Seal structure and control valve using the same

A sealing structure and control valve technology, which is applied in shaft seals, engine seals, valve lifts, etc., can solve the problems of reduced sealing ability and responsiveness, and achieve the effect of reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the sealing structure and control valve according to the embodiment of the present invention will be described in detail with reference to the drawings. The drawings described below are correct drawings based on design drawings.

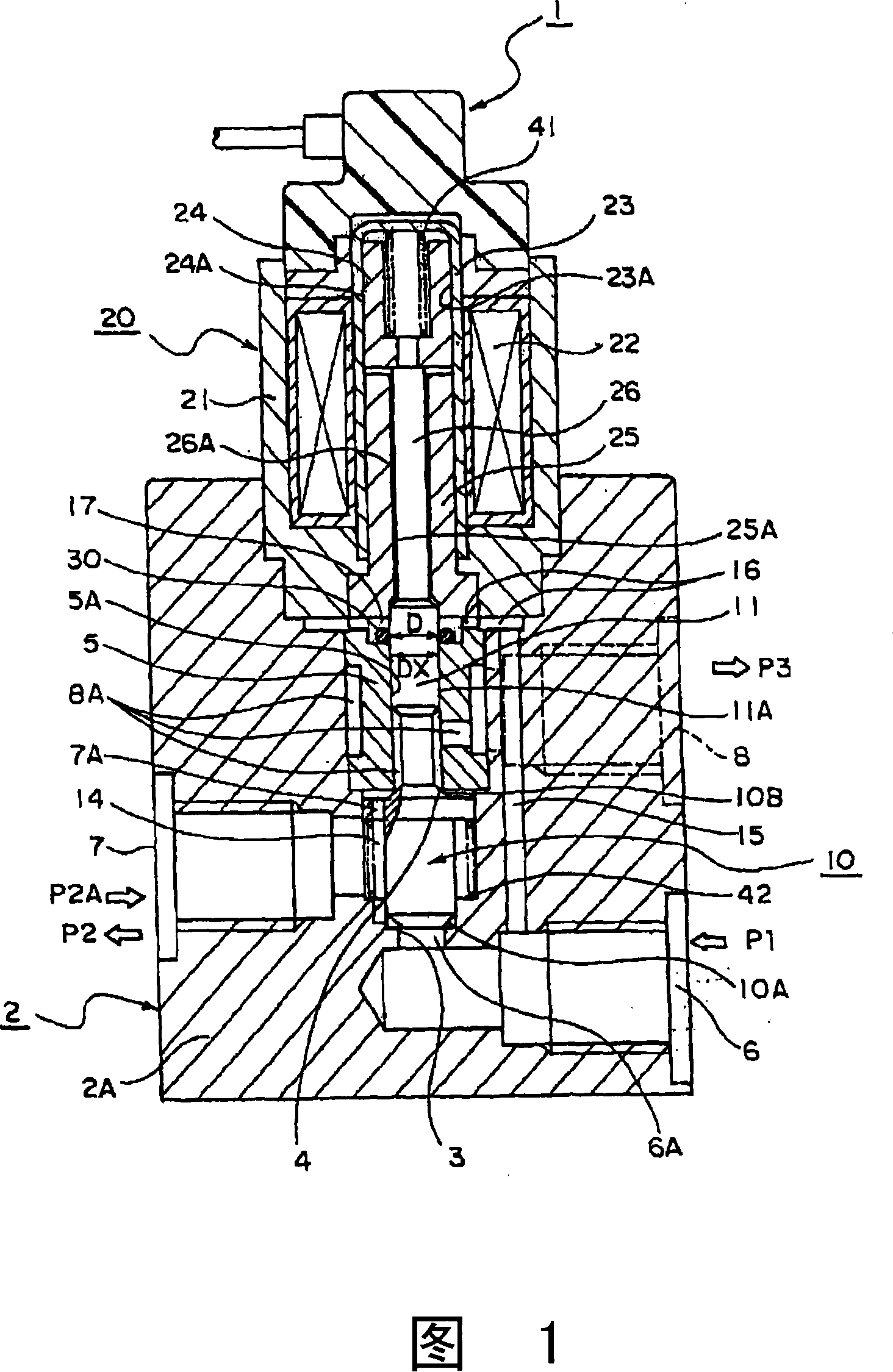

[0022] Fig. 1 is a sectional view showing a control valve according to an embodiment of the present invention. In Fig. 1, 1 is a control valve. This control valve 1 is formed by combining a valve unit 2 and a solenoid unit 20 . A valve housing (also referred to as a valve body) 2A forming an outer diameter of the valve portion 2 is provided on the control valve 1 . A valve chamber 14 is provided on the axis of the valve housing 2A. A first fluid passage 6 through which a first operating fluid (also referred to as operating fluid) P1 flows into the valve chamber 14 from the outside is provided centering on the valve chamber 14 . A first communication passage 6A is formed between the first fluid passage 6 and the valve chamber 14 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com