Patents

Literature

83results about How to "Avoid crimping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deformation medical device without material deformation

InactiveUS20050038497A1Avoid crimpingSolution value is not highStentsBlood vesselsInsertion stentMedical device

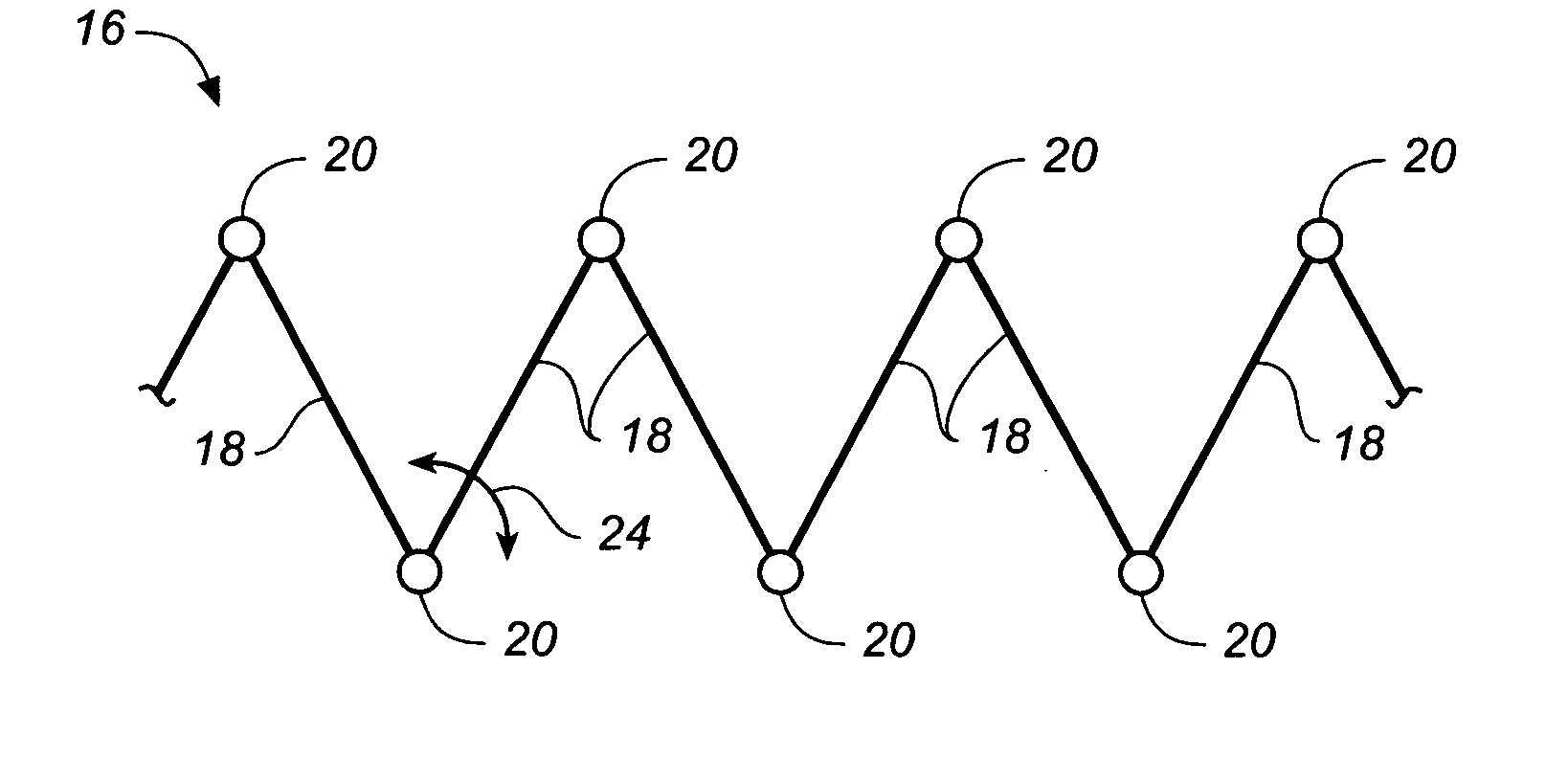

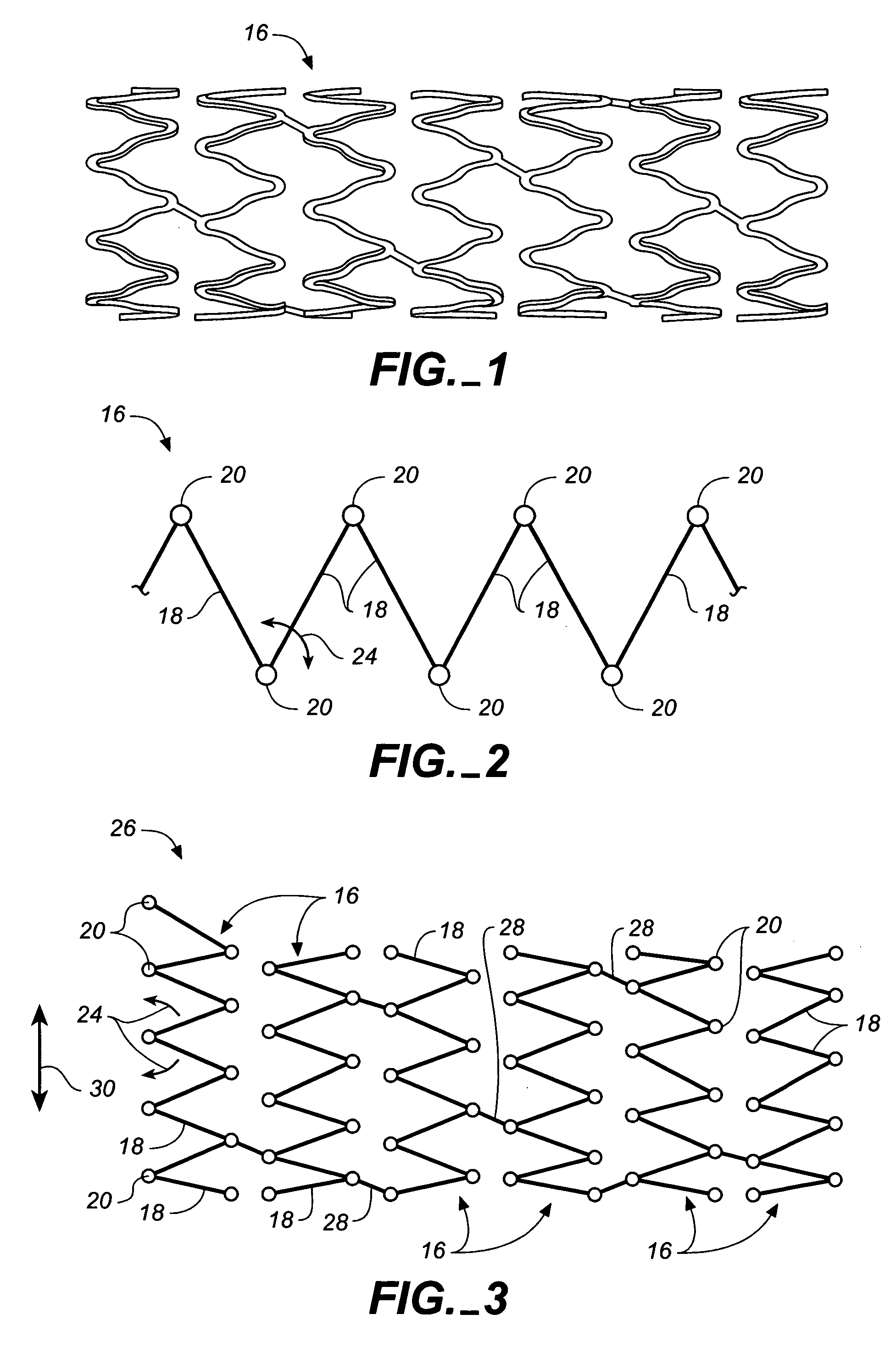

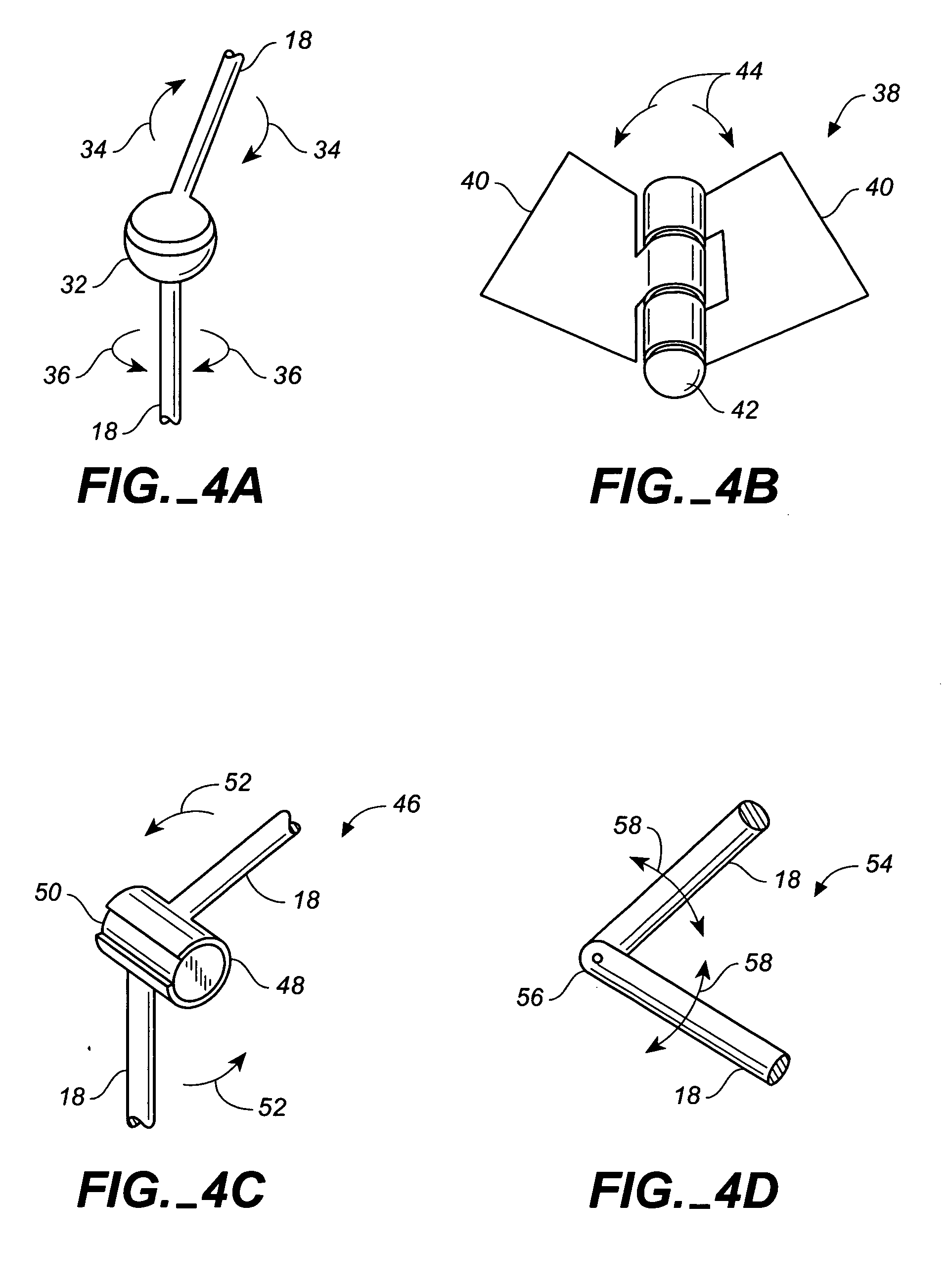

One embodiment of the present invention provides a stent made of a relatively inflexible material yet which can still be moved from the crimped or radially contracted insertion position to the radially expanded deployed position. In one embodiment, portions of the stent are made out of relatively inflexible material and are connected together with a hinge connection.

Owner:BOSTON SCI SCIMED INC

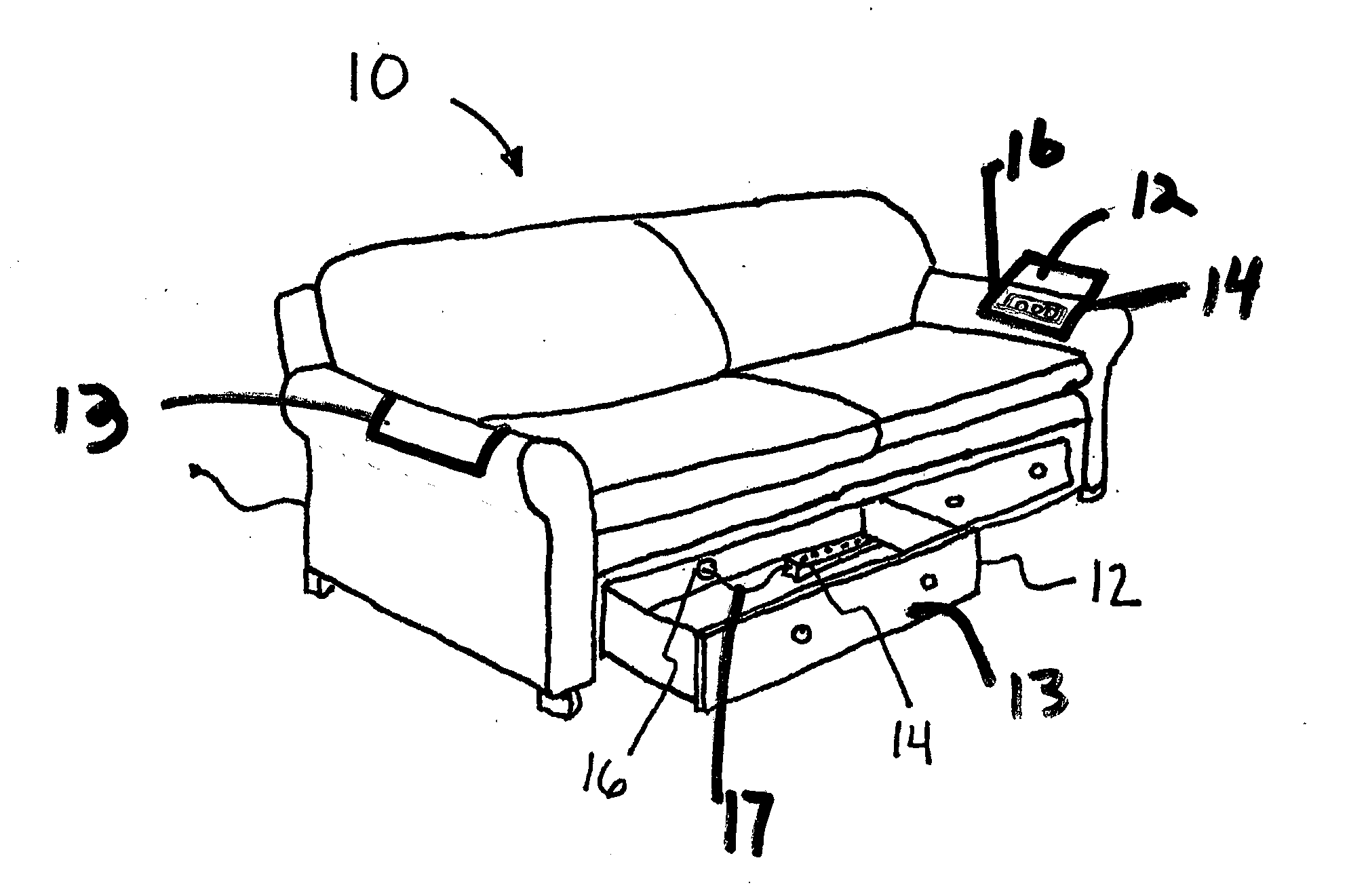

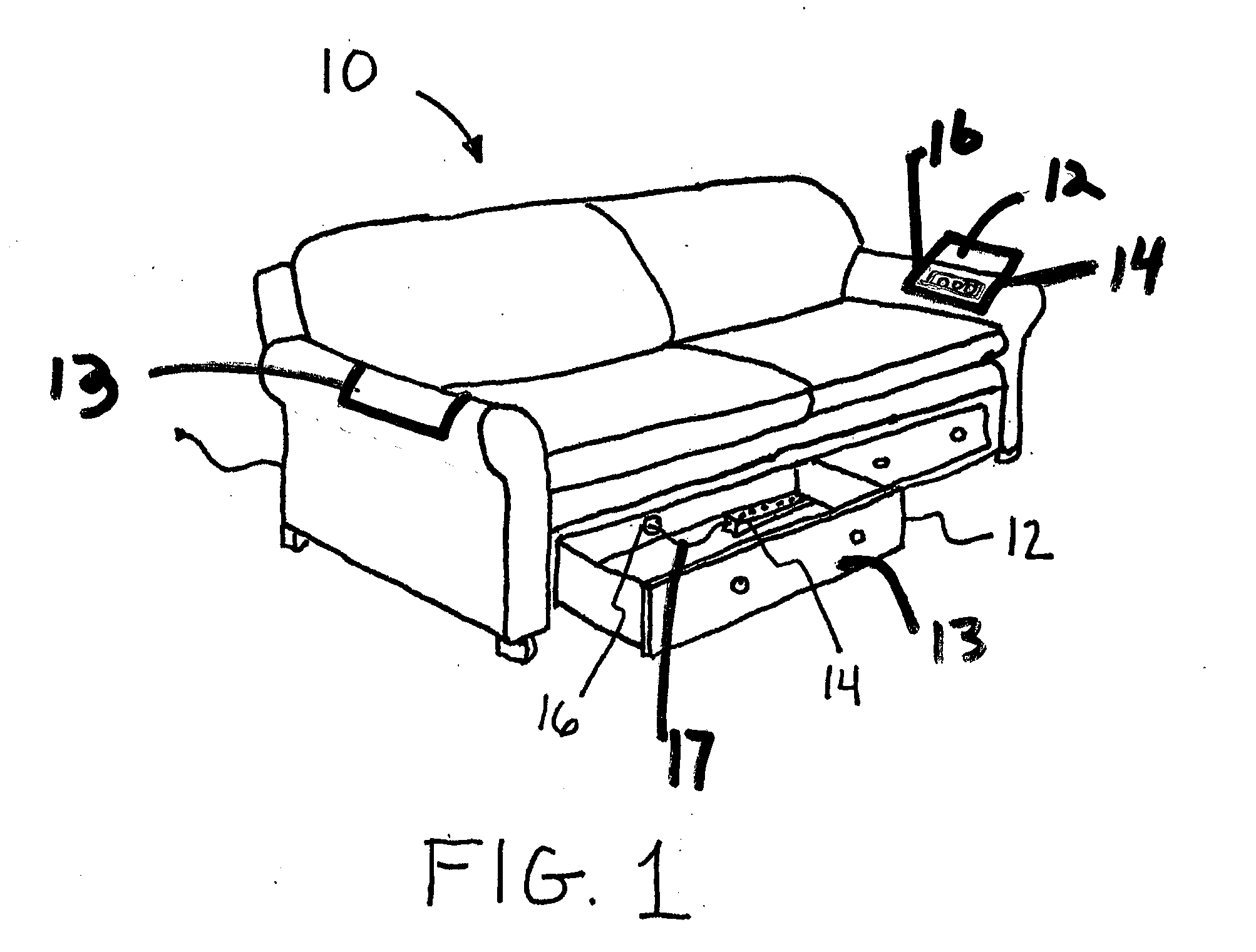

Seating furniture with built-in media dock

An article of furniture for storing and powering electronic equipment including a seating area, at least one concealable compartment located within the seating area, and a power source located within the compartment. The power source having a power cable that is attached to the interior frame of the article of furniture and concealed until it is needed. The power source includes power cables that protrude from the article of furniture for connection with a building's power supply. The compartment holds and conceals power supply components for electrical devices within the interior frame of the article of furniture to allow access and ease of use without having to mange a number of power cords.

