Hinge mechanism and panel apparatus

A hinge mechanism and technology on the back side, applied in the field of panel devices, can solve the problems of poor operability and large operating force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

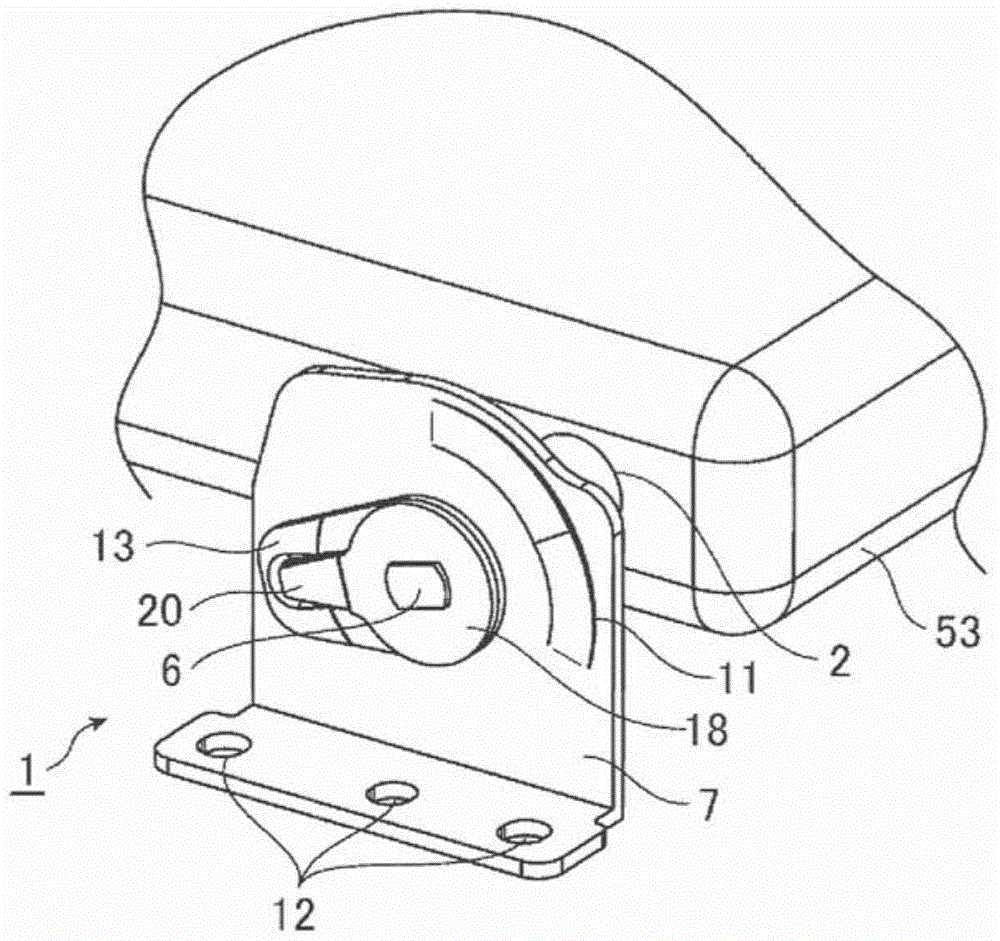

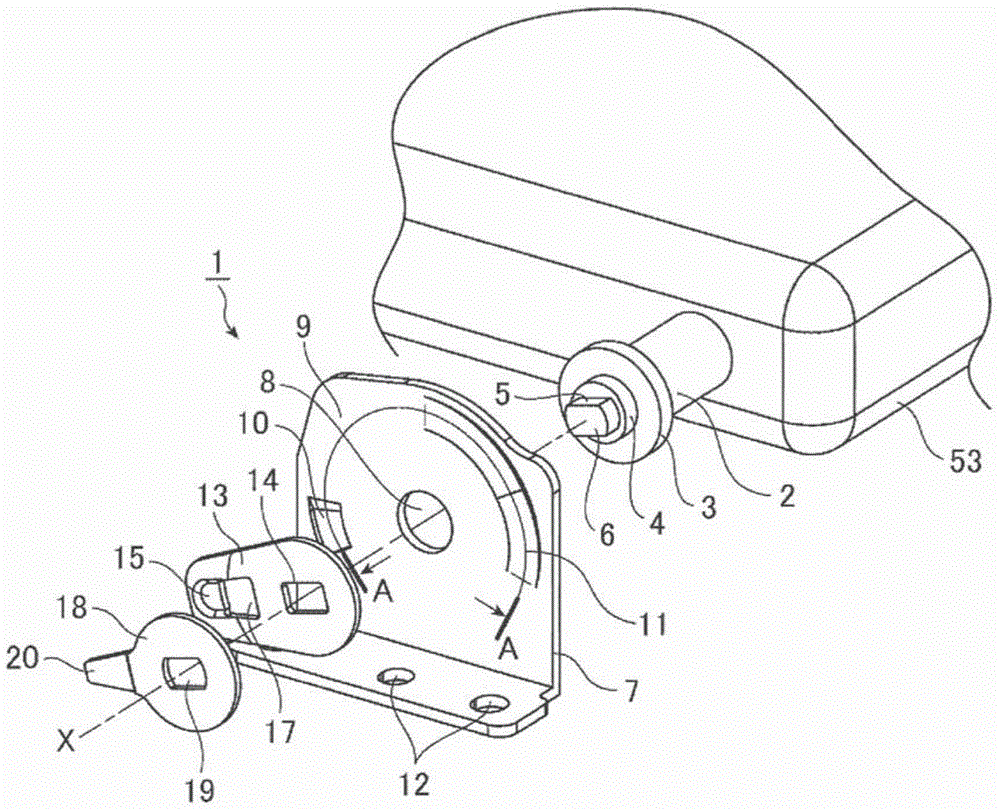

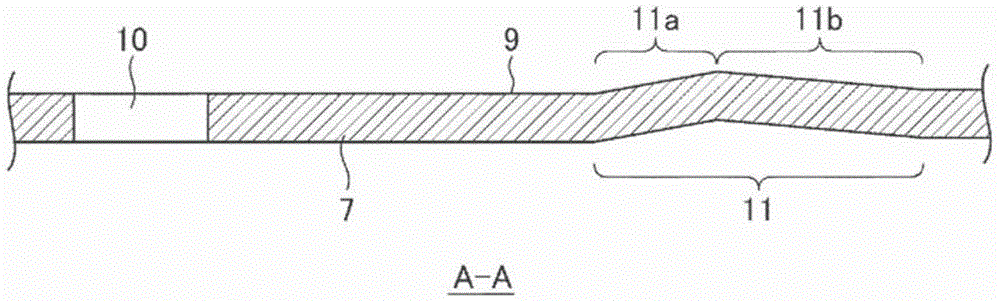

[0046] figure 1 It is an external perspective view showing the structure of the hinge mechanism 1 according to the first embodiment, figure 2 It is an exploded perspective view. image 3 is along figure 2 A cross-sectional view obtained by cutting the housing (fixed part) 7 along the line A-A shown. In Embodiment 1, a case where the hinge mechanism 1 is applied to a vehicle-mounted seatback display device (panel device) will be described as an example. Figure 4 It shows the state where the panel unit (rotating member) 53 of the seatback display device 51 to which the hinge mechanism 1 is applied is accommodated in the main body unit (fixing member) 52, Figure 5 It shows the state where the panel unit 53 is rotated to and held at the viewing position.

[0047] like Figure 4 and Figure 5 As shown, a seatback display device 51 is provided on the back of a reclining seat 50 such as a driver's seat and a passenger seat of an automobile. The seatback display device 51 i...

Embodiment approach 2

[0082] Figure 11 It is an external perspective view showing the structure of the hinge mechanism 1 according to the second embodiment, Figure 12 It is an exploded perspective view. Figure 13 is along Figure 12 The sectional view obtained by cutting the housing 7 with the D-D line shown, Figure 14 It is a cross-sectional