 12c ascends to be engaged with the rear side of the pin 4.

Owner:SHIMA SEIKI MFG LTD

Production process of high-strength 6-series aluminum alloy profiles

ActiveCN111020251AEliminate compositional inhomogeneitiesImprove diffusion abilitySolution treatmentElectric machinery

The invention belongs to the field of aluminum alloy production processes, and relates to a production process of high-strength 6-series aluminum alloy profiles. The production process includes the following steps that aluminum alloys are batched according to a certain mass percentage; the prepared aluminum alloy raw material is placed in a smelting furnace to be smelted into a liquid aluminum alloy, the liquid aluminum alloy is melted and cast into aluminum alloy ingots; the aluminum alloy ingots are heated to 565 DEG C, the temperature is kept for 8h, and then the aluminum alloy ingots are subjected to air cooling to a room temperature; the aluminum alloy ingots are preheated to 515 DEG C, an extrusion container is heated, the temperature is raised to 450+ / -10 DEG C, and then extrusion is carried out to obtain the aluminum alloy profiles; the extruded aluminum alloy profiles are subjected to solution treatment, a solution treatment temperature is 565 DEG C, the temperature is kept for 55 min, and the aluminum alloy profiles after the solution treatment are quenched with quenching liquid; the quenched aluminum alloy profiles are cold-treated; and the cold-treated aluminum alloy profiles are subjected to aging treatment. According to the production process of the high-strength 6-series aluminum alloy profiles, the alloy compositions of the aluminum alloys are improved and a heat treatment process is optimized through improvement of the process so that the production process of the high-strength 6-series aluminum alloy profiles can adapt to the use requirements of aluminum alloy motor shells.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

