Bearing bush and composite motion device using this bearing bush

一种轴承衬套、复合运动的技术,应用在轴承部件的刚性支架、轴承、机电装置等方向,能够解决不提高滑动阻力、花费工时等问题,达到提高精度、廉价制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

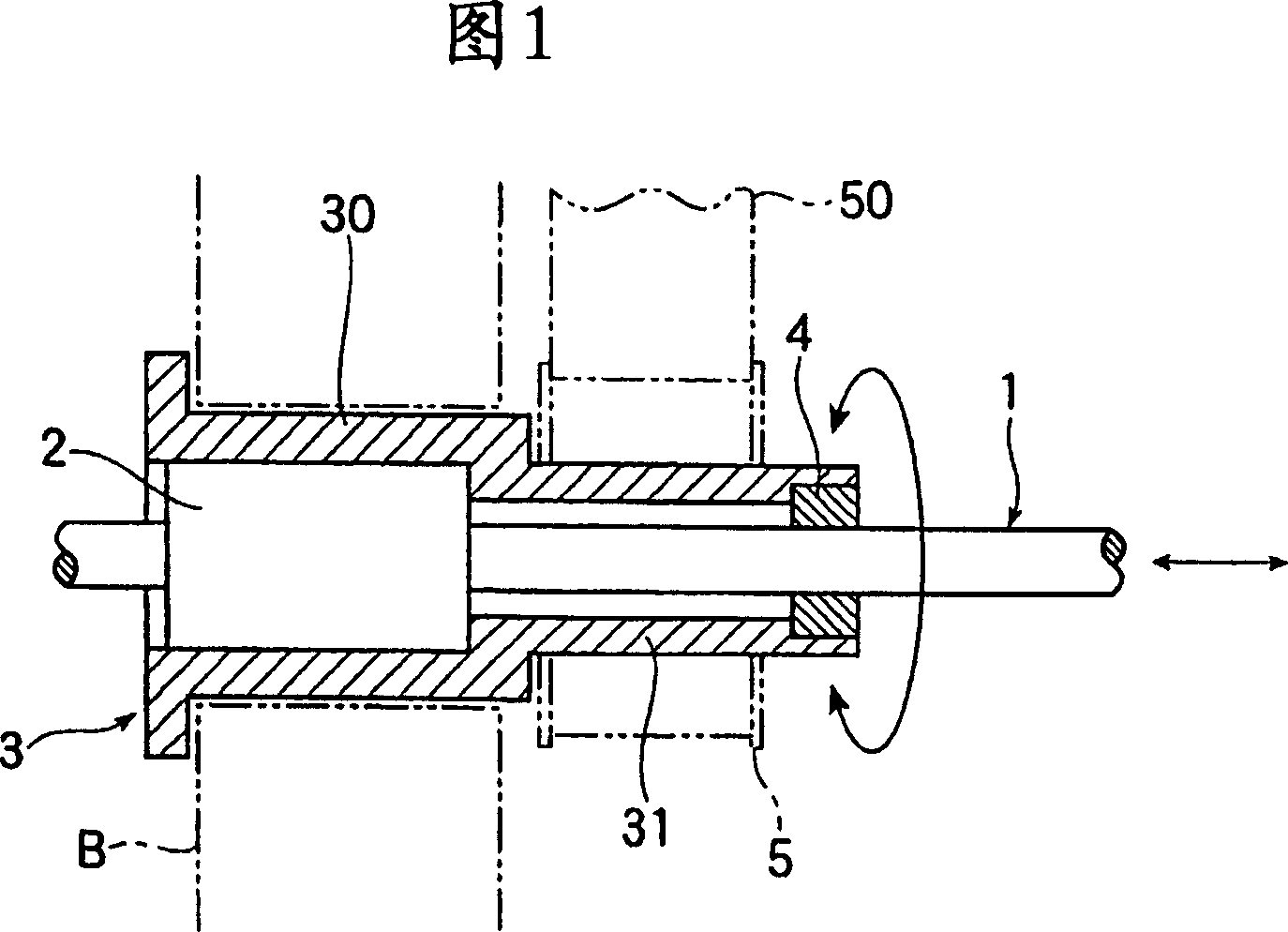

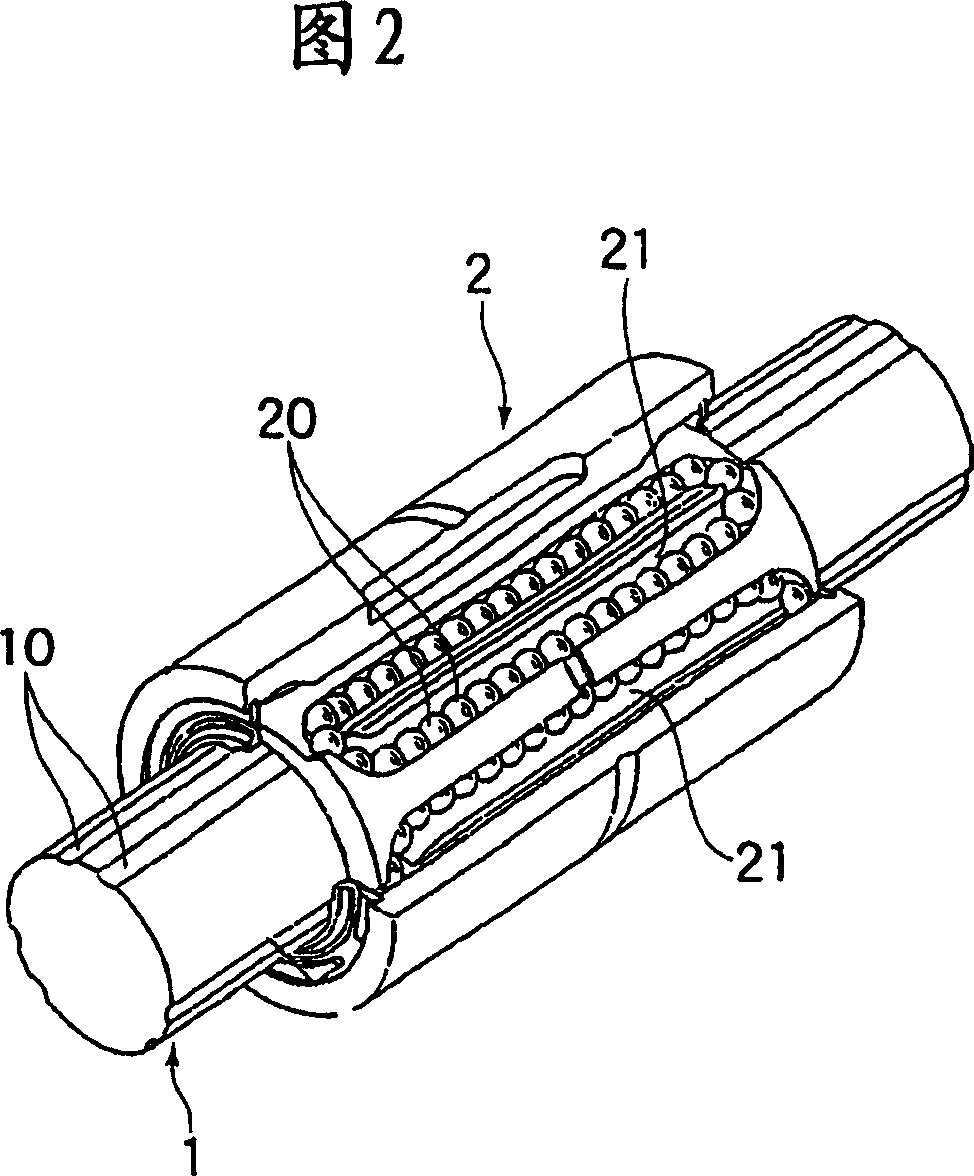

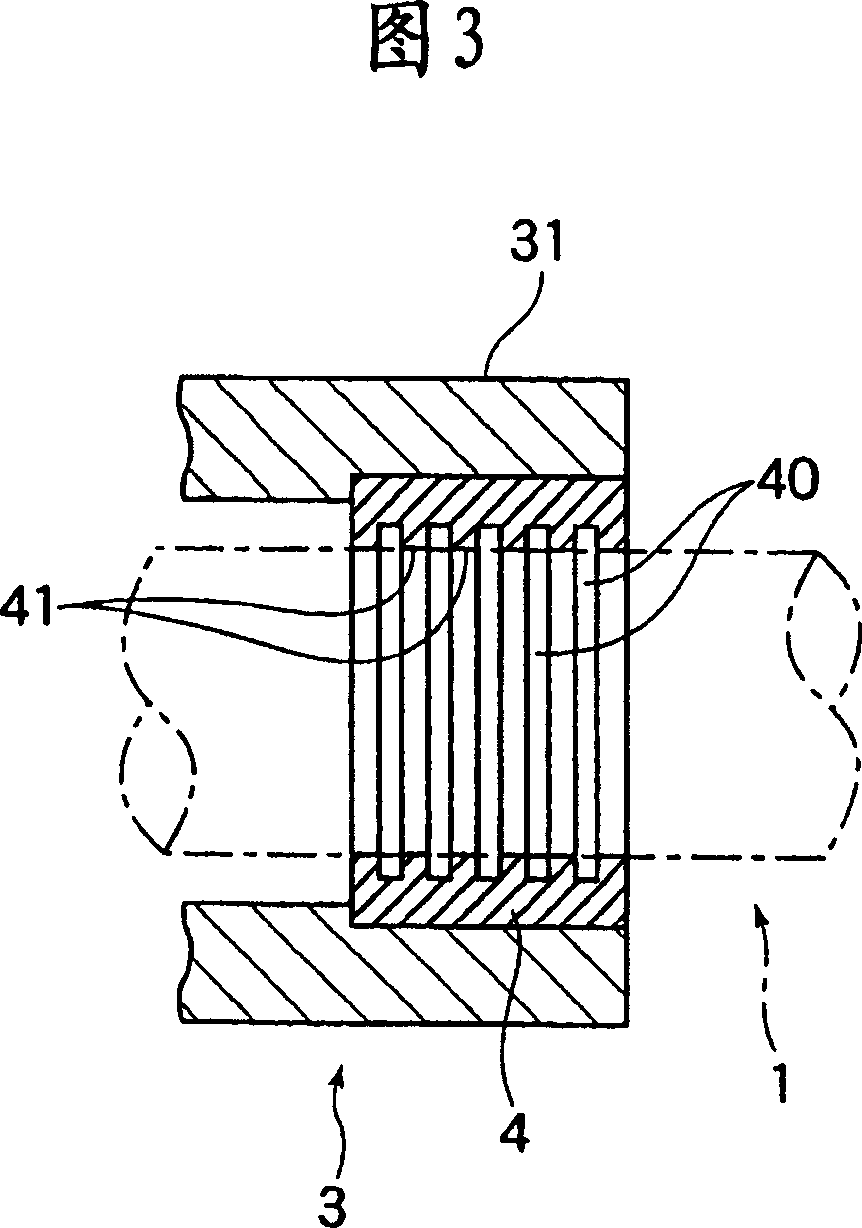

[0030] Next, the bearing bush of the present invention will be described in detail with reference to the accompanying drawings.

[0031] FIG. 1 is a diagram showing an example of a compound kinematic device that supports the forward and backward motion of a spline shaft using a bearing bush according to the present invention. This device is used as a main shaft of a tool changing device, etc., and consists of a spline shaft 1 used as the main shaft, a spline nut 2 that can freely reciprocate in the axial direction of the spline shaft 1, and a spline nut 2 that holds the spline nut 2. At the same time, the housing 3 rotatably supported relative to the fixed part B and the bearing bush 4 provided at one end of the housing 3 and guiding the advance and retreat of the spline shaft 1 relative to the housing 3 constitute.

[0032] The spline shaft 1 is provided with an axial forward and backward movement by a ball screw device not shown, a hydraulic cylinder, a pneumatic cylinder, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com