Owner:WILSON JR EDWARD EARL

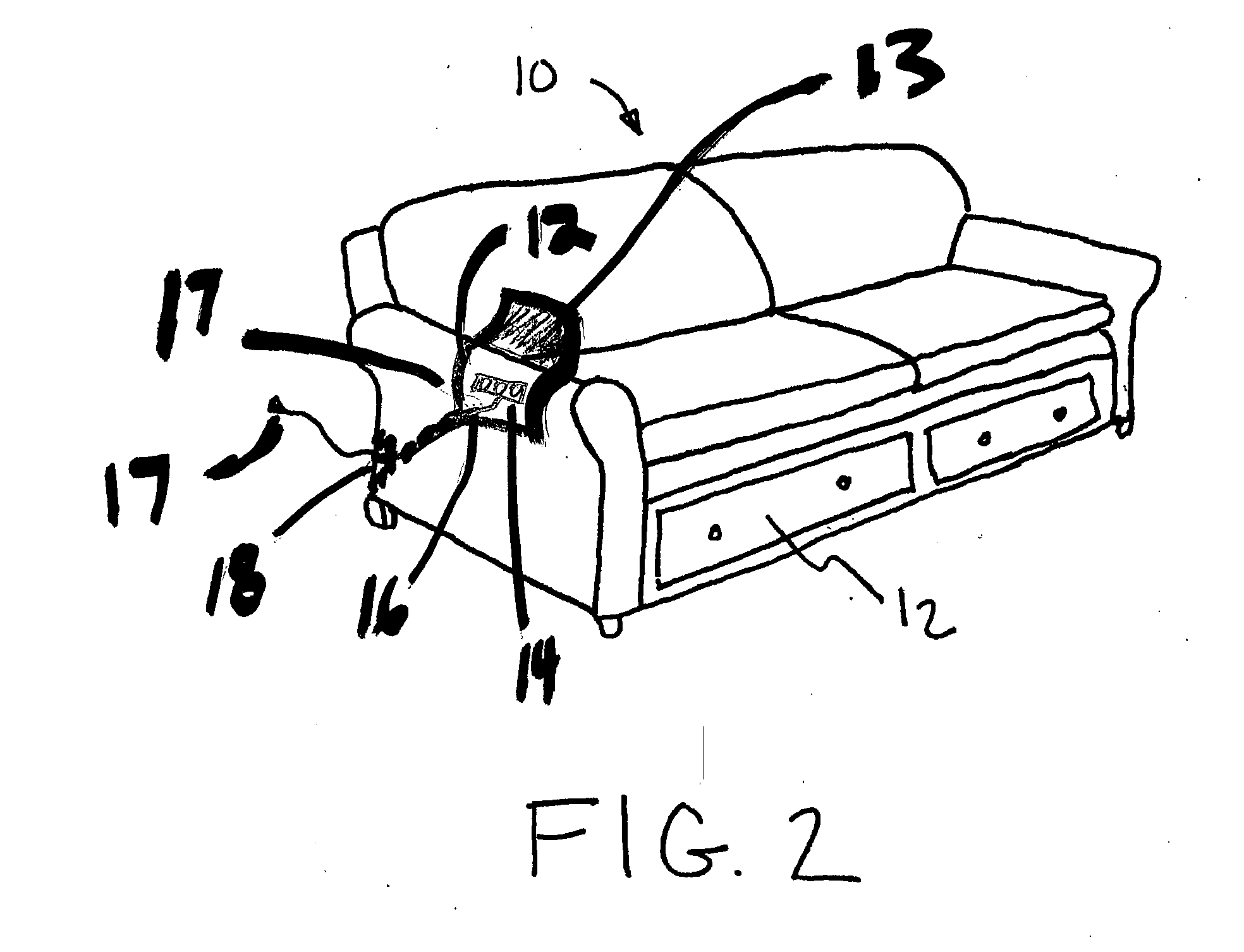

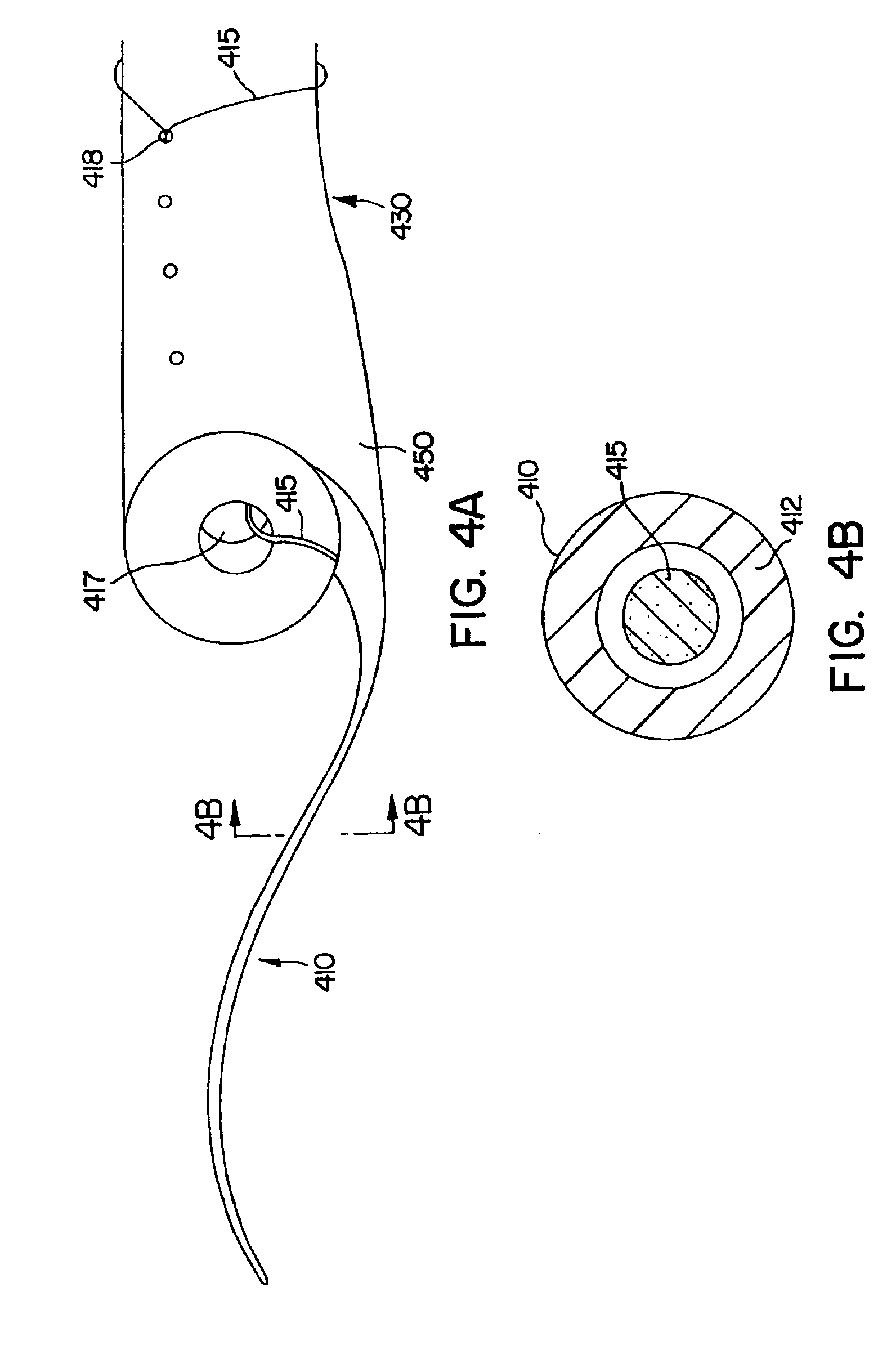

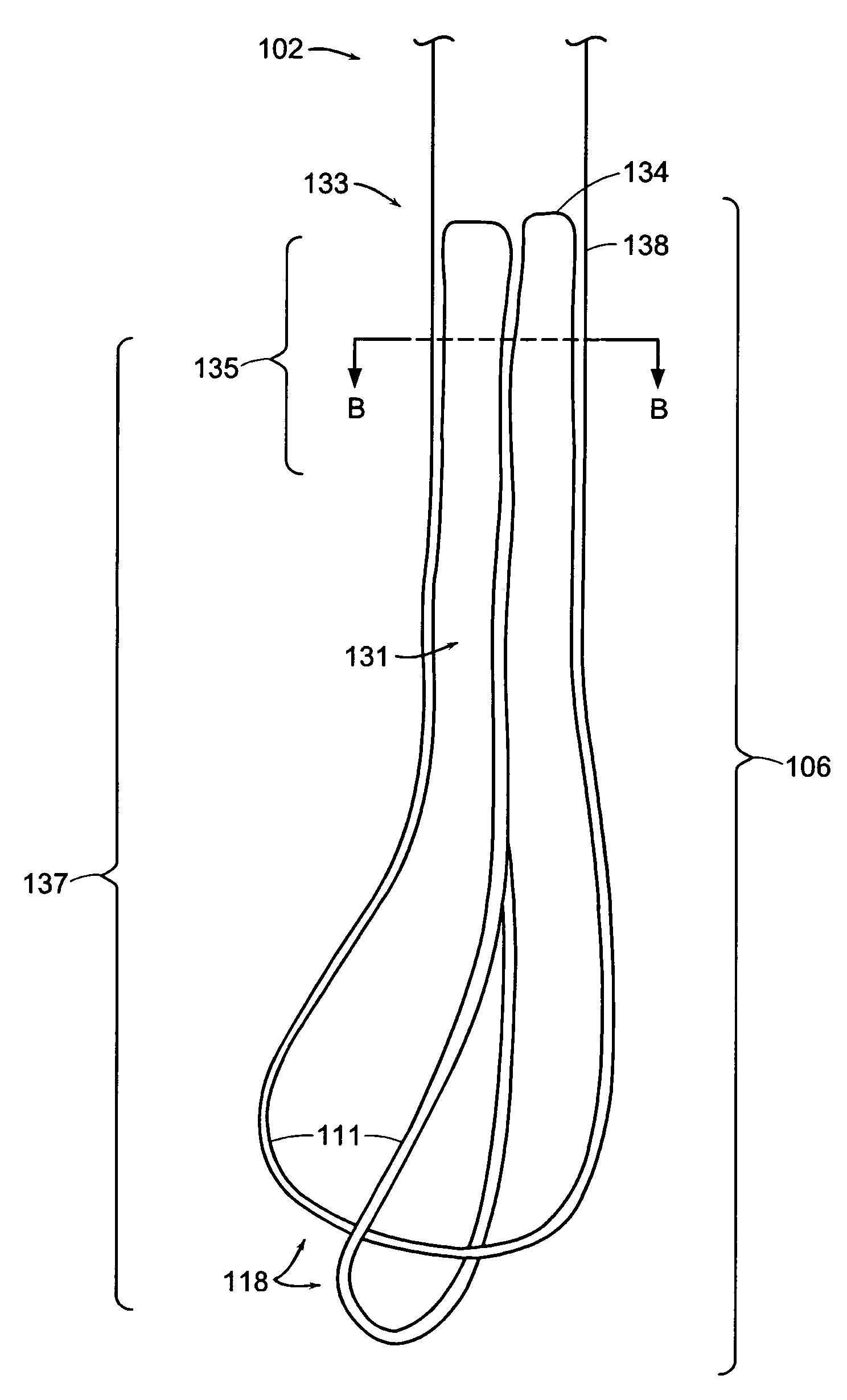

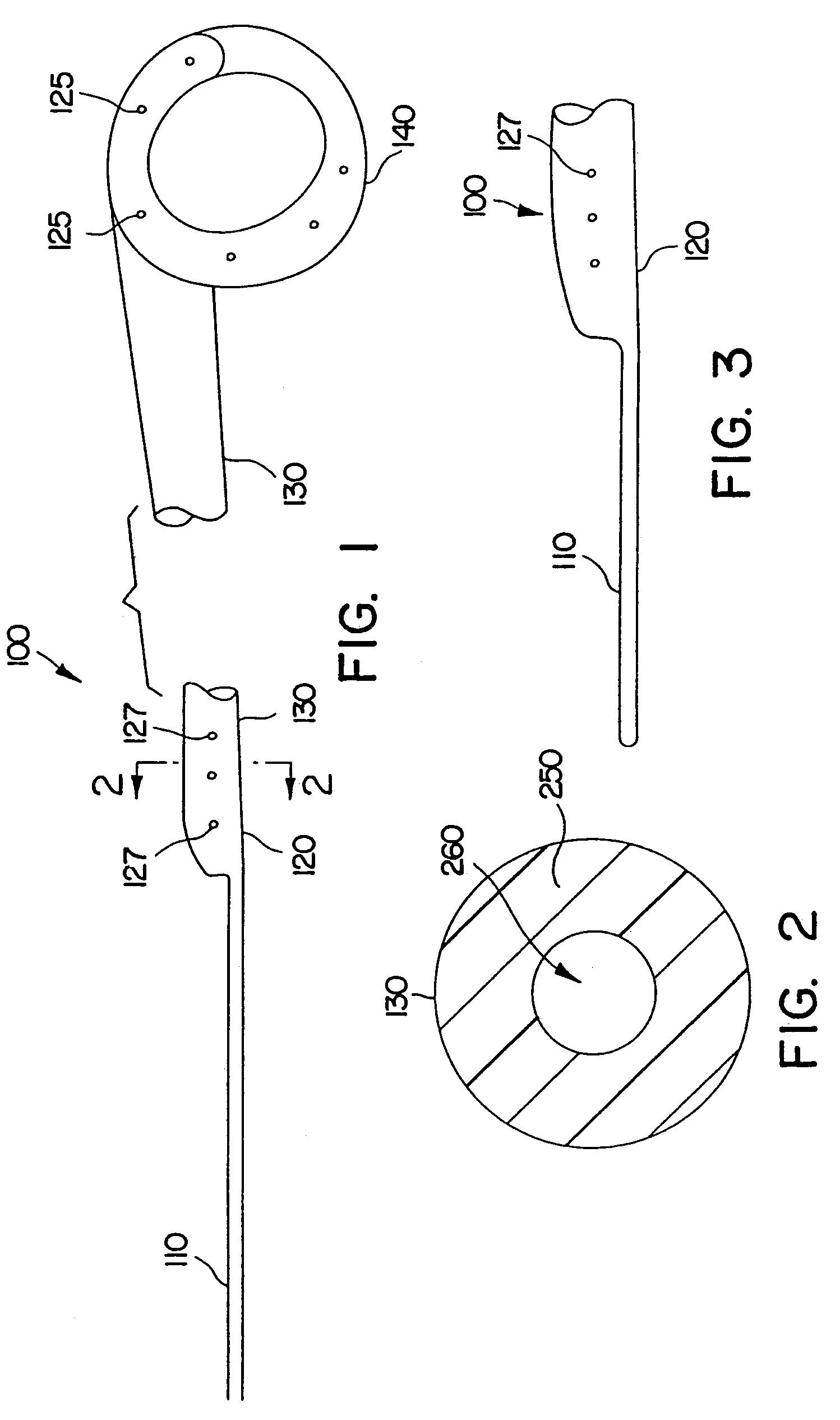

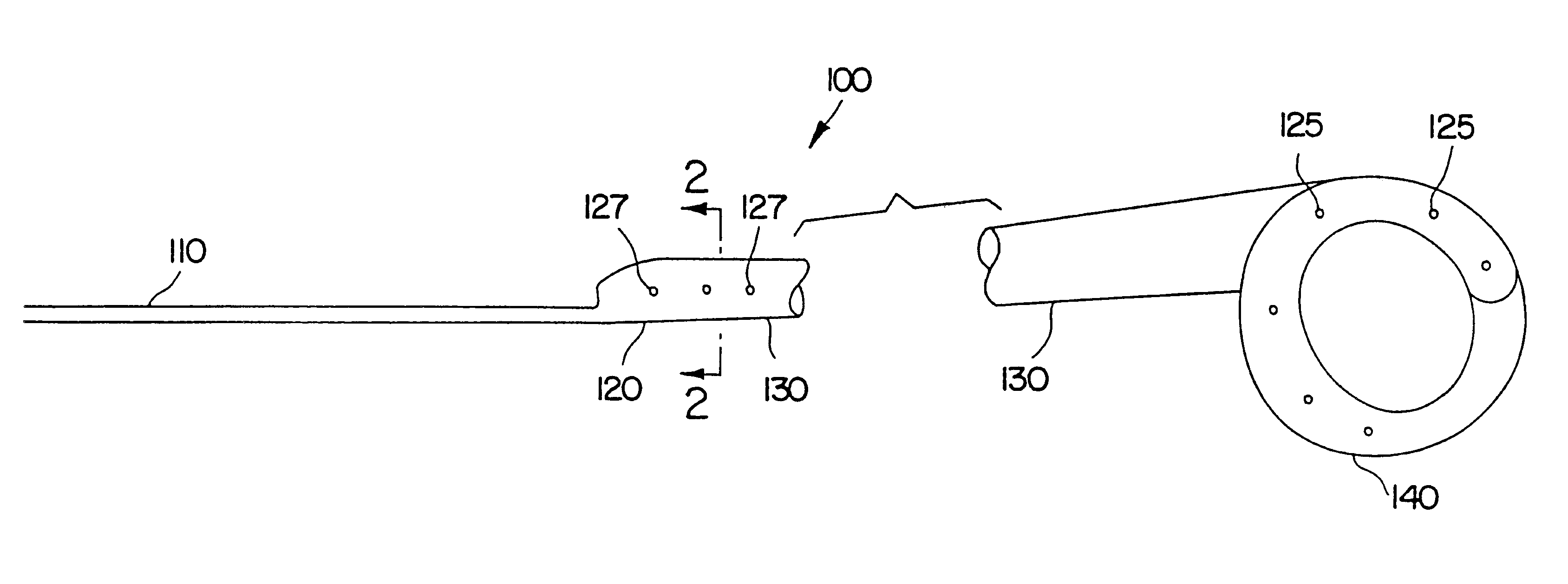

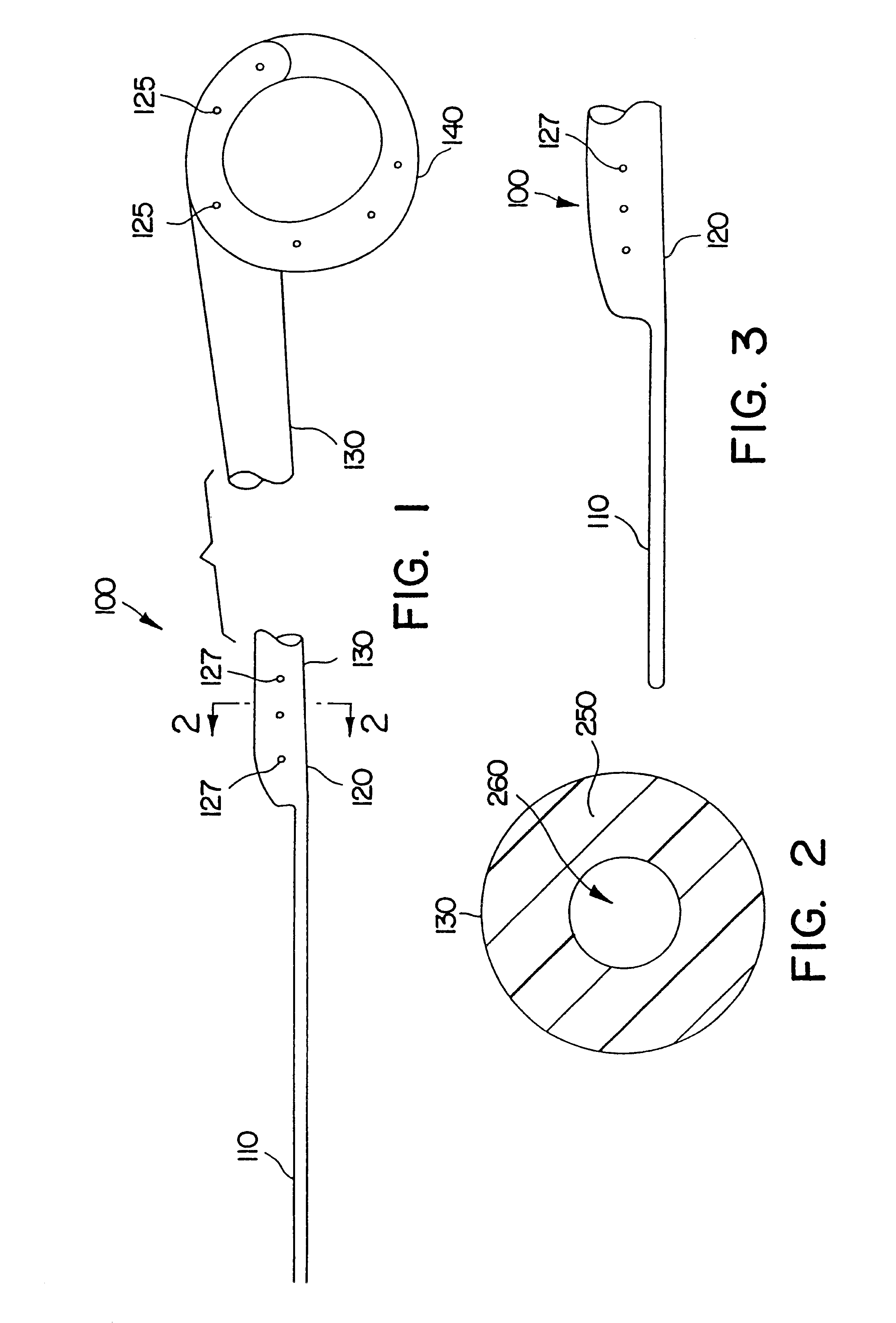

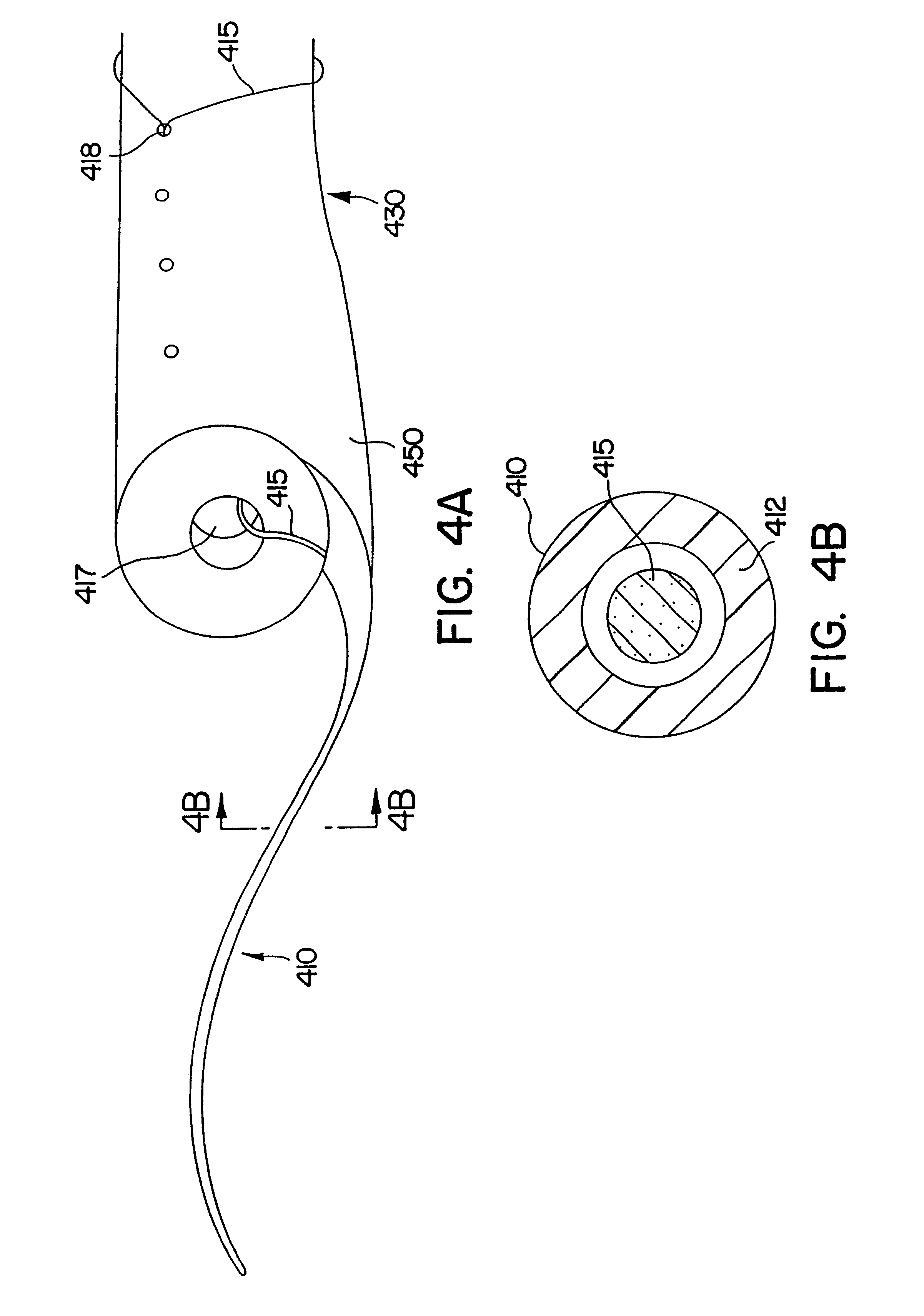

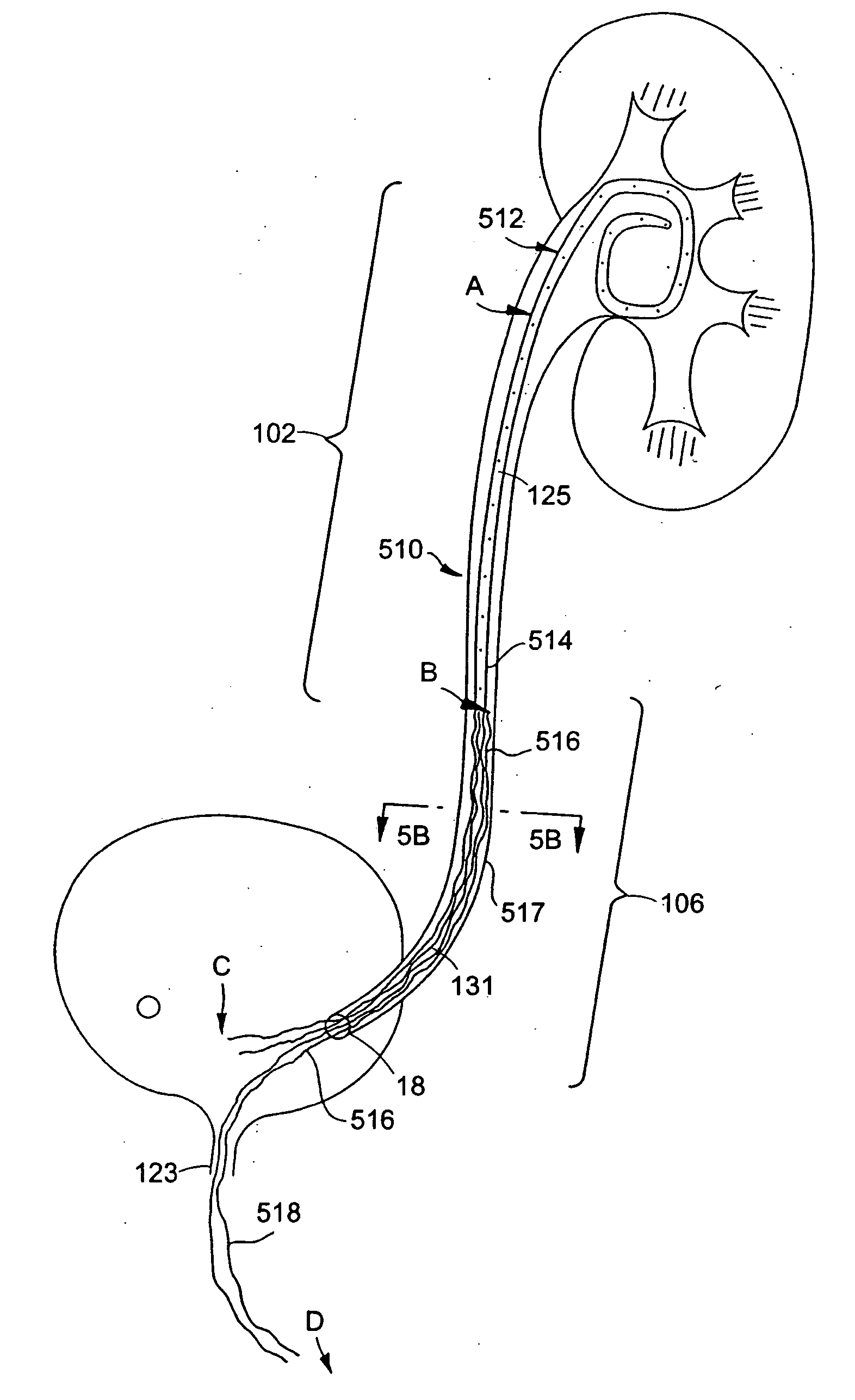

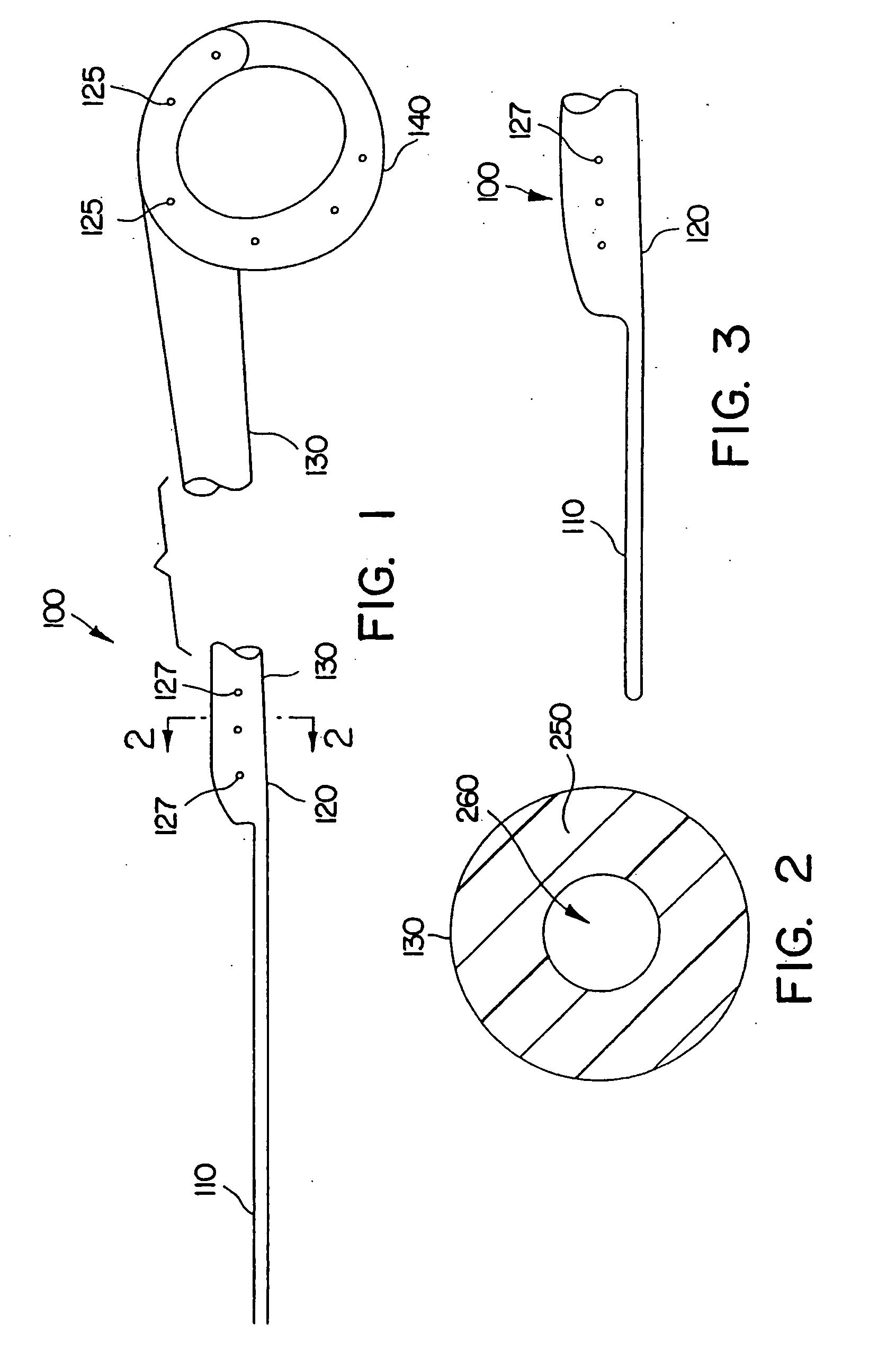

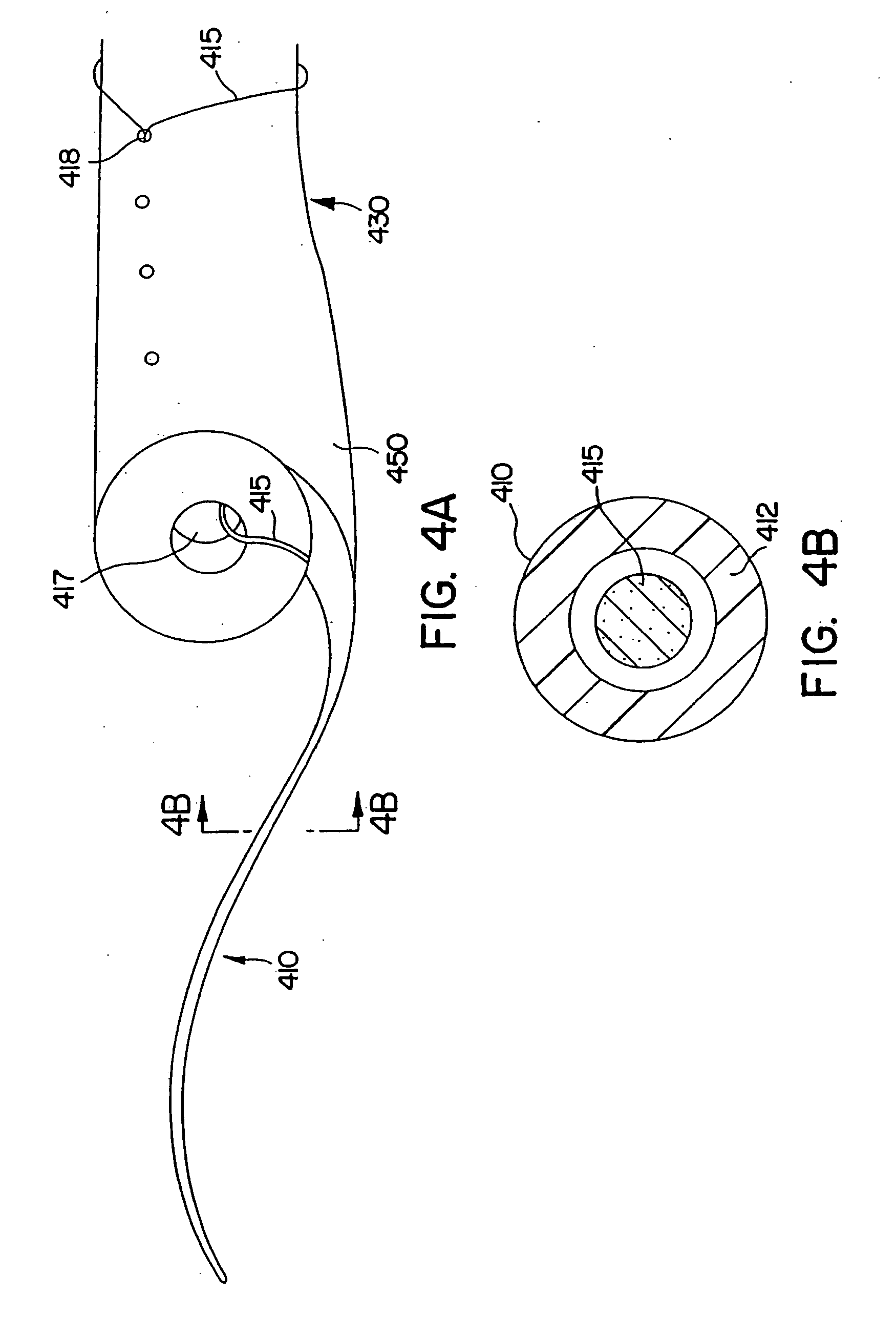

Ureteral stent with small bladder tail(s)

InactiveUS6945950B2Decreases patient discomfortInhibit migrationUrinary bladderStentsInsertion stentLeft ureter

A ureteral stent for assisting movement of urine along a patient's ureter and into the patient's bladder. The stent includes an elongated tubular segment extending toward the bladder from a kidney end region for placement in the renal cavity to a bladder end region. A central lumen connects at least one opening at the first end region to at least one opening in the bladder end region. Thin flexible tail(s) are attached to the bladder end region of the tubular segment at a point outside the bladder so as to receive urine from the opening in the bladder end region and to transport urine from there across the ureter / bladder junction and into the bladder. The tails include an elongated external urine-transport surface configured to transport urine. The transporting surface(s) are configured to extend along at least part of the ureter, across the ureter / bladder junction, and into the bladder.

