Ultrathin wheel shaft type wheel hub motor

An in-wheel motor, ultra-thin technology, applied in the direction of motor vehicles, electromechanical devices, electrical components, etc., to achieve significant market competitive advantages, high efficiency, and simplify the overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

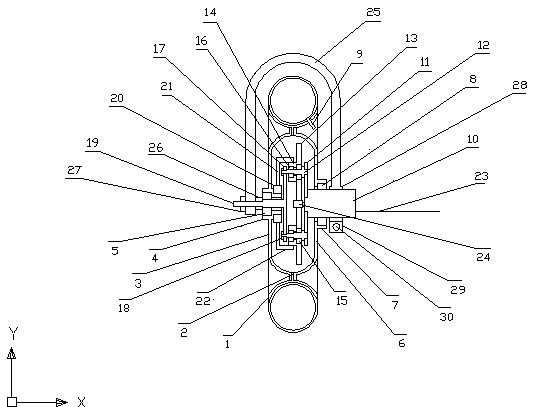

[0011] exist figure 1 In the schematic diagram of the front view section structure of the ultra-thin hub motor, the ultra-thin hub is provided with an aluminum alloy tire ring 1, and the center of the inner circle of the aluminum alloy tire ring is provided with a positioning platform ring 2 for the hub end cover, and the positioning platform The left hub end cover 3 is installed on the left side of the circle, and the left hub bearing frame 4 is arranged in the middle of the left hub end cover. The middle part of the end cover is provided with a right wheel hub bearing frame 7, and the right inner circle of the right wheel hub bearing frame is tightly matched with the right wheel hub bearing 8. Tire groove is arranged, and wheel inner tube and outer tire are installed in the tire groove, and the aluminum alloy tire rim is provided with valve hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com