Gaseous fuel injection valve

A gaseous fuel and injection valve technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as reduced valve core opening responsiveness, reduce sucker effect, improve closing responsiveness, and reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described based on the preferred embodiments of the present invention shown in the accompanying drawings.

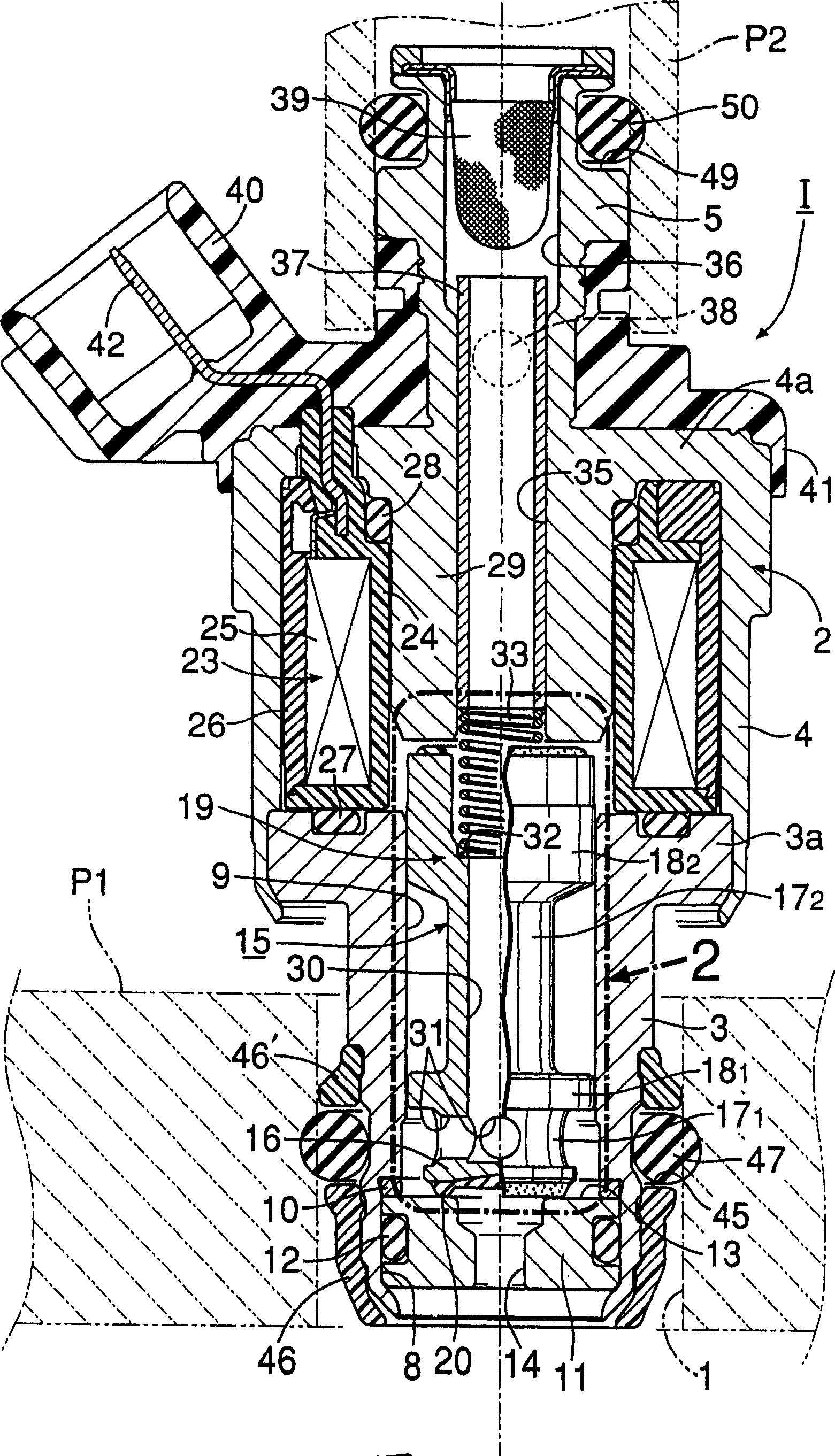

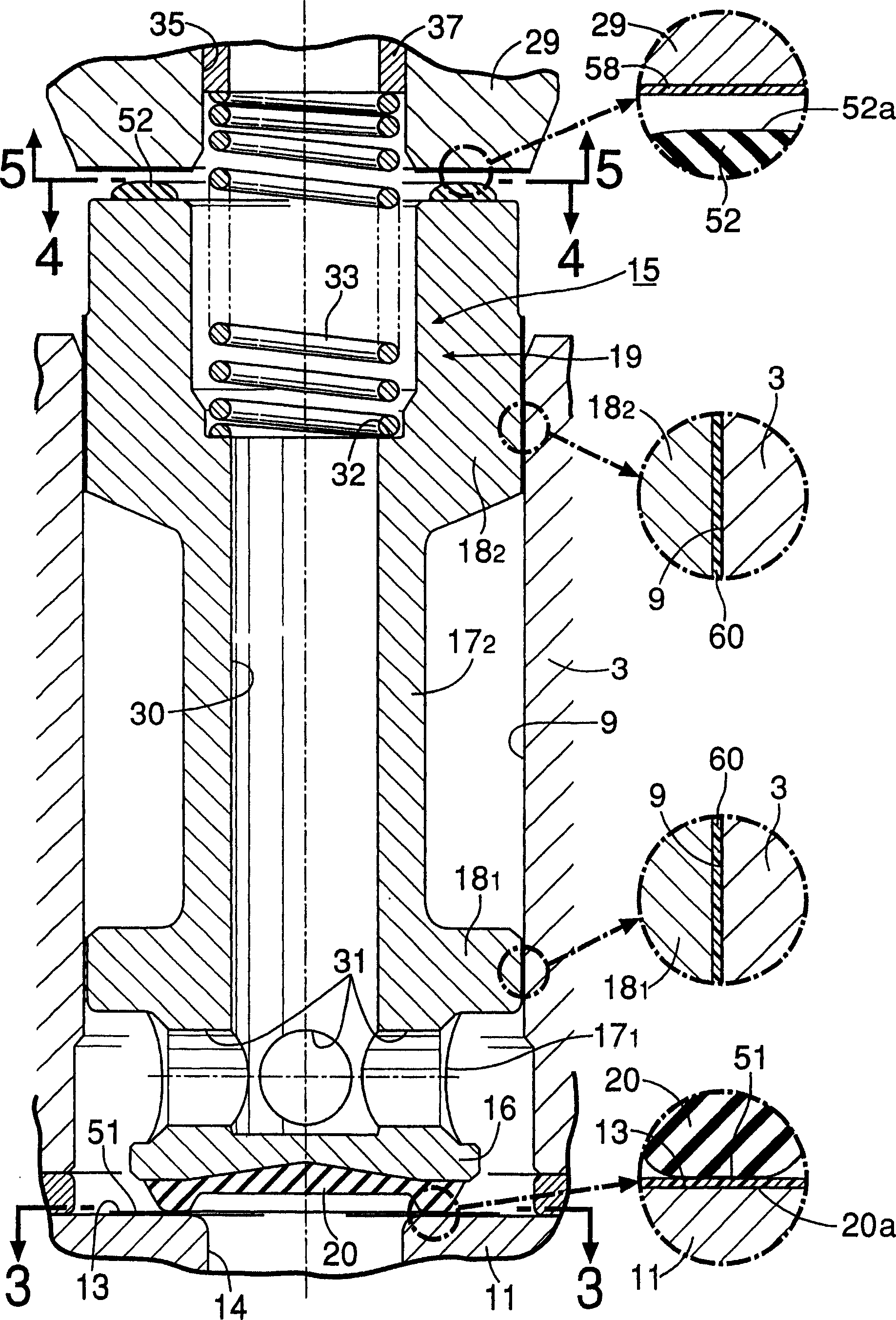

