Patents

Literature

108results about "Auxillary non-insulated conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

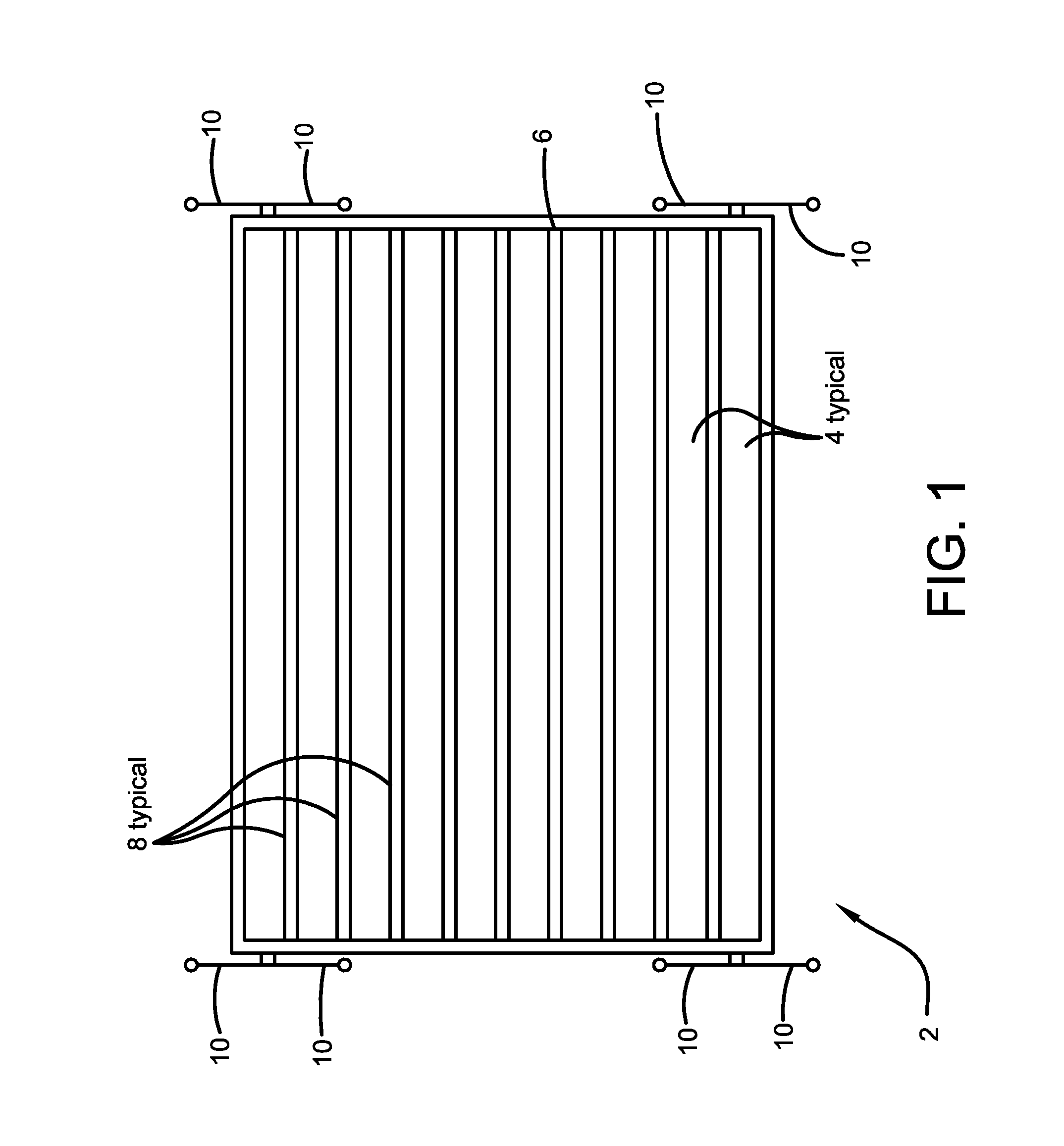