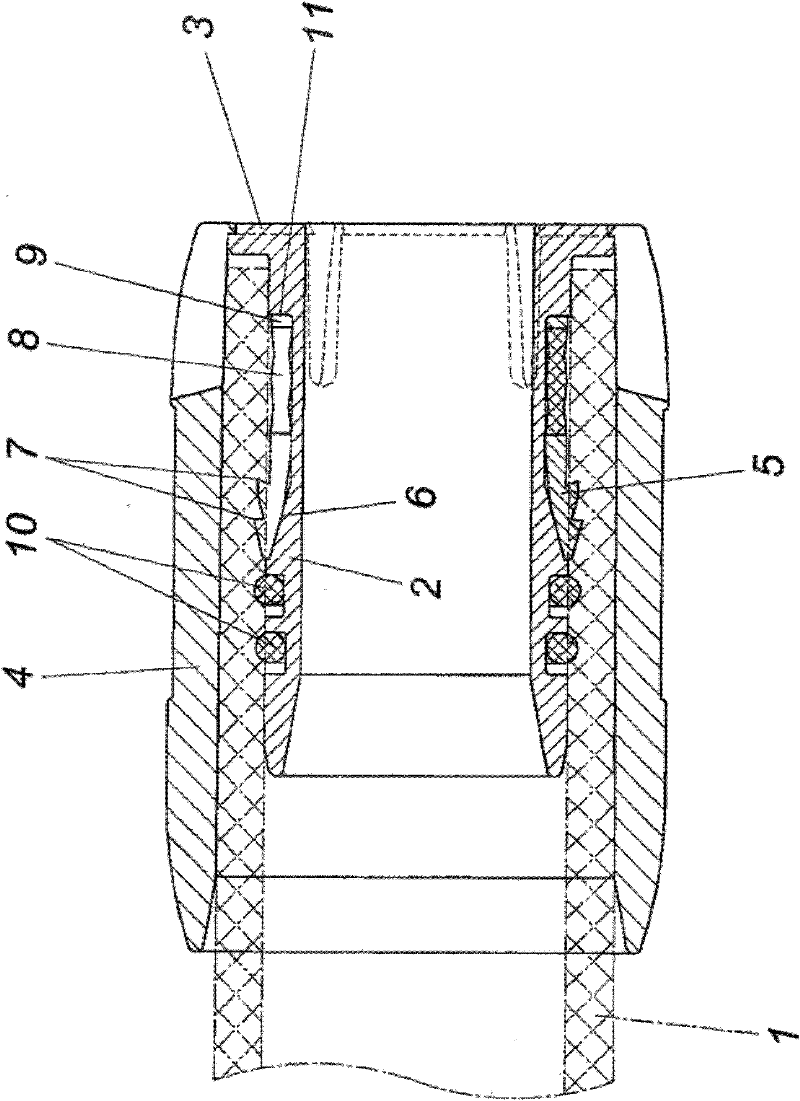

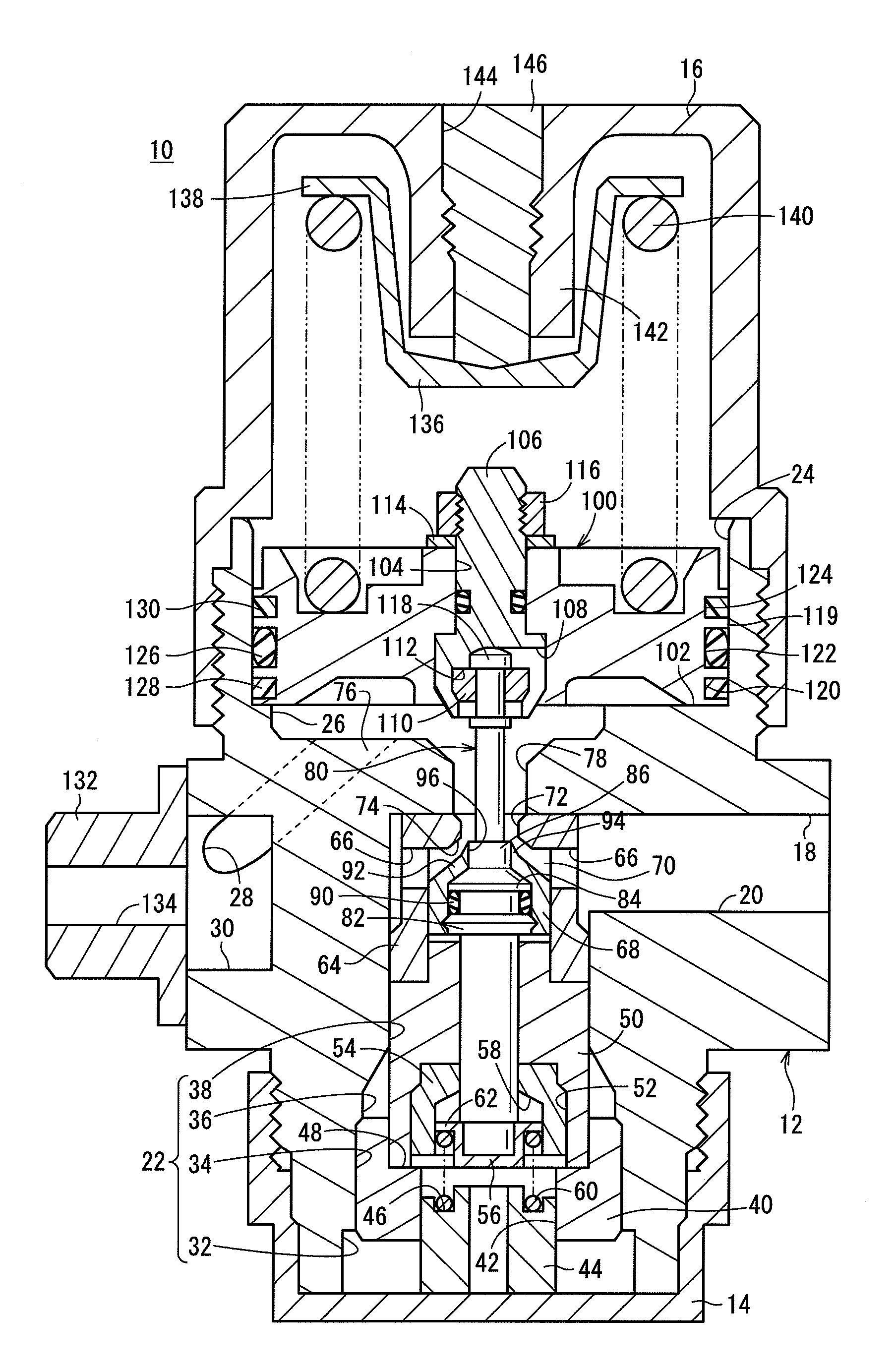

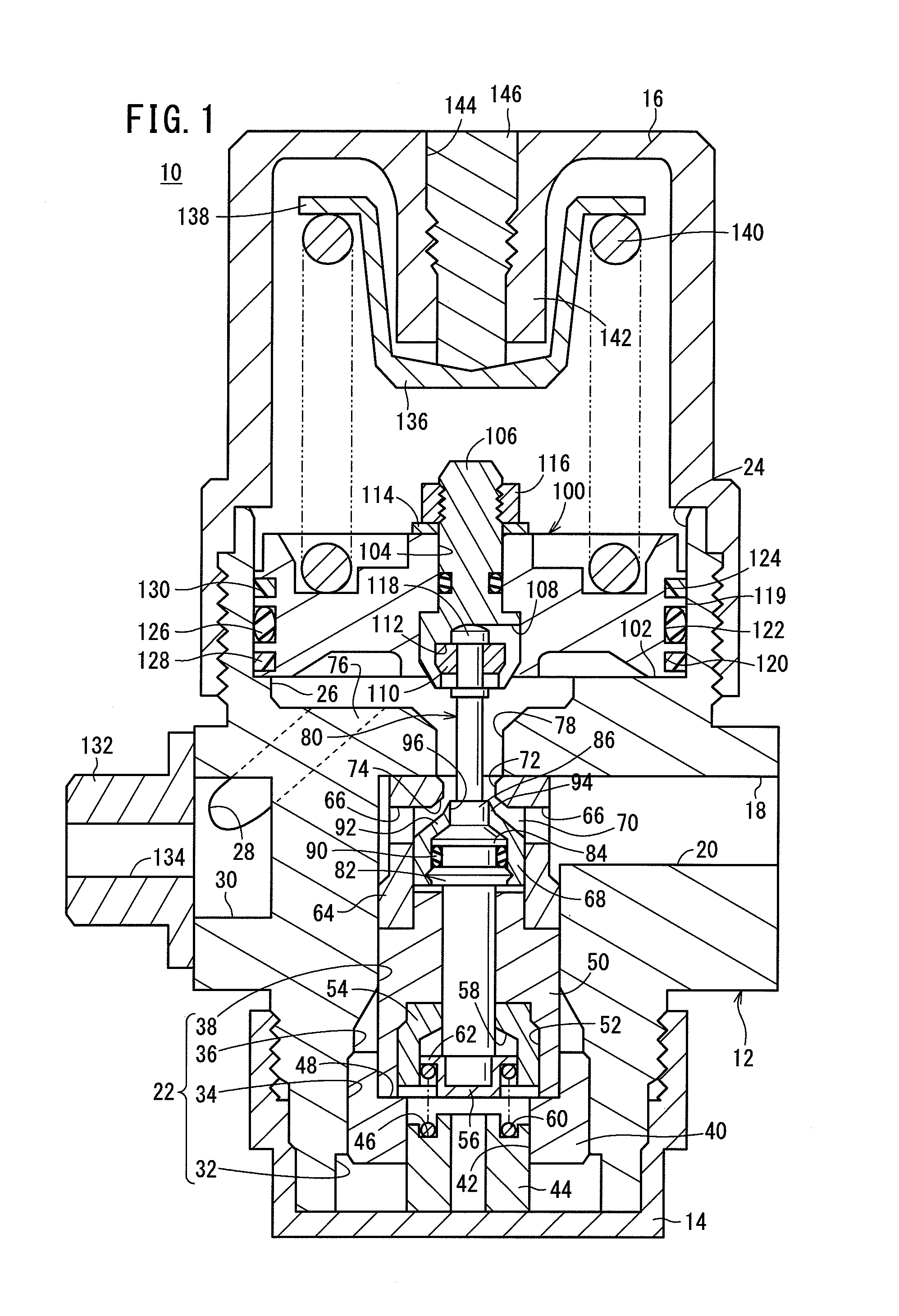

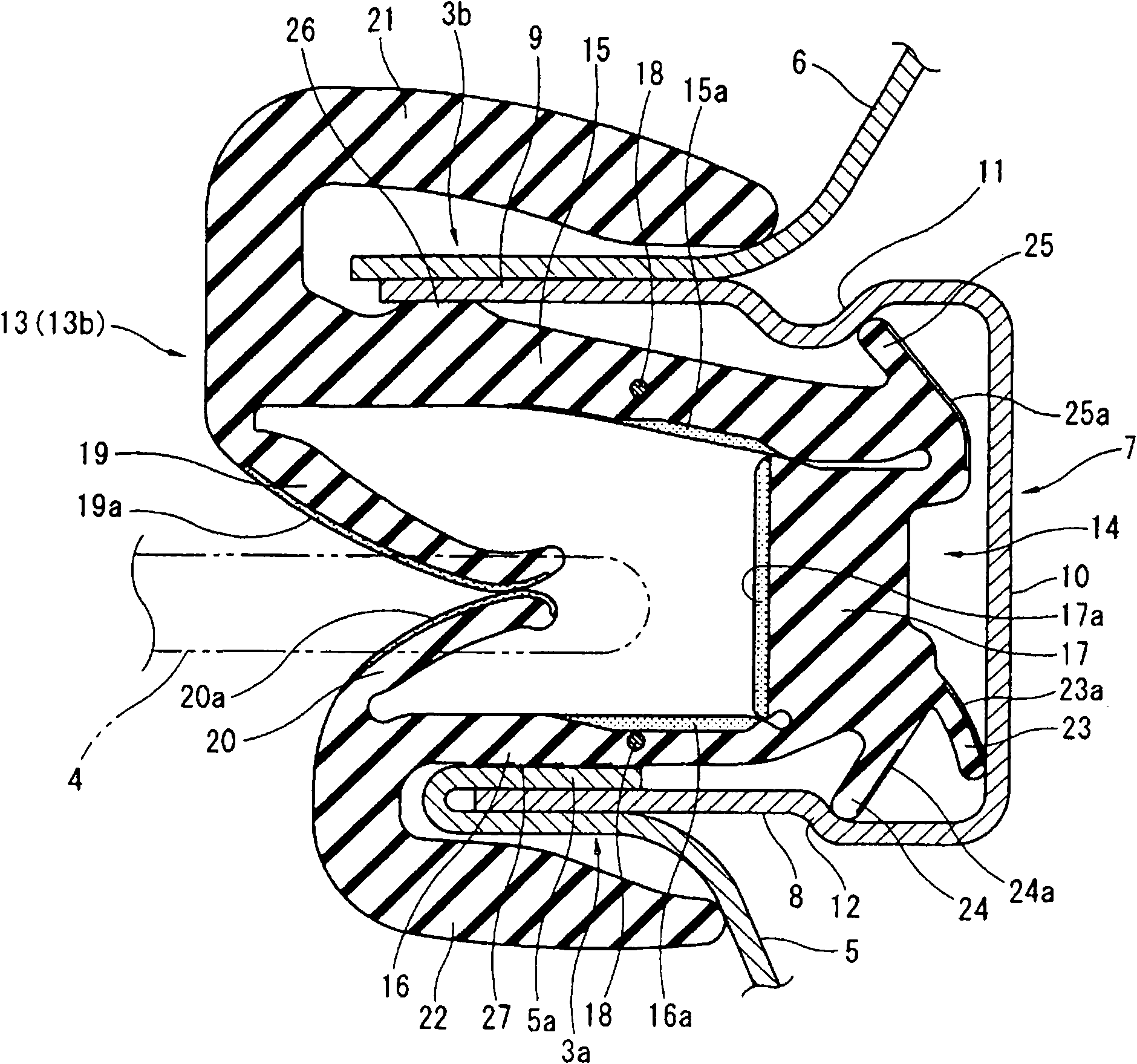

Solenoid actuator

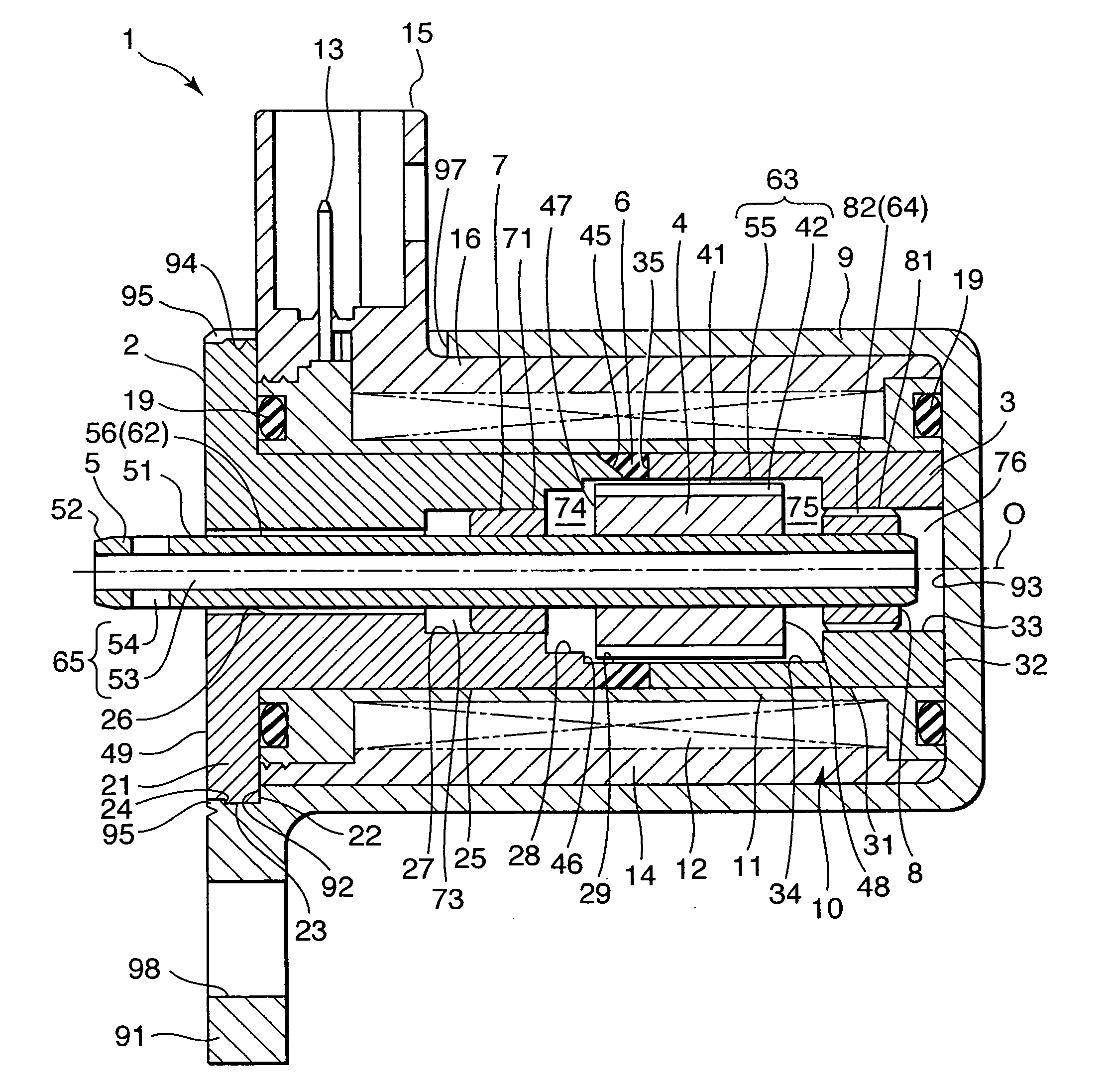

InactiveUS20100111727A1Reduced sliding resistanceAvoid depositionOperating means/releasing devices for valvesPiston pumpsHydraulic equipmentEngineering

A solenoid actuator (1) attached to hydraulic equipment comprises a shaft (5) connected to the hydraulic equipment, a plunger (4) fixed to the shaft (5), a coil (12) which magnetically drives the plunger (4), and a first bearing (7) and a second bearing (8) supporting the shaft (5) on either sides of the plunger (4). A plunger front chamber (74) is formed between the first bearing (7) and the plunger (4), and a plunger rear chamber (75) is formed between the plunger (4) and the second bearing (8). By providing a plunger exterior oil passage (63) on the outside of the plunger (4) to connect the plunger front chamber (74) to the plunger rear chamber (75), working oil flows through the plunger exterior oil passage (63) every time the plunger (4) strokes, thereby preventing a deposit of contaminant on the plunger (4) without increasing a stroke resistance of the plunger (4).

Owner:KYB CORP

Pressure reducing valve

ActiveUS20140290760A1Displacement speedIncrease sliding resistanceOperating means/releasing devices for valvesFluid pressure control without auxillary powerEngineeringMechanical engineering

A pressure reducing valve has a seal member, which is mounted on a side wall of a piston. The seal member is arranged between a first ring and a second ring. Consequently, depending on the direction of displacement of the piston, the first ring or the second ring is positioned on one of a displacement direction upstream side or a displacement direction downstream side of the seal member. The first ring and the second ring are made of a resin material, for example a polytetrafluoroethylene resin or a polyetheretherketone resin, having lower coefficient of friction compared with that of the seal member.