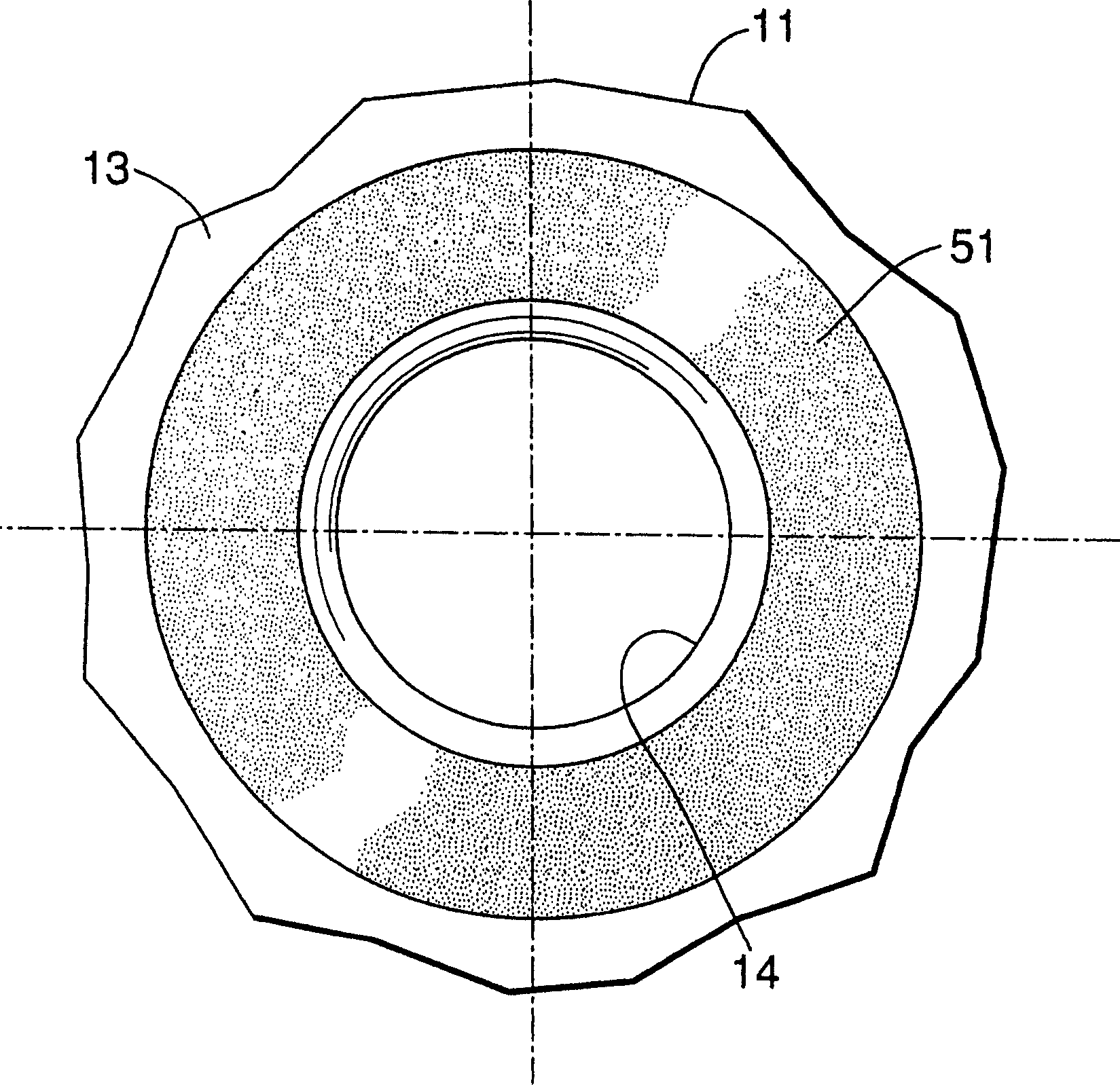

[0032] figure 1 It is a longitudinal sectional view of the gas fuel injection valve according to the first embodiment of the present invention. figure 2 yes figure 1 Enlarged view of 2 parts. image 3 yes figure 2 The 3-3 arrows point to the view. Figure 4 yes figure 2 The 4-4 arrows point to the view. Figure 5 yes figure 2 The 5-5 arrows point to the view. Figure 6 yes Figure 5 The three-dimensional view of the main part. Figure 7 yes Figure 4 The enlarged view of the 7-7 line section. Figure 8 represents the manufacturing process and Figure 7 corresponding figure. Figure 9 is the second embodiment of the present invention and figure 1 corresponding figure. Figure 10 It is a performance comparison line diagram of the injection valve related to the present invention and the convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com