Glass run for vehicle

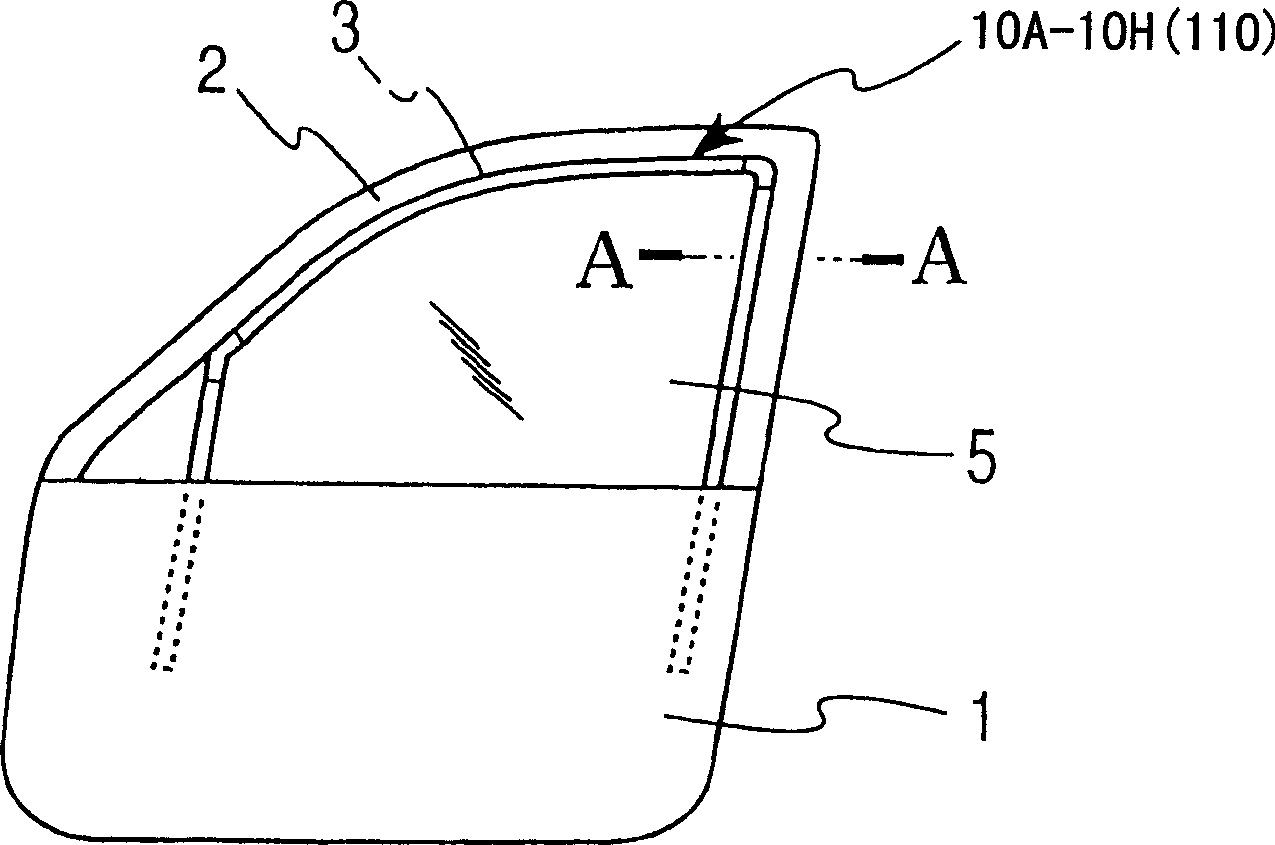

A technology for glass guide grooves and door glass, which is applied to vehicle parts, engine sealing, sealing devices, etc., can solve the problems of reducing the molding rate, damaging productivity, and complicated molding work, and achieving the effect of easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