Owner:BOSTON SCI SCIMED INC +1

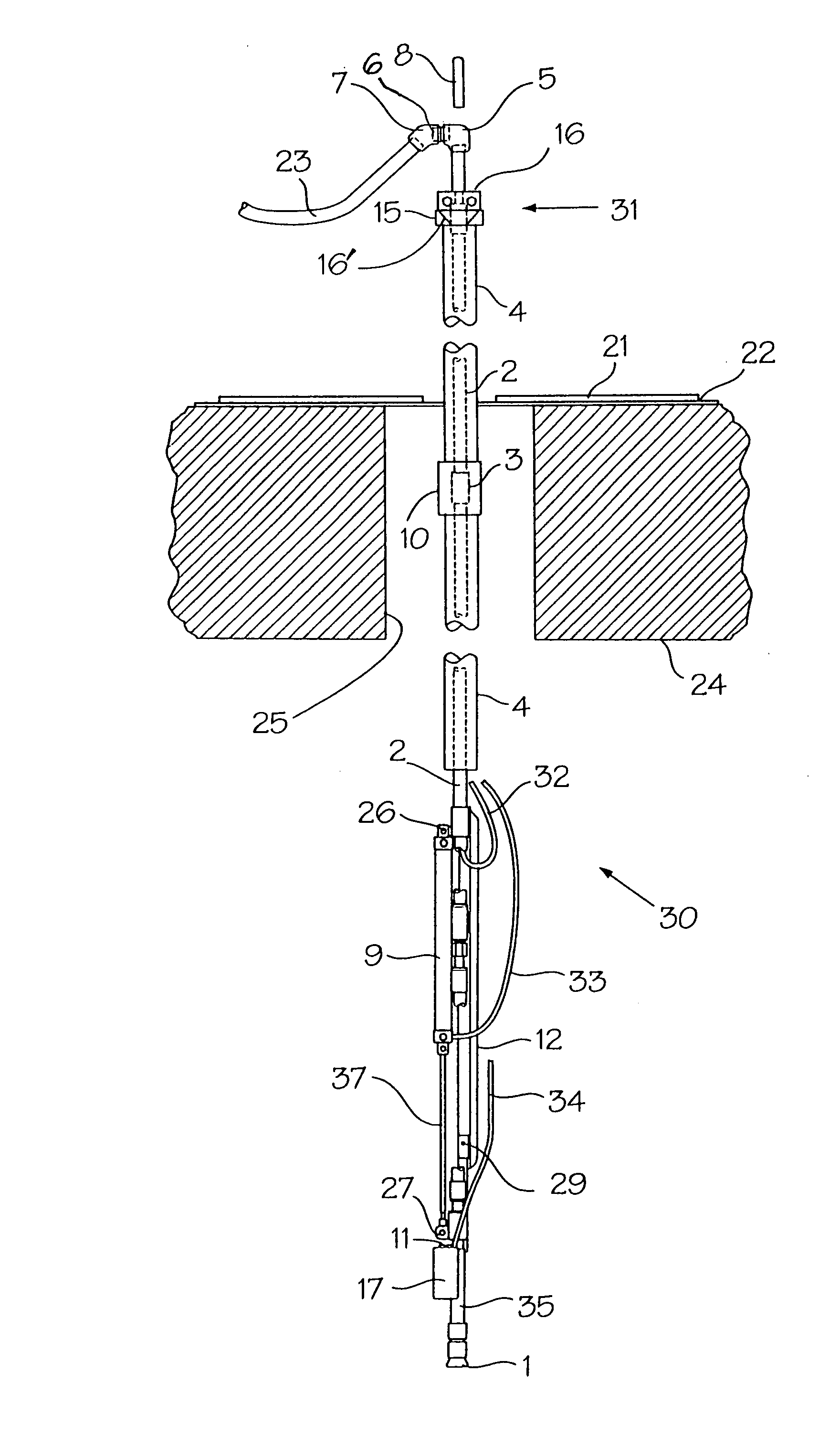

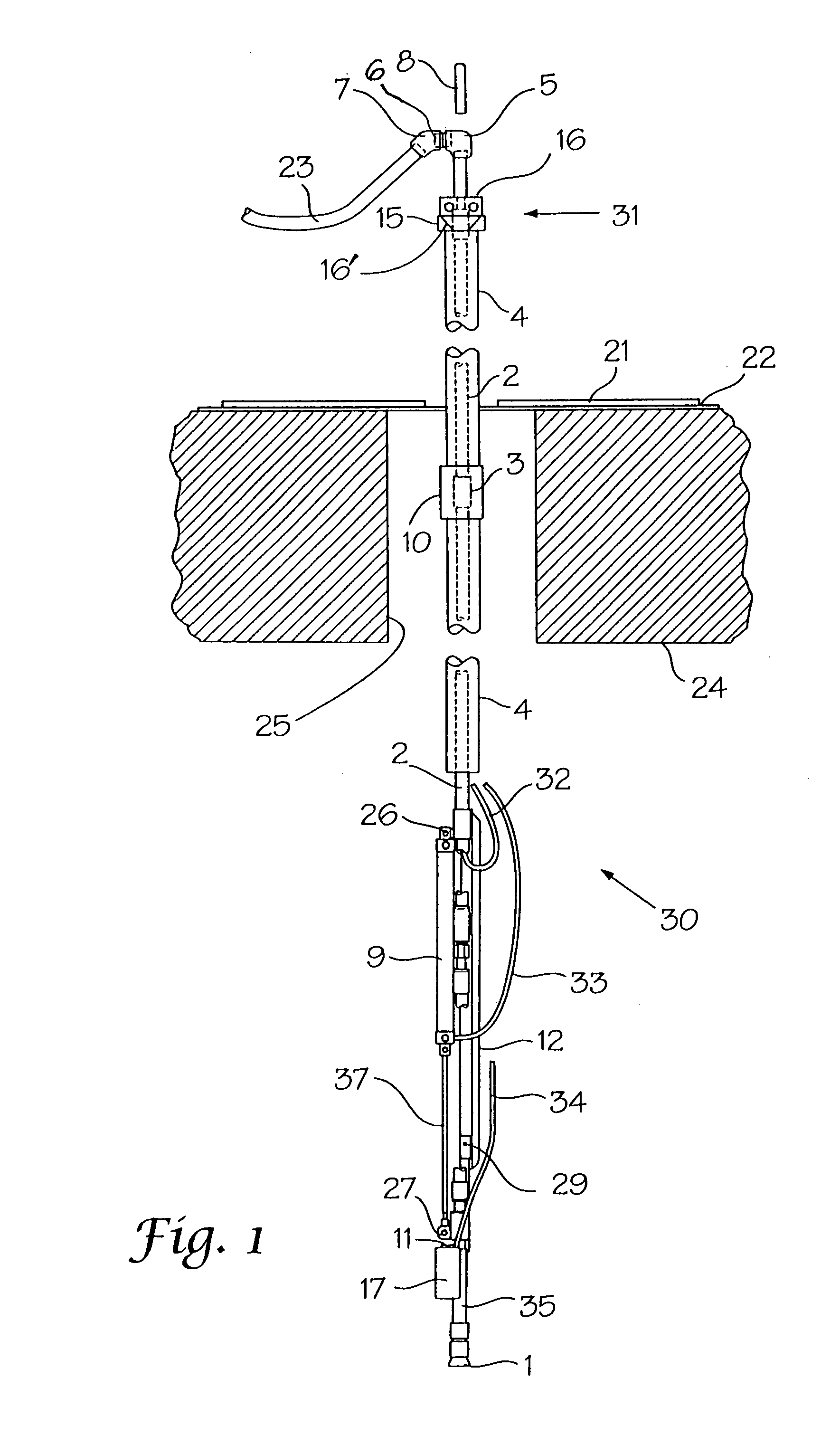

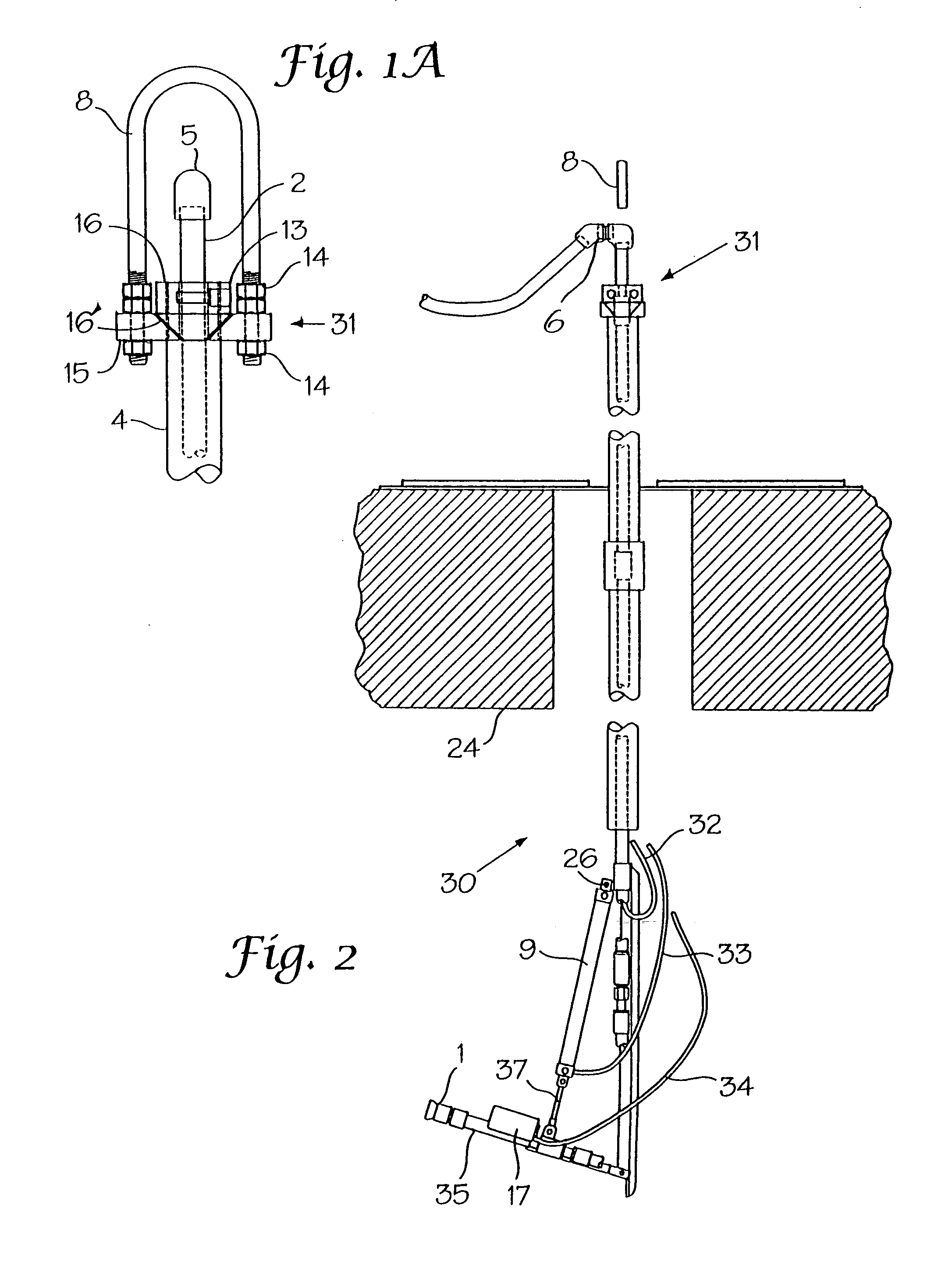

Directed spray mast

InactiveUS6889920B2Prevent crushingAvoid crimpingHollow article cleaningLiquid spraying apparatusSprayerWastewater

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

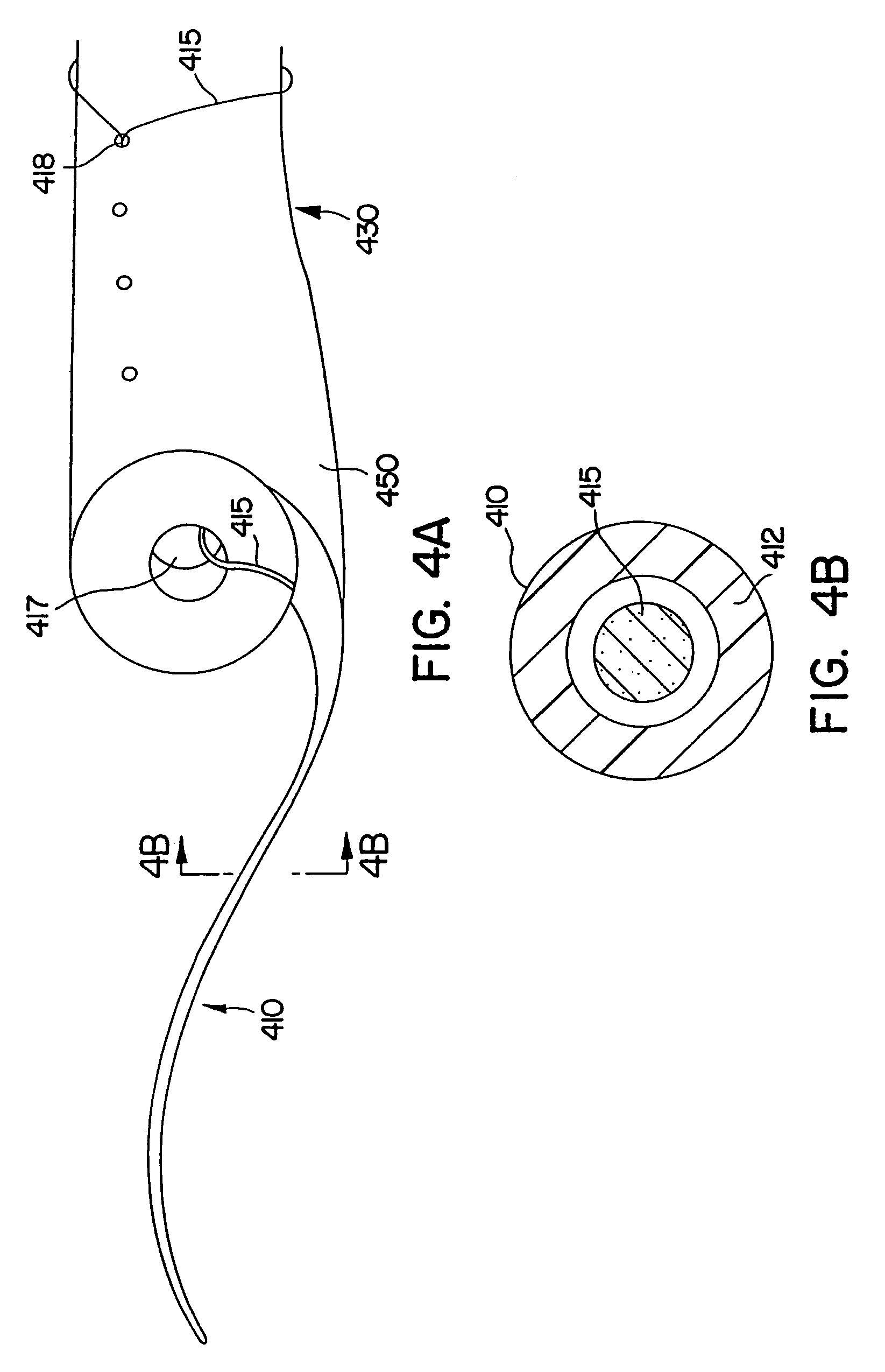

Ureteral stent for improved patient comfort

A ureteral stent for assisting the movement of urine along a patient's ureter and into the patient's bladder. The stent includes an elongated tubular segment extending toward the bladder from a kidney end region for placement in the renal cavity to a bladder end region. A central lumen connects at least one opening at the first end region to at least one opening in the bladder end region. Thin flexible tail(s) are attached to the bladder end region of the tubular segment at a point outside the bladder so as to receive urine from the opening in the bladder end region of the tubular segment and to transport urine from there across the ureter / bladder junction and into the bladder. The tails include an elongated external urine-transport surface sized and configured to transport urine along the ureter. The urine transporting surface(s) are sized and configured to extend along at least part of the ureter, across the ureter / bladder junction, and from there into the bladder. In some embodiments, the distal region includes a tubular body with a lumen in fluid communication with an interstitial area defined by one or more flexible filaments of the proximal region forming at least one loop.

Owner:BOSTON SCI SCIMED INC

Medical device with tail(s) for assisting flow of urine

InactiveUS6849069B1Decrease patient discomfortDecreases patient discomfortUrinary bladderStentsInsertion stentLeft ureter

A ureteral stent for assisting movement of urine along a patient's ureter and into the patient's bladder. The stent includes an elongated tubular segment extending toward the bladder from a kidney end region for placement in the renal cavity to a bladder end region. A central lumen connects at least one opening at the first end region to at least one opening in the bladder end region. Thin flexible tail(s) are attached to the bladder end region of the tubular segment at a point outside the bladder so as to receive urine from the opening in the bladder end region of the tubular segment and to transport urine from there across the ureter / bladder junction and into the bladder. The tails include an elongated external urine-transport surface sized and configured to transport urine along the ureter. The urine transporting surface(s) are sized and configured to extend along at least part of the ureter, across the ureter / bladder junction, and from there into the bladder.

Owner:BOSTON SCI CORP

led rotary built-in power fluorescent lamp

InactiveCN102287737AWon't shakeFirmly connectedPoint-like light sourceElongate light sourcesElectricityEngineering

Owner:NINGBO TONGTAI ELECTRIC

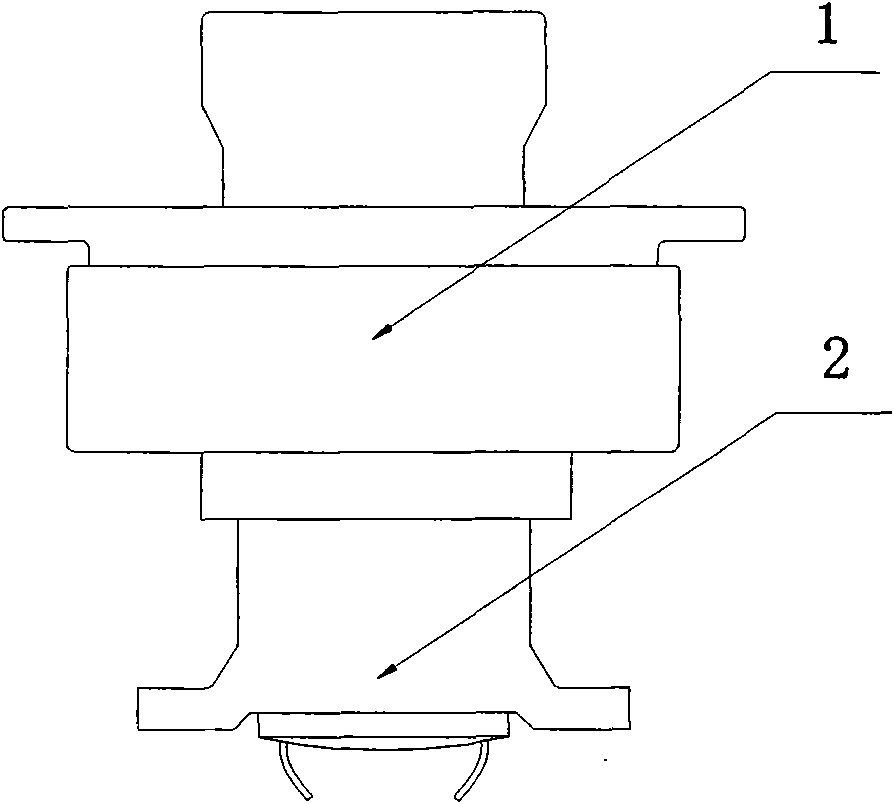

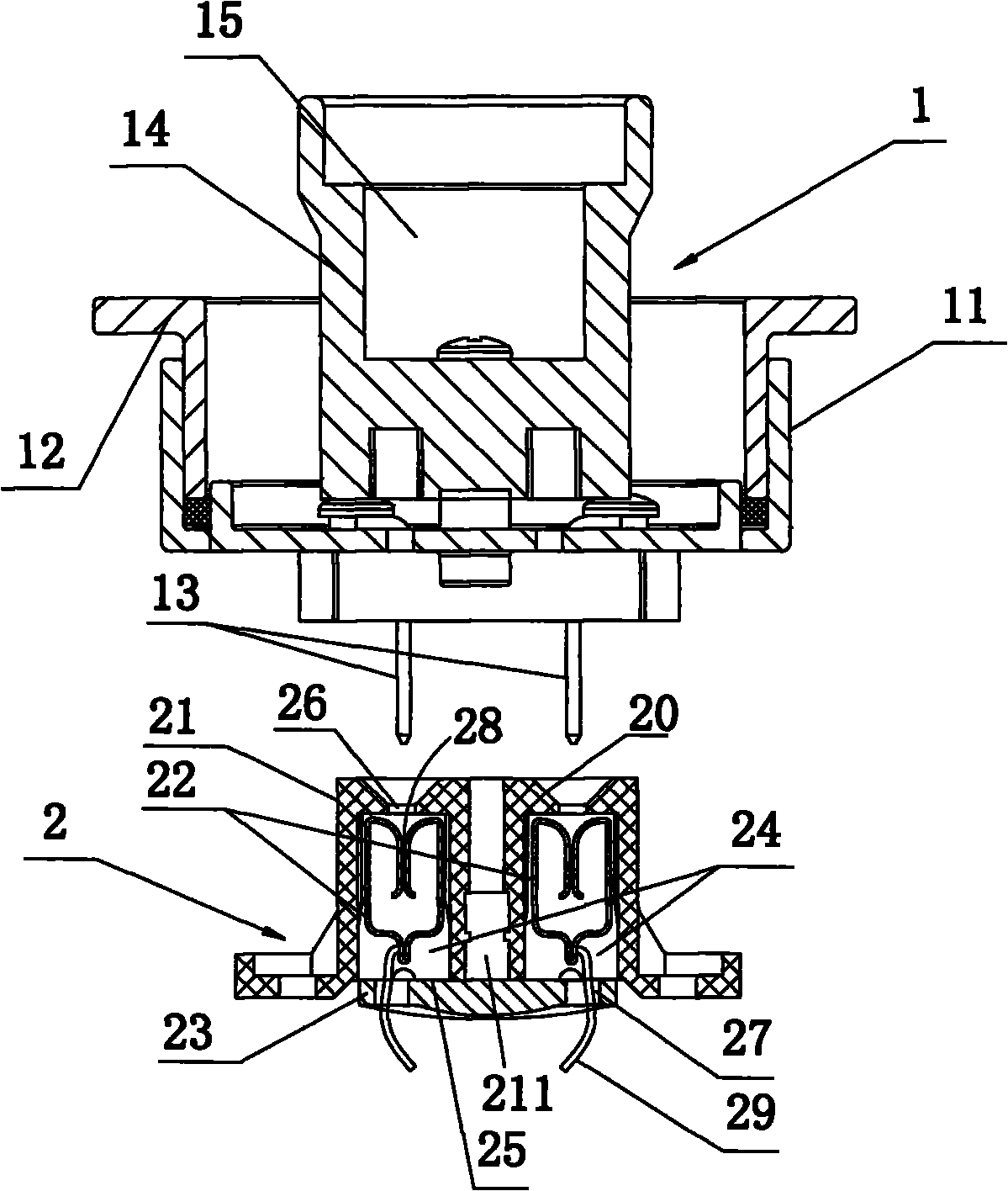

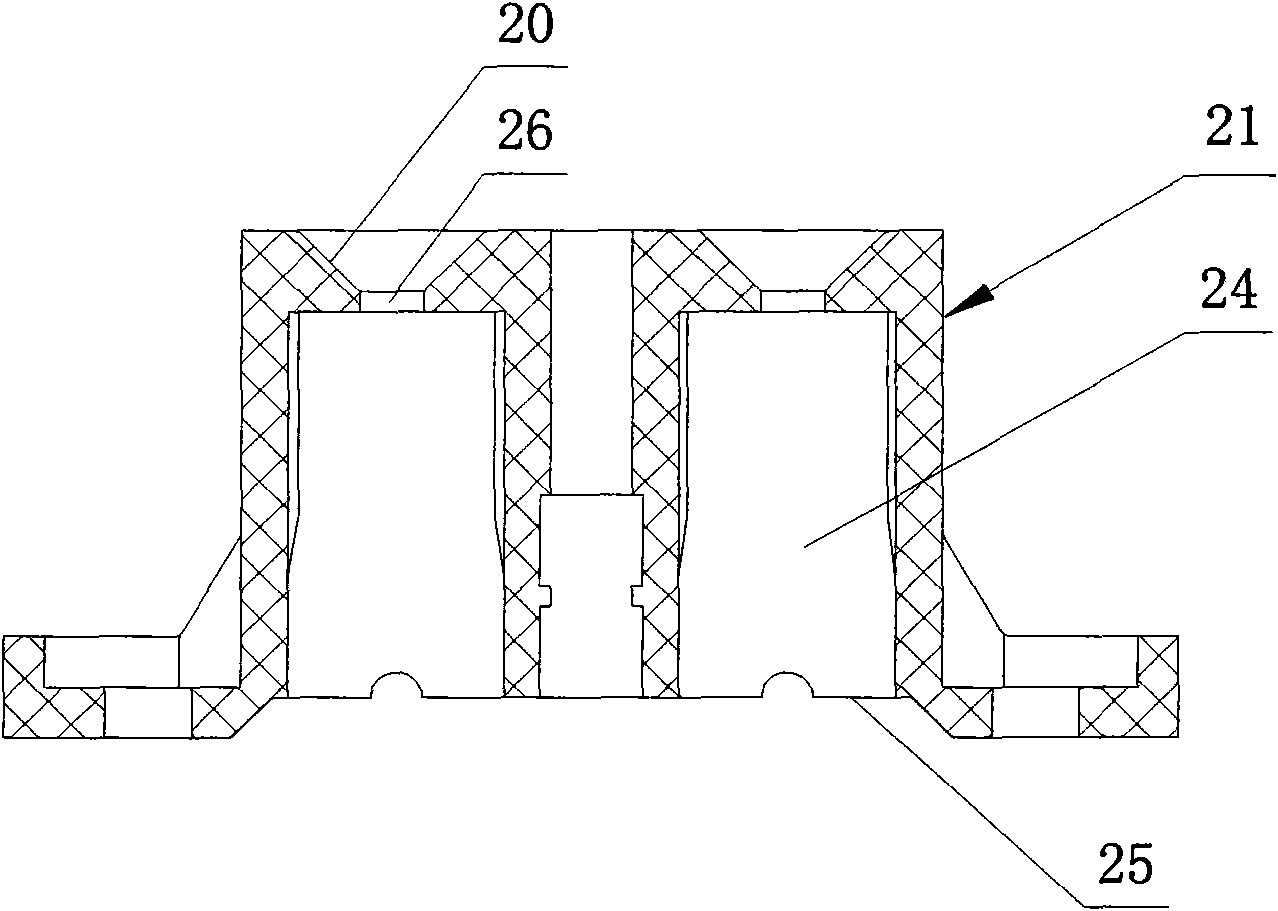

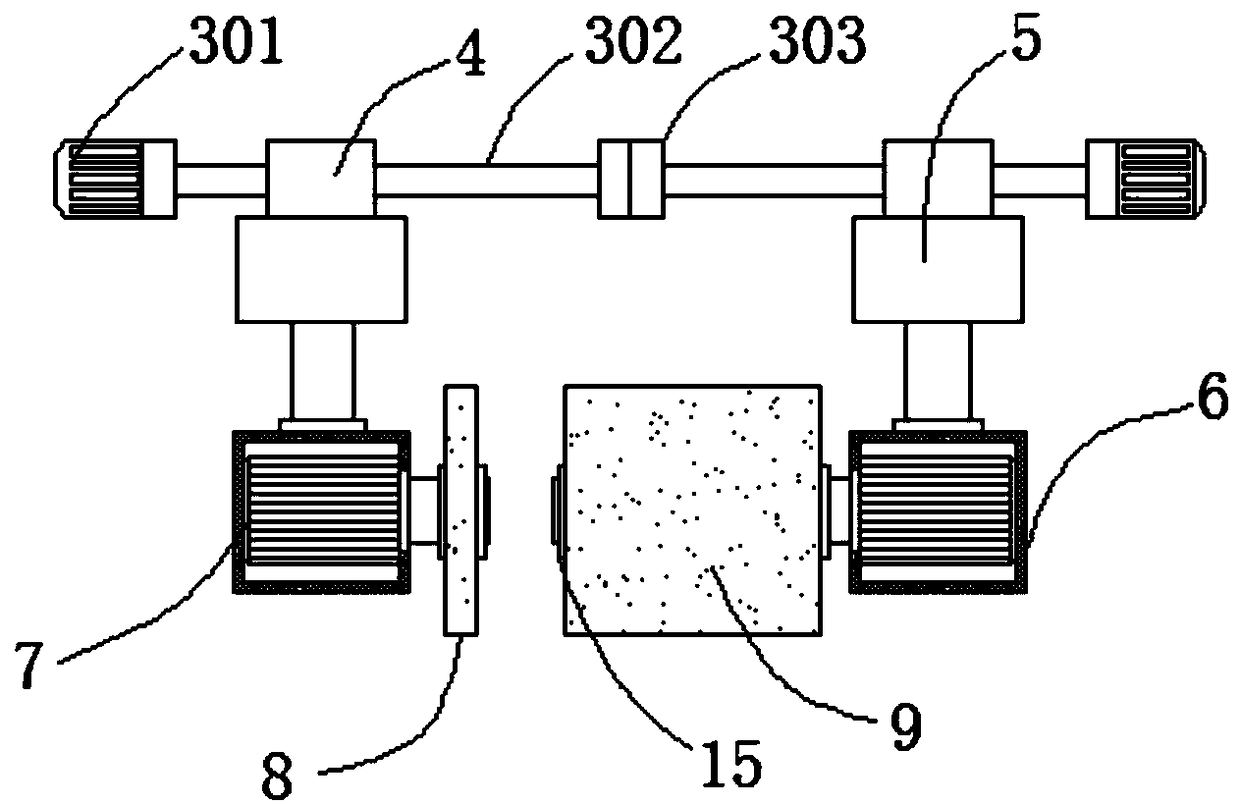

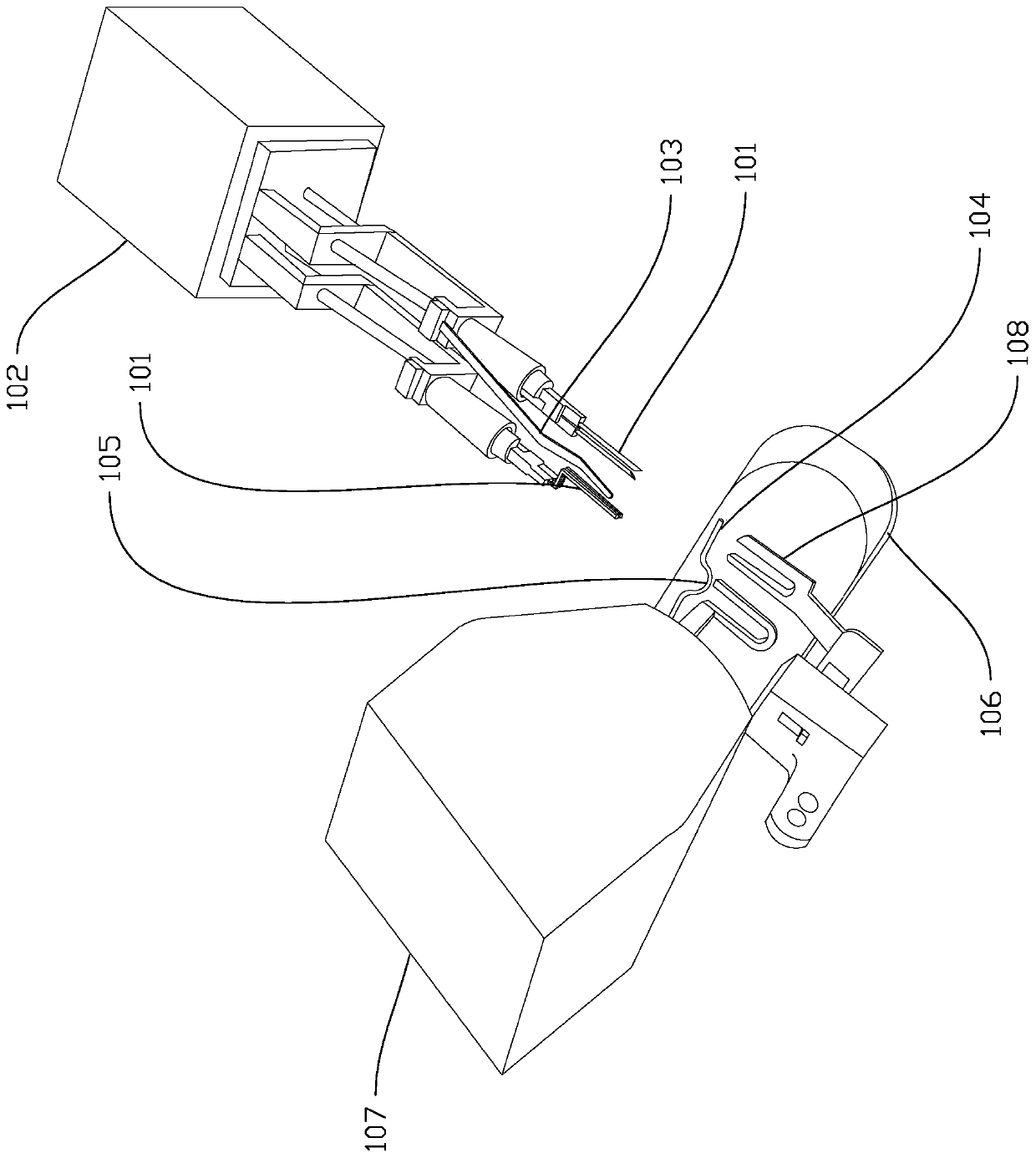

Power supply communication structure and lamp utilizing power supply communication structure

