Method for producing a woven fabric and woven fabric produced thereby

A fabric and fabric layer technology, applied in the field of fabric manufacturing, can solve problems such as not being able to meet the needs of pipeline lines, and achieve the effects of improved lateral stability, simple weaving, and low firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] "Fabrics of the Invention" are discussed below. Fabric straps should also be included in this term, as conventional thinking has a larger longitudinal dimension than a transverse dimension.

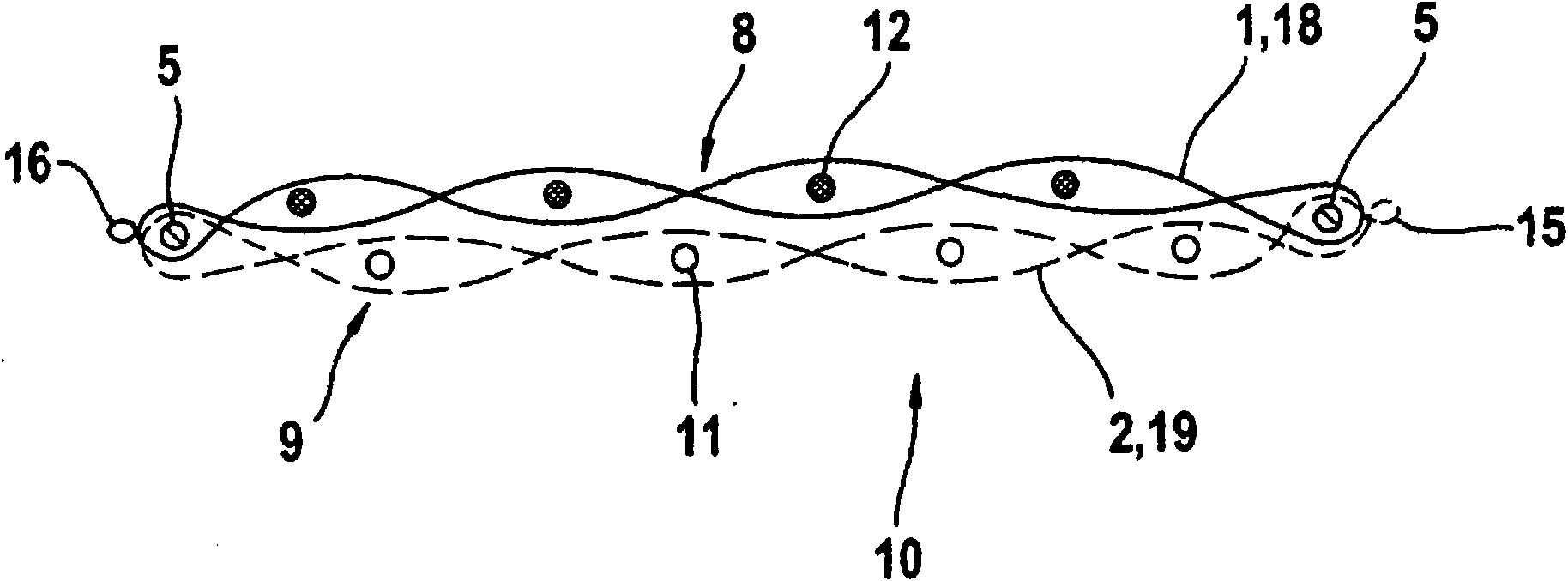

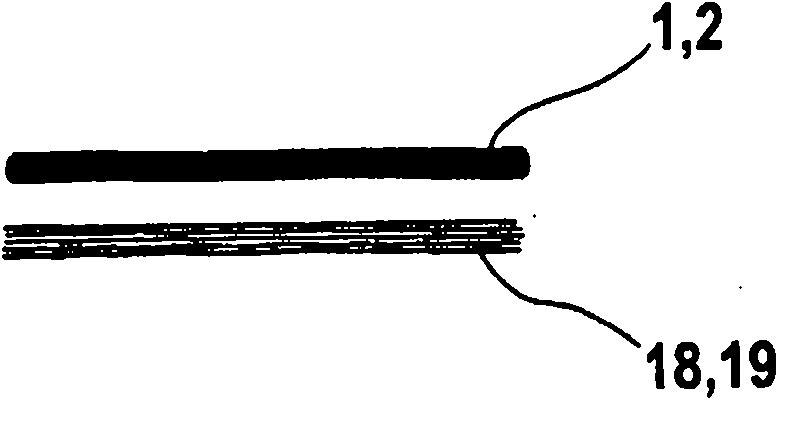

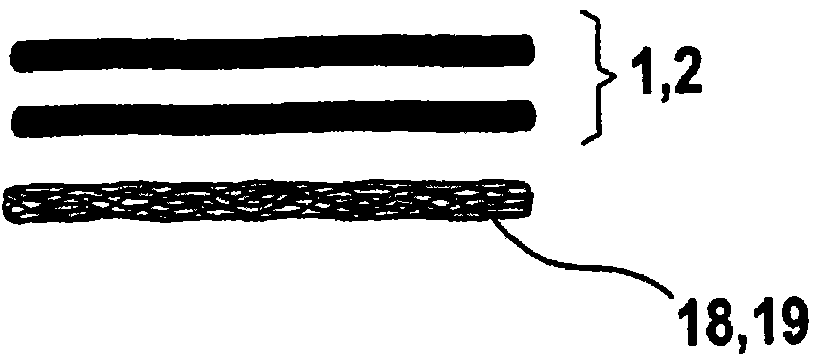

[0034] figure 1 Shown is a fabric according to the invention, here the fabric is integrally integrated as an upper fabric layer 8 and a lower fabric layer 9 into a tubular fabric 10, shown in longitudinal section transversely to the tubular fabric, the tubular fabric The fabric has an upper fabric layer 8 and a lower fabric layer 9 and corresponding upper warp threads 12 and lower warp threads 11 . In fact, the number of warp threads of this tubular fabric is significantly higher. To simplify the illustration, only four warp threads are shown symbolically in each case here. The upper fabric layer 8 also includes monofilament weft yarns 1 and multifilament weft yarns 18 , and the lower fabric layer 9 also includes monofilament weft yarns 2 and multifilament weft yarns 19 . Weft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com