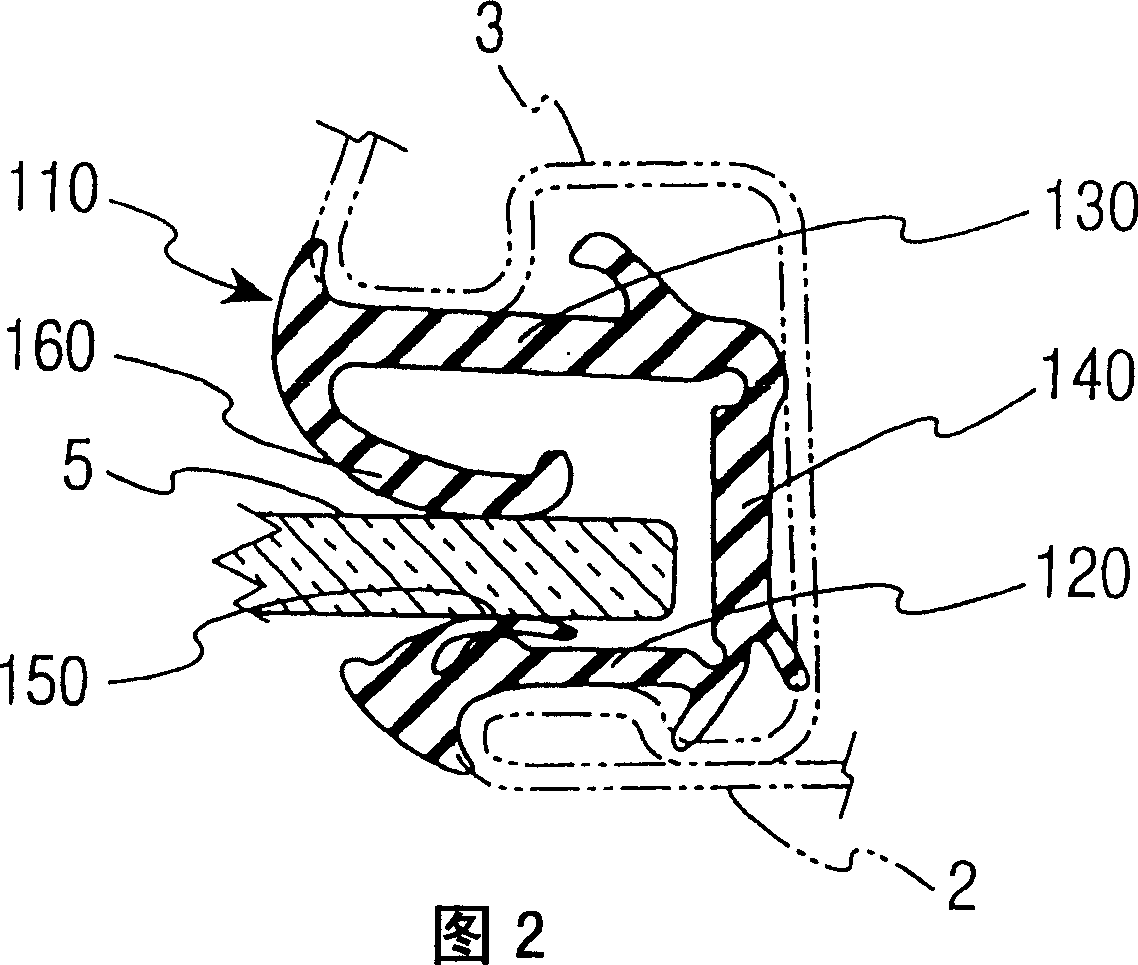

Examples

no. 2 example

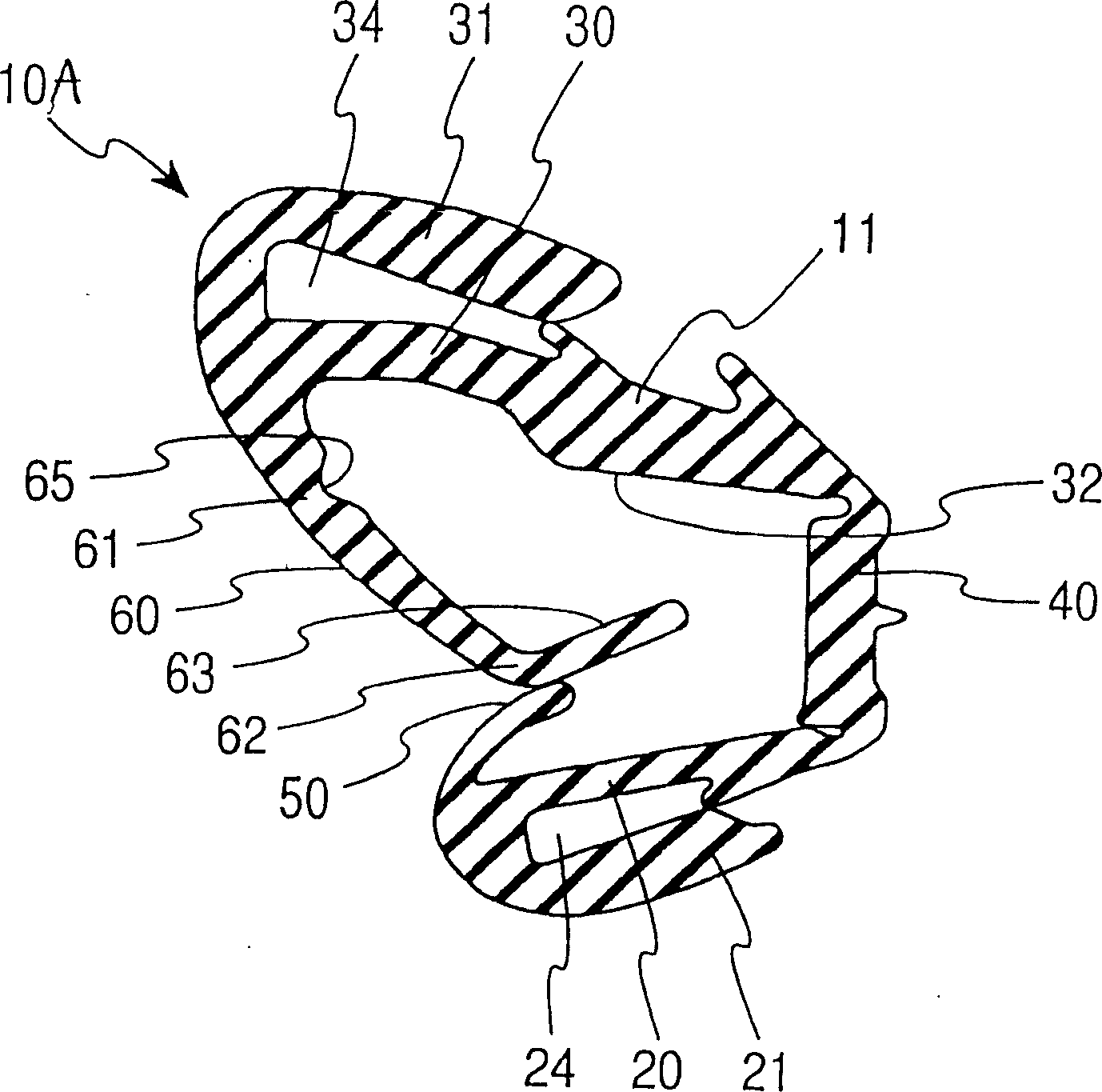

[0083] The following is based on Figure 4 with 6 The second embodiment will be described. Figure 6 After installing the glass guide groove 10B on the channel 3 of the door frame 2 figure 1 Sectional view of line A-A. The second embodiment is different from the first embodiment in the contact surface 32 of the inner side wall 30 of the glass run channel 10B and the inner side sealing lip body 61, and the other parts are similar. Therefore, the description of the contact surface 32 and the other parts other than the inside seal lip body 61 are omitted. The contact surface 32 has an inner side wall protrusion 33 near the middle of the inner surface of the inner side wall 30. From the protrusion 33 to the bottom wall 40, an arc-like curved surface is continuously formed in the cross section.

[0084]Therefore, when the door glass 5 is inserted at a predetermined position inside the U-shaped cross-section of the glass guide groove 10B, the front end portion 63 of the inner side seal...

no. 3 example

[0090] The following is based on Figure 7 with 9 The third embodiment will be described.

[0091] Figure 7 Shown is a sectional view of the extruded part to be installed on the vertical side of the door frame 2.

[0092] The vehicle interior sealing lip 60 extends from the vicinity of the front end of the vehicle interior side wall 30 to the inside of the U-shaped cross-section of the glass run channel body 11. The inner side cover lip 31 extends to the inner side of the vehicle at the front end of the inner side wall 30 of the vehicle.