Owner:HONDA MOTOR CO LTD

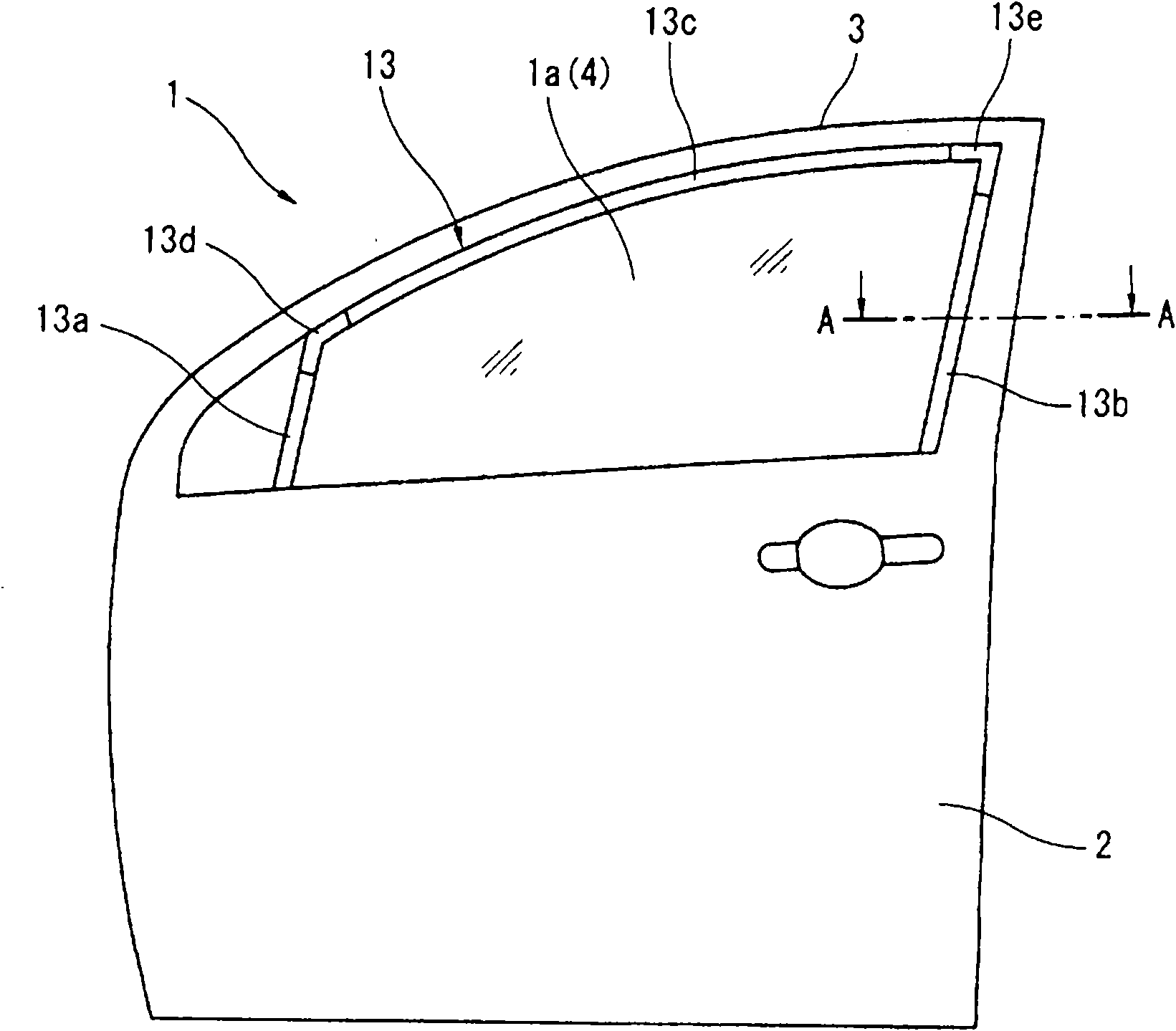

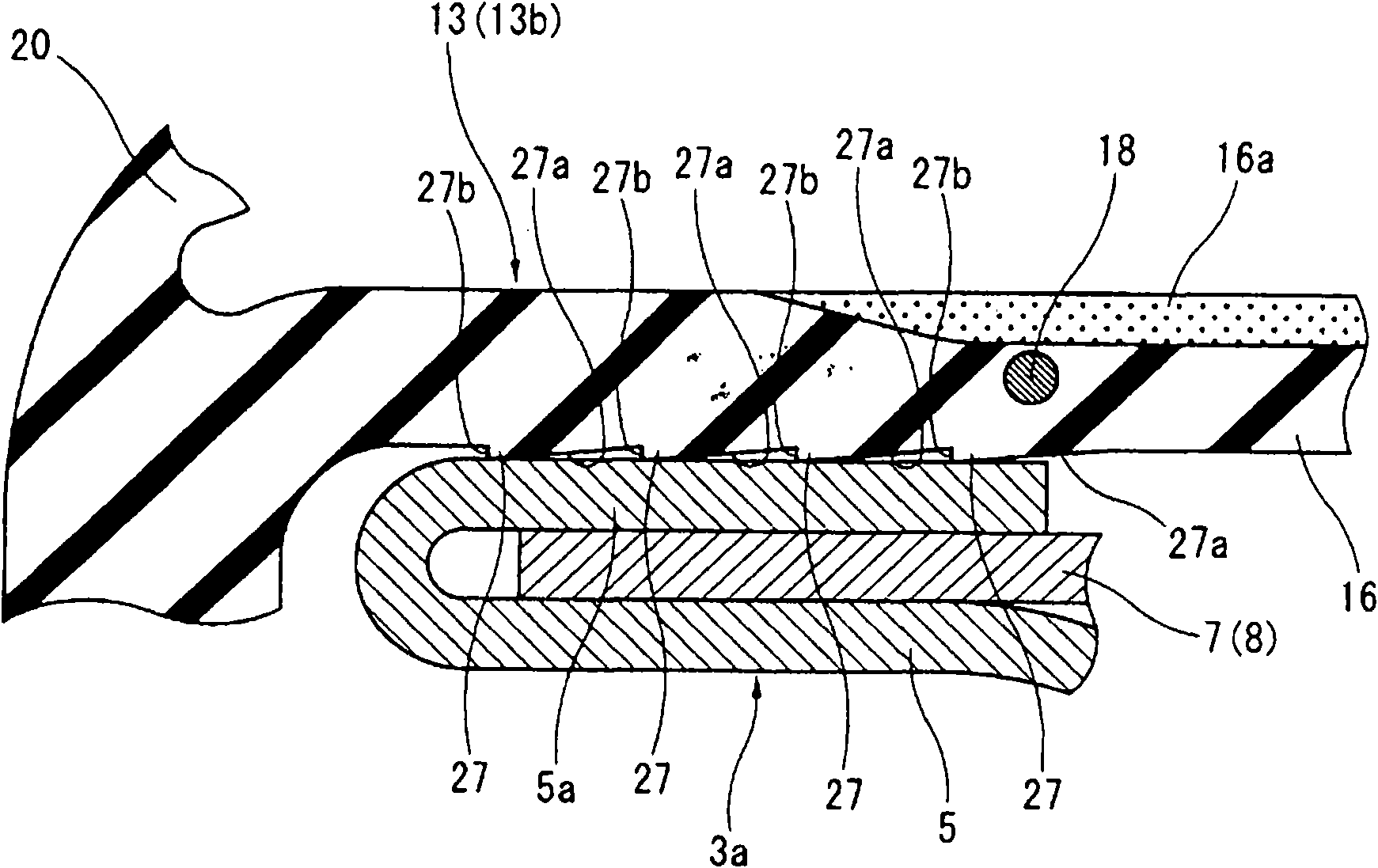

Door and window glass guide slot

The invention provides a door and window glass guide slot for reducing friction noise between door and window glass and a window frame part during the lifting action of the door and window glass and increasing retention relative to the window frame part. The solution scheme is as follows: a plurality of raised strip parts (27) are formed side by side on a contact surface of a longitudinal side part (13b) of the door and window glass slot extending along the vertical direction and an overlapped flange part (3a) at the outer side of a cab at the side of a window frame part (3), wherein the raised strip parts (27) incline towards the opening end of the longitudinal side part (13b) of the door and window glass guide slot, and the sections of the raised strip parts (27) are approximately jagged. Therefore, the contact area between the longitudinal side part (13b) of the door and window glass slot and the overlapped flange part (3a) at the outer side of the cab is reduced, the friction noise generated when the door and window glass (4) doing the lifting action is pulled and drawn and the longitudinal side part (13b) of the door and window glass slot moves along the vertical direction is reduced, and meanwhile, the longitudinal side part (13b) of the door and window glass slot is prevented from loosening by utilizing all the raised strip parts (27), and the retention of the longitudinal side part (13b) of the door and window glass slot relative to the window frame part (3) is increased.

