Yarn carrier of weft knitting device

A technology for flat knitting machines and yarn guides, which is applied in weft knitting, textiles, papermaking, knitting, etc., and can solve the problems of increasing the wear and tear of the sliding parts of the yarn guide rail 52 and the yarn guide 51

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Next, preferred embodiments of the yarn guide for a flat knitting machine according to the present invention will be described with reference to the drawings.

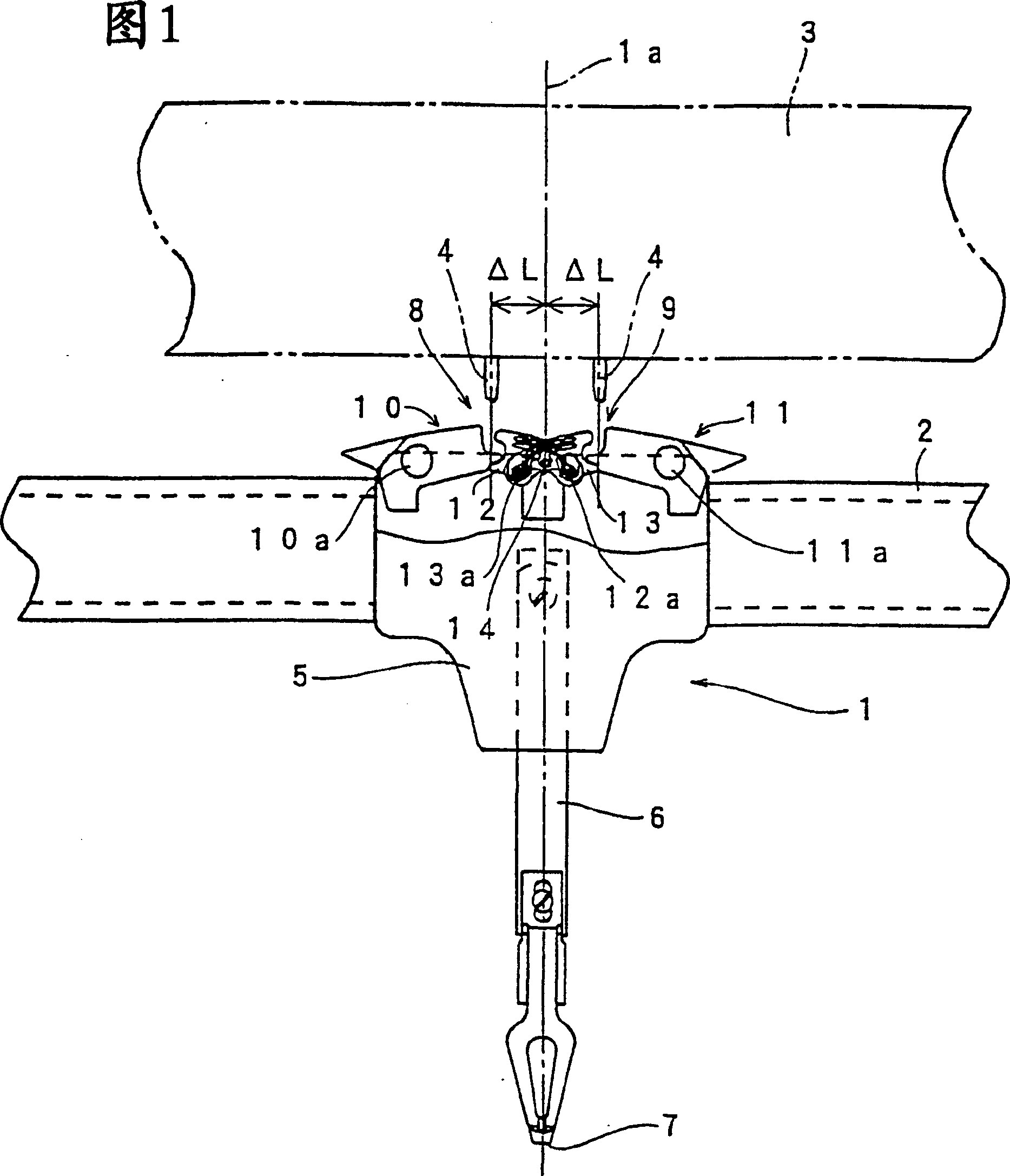

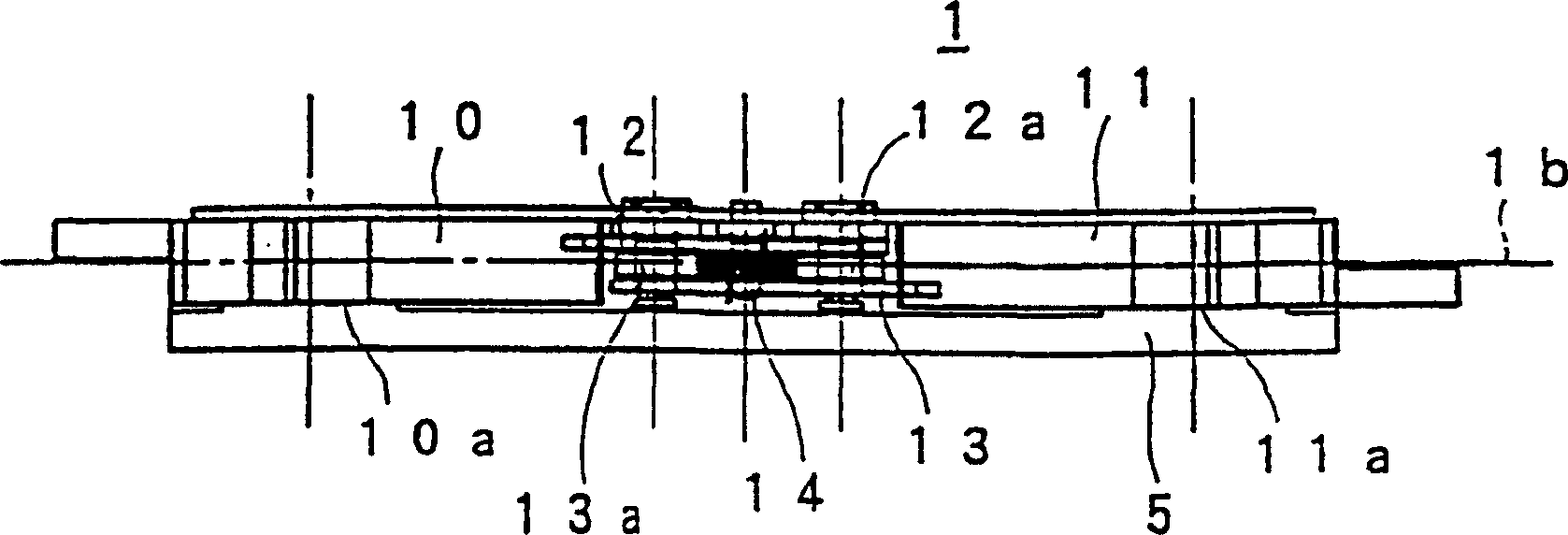

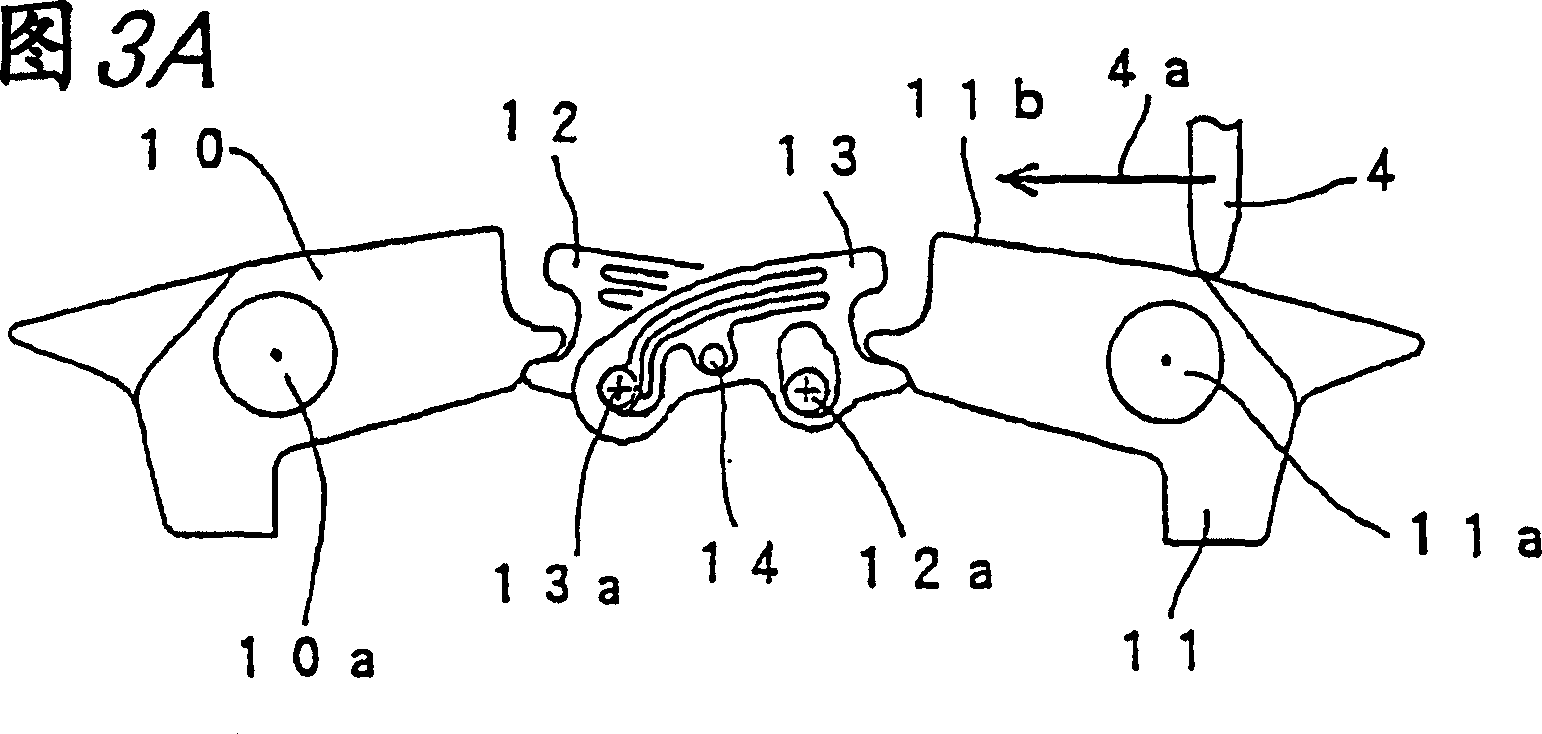

[0044] Fig. 1 is a cross-sectional view showing a part of the schematic configuration of a yarn guide 1 according to an embodiment of the present invention. The yarn guide 1 is above the needle bed of the flat knitting machine, and can travel in both reciprocating directions along the yarn guide track 2, and the yarn guide track 2 is erected parallel to the length direction of the needle bed. The yarn guide 1 is selected by the extendable and retractable pin 4 from the triangular carriage 3, and is engaged with the protruding pin 4 to drive. The yarn guide rod 6 hangs down below the housing 5 of the yarn guide 1 . The thread supply opening 7 is arranged on the front end of the yarn guide bar 6, and can supply the braiding thread to the tooth gap between the front and rear needle seats of the flat knitting machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com