InactiveCN101902003AReduce in quantityAvoid crimpingCoupling device connectionsElectric discharge tubesEngineeringSafe operation

The invention relates to a power supply communication structure and a lamp utilizing the power supply communication structure. The power supply communication structure comprises a terminal and a lamp holder assembly, wherein two conducting seats are arranged in the terminal, and both of the conducting seats are respectively connected with lead wires and connected with the anode and the cathode of the power supply through the lead wires; the lamp holder assembly is provided with two conducting strips, and the inner ends of the two conducting strips are respectively connected with lead wires and connected with the anode and the cathode of a light source through the lead wires; and the lamp holder assembly and the terminal are plugged with the two conducting seats through the outer ends of the conducting strips so as to form a detachable connection. The lamp comprises a light source part and an electric part, wherein the light source part comprises the lamp holder assembly and the light source; the electric part comprises the terminal; and the light source part is connected with the electric part through a rotation shaft to form a rotatable connection which enables the conducting strips to be plugged in or out of the conducting seats correspondingly to switch on or off the light source. The power supply communication structure requires no lead wire for connection. The lamp has the advantages of simple structure and safe operation.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

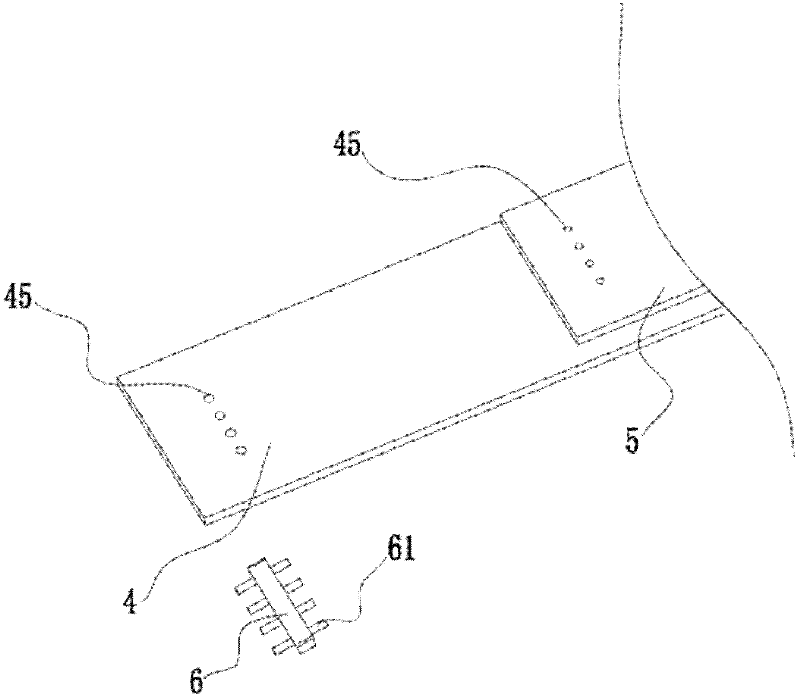

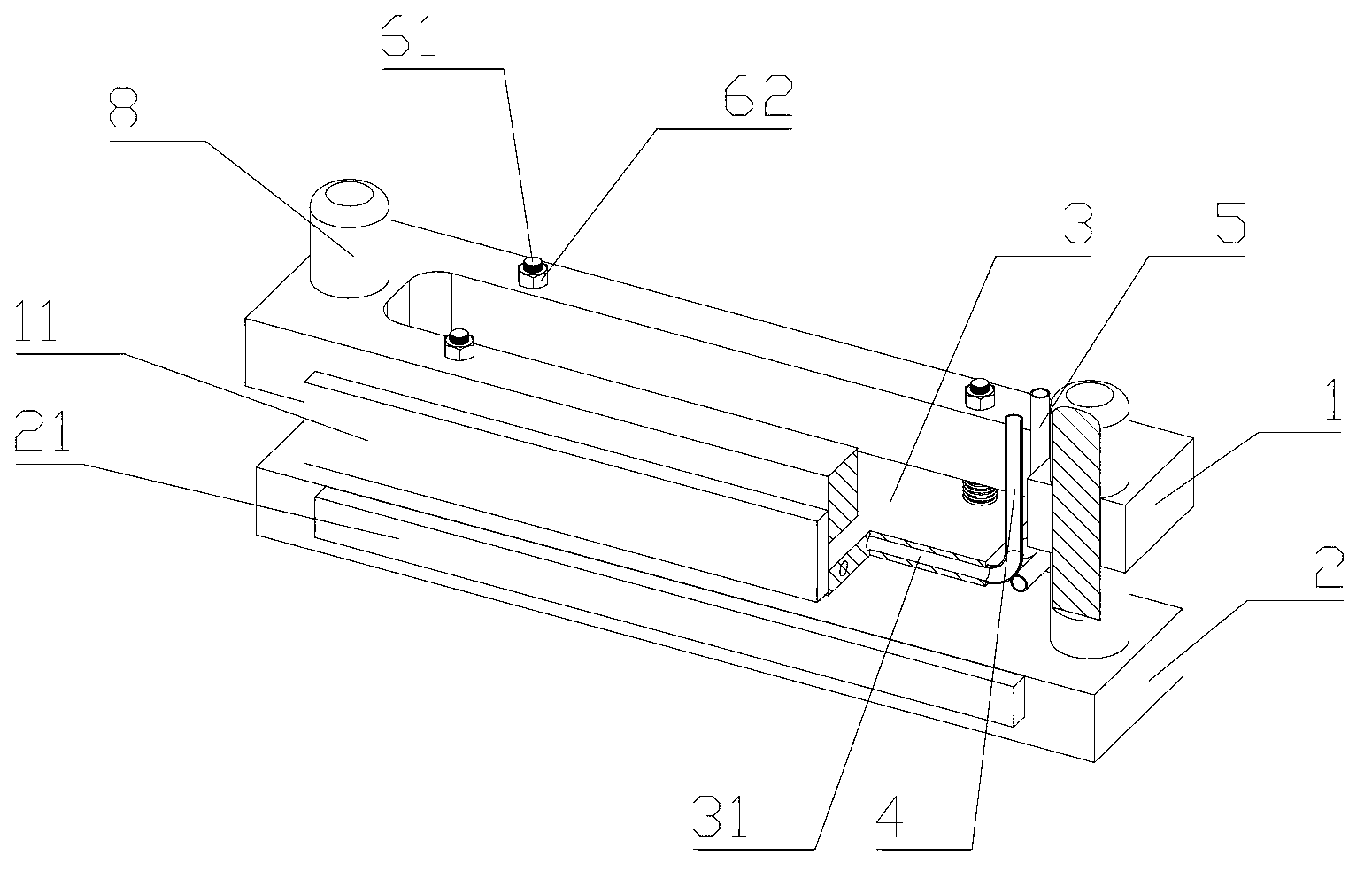

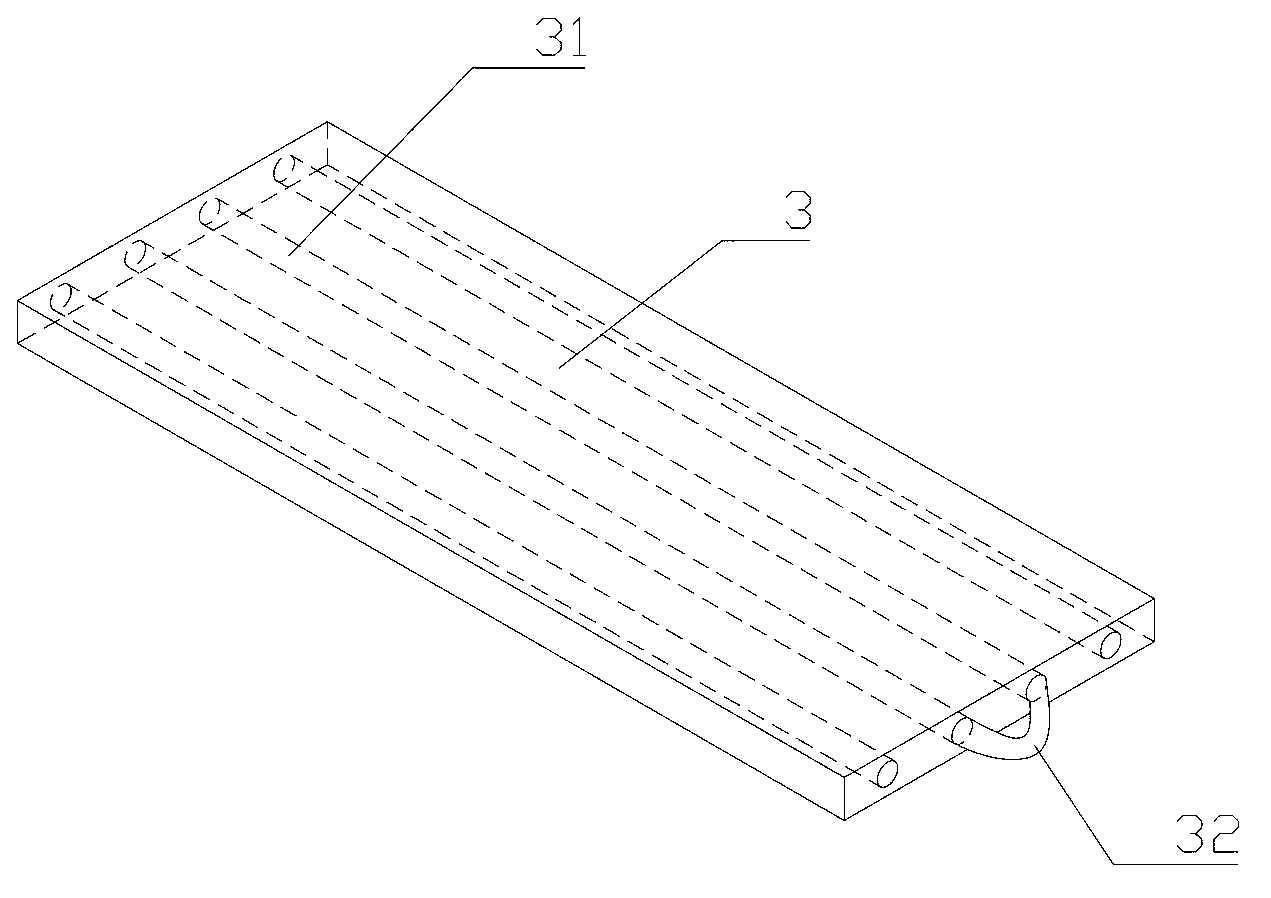

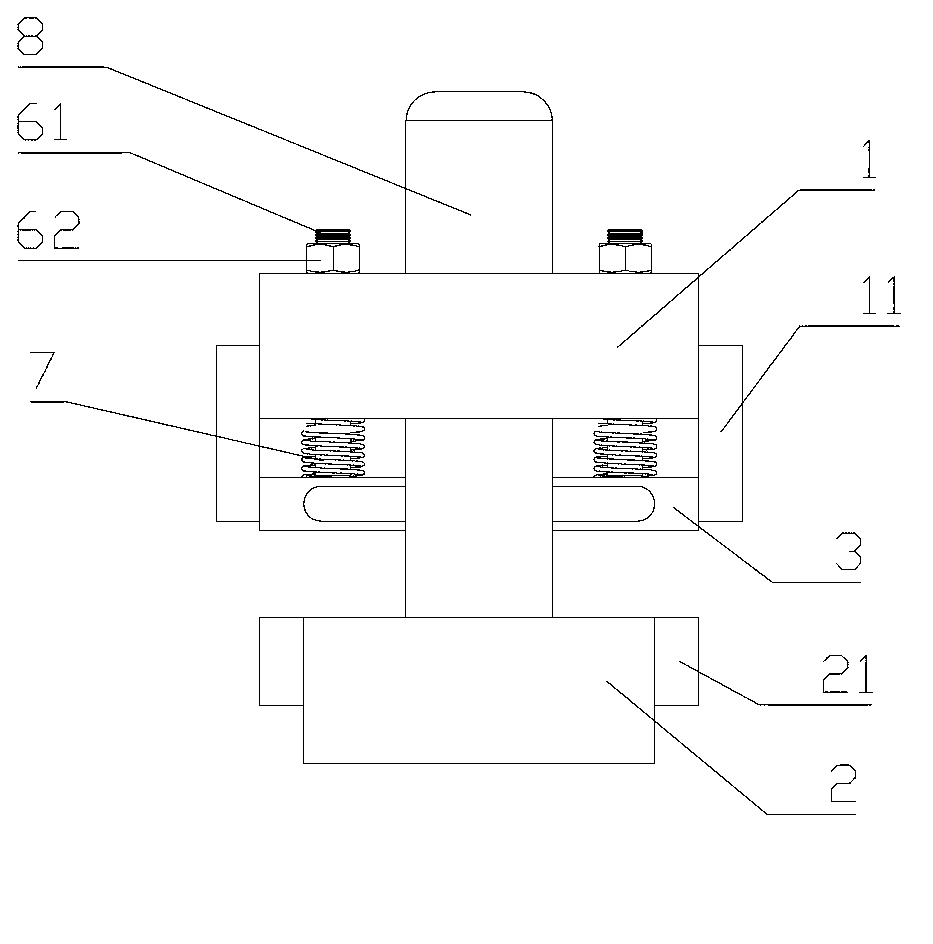

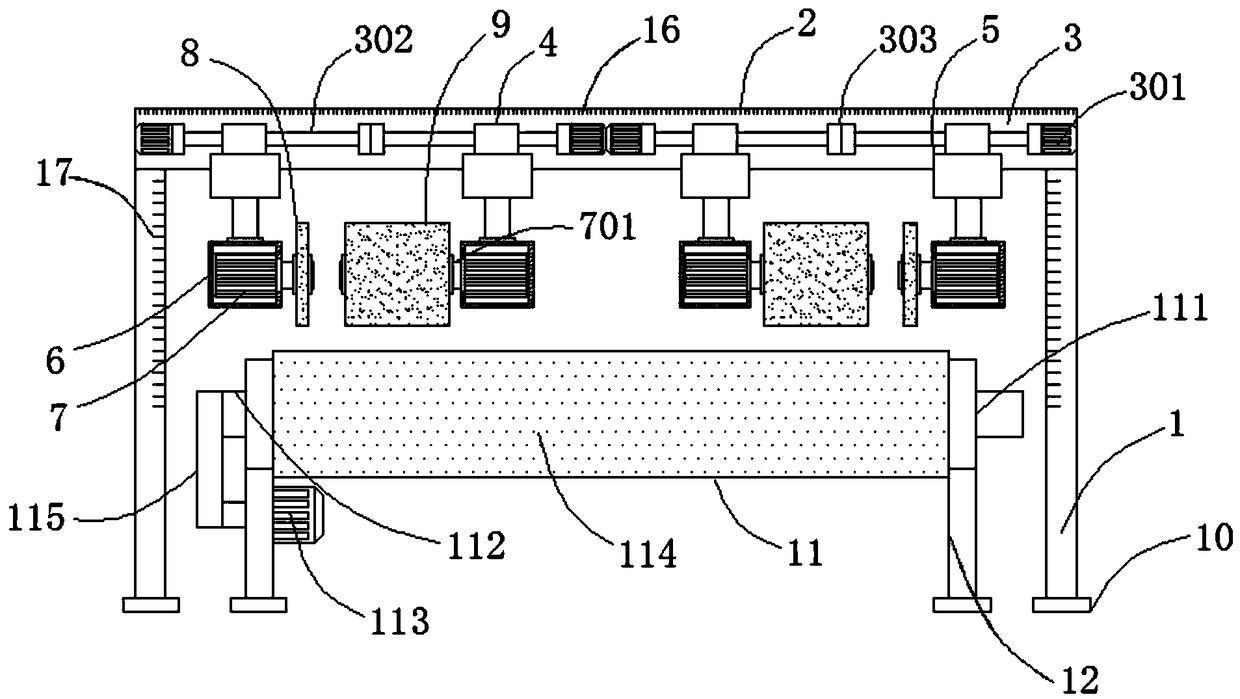

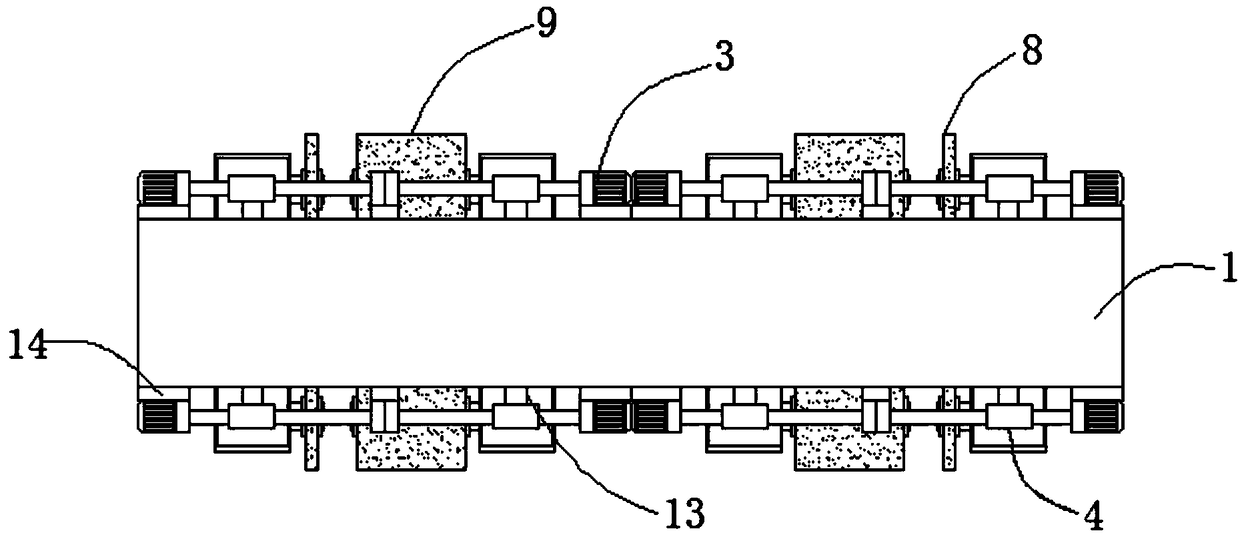

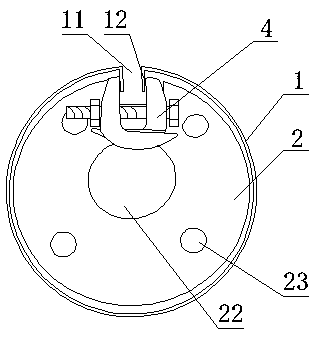

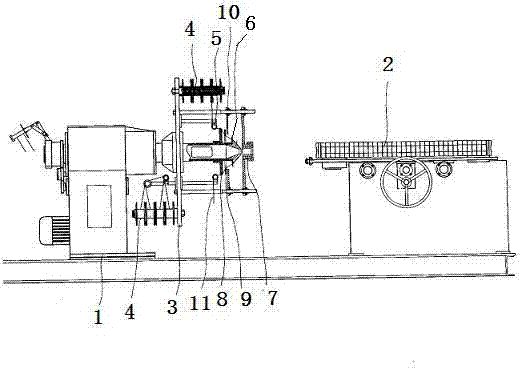

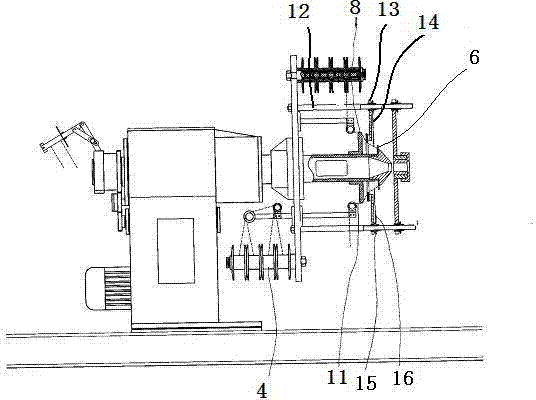

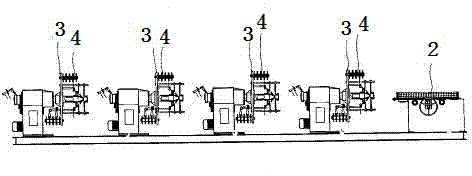

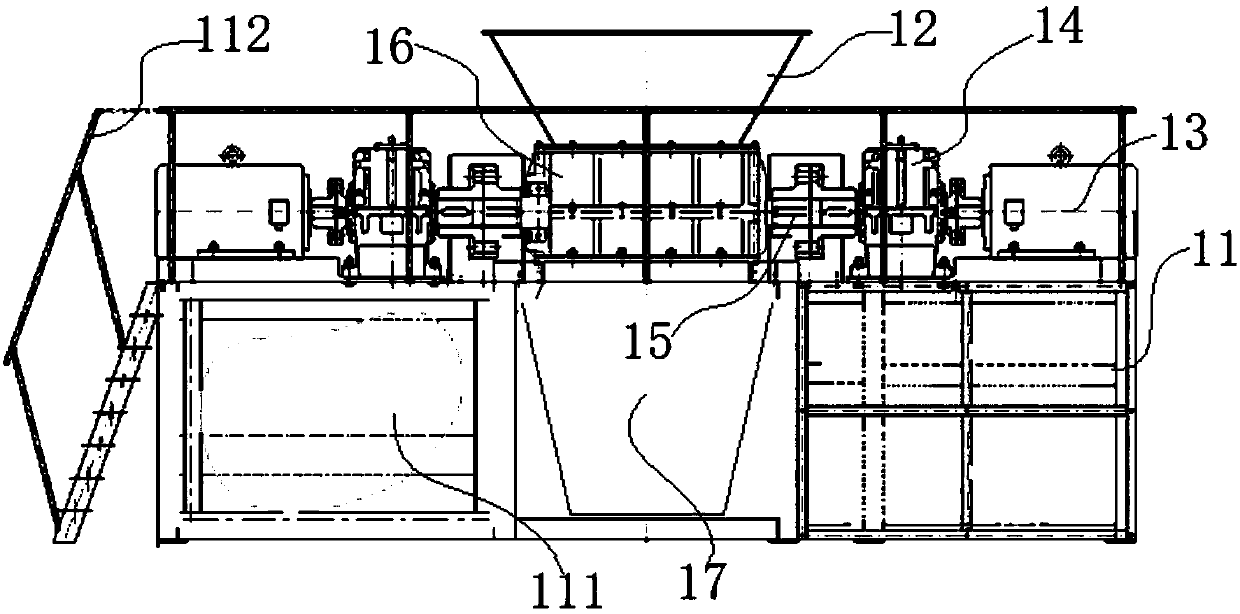

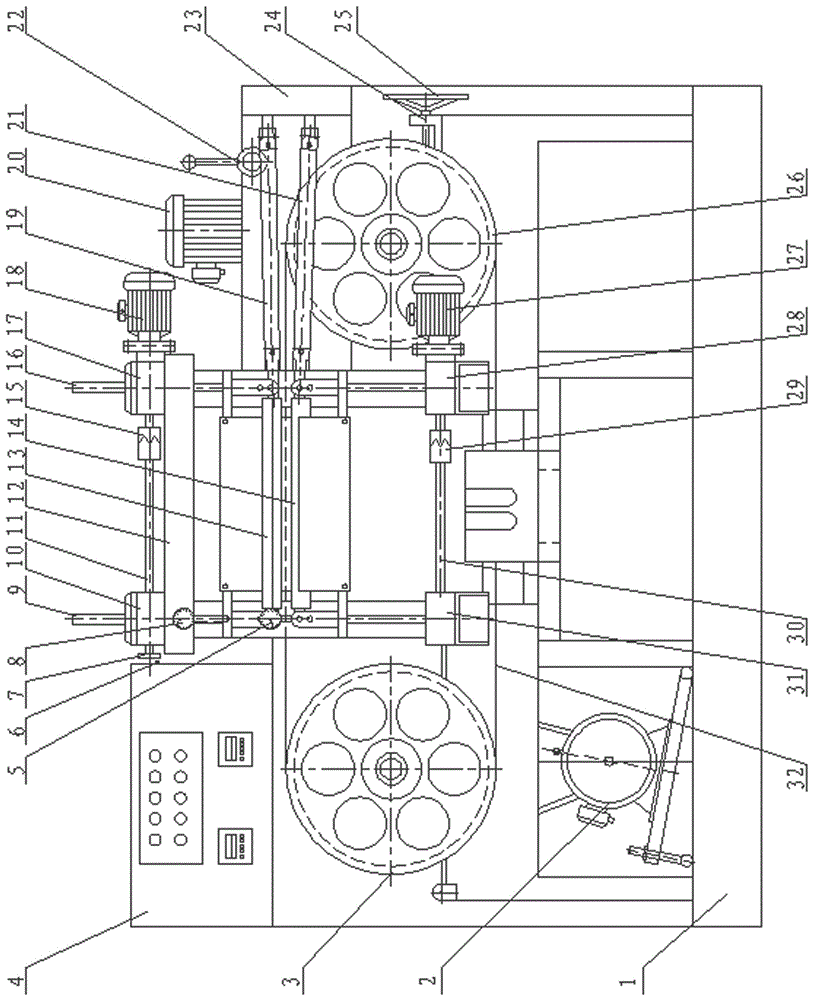

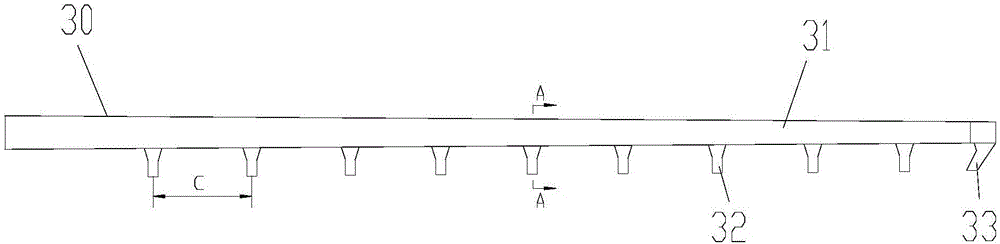

Cutter system of plate casting machine

ActiveCN103223521AAvoid crooked or even continuous cuttingAvoid crimpingShearing machinesMaintainance and safety accessoriesMechanical engineering

The invention discloses a cutter system of a plate casting machine, belonging to the field of processing and manufacturing of batteries. The cutter system of the plate casting machine solves the problems of curled deformation of a plate grid at the notch position of the plate grid in the plate cutting process of the plate casting machine and deformation of the plate grid in the plate collecting process and hanging process. The cutter system of the plate casting machine comprises an upper cutter body, an upper blade arranged on the upper cutter body, a lower cutter body and a lower blade arranged on the lower cutter body, wherein the upper cutter body can move up and down relative to the lower cutter body; the lower part of the upper cutter body is connected with a pressing plate for pressing the plate grid to be cut; a cooling system is arranged on the pressing plate; the phenomena that the plate is cut slantways, even cannot be cut off caused by movement of the grid plate are avoided by pressing the plate grid by the pressing plate in the plate cutting process of the plate grid; in addition, the pressing plate is provided with the cooling system for cooling the plate grid, so curled deformation at the position of the plate grid notch is avoided.

Owner:CHAOWEI POWER CO LTD

Automatic textile-fabric processing edge pressing device

InactiveCN109230752APrevent crimpingImprove processing efficiencyWebs handlingHydraulic cylinderEngineering

The invention discloses an automatic textile-fabric processing edge pressing device. The automatic textile-fabric processing edge pressing device comprises standing columns and a machine frame arranged between the tops of the standing columns, wherein the front side and the back side of the machine frame are each provided with two groups of symmetrically-arranged servo driving devices, guiding blocks run through on the four groups of servo driving devices in a threaded manner, hydraulic cylinders are installed at the bottoms of the guiding blocks, frames are connected to piston rods of the output ends of the hydraulic cylinders, rotating motors are installed in the frames, output shafts of the rotating motors are each provided with a pressing roller and a limiting roller, and a conveying mechanism is arranged at the portion, located at the bottoms of the pressing rollers and the limiting rollers, between the standing columns, and is located in the middle of the bottom of the machine frame. According to the automatic textile-fabric processing edge pressing device, edge pressing treatment is carried out through the pressing rollers, a fabric is limited through the limiting rollers, it is avoided that pressed edges of the fabric are folded, and meanwhile the two edges of the fabric are pressed; the processing efficiency is improved, the processing mode is automatic, labor is saved, the edges of the fabric can be continuously pressed, and the edge pressing quality is improved.