Owner:KINUGAWA RUBBER IND CO LTD

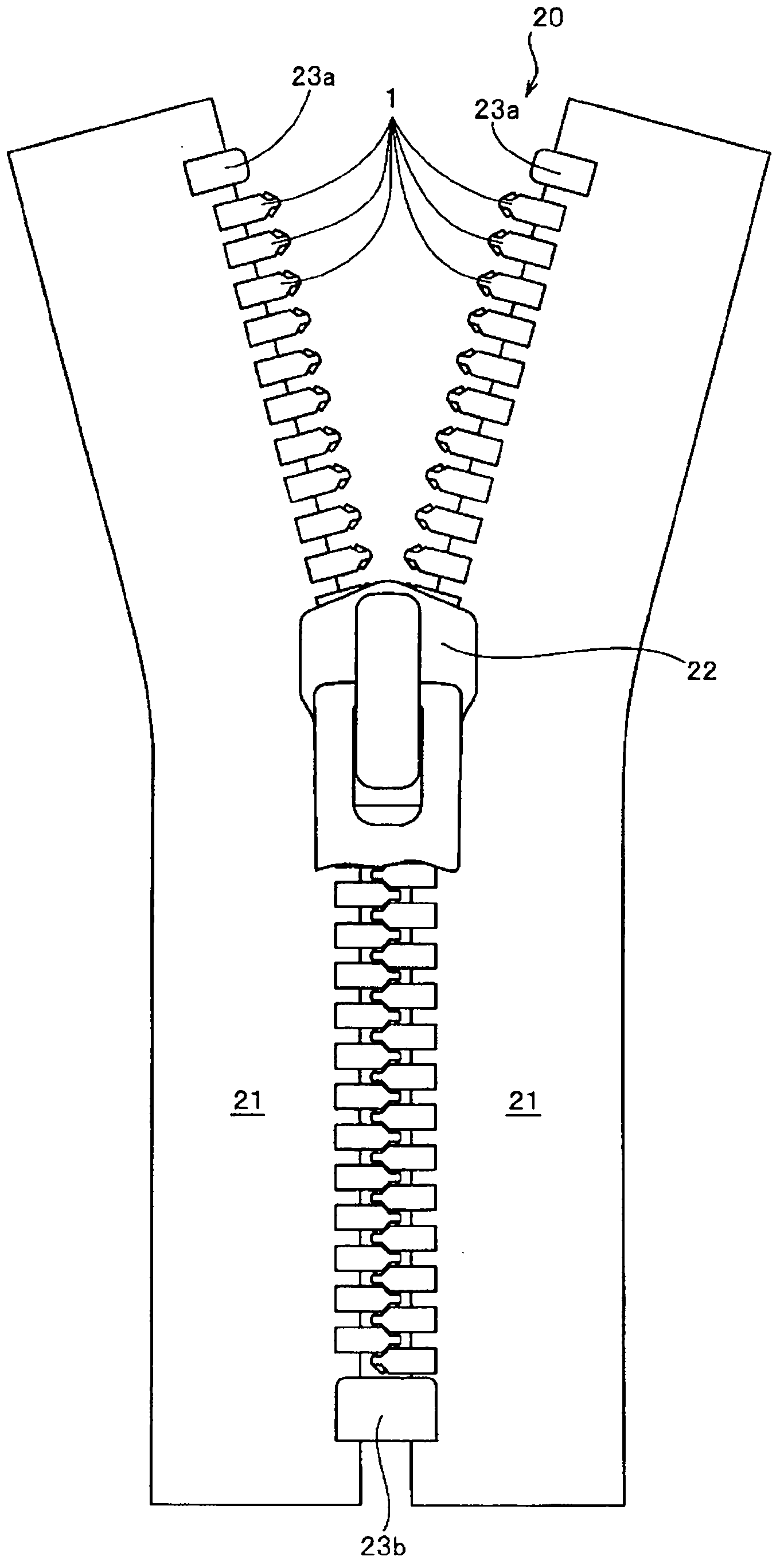

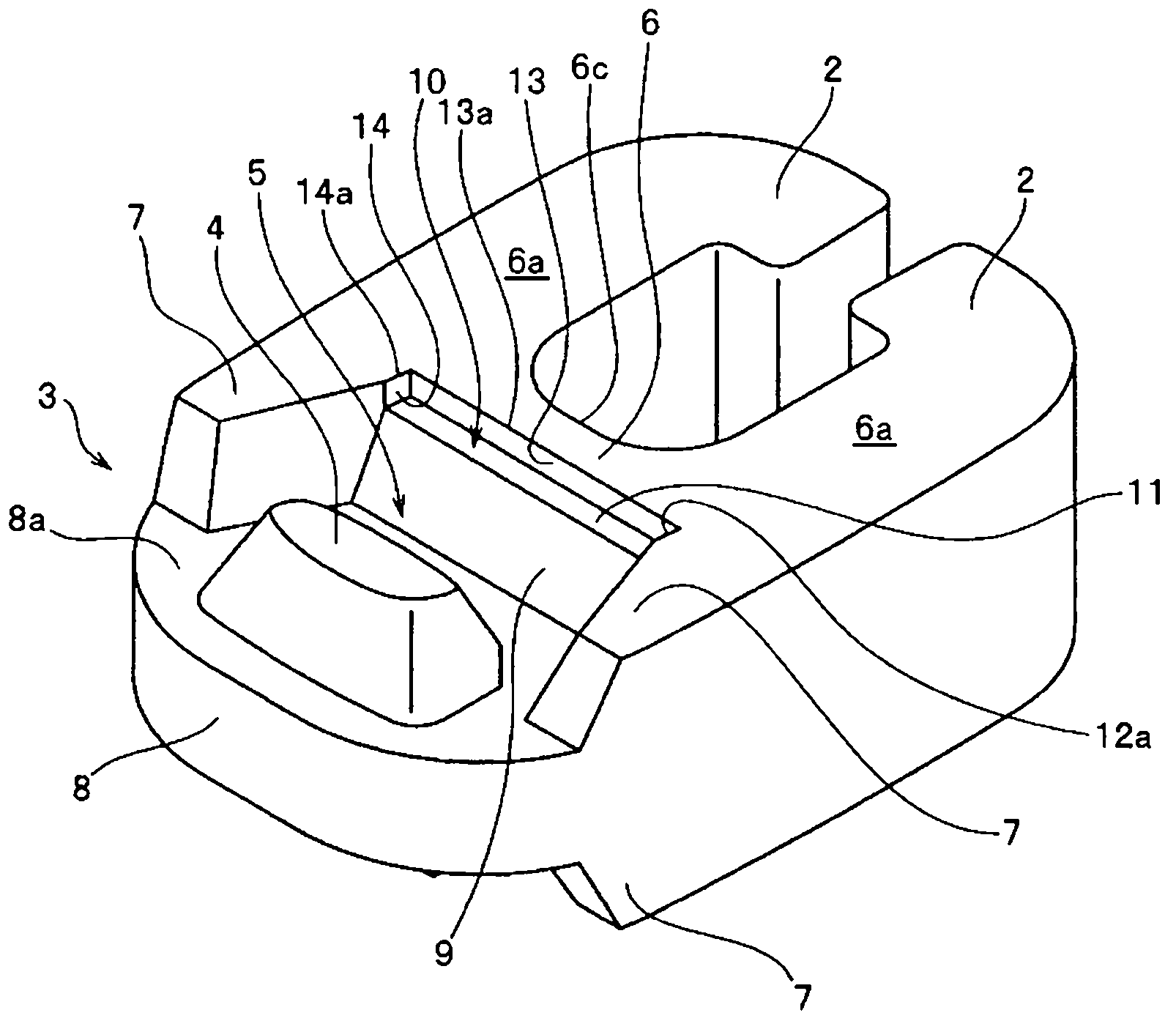

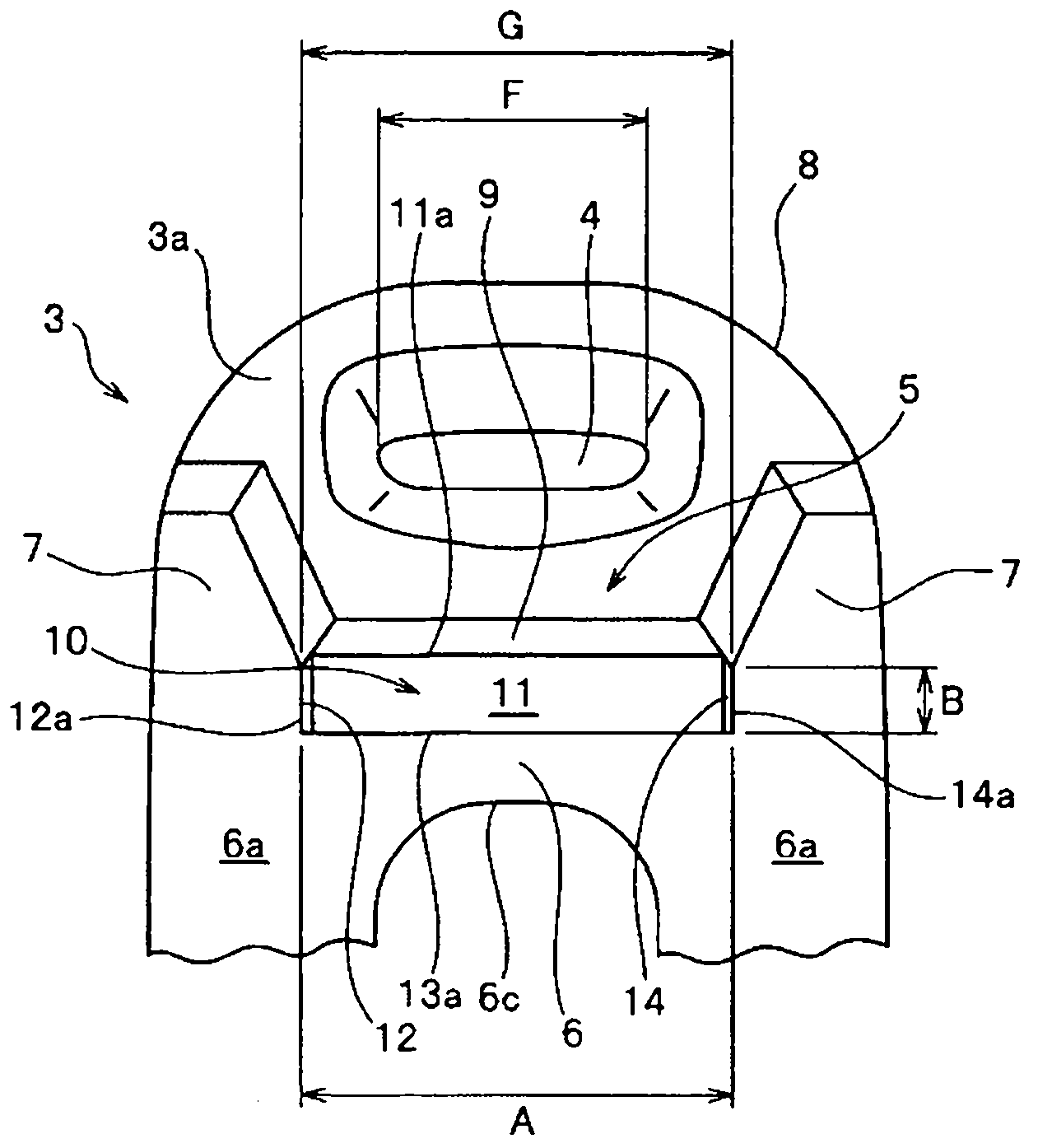

Metal double-sided tooth and slide fastener

ActiveCN102858200AIncrease sliding resistanceNo increase in sliding resistanceSlide fastenersPush outFastener

Provided is a metal double-sided tooth configured in such a manner that a fluid protrusion does not get pushed out from the boundary surface between an interlock recess and a body. Also provided is a slide fastener that uses the metal double-sided tooth. The shape of the inner peripheral surface of the interlock recess (5) exhibits a roughly conical shape, and straddles the boundary surface (9) of the interlock recess (5) and the body (6), together with the surface (6a) and undersurface (6b) of the body (6) to form a recessed portion (10). When the metal double-sided tooth (1) is attached to fastener tape, the fluid protrusion produced by crimping a pair of legs (2) can be prevented from getting pushed outside from the surface and undersurface of the body or the side of the interlock recess, until sliding friction has been generated in the slider.

Owner:YKK CORP

Chain drive system

An object of the present invention is to provide a chain drive system that can reduce sliding resistance between a chain and a guide shoe, minimize increase of sliding resistance over time, and reduce production cost. Provided is a chain drive system 100 including