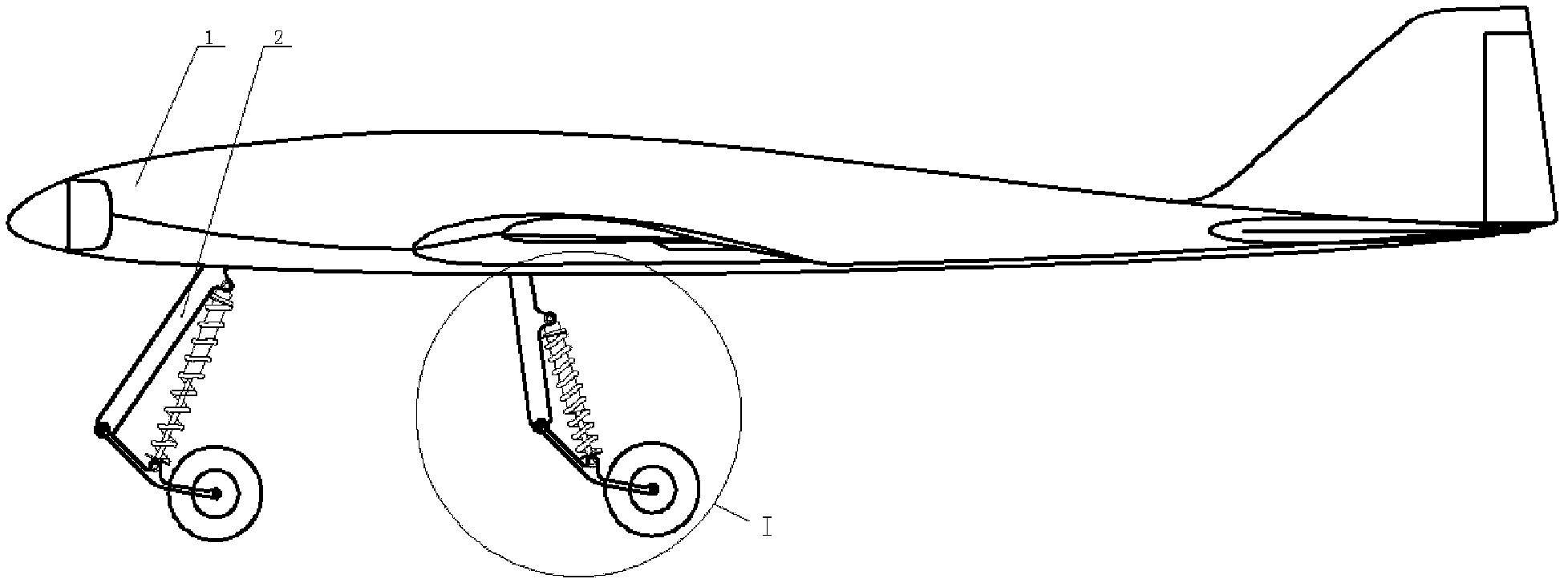

Sledge and wheel integrated landing gear for unmanned aircraft

A landing gear and skid wheel technology, applied in the field of drones, can solve problems such as increased installation complexity and overall weight, complicated drone operating environment, and poor sealing performance of shock absorbers, so as to improve landing safety High performance, light weight, and the effect of increasing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