Owner:XINCHANG SANWEI PRECISION MACHINERY

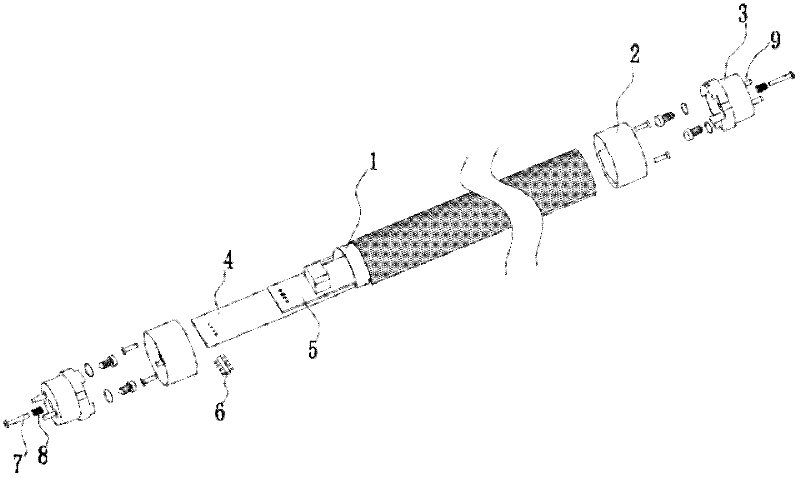

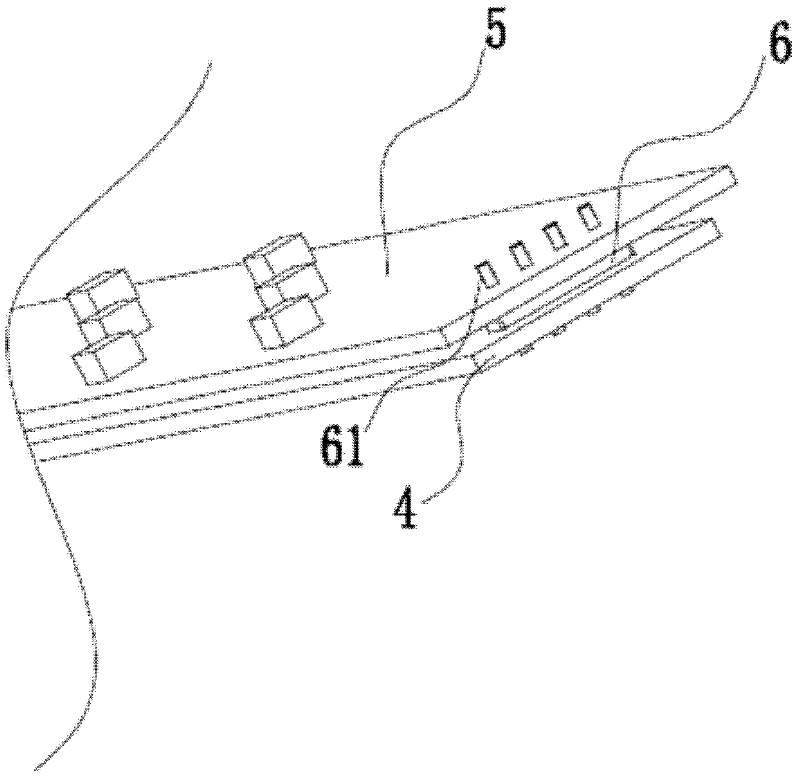

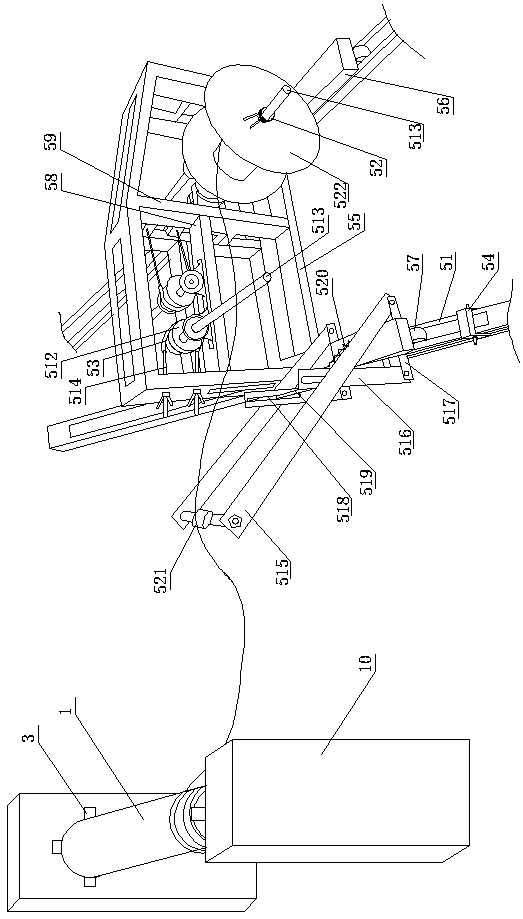

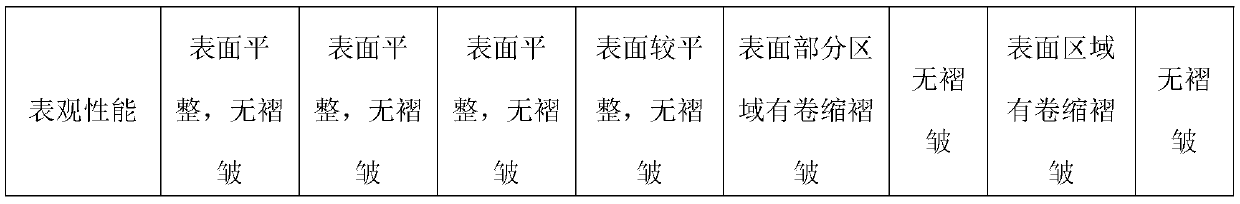

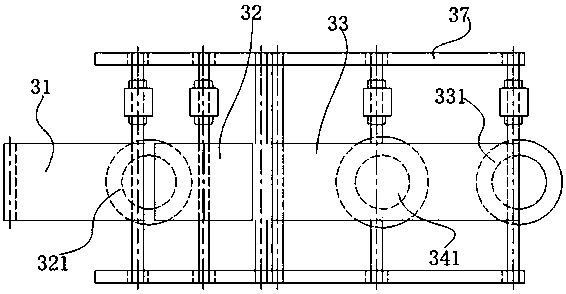

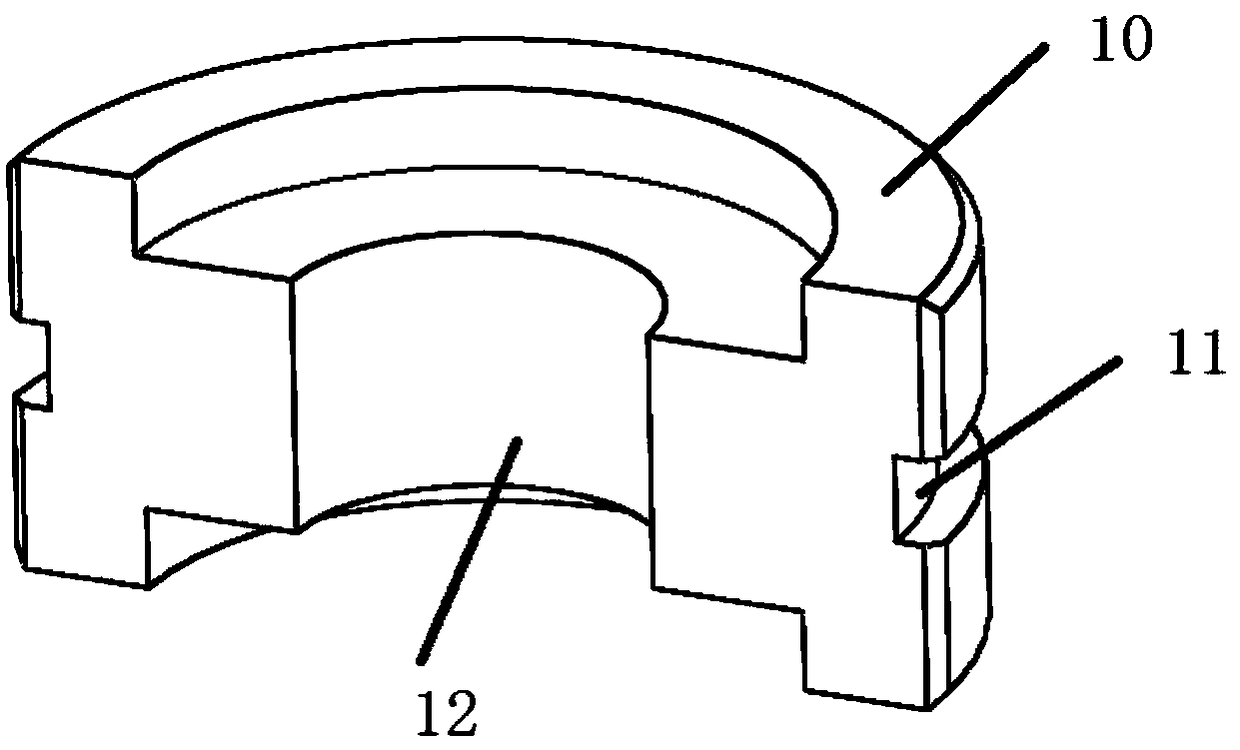

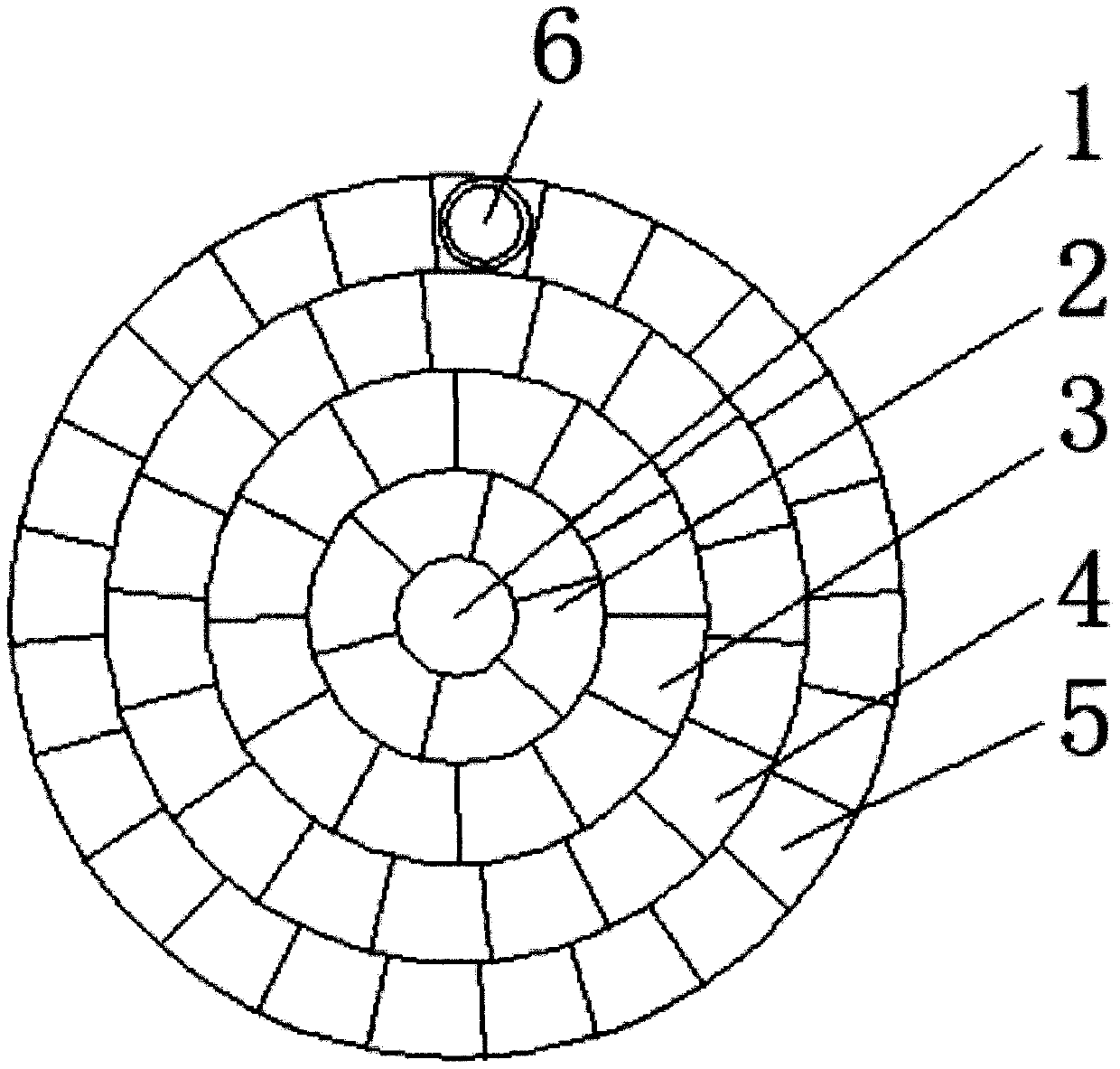

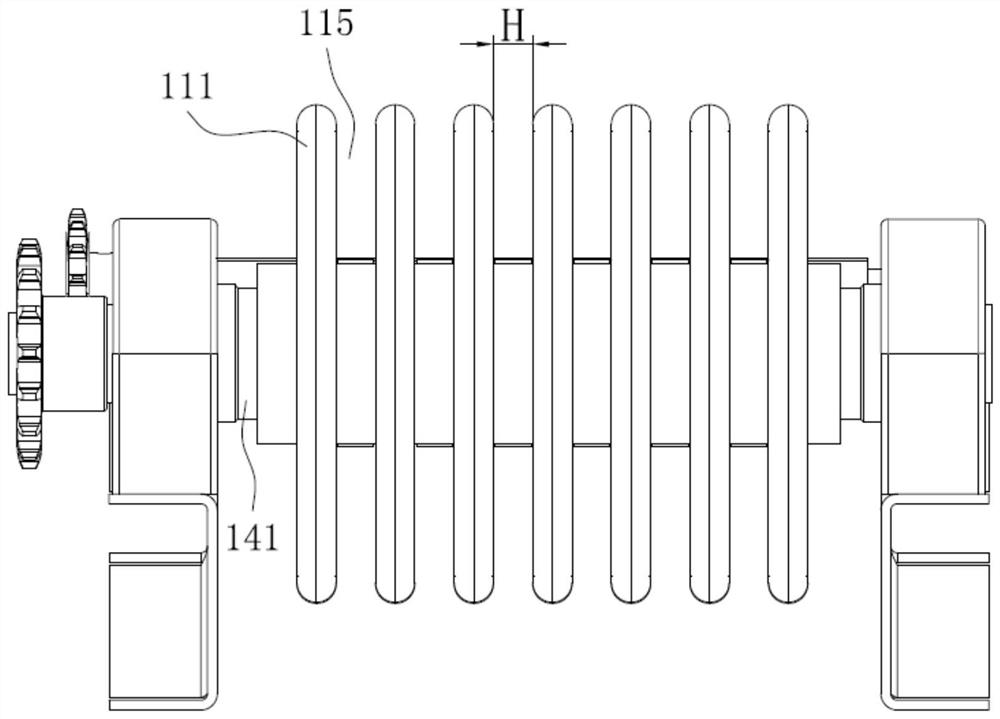

Automatic winding device for reactor coil

The invention discloses an automatic winding device of a reactor coil, which comprises a pay-off mechanism and a winding mechanism, wherein the pay-off mechanism comprises a pay-off rack and a wire coil, the wire coil is arranged on the pay-off rack, the winding mechanism comprises a winding machine and a winding tool, and the winding tool is arranged between two tips of the winding machine; a guide rail is arranged on the ground at the bottom of the pay-off rack and is parallel to the axis of the tip; the winding tool comprises an elastic die, an inner supporting plate and a cross, the elastic die is cylindrical, and an adjusting seam is axially formed on the elastic die; the two inner supporting plates are respectively arranged at two ends of the elastic die and are clamped on the innersurface of the elastic die; the number of the cross is two, and the elastic die is clamped between the two crosses. The wire coil can translate in the direction parallel to the axial direction of thecoil along with the winding of the wire during paying off, so that the wire pressing is effectively prevented; and after the coil is wound and shaped, the wire coil can be quickly demolded, so that the production efficiency can be effectively improved.

Owner:河南合瑞电气有限公司

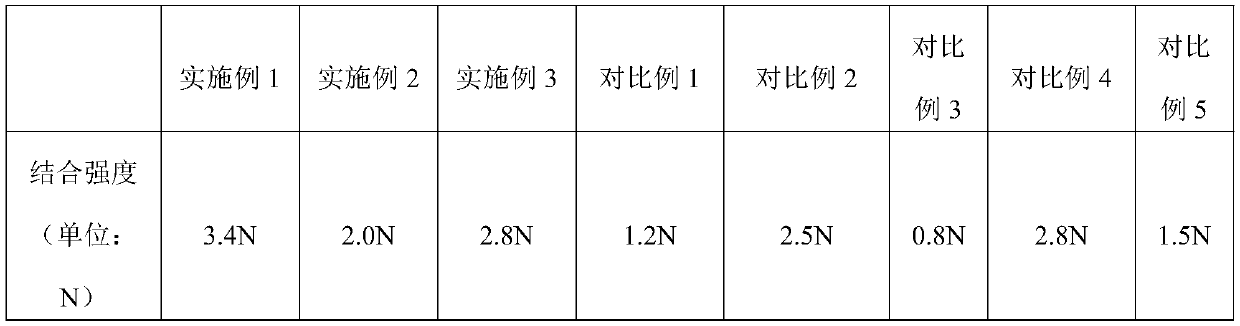

Preparation method of metal plated film for battery

InactiveCN111020521AControl timeAvoid crimpingElectrode carriers/collectorsVacuum evaporation coatingMetal membraneVacuum evaporation

The invention relates to a preparation method of a metal plated film for a battery. The preparation method comprises the following steps that (1) a base film is taken, surface treatment is carried outon the surface of the base film, and a first metal layer is evaporated on the surface of the base film in a vacuum evaporation chamber filled with metal steam; (2) after the base film evaporated withthe metal layer is treated, the base film is evaporated with the next metal layer in the vacuum evaporation chamber continuously; and (3) a plurality of metal layers are circularly evaporated on thebase film according to the step (2), so that the thicknesses of all the metal layers meet the set requirements, therefore the process is completed. Compared with the prior art, the preparation methodof the metal plated film for the battery realizes the high-performance coating of thick metal on the base film by adopting a mode of evaporating the metal layer for multiple times, and the film is good in overall performance, long in service life and the like.

Owner:浙江长宇新材料股份有限公司

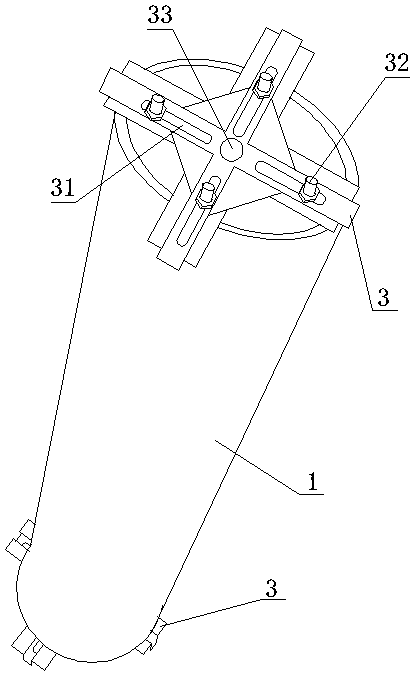

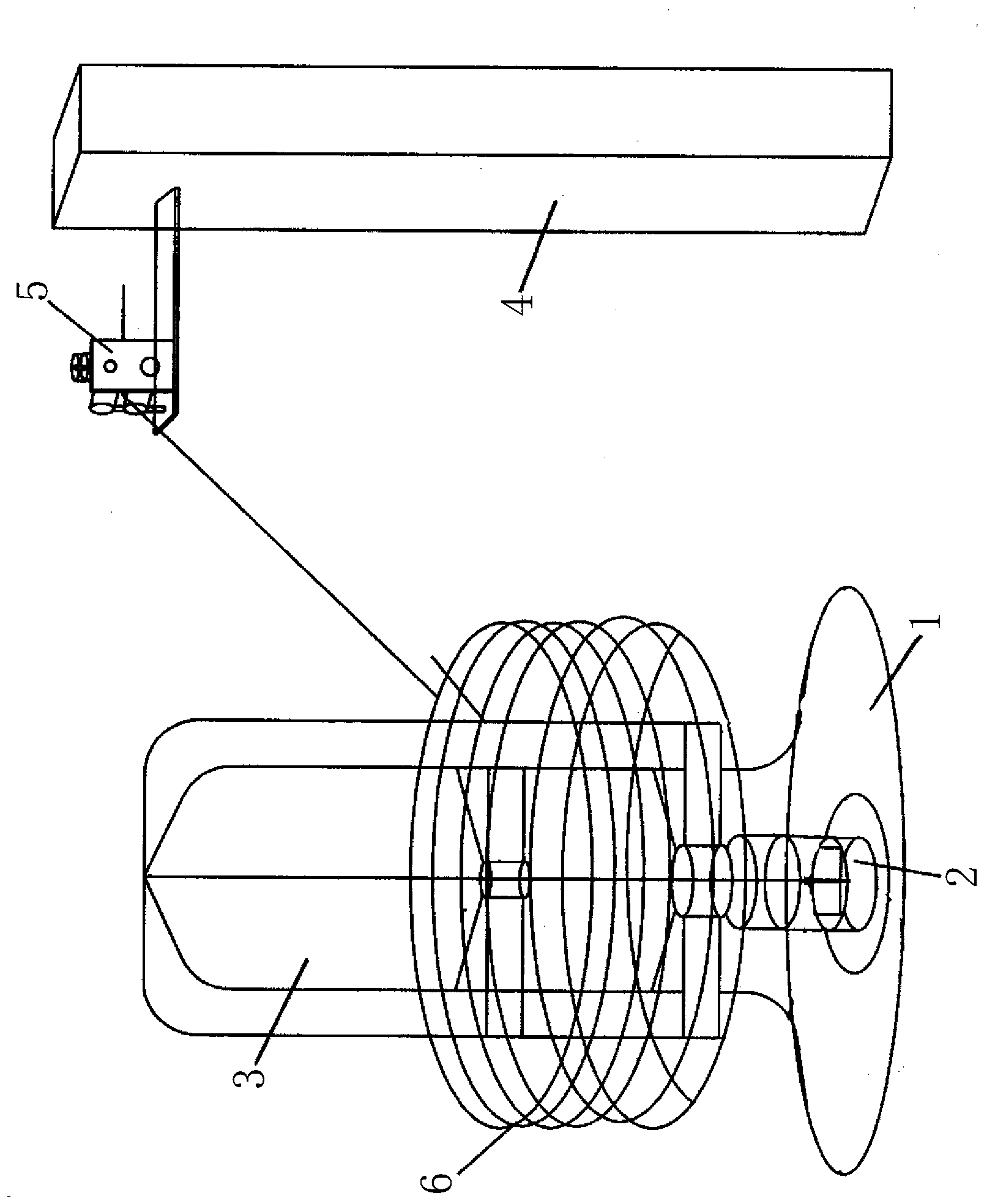

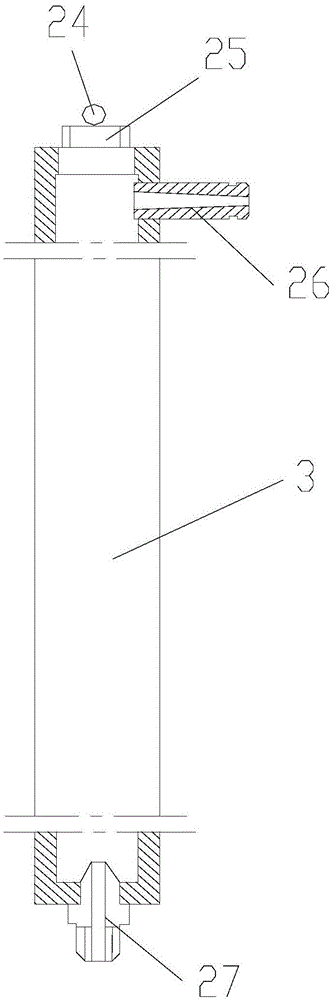

Vertical rotation pay-off stand

InactiveCN103058010AConvenient, efficient and smooth centralized pay-offAvoid crimpingFilament handlingEngineeringWire rod

The invention discloses a vertical rotation pay-off stand which is characterized in that the pay-off stand is arranged in the middle of a base plate and supported by a spindle, a bracket is arranged on one side of the pay-off stand, and a drawing universal wheel is arranged on the upper end of the bracket. The vertical rotation pay-off stand is used for paying off of tire bead steel wire rods, convenient efficient smooth centralized paying-off is achieved, paying-off restraining and locking are avoided, and the pay-off stand is easy to produce.

Owner:SHANDONG DAYE

Ureteral stent for improved patient comfort

InactiveUS20060122707A1Decreases patient discomfortInhibit migrationStentsWound drainsInsertion stentLeft ureter

A ureteral stent for assisting the movement of urine along a patient's ureter and into the patient's bladder. The stent includes an elongated tubular segment extending toward the bladder from a kidney end region for placement in the renal cavity to a bladder end region. A central lumen connects at least one opening at the first end region to at least one opening in the bladder end region. Thin flexible tail(s) are attached to the bladder end region of the tubular segment at a point outside the bladder so as to receive urine from the opening in the bladder end region of the tubular segment and to transport urine from there across the ureter / bladder junction and into the bladder. The tails include an elongated external urine-transport surface sized and configured to transport urine along the ureter. The urine transporting surface(s) are sized and configured to extend along at least part of the ureter, across the ureter / bladder junction, and from there into the bladder. In some embodiments, the distal region includes a tubular body with a lumen in fluid communication with an interstitial area defined by one or more flexible filaments of the proximal region forming at least one loop.

Owner:BOSTON SCI SCIMED INC

Synchronous tension adjustment winding machine

The invention belongs to the technical field of winding machines and discloses a synchronous tension adjustment winding machine. The synchronous tension adjustment winding machine is mainly technically characterized by comprising a frame, a traction mechanism, a turntable, a pay-off mechanism, a pay-off reversing mechanism, a wire distribution disc and a mouth, wherein a fixing disc is arranged on one side of the pay-off reversing mechanism close to the wire distribution disc; a tension adjusting ring is arranged on one side of the fixing disc close to the wire distribution disc; an inner diameter of the tension adjusting ring is smaller than an outer diameter of the fixing disc; the tension adjusting ring is connected with the fixing disc through a position adjusting mechanism; a framework layer wire reaches the outer side of the fixing disc through the pay-off mechanism and the pay-off reversing mechanism and enters the wire distribution disc and the mouth through the inner side of the tension adjusting ring; the wire is bent in a certain angle between the fixing disc and the tension adjusting ring; and the bending angle of the wire is adjusted by adjusting the distance between the fixing disc and the tension adjusting ring. Therefore, the adjustment is convenient and rapid, each framework layer wire has uniform tension, and the produced steel tube has high quality and high pressure resistance.

Owner:河北瑞兴橡塑有限公司

Light and thin metal fine crushing treatment device and fine crushing and sorting process thereof

InactiveCN107890939AAvoid material jamsPrevent lockDirt cleaningMagnetic separationThin metalEngineering

The invention discloses a light and thin metal fine crushing treatment device and a fine crushing and sorting process thereof and belongs to the technical field of metal crushing and sorting. The light and thin metal fine crushing treatment device comprises a tearing device, a crushing device and a sorting device which are arrayed according to working processes. The tearing device and the crushingdevice are connected through a feeding packing auger. The crushing device and the sorting device are connected through a feeding conveyor belt. The tearing device comprises a frame-shaped rack and afeed port fixed to the middle portion of the upper end face of the rack and further comprises a tearing mechanism. The crushing device comprises a hollow machine box, a feeding hopper formed in the top of the machine box and a crushing mechanism in the machine box. The sorting device comprises a frame-shaped fixing frame and a magnetic roller fixed to the fixing frame through a bearing. The two sides of the roller face of the magnetic roller are provided with a feeding conveyor belt and a discharging conveyor belt which are fixed to the fixing frame. The starting end of the discharging conveyor belt is infinitely attached to the roller face of the other side of the magnetic roller. By means of the light and thin metal fine crushing treatment device and the fine crushing and sorting processthereof, the problems that time and labor are wasted in metal crushing and manual sorting after crushing.