a plurality of sprockets 101 and 102 over which a chain 130 passes over, and one or more guides 110 and 120 that guide the chain 130. The guides 110 and 120 include integral or separate guide shoes 111 and 121 each having a chain running surface. The chain running surfaces include, in part thereof, a lubricated area 114 where a solid lubricant P is held.

Owner:TSUBAKIMOTO CHAIN CO

Contact and method for manufacturing metal component

ActiveUS20130045617A1Increase contact pressureImprove electrical contact reliabilityEngagement/disengagement of coupling partsContact member manufacturingResistElectroplating

A method for manufacturing a metal component includes the steps of forming a resist film on a surface of an electrode plate, making the resist film exposed to light by use of a photomask having a mask pattern, in at least part of a rim of which a fine concavity and convexity are drawn, developing the resist film, to form an opening for molding in the resist film, and epositing an electroforming material by electroforming inside the opening for molding, to mold the material.

Owner:ORMON CORP

Unmanned aerial vehicle retractable type ski recovery device

PendingCN108674638AReduce coefficient of frictionStrong toughnessSkis/runnersUndercarriagesWear resistantEngineering

The invention discloses an unmanned aerial vehicle retractable type ski recovery device. The unmanned aerial vehicle retractable type ski recovery device comprises that a front shrinking cylinder is installed inside a belly of a machine body, the top end of a front shock absorber is fixedly installed at the bottom of the front shrinking cylinder and the bottom end of the shock absorber is installed on a front sliding block through a hanging lug and a connecting bolt, the front sliding block is installed in a guide groove of a front sliding seat, and the front sliding seat is installed on a front sliding seat base. An electromagnetic switch is installed on the bottom face of the belly of the machine body, and the electromagnetic switch is located right above a suction cup. A rear shrinkingcylinder is installed in a belly of the machine body, the top end of a rear shock absorber is fixedly installed at the bottom of the rear shirking cylinder and the bottom end of the rear shock absorber is installed on a rear sliding block through a hanging lug and a connecting bolt, and metal ploughs are installed on the outside of two sides of the rear end of a ski. The unmanned aerial vehicle retractable type ski recovery device is simple in structure and realizable in separation, and can obtain good landing buffering performance; a replaceable wear resistant layer is installed on the frontpart of the ski to effectively protect a ski body structure; and the metal ploughs are installed on the rear portion of the ski to play the role of stable guidance and deceleration.

Owner:西安爱生无人机技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com