Seat slide apparatus for vehicle

A technology for vehicles and seats, applied in vehicle seats, special positions of vehicles, movable seats, etc., can solve problems such as differences in operating characteristics, noise differences, and increased motor operating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

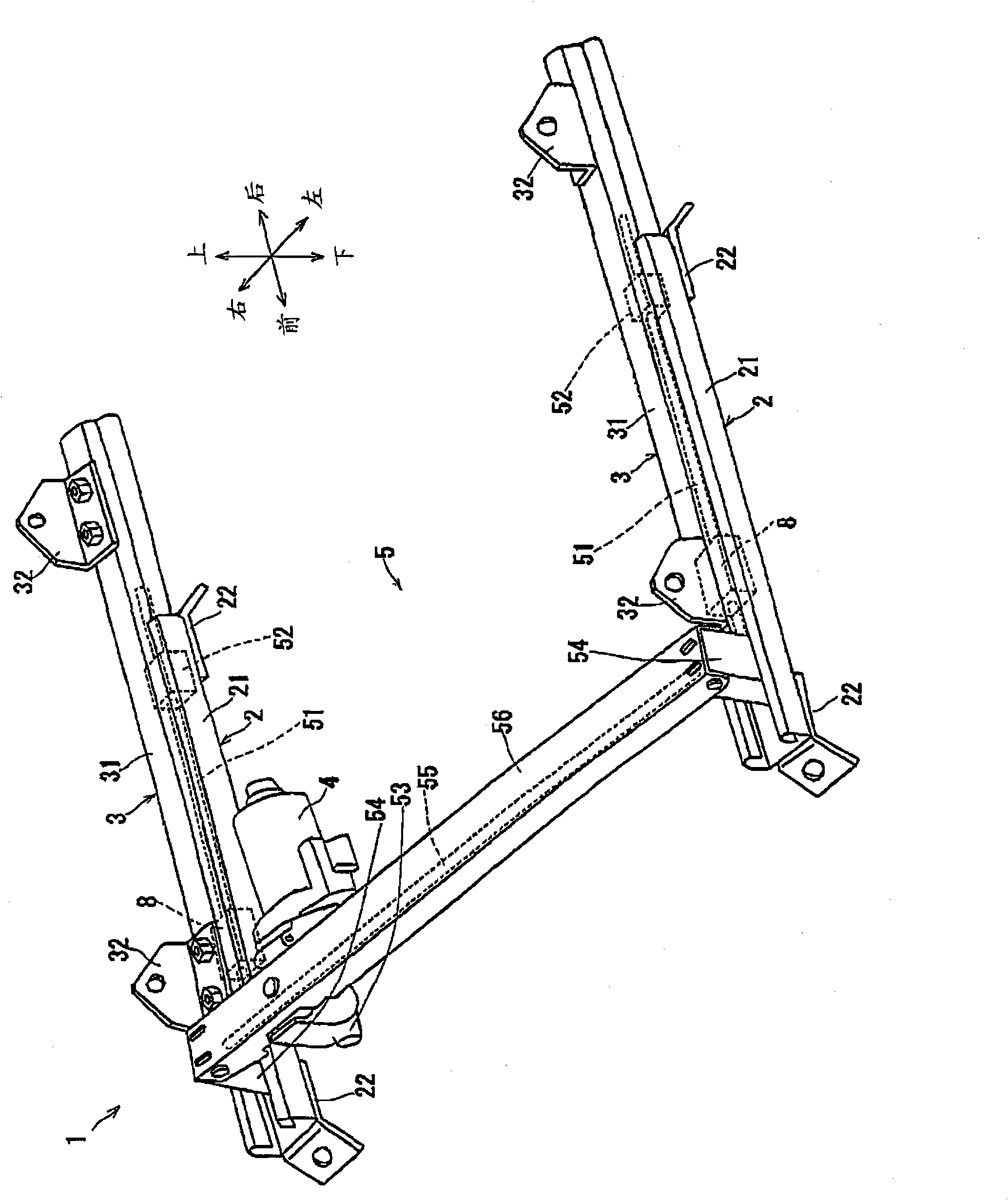

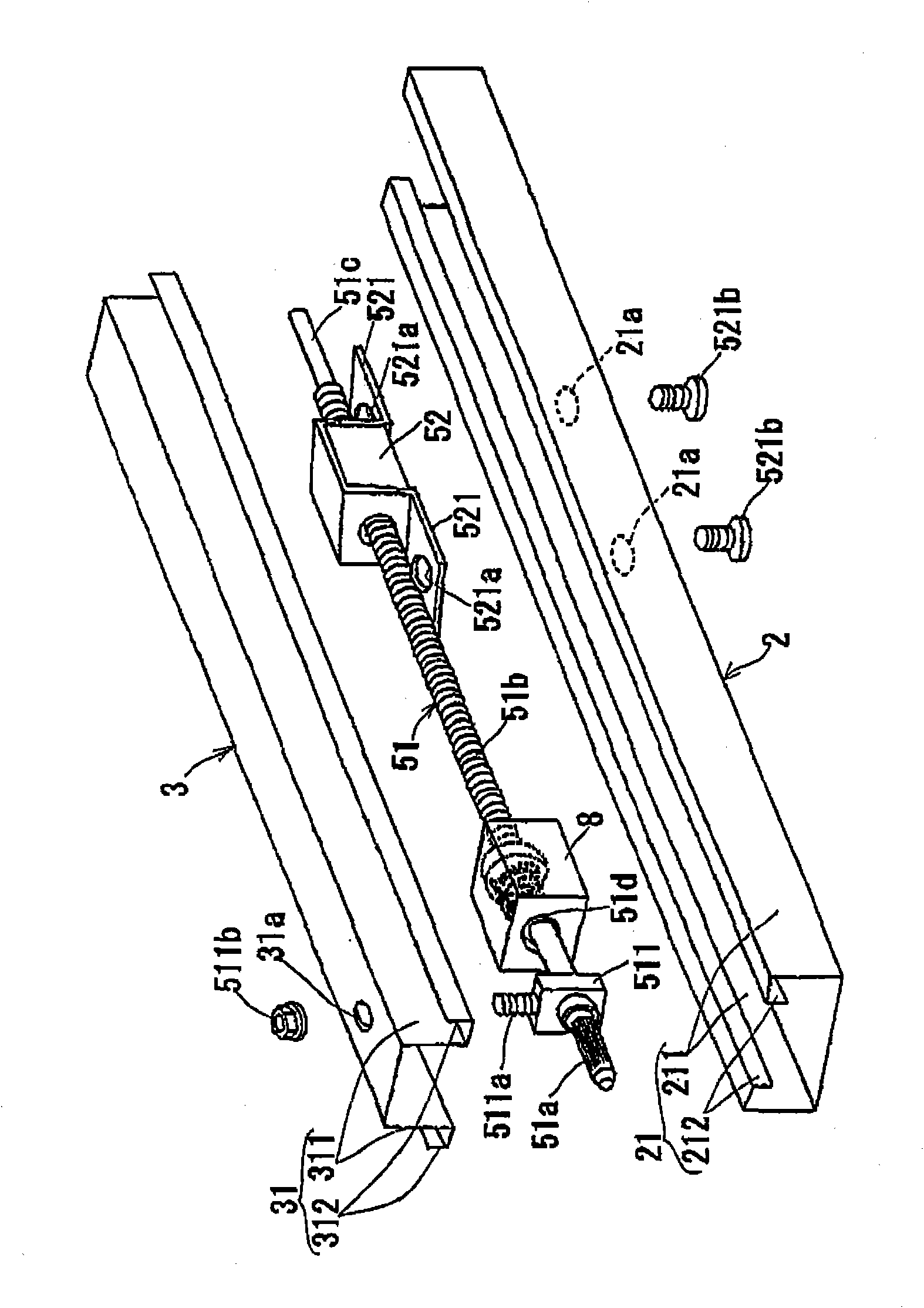

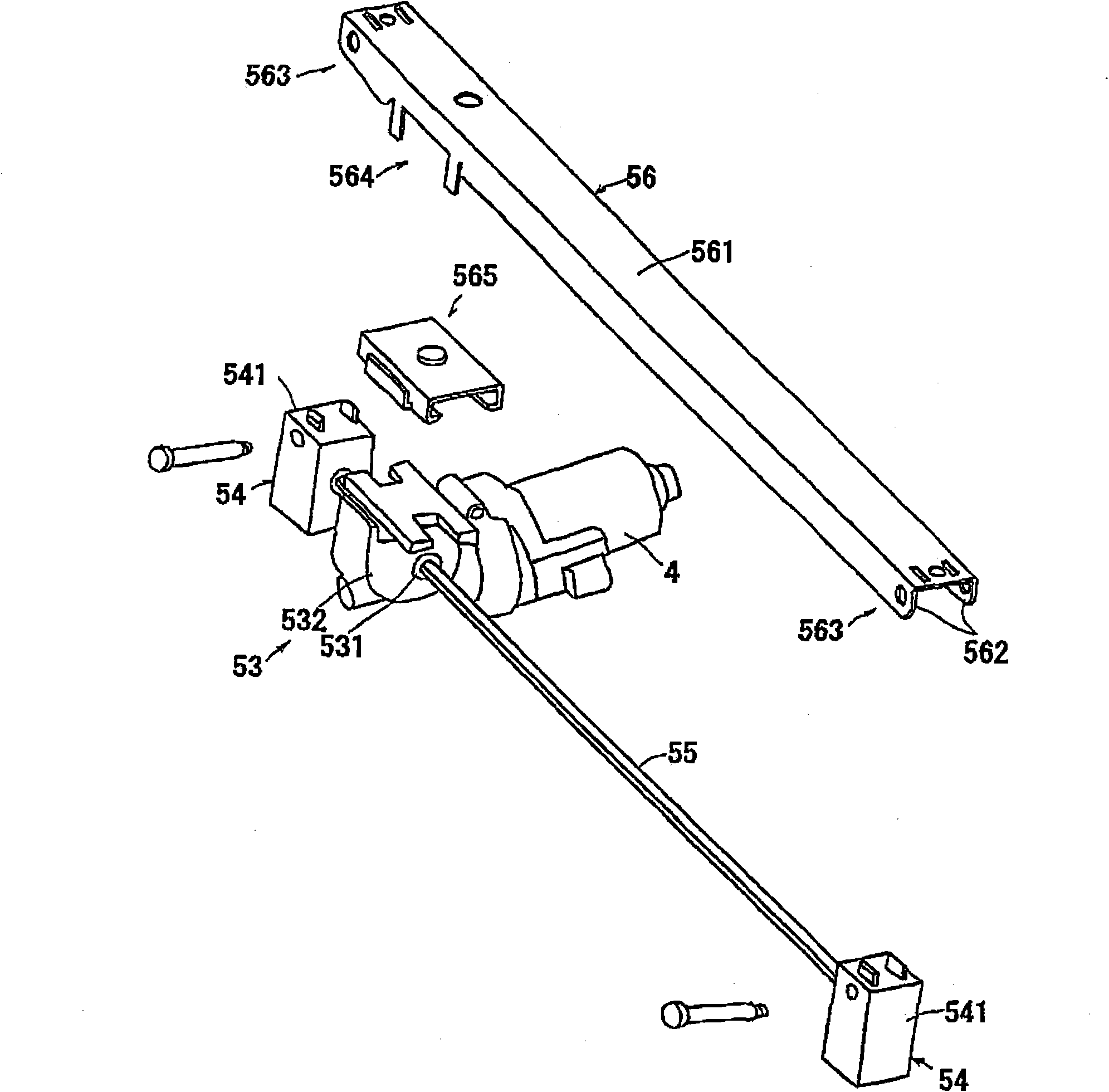

[0032] The following will refer to Figures 1 to 5 A first embodiment of the vehicle seat sliding apparatus 1 is described. According to the first embodiment, the vehicle seat sliding apparatus 1 is applied to a front seat of a vehicle. Directions such as "front", "rear", "left", "right" ("wide"), "upper" and "lower" used in the following description correspond to the front, rear, left and right ( width), top, bottom, etc.

[0033] Such as figure 1 As shown in , the vehicle seat sliding device 1 includes a pair of lower rails 2 (right lower rail and left lower rail), a pair of upper rails 3 (right upper rail and left upper rail), a motor 4, a transmission mechanism 5 and a pair of sliding resistance applying devices 8 (right sliding resistance applying means and left sliding resistance applying means) (sliding resistance applying part). The lower left rail and the lower right rail 2 include substantially the same structure and function as each other. Therefore, the follow...

no. 2 approach

[0055] The following will refer to Figure 6-8 A vehicle seat sliding apparatus according to a second embodiment is described. In the following description, structures similar to those of the first embodiment are denoted by the same reference numerals. In addition, detailed descriptions of similar structures will be omitted and only different structures will be described in detail. In the first embodiment, the sliding resistance applying device 8 is provided on the screw shaft 51 . However, in the second embodiment, the sliding resistance applying device 9 is provided on the propeller shaft 55 . Therefore, the case body 81 and the coil spring 82 of the sliding resistance applying device 9 are configured similarly to those in the first embodiment, but the structure of the bush 93 is different from that in the first embodiment.

[0056] The bush 93 has a structure similar to that of the bush 83 of the first embodiment, of the large-diameter portion 831 , the small-diameter po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com