Owner:安徽华龙环保技术工程有限公司

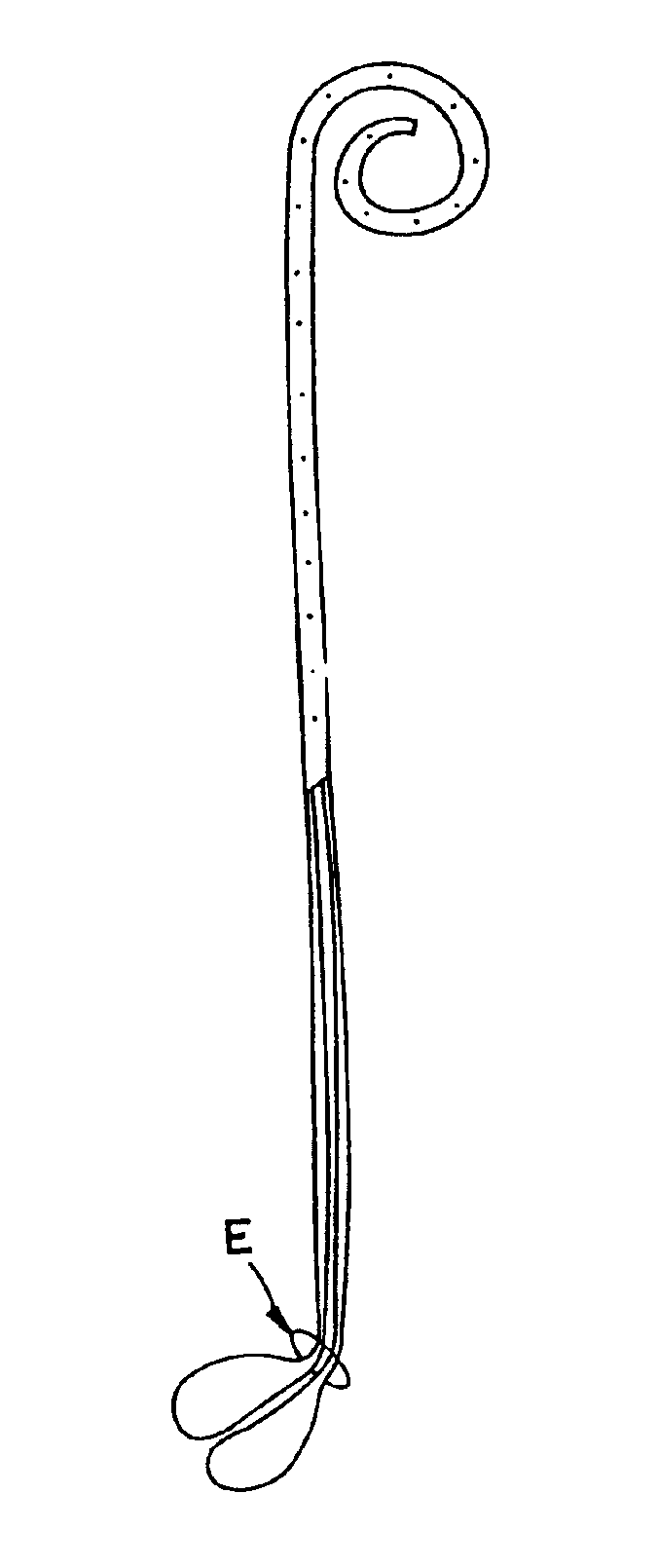

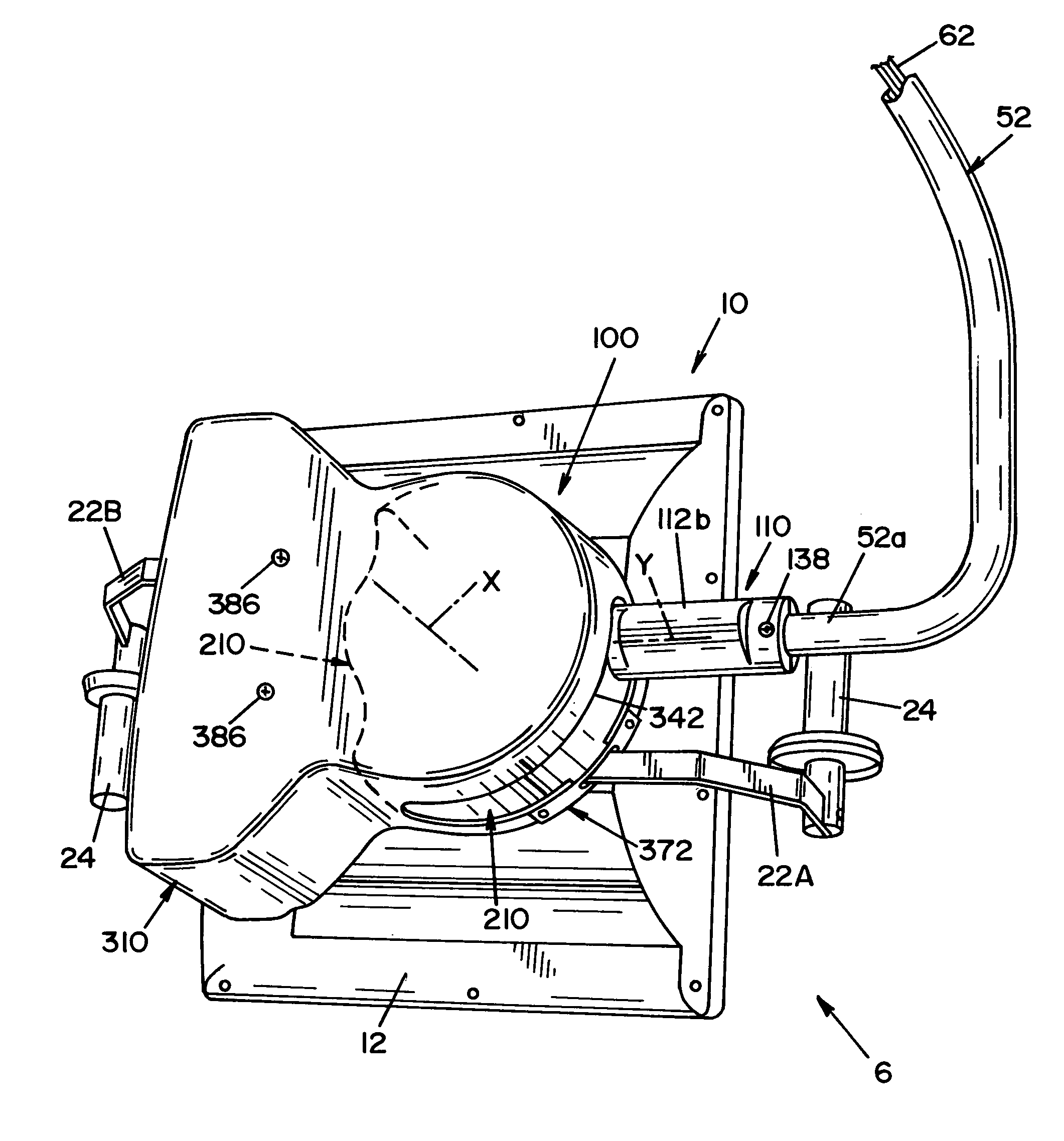

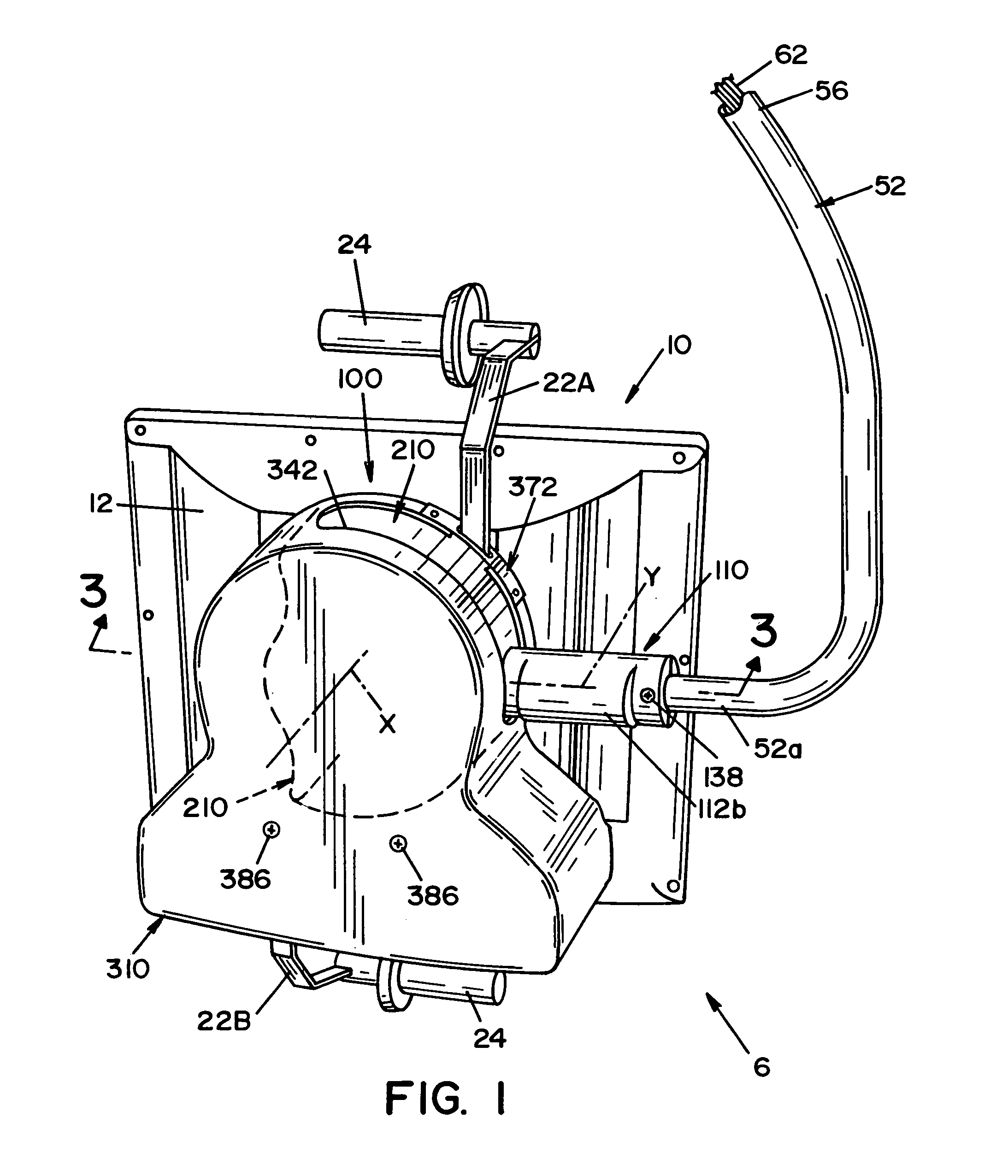

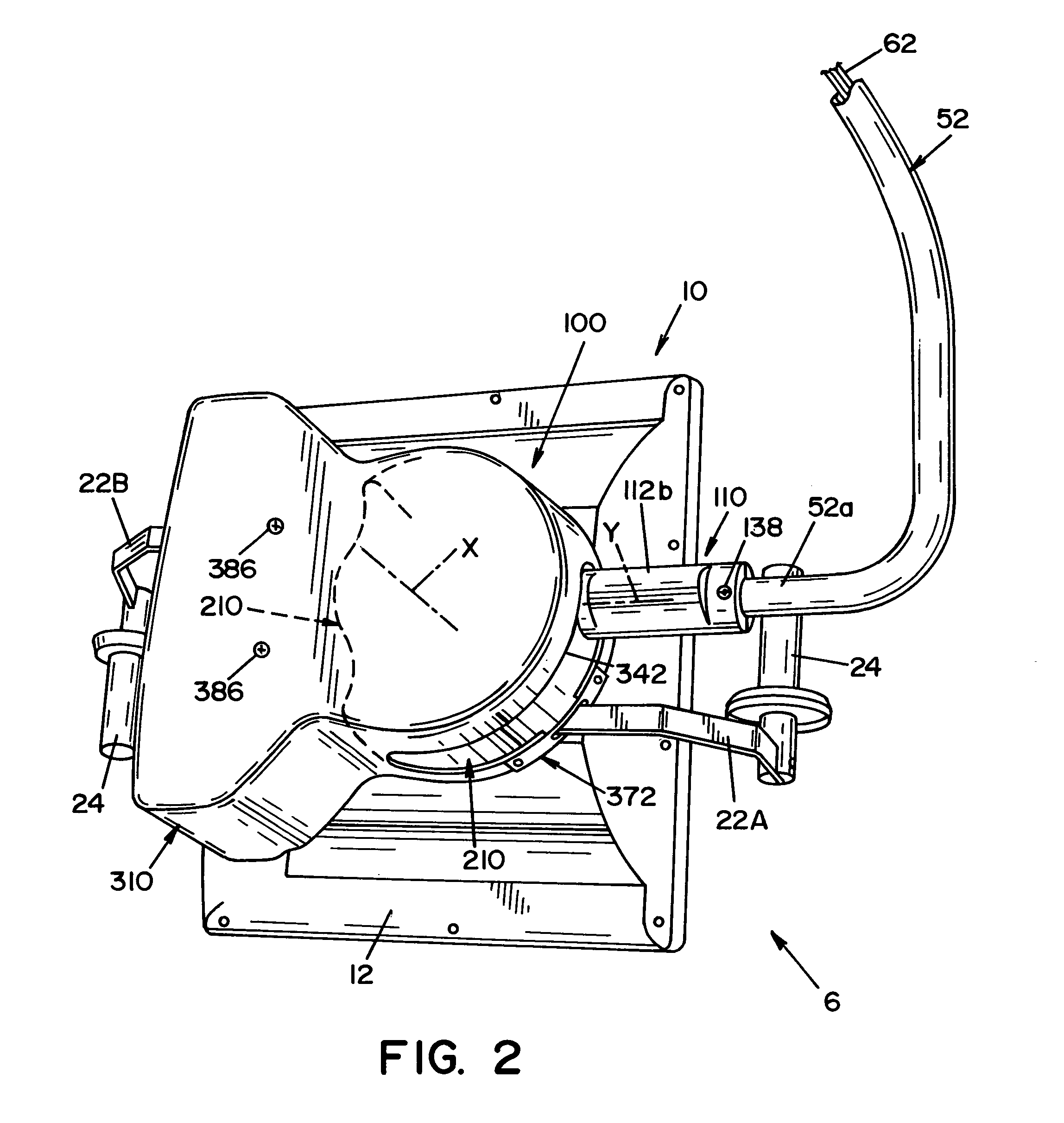

Cover assembly for video monitor

InactiveUS7091416B1Easy to cleanPrevent kinkingDigital data processing detailsDiagnosticsData connectionSurface mounting

A cover assembly for enclosing data connections on a monitor that is mounted to a tubular support arm that has data cables extending therethrough. The cover assembly includes a sleeve surrounding a portion of the tubular support arm. The sleeve defines a passage between the sleeve and the tubular support arm for the cables to extend therethrough. A shield is connected to the second end of the tubular support arm. The shield has an arcuate outer surface with an aperture therethrough. The aperture is dimensioned to receive one end of the sleeve. A cover having an inner arcuate surface mounted to the monitor to be movable therewith. The cover encloses the shield with the arcuate outer surface of the shield facing the arcuate inner surface of the cover. The sleeve extends through a slot in the cover, wherein the monitor is rotatable about a first axis and further is rotatable about a second axis that is perpendicular to the first axis.

Owner:AMERICAN STERILIZER CO

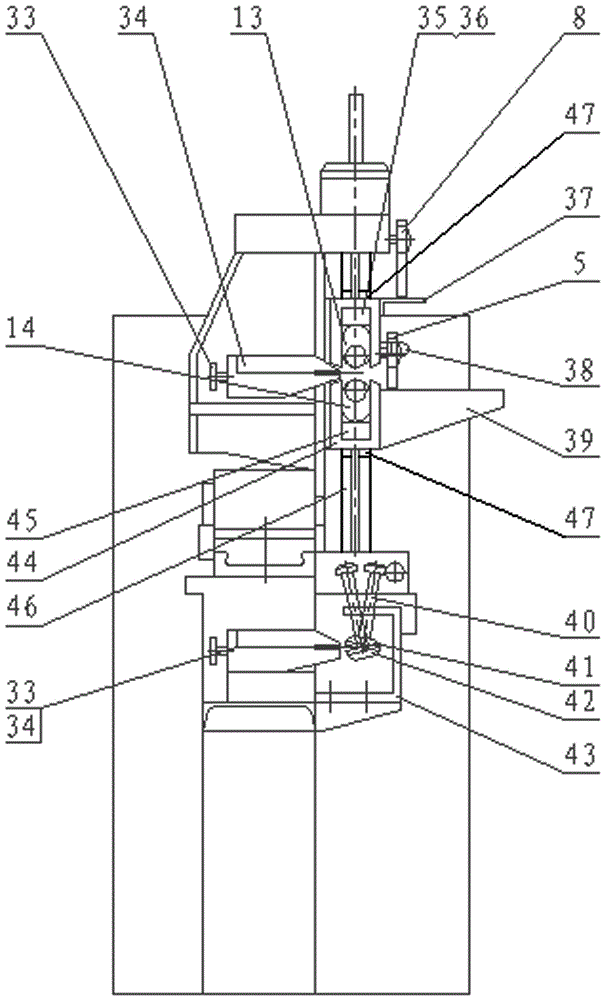

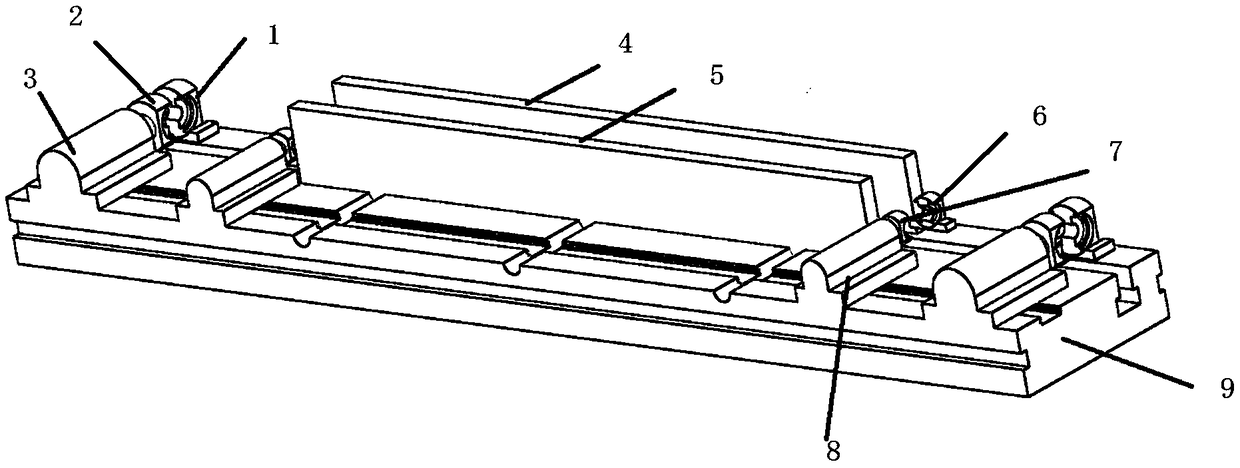

Rubber ultra-thin dialysis cutting machine

ActiveCN104227764BMeet the requirements of dialysis testingImprove Slicing AccuracyPreparing sample for investigationMetal working apparatusControl systemEngineering

The invention relates to a rubber ultra-thin dialysis slitting machine, which mainly includes a workbench, an upper and lower top knife mechanism, a belt knife transmission mechanism, a feeding transmission mechanism, an upper and lower lifting transmission mechanism, a knife sharpening mechanism and a control mechanism all arranged on a frame. system, its technical feature is that the up and down lifting transmission mechanism includes an up and down lifting combination device, an up and down lifting motor, an up and down foot hanging device, and a screw rod; Two worm gear elevators, the lower lifting combination device includes two worm gear elevators connected and fixed on the frame through the connecting shaft, the worm gear elevators are respectively connected to the two ends of the screw rod, and the worm gear elevators are respectively connected with the upper and lower lifting motors Connection; the upper and lower foot-hanging devices respectively include a foot-hanging seat and a hanging foot. The foot-hanging seat is installed on the slider in the linear guide rail on the frame. state, the hanging feet are installed in the hanging foot seat, and flower rollers are respectively arranged on the hanging feet.

Owner:TAIXING SHUANGYANG LEATHER RUBBER MACHINERY FACTORY

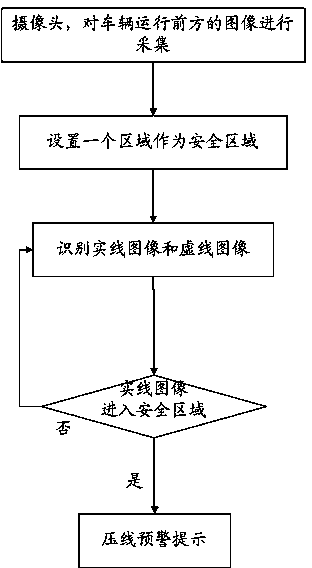

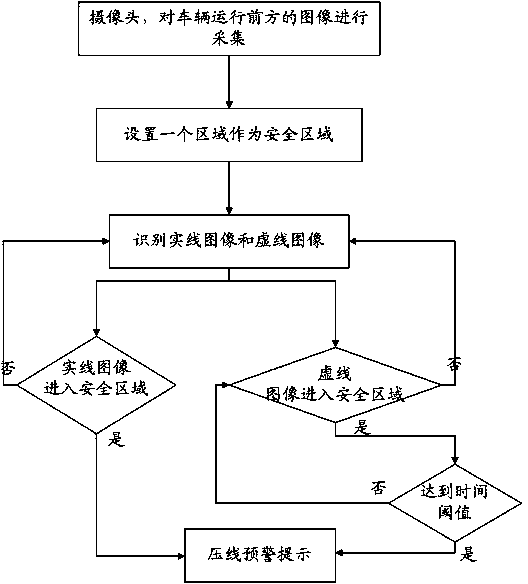

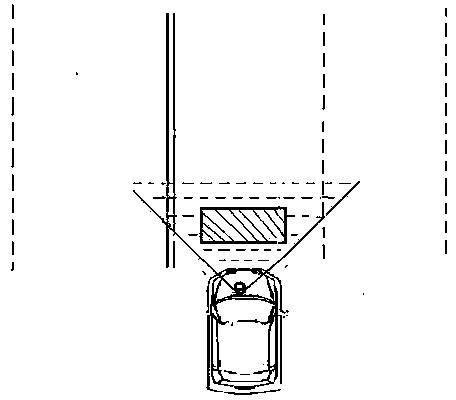

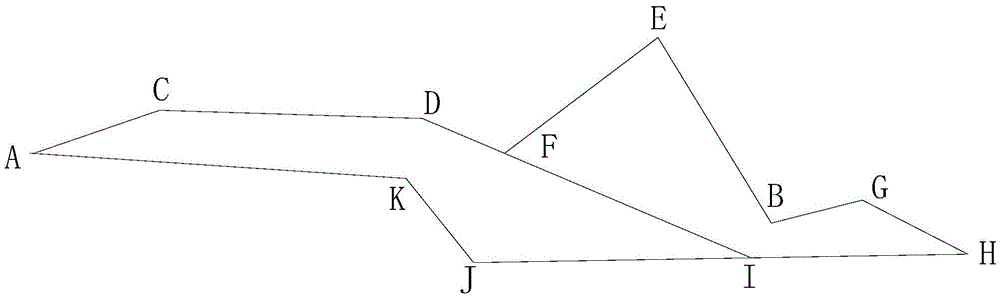

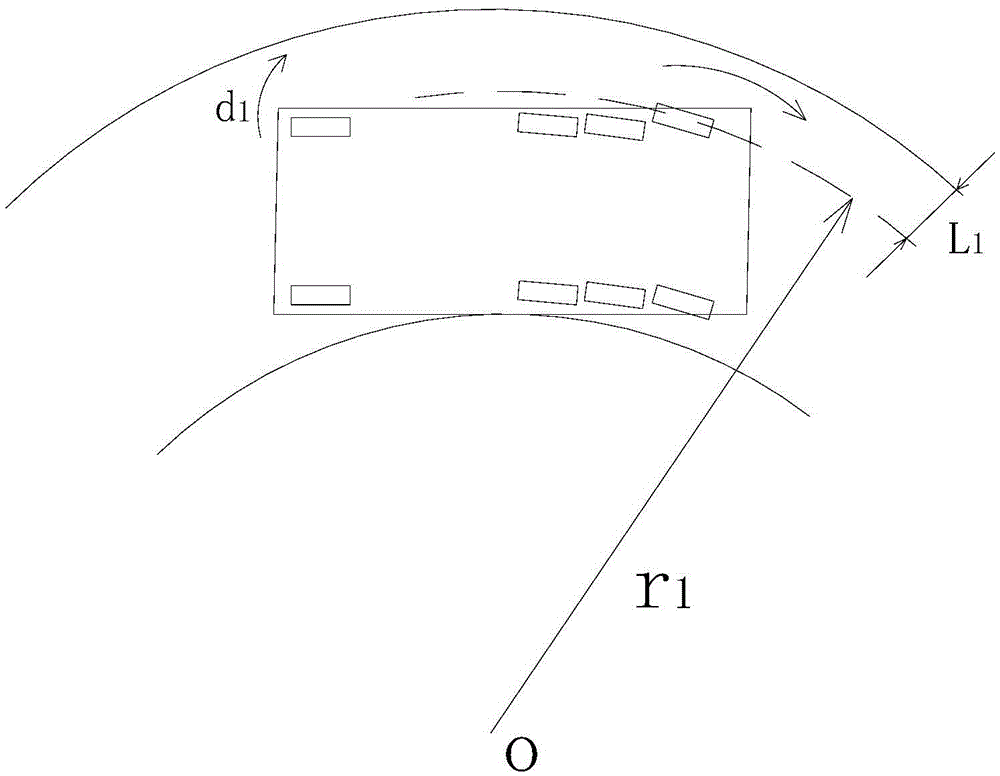

Method and system for preventing line pressing unlawful act of important transport vehicle

InactiveCN103991410AImprove accuracyAvoid crimpingSignalling/lighting devicesSafety zoneRoad surface

The invention provides a method for preventing the line pressing unlawful act of an important transport vehicle. The method includes the steps that an image of the road in front of the vehicle is collected through a camera, the dotted line position and the full line position in front are obtained, a safety region is set in a collecting visual field of the camera, marker lines on the two sides of the vehicle are not located in the safety region when the vehicle is driven normally, and when the position of a full line image is located in the safety region, a line pressing early warning prompt is given. According to the method, the problems that in the prior art, data of the two sides of the vehicle need to be collected and processed respectively, two cameras are needed, and the data collecting and processing amount is large are solved and cost is reduced. The position of the vehicle relative to the marker lines is judged through the preset safety region, the method is easy to achieve, the position of the safety region is reasonably set according to different vehicles and current road information, the accuracy degree for judging the positions between the marker lines and the vehicle is improved, and therefore the accuracy of line pressing early warning is improved.

Owner:国通道路交通管理工程技术研究中心有限公司 +1

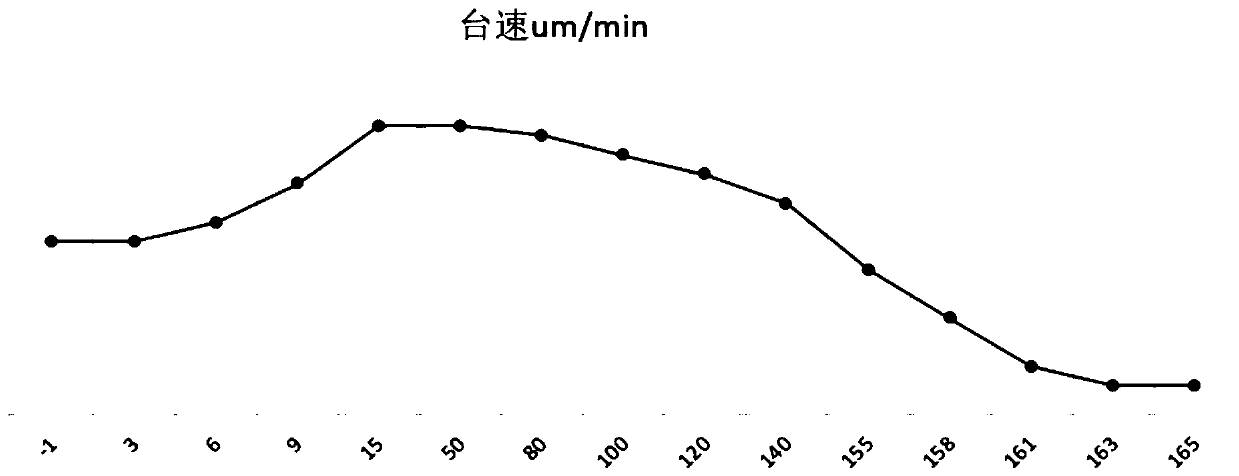

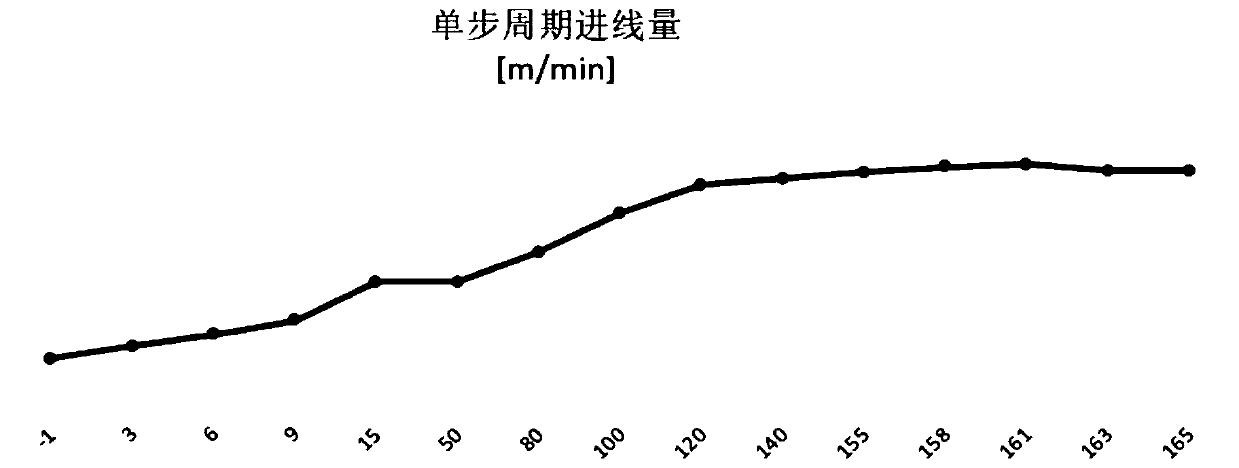

Reverse cutting process for diamond wire

InactiveCN111483067AImprove stabilityAvoid disconnection of pay-off reelFine working devicesWire cuttingEngineering

The invention belongs to the technical field of diamond wire cutting, and particularly relates to a reverse cutting process for a diamond wire. The reverse cutting process comprises the following steps: selecting and cleaning a qualified crystal bar, filling the crystal bar into a clamping guide rail of a cutter workbench, adopting the diamond wire with the diameter of 45 [mu]m-60[mu]m as a cutting wire, spreading a cutting wire net, adding cooling liquid, placing the diamond wire for cutting onto a take-up wheel from a pay-off wheel, setting diamond wire operation speed to be 600 m / min-2100m / min, and setting cutting workbench feeding speed to be 200-3500 [mu]m / min, changing a cutting direction to be reverse cutting from front cutting before cutting, starting a cutter to start cutting, andtaking down the crystal bar by an unloading vehicle after cutting is accomplished. The reverse cutting process adopted by the invention is consistent in cutting direction in the whole process, improves the problem that surface quality and chromatic aberration of a silicon slice is poor, improves silicon slice surface quality, and reduces production cost.