view cut along line E-E. Figure 15 It is a front view of the click plate 13 and the friction plate 18. for Figure 11 to Figure 15 neutralize Figure 1 to Figure 9 The same or corresponding parts are marked with the same reference numerals, and descriptions are omitted. The case where the hinge mechanism 1 according to the second embodiment is applied to the seatback display device 51 will be described as an example. Figure 4 and Figure 5 .

[0083] like Figure 11 and Figure 12 As shown, the hinge mechanism 1 involved in Embodiment 2 includes: the shaft 2 fixed to the panel unit 53; the housing 7 fixed to the main body unit 52; the ring-sha...

Embodiment approach 3

[0102] Figure 19 It is an external perspective view showing the structure of the hinge mechanism 1 according to the third embodiment, Figure 20 It is an exploded perspective view. for Figure 19 and Figure 20 neutralize Figure 11 ~ Figure 17 The same or corresponding parts are marked with the same reference numerals, and descriptions are omitted. The case where the hinge mechanism 1 according to Embodiment 3 is applied to the seatback display device 51 will be described as an example. The seatback display device 51 follows the Figure 4 and Figure 5 .

[0103] like Figure 19 and Figure 20 As shown, a sliding convex portion 40 that presses and slides the housing 7 protrudes on the inner peripheral side of the ring arm 31b. Therefore, the force for holding the panel unit 53 can be increased without enlarging the size of the hinge mechanism 1 or increasing the number of parts by utilizing the sliding resistance generated when the sliding protrusion 40 slides on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com