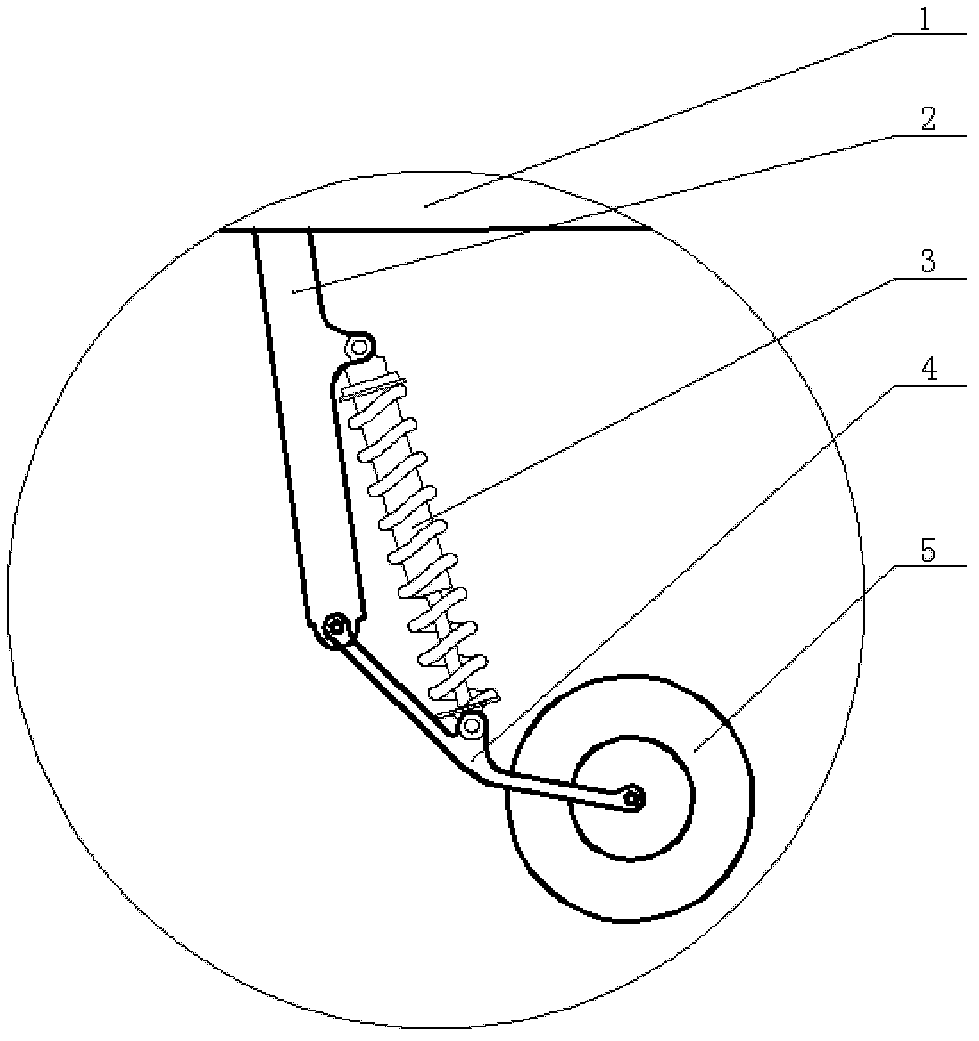

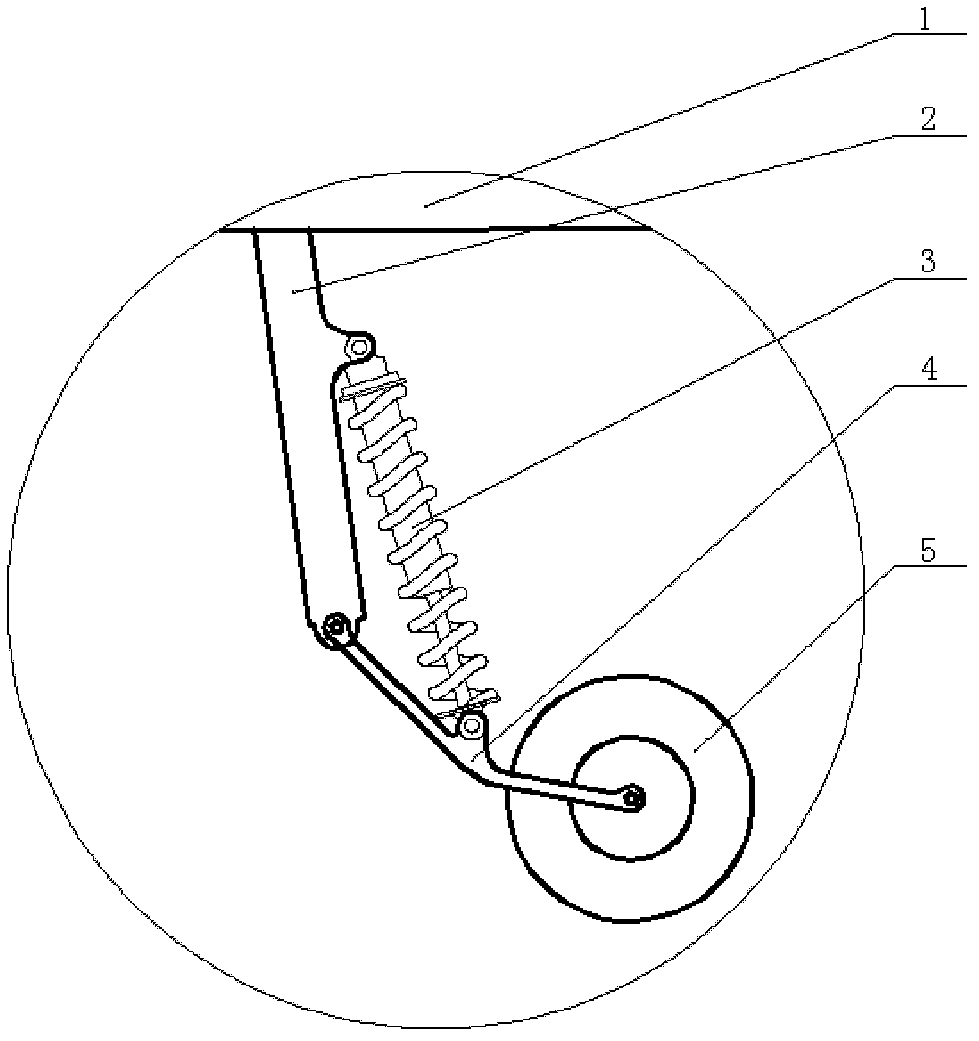

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0021] An unmanned aerial vehicle skid-wheel integrated landing gear includes a support arm 2 and a wheel 5. The upper end of the support arm is installed on the bottom of the drone fuselage 1, and the wheel is installed on the lower end of the support arm. A plurality of landing gears can be installed on the bottom of the fuselage of the drone involved in the present invention. In this embodiment, three landing gears are installed in total, and one front end and two rear ends are arranged side by side.

[0022] The innovation point of the present invention is:

[0023] A skid 4 is installed between the said wheel and the support arm, the upper end of the skid is hinged on the lower end of the underc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com