Owner:QINGDAO GAOCE TECH CO LTD

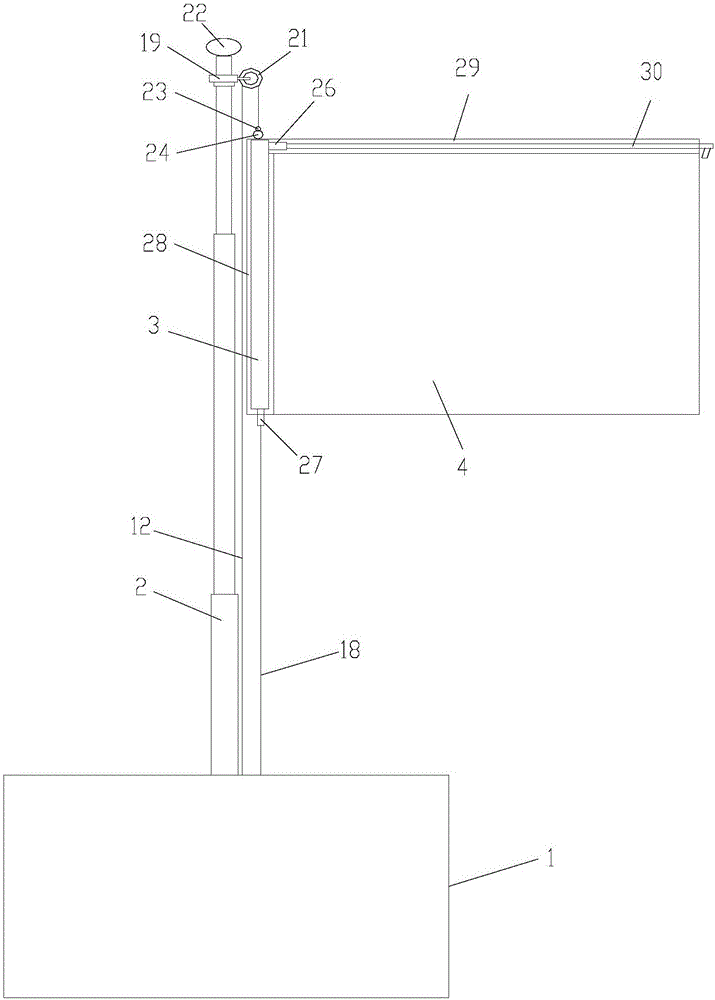

Unfolding and waving device for flag

ActiveCN106297598ACover up traces of artificial coercionPlay the role of "Gang Ju Mu Zhang"Flags/bannersEngineeringWinch

The invention provides an unfolding and waving device for a flag. The unfolding and waving device consists of a flag pole base, a main flag pole, an auxiliary flag pole and a flag, wherein a fixed pulley is arranged at the top of the main flag pole; a flag hoisting winch mechanism, a flag falling winch mechanism and an air supply system are arranged in the flag pole base; the flag hoisting winch mechanism is connected with the top end of the auxiliary flag pole through a flag hoisting rope with one end bypassing the fixed pulley; the flag falling winch mechanism is connected with the lower end of the auxiliary flag pole through a flag falling rope; a flag rope tube is arranged at the upper edge of the flag; the air supply system communicates with one end of the flag falling rope through a winding drum spindle in the flag falling winch mechanism and conveys air into the flag falling rope; the other end of the flag falling rope is connected with the lower end of the auxiliary flag pole; the upper end of the auxiliary flag pole is perpendicularly connected with one end of the flag rope tube; the air in the flag falling rope enters the flag rope tube through the auxiliary flag pole; the air in the flag rope tube is uniformly and downwards sprayed out to hoist the flag under the counter-acting force of the air to realize unfolding and waving. The unfolding and waving device for the flag simulates a dynamic effect that the flag is blown by natural wind to wave, so that the flag can achieve a naturally unfolding and waving effect in a flag hoisting process under an environment without wind and the like.

Owner:许旸

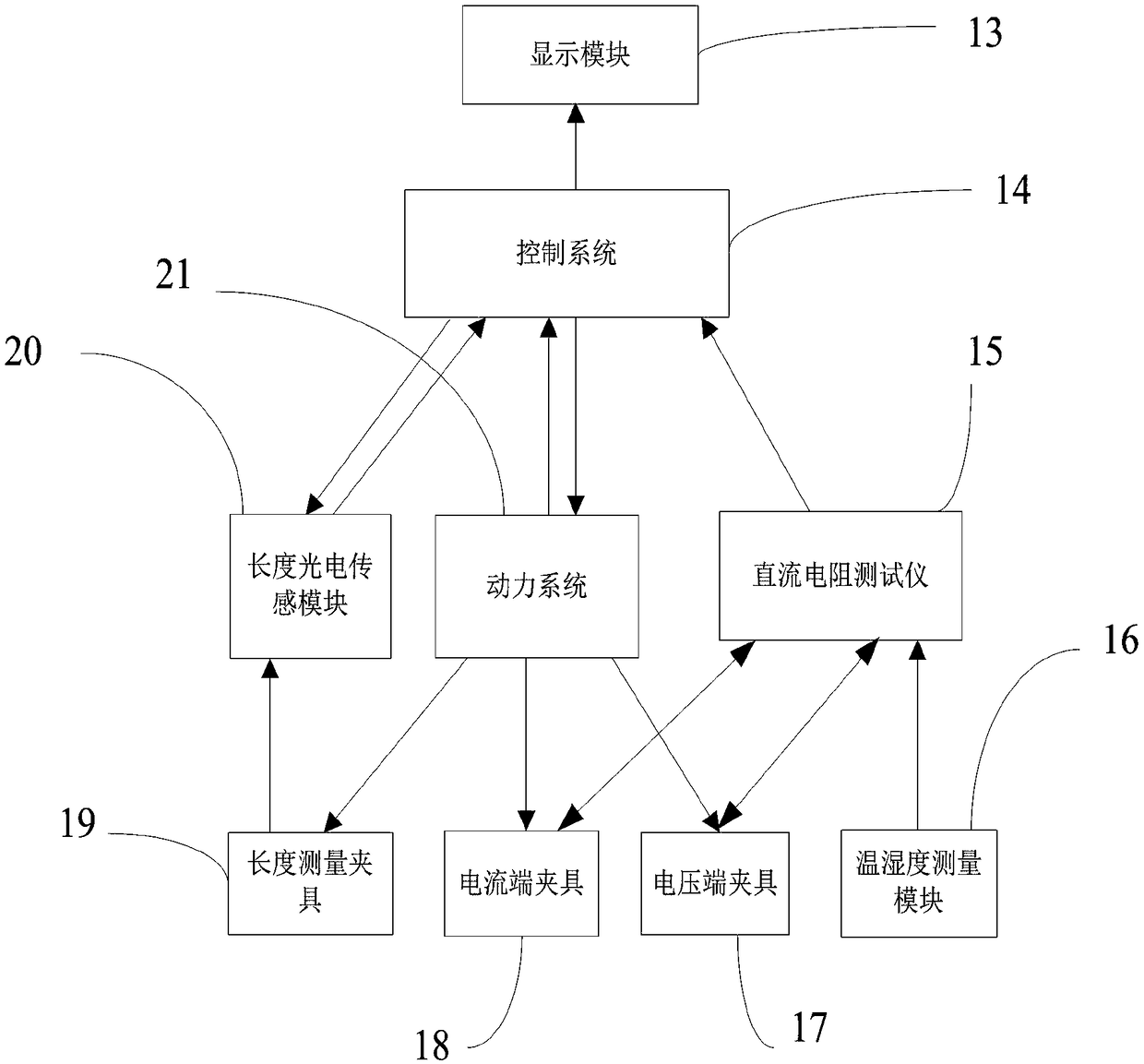

Wire cable conductor DC resistance auxiliary measuring device and measuring method

InactiveCN108872707AAvoid crimpingImprove measurement accuracyResistance/reactance/impedenceMeasurement deviceElectrical conductor

The invention discloses a wire cable conductor DC resistance auxiliary measuring device and a measuring method; the measuring device comprises a current terminal clamp, a potential terminal clamp, a length measuring clamp, a length photoelectric sensing module, a humiture measuring module, a pedestal, a power system, a control system and a display module; the current terminal clamp, the potentialterminal clamp, the length measuring clamp and the length photoelectric sensing module are respectively connected with the pedestal; the control system is connected with the power system, the length photoelectric sensing module, a DC resistance tester, and the display module; the humiture measuring module is connected with the DC resistance tester; the power system is respectively connected with acurrent terminal power portion of the current terminal clamp, a potential terminal power portion of the potential terminal clamp, and a clamp force application structure of a length measuring clamp II of the length measuring clamp; the current terminal power portion and the potential terminal power portion are respectively connected with the pedestal. The measuring device can improve the conductor DC resistance measuring accuracy, is convenient in operation, timesaving and labor saving, can reduce test material cost, and can improve work efficiency.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

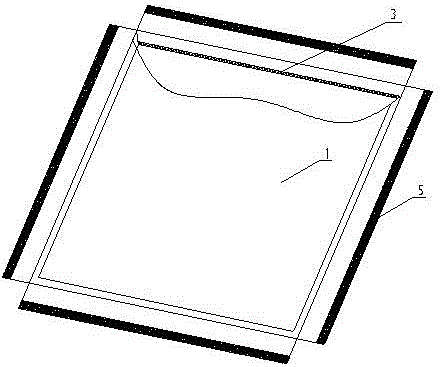

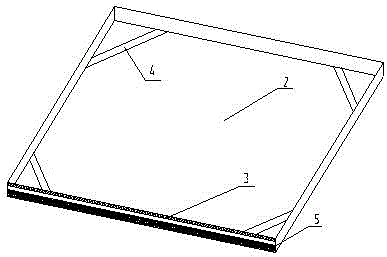

Novel quilt cover making sleeving quilt convenient

The invention relates to a novel quilt cover which is convenient for covering a quilt core. It includes the quilt cover body, connecting body, and quilt core fixing belt. The quilt cover body is formed by detachably connecting an upper quilt cover surface A and a lower quilt cover surface B through a connecting body. Concealed zipper and Velcro fastening at the body. The four corners of the lower quilt cover surface B are respectively provided with quilt core fixing belts. The quilt cover body adopts a box structure, the upper quilt cover surface A is in the shape of the upper cover of the box, and the lower quilt cover surface B is in the shape of a box body. The quilt core fixing belt is used to fix the quilt core to prevent the quilt core from shrinking into a ball in the quilt cover during use. The present invention is simple in structure, easy to use, and can be divided into two for washing, which is not as time-consuming and laborious as cleaning traditional quilt covers, and is convenient for drying. One person can easily put the quilt core into or take it out of the quilt cover, and use it as an upper or lower quilt cover. After the surface is integrated, the zipper and Velcro are hidden in the quilt cover. After a long time of use, the zipper will not be exposed. It is safe, beautiful, practical and popular.

Owner:杨春

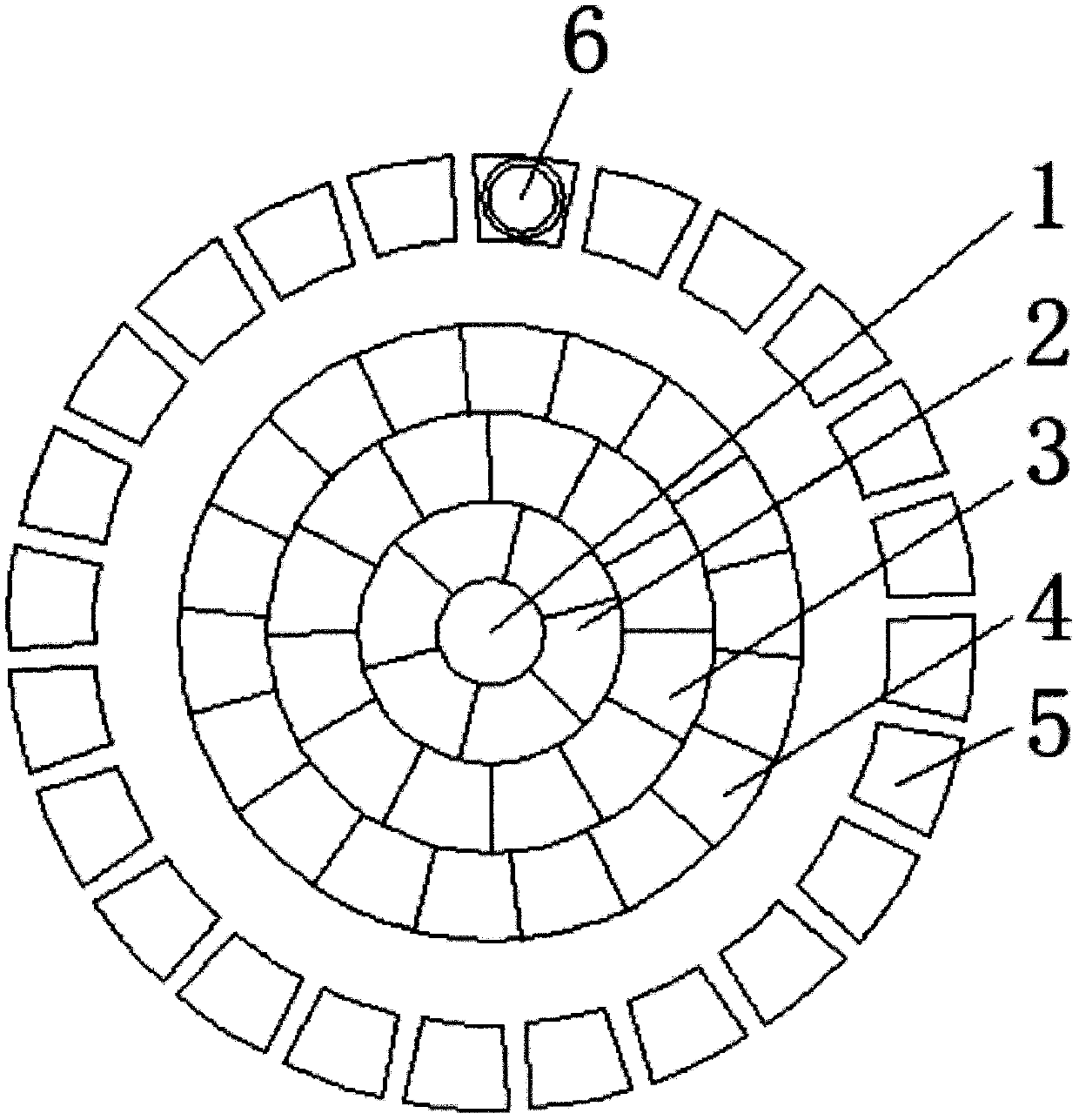

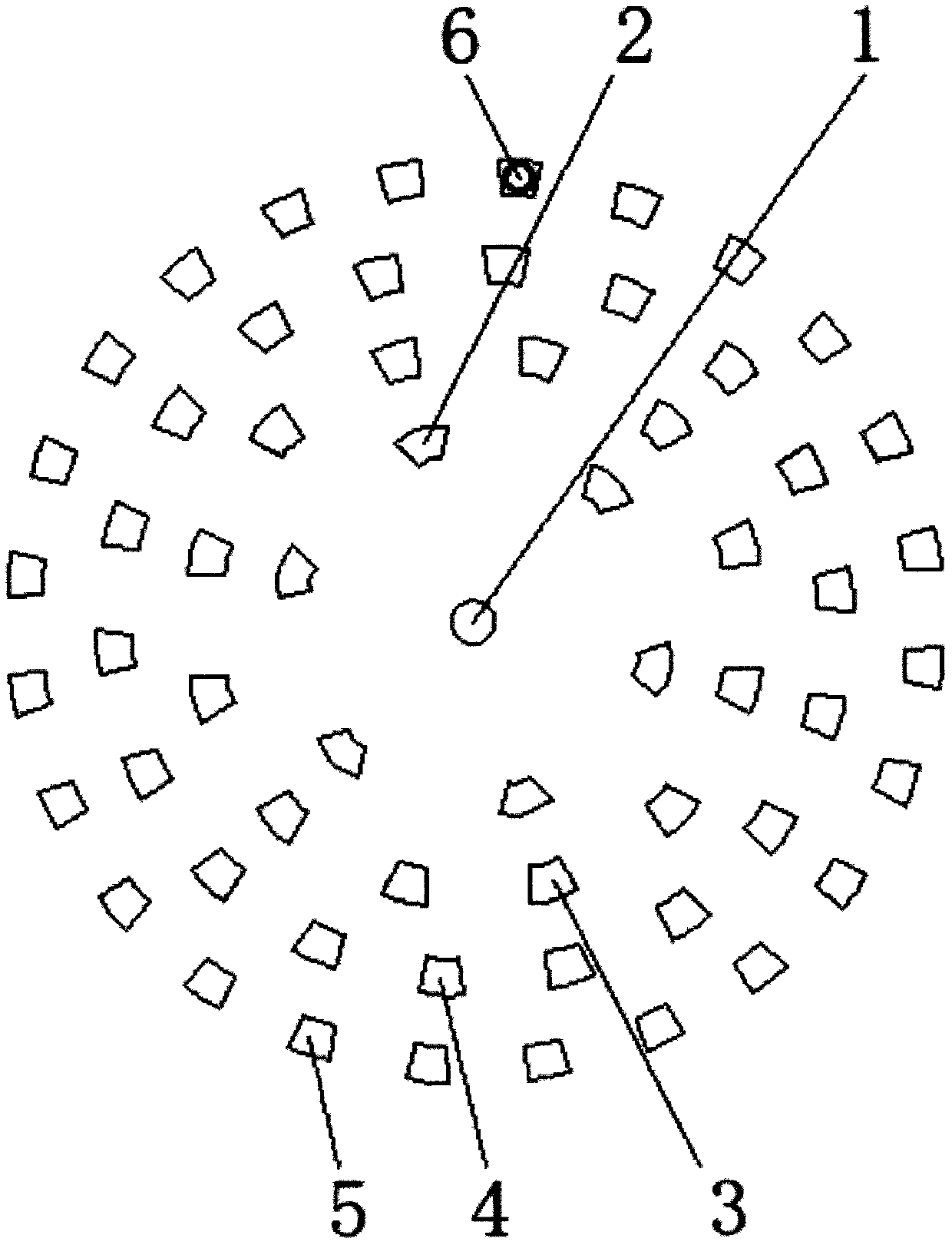

Special-shaped monofilament intelligent conductor structure

PendingCN110517807AIncrease the compression factorSmall outer diameterAuxillary non-insulated conductorsElectrical conductorFiber optic sensor

The invention relates to the technical field of cables, in particular to a special-shaped monofilament intelligent conductor structure comprising a conductor center line, a first layer of conductor special-shaped monofilament, a second layer of conductor special-shaped monofilament, a third layer of conductor special-shaped monofilament and a fourth layer of conductor special-shaped monofilament.The first layer of conductor special-shaped monofilament is twisted on the outer side of the conductor center line. An optical fiber sensor is twisted between the sides of the fourth layer of conductor special-shaped monofilament. The special-shaped monofilament intelligent conductor structure is enabled to have the advantages of improving the compaction coefficient of the conductor, realizing real-time temperature measurement of the conductor and avoiding connection pressure through the arrangement of the conductor center line, the first layer of the conductor special-shaped monofilament, thesecond layer of the conductor special-shaped monofilament, the third layer of the conductor special-shaped monofilament, the fourth layer of the conductor special-shaped monofilament and the opticalfiber sensor so that the problems that the current cable gap inside the conductor is large, the cable runs at high temperature, which affects the service life of the cable, and the temperature measurement optical fiber is placed inside the conductor and is subjected to connection pressure of the conductor can be solved.

Owner:广州岭南电缆股份有限公司

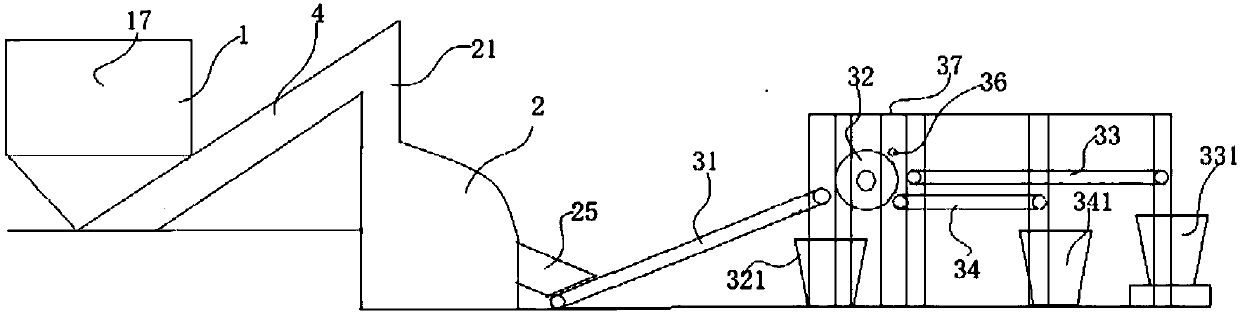

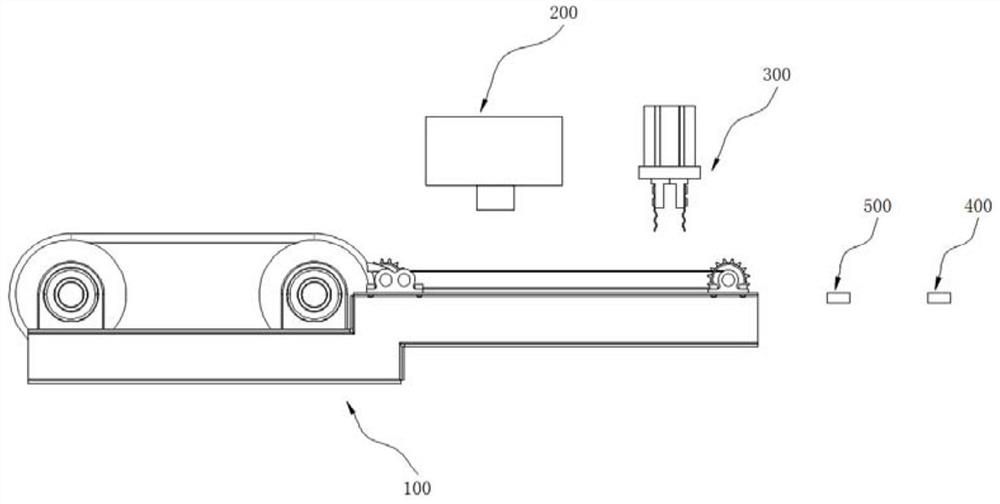

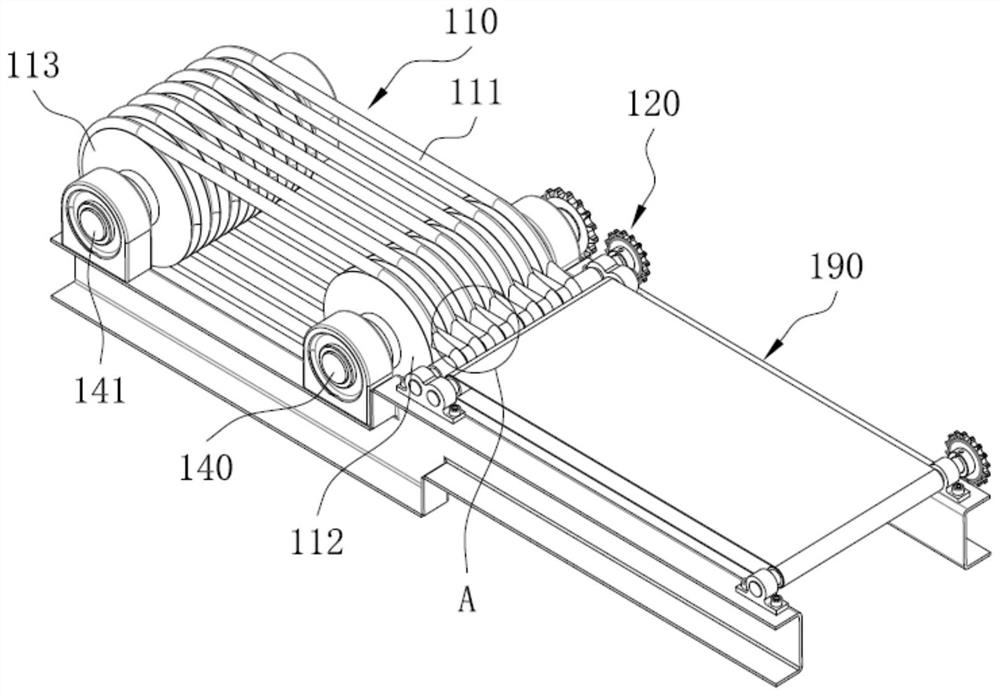

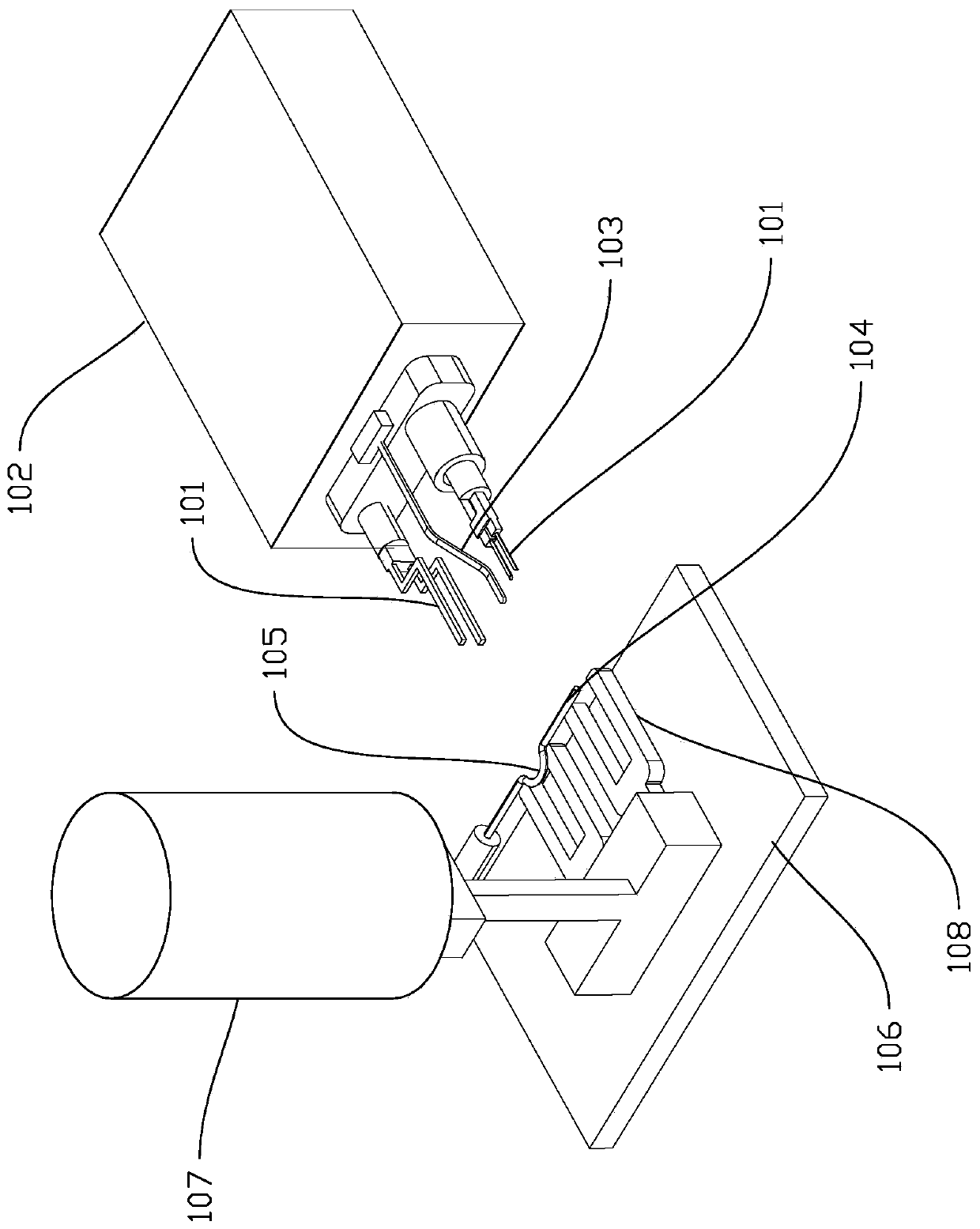

Shrimp processing and feeding equipment and method thereof

PendingCN113229327ARealize automated productionAvoid crimpingConveyorsClimate change adaptationShrimpEngineering

The invention relates to the technical field of shrimp production, in particular to shrimp processing and feeding equipment and a method thereof. The shrimp processing and feeding equipment comprises a directional conveying device capable of adjusting the conveying posture of shrimp bodies and enabling shrimps to be conveyed with the heads or the tails in front; a shrimp body identification system arranged on the directional conveying device and used for identifying the body characteristics of the currently conveyed shrimp bodies; a shrimp clamping device arranged above the directional conveying device and used for clamping shrimp bodies conveyed on the directional conveying device, wherein the shrimp clamping device comprises two sets of clamping pieces which are symmetrically arranged and a clamping piece driving unit which is connected with the two sets of clamping pieces and used for driving the two sets of clamping pieces to move relatively; a straight shrimp stopping block provided with a straight shrimp end face opposite to the shrimp body moving direction of the shrimp clamping device; and a shrimp body limiting block is provided with a shrimp body limiting groove for embedding the shrimp body; wherein the body characteristics comprise the shrimp head orientation, the shrimp body extension direction and the body segment position of the shrimp body. Automatic production of the shrimp bodies is achieved, manual grabbing, placing and feeding are not needed, and the production efficiency is improved.