[0093] The outer side sealing lip 50 extends from the vicinity of the front end of the outer side wall 20 to the inside of the U-shaped cross-section of the glass run channel body 11. The outer cover lip 21 extends to the outer side of the vehicle at the front end of the outer side wall 20.

[0094] Such as Picture 9 As shown, when the glass run channel 10C is installed on the channel 3 of the door frame 2, the inner side wall of the channel ...

no. 4 example

[0107] The following is based on Figure 8 with 10 The fourth embodiment of the present invention will be described. Figure 8 For the edge figure 1 A cross-sectional view of the glass run channel 10D along the line A-A. Picture 10 Install the glass guide groove 10D on the rear edge of the channel 3 in the door frame 2 figure 1 A cross-sectional view of the glass guide groove 10D on the line A-A. The fourth embodiment is different from the first embodiment in the shape of the inner side sealing lip 60, and other parts are the same. Therefore, the description of the parts other than the inside seal lip 60 is omitted.

[0108] The vehicle interior sealing lip 60 includes a root 61 of the vehicle interior sealing lip and a front end portion 62 thereof, wherein the root 61 extends from the vehicle interior side wall 30 toward the inside of the U-shaped cross-section of the glass runner body 11, and the front end portion 62 is from the vehicle interior The root 61 of the sealing lip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com