Owner:DENSEA AQUATIC TECH (HUAZHOU) CO LTD

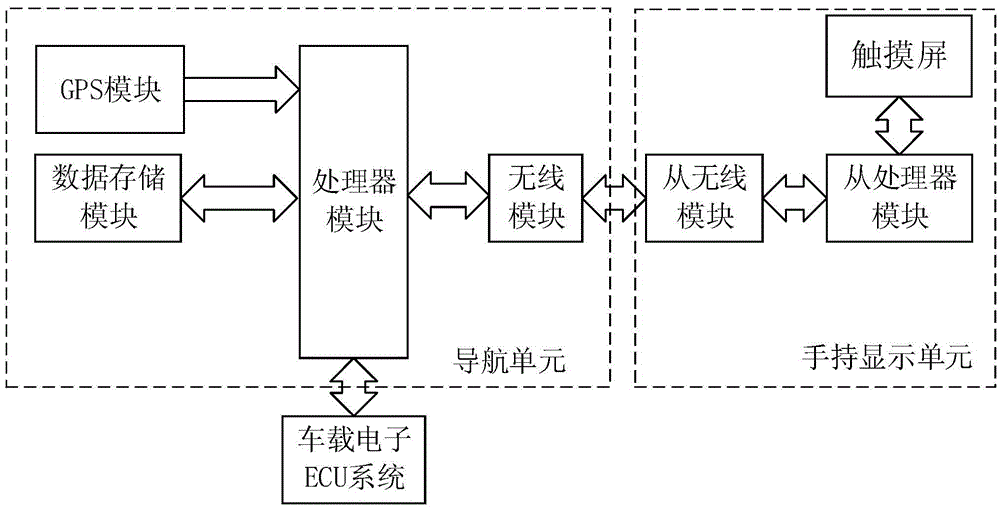

Portable navigation system and working method thereof and vehicle

ActiveCN105676244AEasy to viewGuaranteed to arrive on the wayInstruments for road network navigationSteering linkagesComputer moduleWorking set

The invention relates to a portable navigation system and a working method thereof and a vehicle. The navigation system comprises a handheld display unit and a navigation unit; the handheld display unit can be mounted in a central console in a detachable manner; the central console is internally provided with a power supply interface, and a charging battery interface of the handheld display unit is connected with the power supply interface when the handheld display unit is mounted in the central console of the vehicle; and the navigation unit is also positioned in the central console of the vehicle, and internally provided with a wireless module which is connected with the handheld display unit. According to the navigation system of the invention, the handheld display unit is separate from the navigation unit, a user can check a navigation route by holding the display unit by hand, and especially, a passenger in a co-driver position can assist a driver in navigation.

Owner:江苏千里马科技有限公司

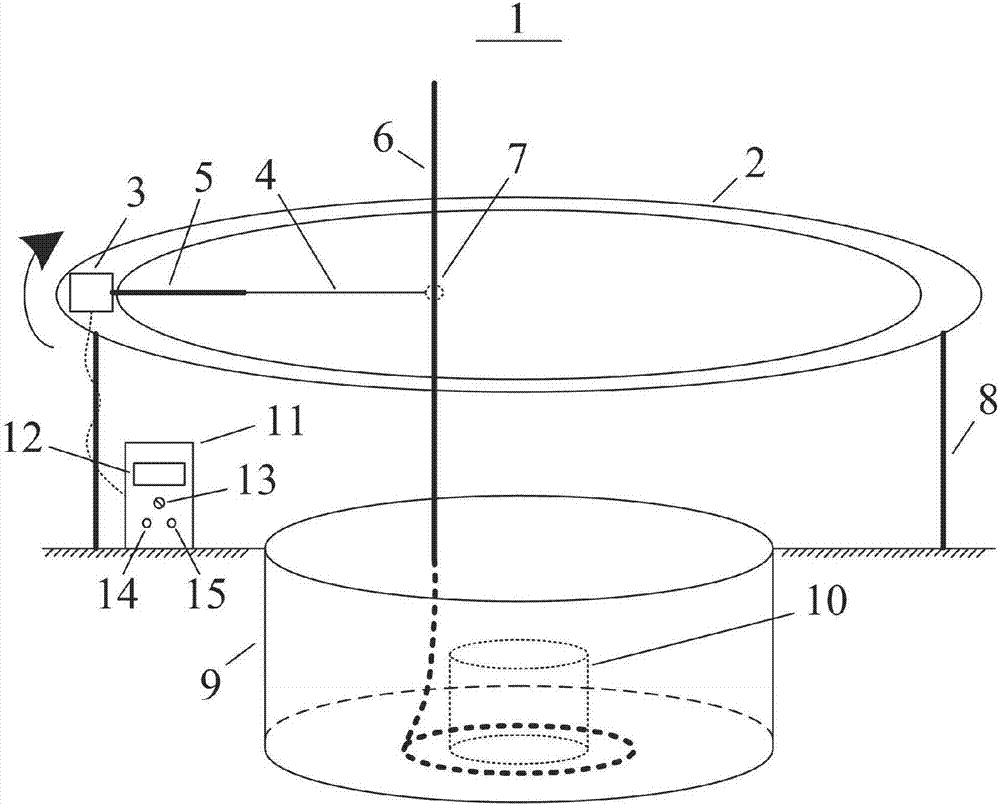

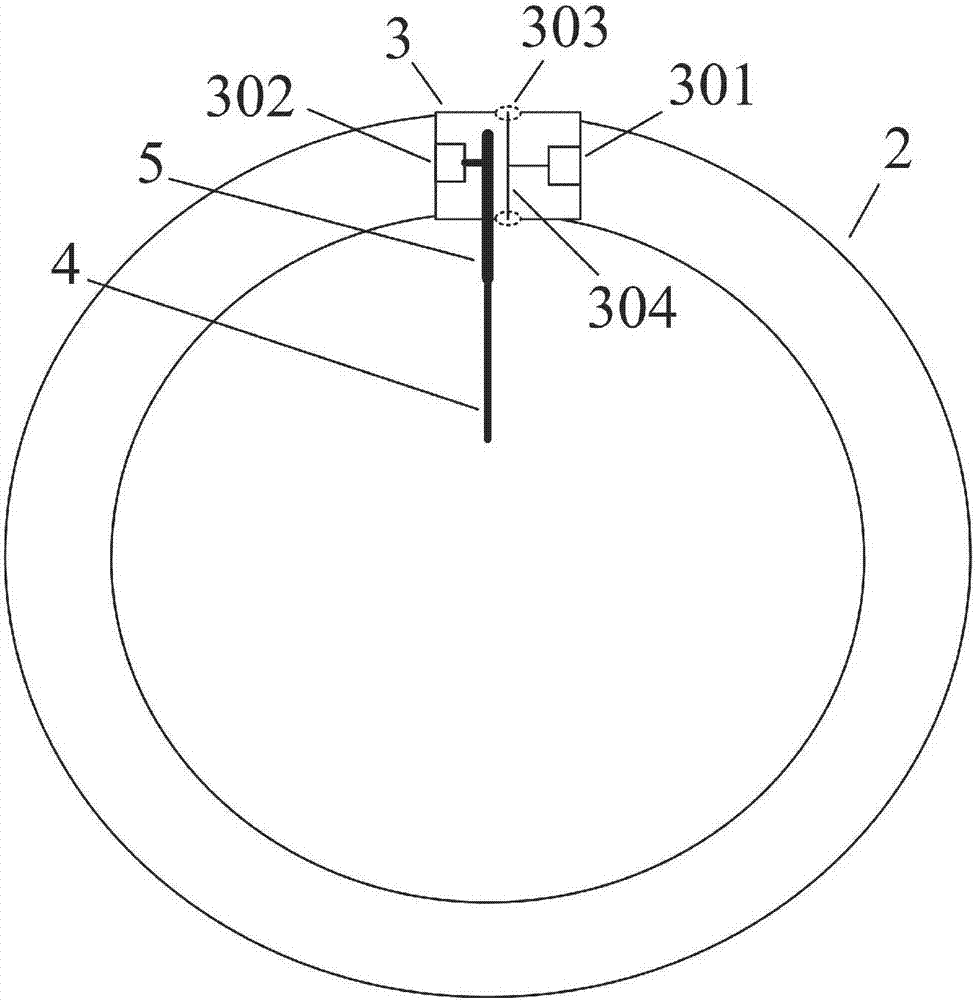

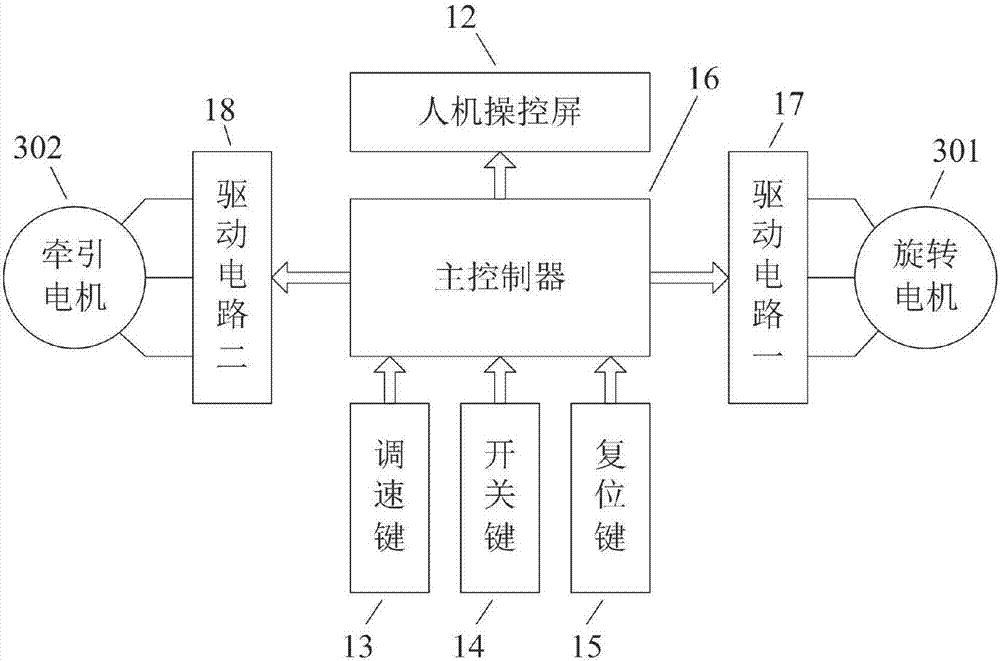

Intelligent wiring device capable of improving submarine cable environment

PendingCN107021380AImprove aestheticsImprove cleanlinessFilament handlingMachine controlMarine engineering

The invention discloses an intelligent wiring device capable of improving the submarine cable environment. The intelligent wiring device comprises a device body. The device body is provided with a sliding guide rail and a submarine cable tank. The sliding guide rail is fixedly connected with the ground through supporting pillars. The sliding guide rail is provided with a driving box, and the driving box is connected with the front end of a worm. The tail end of the worm is fixedly connected with a direction lever. The direction lever is in rolling connection with a submarine cable through a roller. The driving box is electrically connected with a control cabinet. A master controller is installed inside the control cabinet. A man-machine control screen, a speed regulation key, an on-off key and a resetting key are arranged on the front face of the control cabinet. A center frame is installed at the center position of the submarine cable tank. In the using process of the intelligent wiring device, control is stable, the structure is firm and reliable, intelligent wiring of the submarine cable can be realized, and labor force is saved; and moreover, the tightness between the wiring number of turns and coils can be adjusted automatically according to the diameter of the submarine cable, the wiring attractiveness and cleanliness are improved and the intelligent wiring device is suitable for application and popularization.

Owner:ANHUI UNIV OF SCI & TECH

Pants loop feeding mechanism, sewing device and pants loop feeding method

PendingCN110965217AGuaranteed normal loadingGuaranteed accuracyWork-feeding meansPressersPRESSURE FEETEngineering

The invention relates to the technical field of clothing sewing, in particular to a pants loop feeding mechanism, a sewing device and a pants loop feeding method. A first blocking structure and a second blocking structure are arranged between two clamping jaws, so that the extending section of a pants loop is prevented from being overlapped at the ends of the clamping jaws when the clamping jaws are used for driving the pants loop to bend, a pressor foot is prevented from crimping the extending section of the pants loop and covering the end part of the pants loop, and the feeding of the pantsloop and the sewing accuracy and quality of the pants loop are ensured. According to the sewing device disclosed by the invention, the end part and the bending point of the pants loop are crimped by the presser foot, then a clamping assembly is disassembled from a machine head, at the moment, the second blocking structure prevents the extending section from covering the end part, the pants loop sewing operation is facilitated, and the end part and the bending section of the pants loop are prevented from being overlapped and sewn on clothes to cause quality accidents.

Owner:ZHUHAI YUNKONG RUIQI NUMERICAL CONTROL SCI & TECH

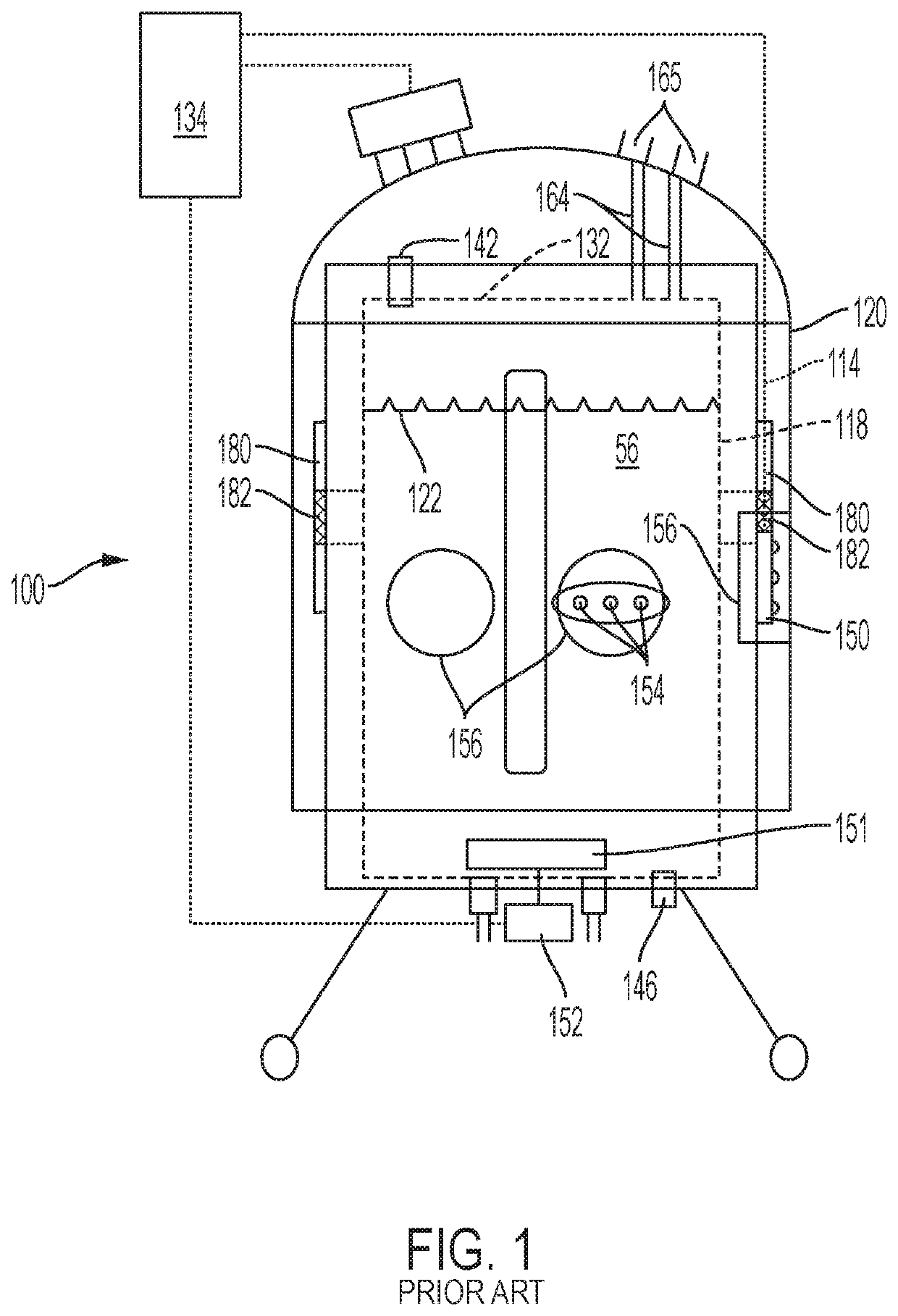

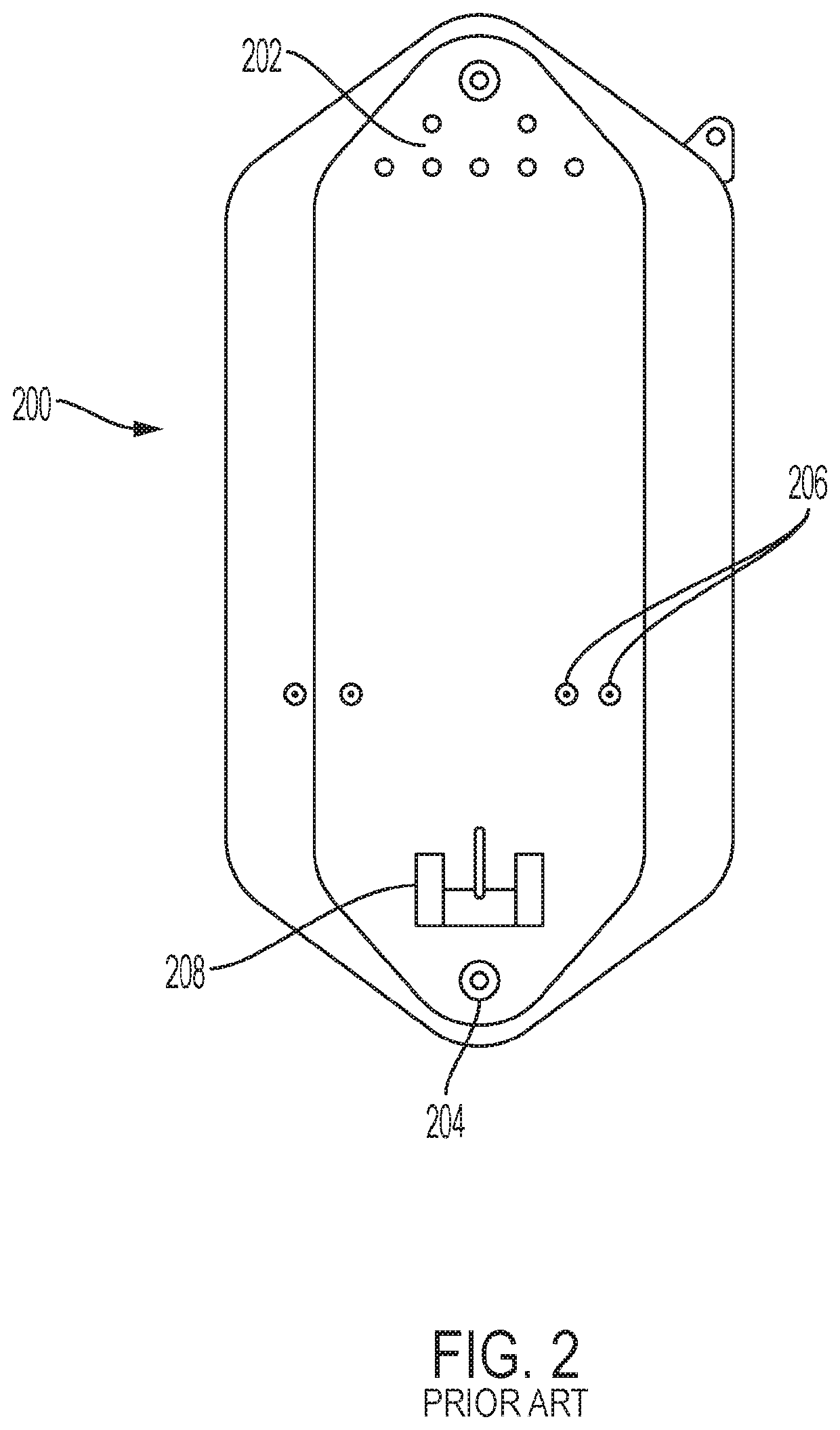

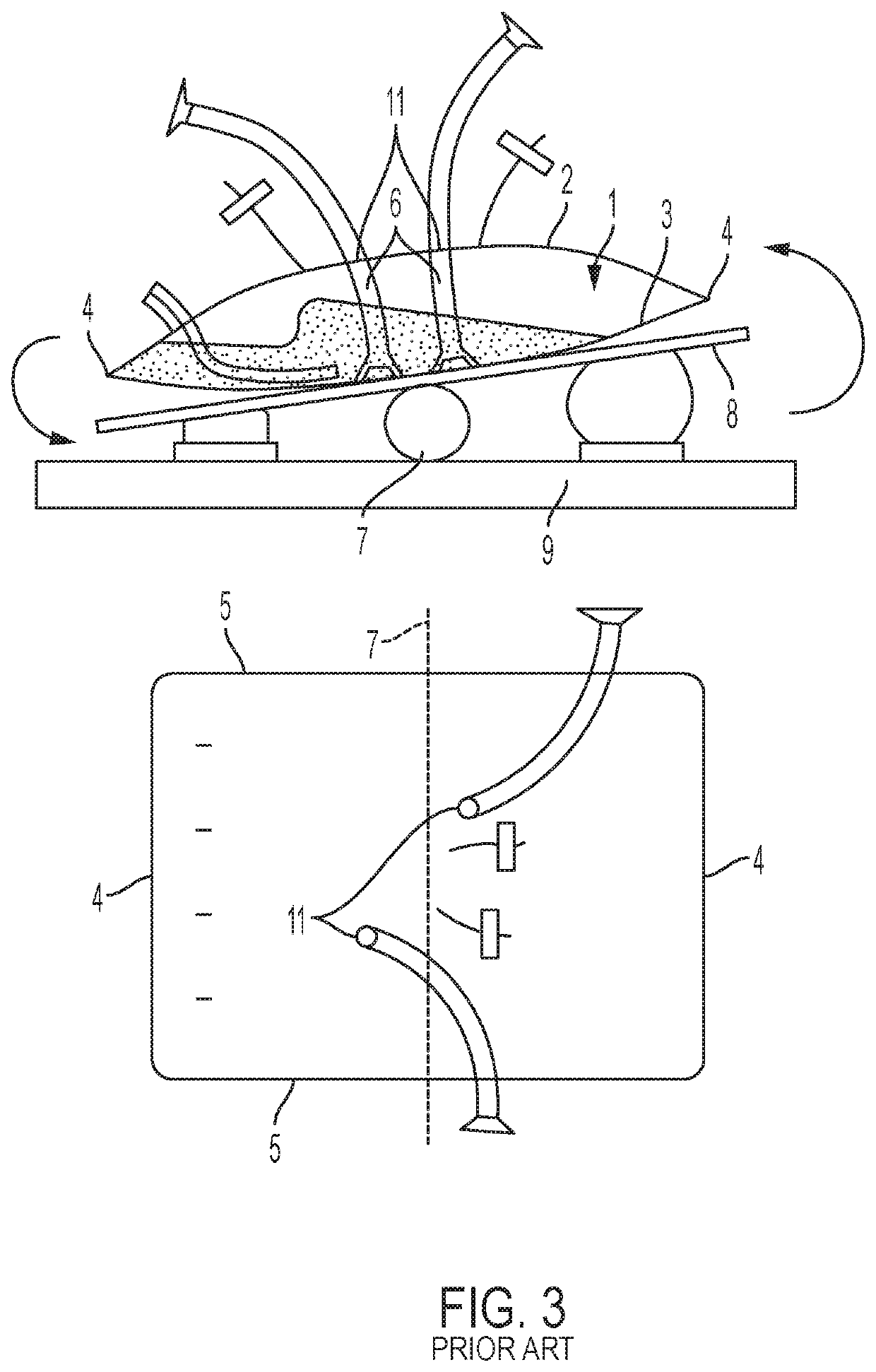

Reinforced bioreactor component structure system for cell cultivation

InactiveUS20210016287A1Avoid crimpingAdd featureBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiochemistry

The present invention involves a reinforced tubing structure that is particularly useful for reinforcing tubing that is present inside disposable bioreactor bags, including for example thermowell tubing.

Owner:GE HEALTHCARE BIO SCI CORP

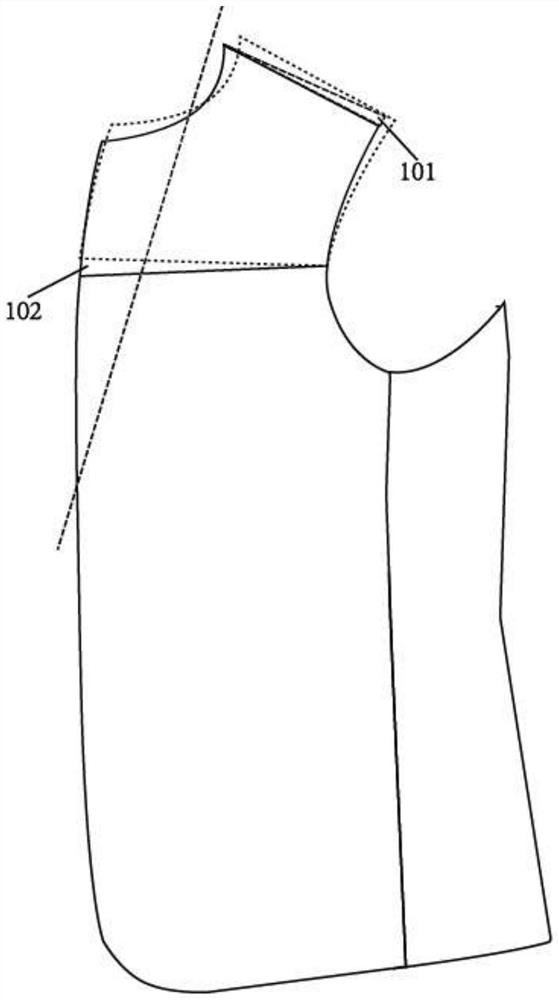

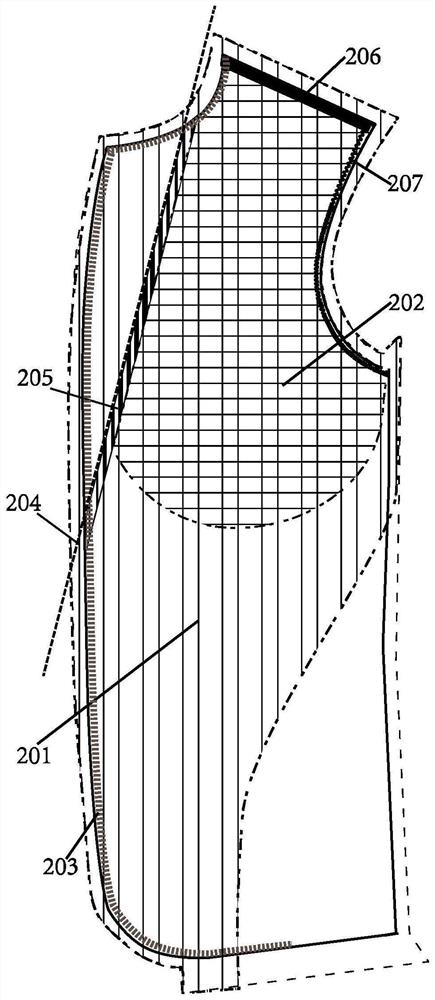

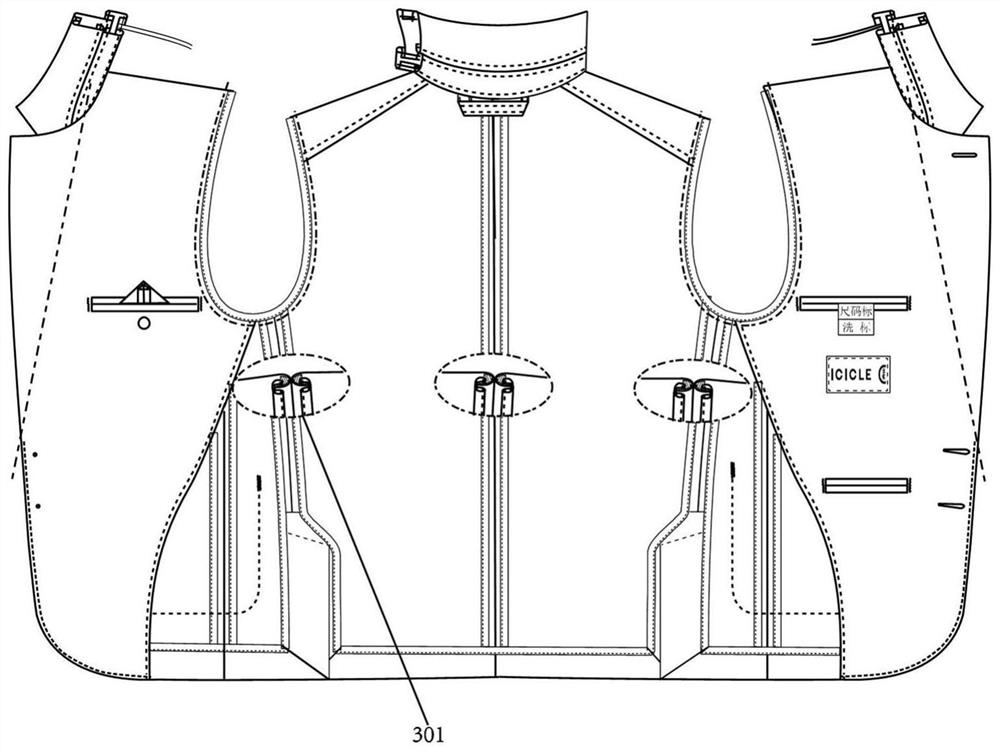

Manufacturing method of primary-color flax lining-free men's suit

ActiveCN112315087AGarment softStable profileJacketsProtective garmentManufacturing engineeringMechanical engineering

The invention provides a manufacturing method of a primary-color flax lining-free men's suit. The manufacturing method comprises the following steps: selecting an easily-stretched silk fabric including primary-color flax and a fabric of pocket cloth for later use; carrying out planar plate making and pattern adjustment; after the model is adjusted, carrying out the three-dimensional tailoring, andcarrying out the floating allowance fine adjustment on an actual mannequin, so that the model is adjusted to accord with ergonomics; performing a garment shrinkage test on the tailored and finely tuned garment, and applying the garment shrinkage to each part in the actual model; after the shrinkage rate is calculated, selecting a sewing detail process and auxiliary materials; carrying out the sewing after a sewing detail process is determined; washing the sewn ready-made clothes with a plurality of pieces of the same fabric; and carrying out the ready-made clothes finishing of the washed ready-made clothes. By adjusting the pattern, the three-dimensional attractive effect is ensured to be achieved under the conditions of no bodice lining, no chest interlining, no shoulder pad and no sleeve cotton, and the technical problems that the primary-color linen fabric is prone to silk stretching, unstable in shrinkage rate and free of chest interlining support are solved.

Owner:上海之禾企业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com