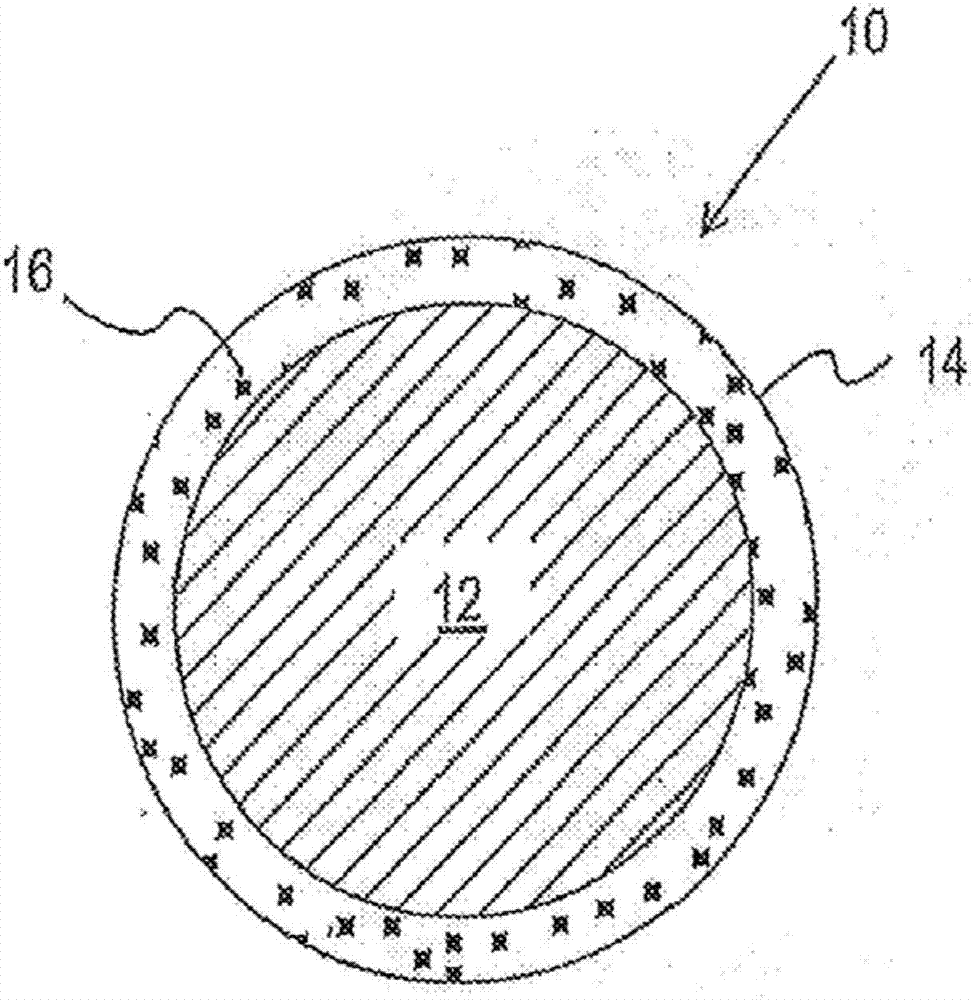

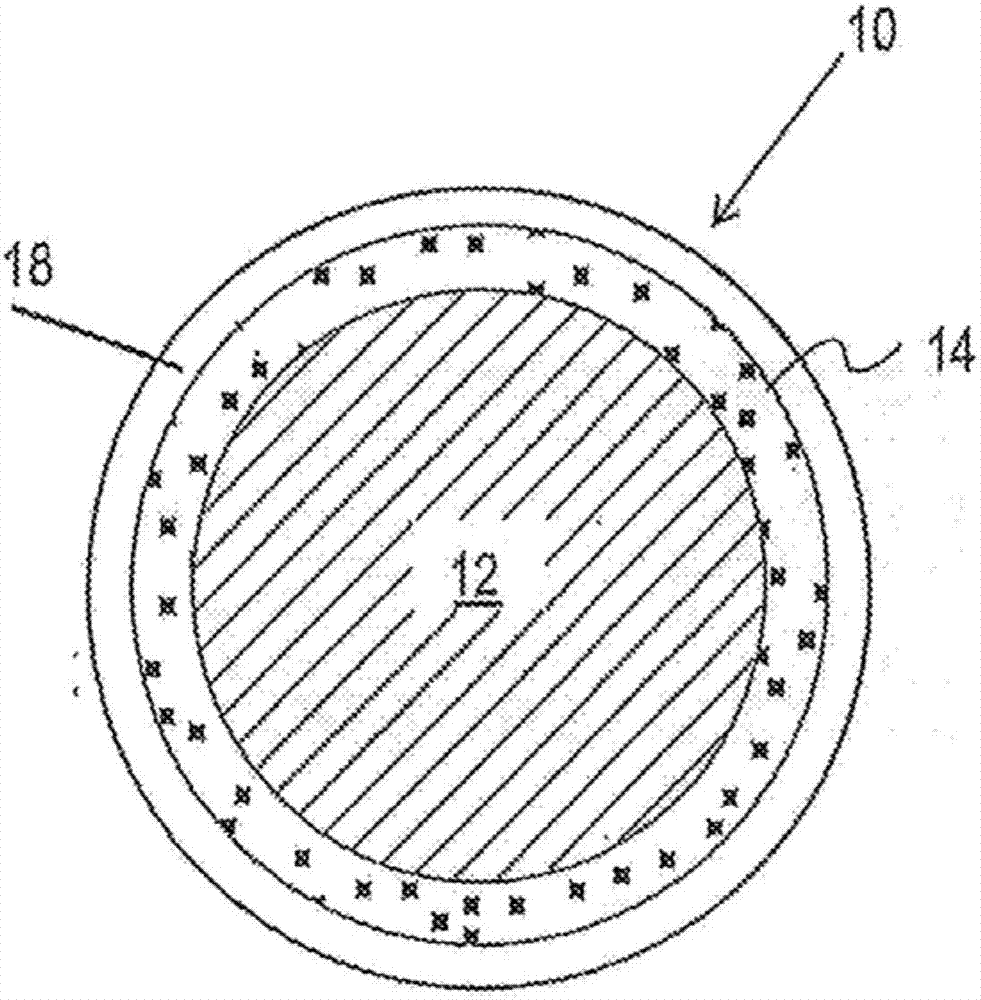

Bonding washer

Owner:HUBBELL INC

Bonding Washer

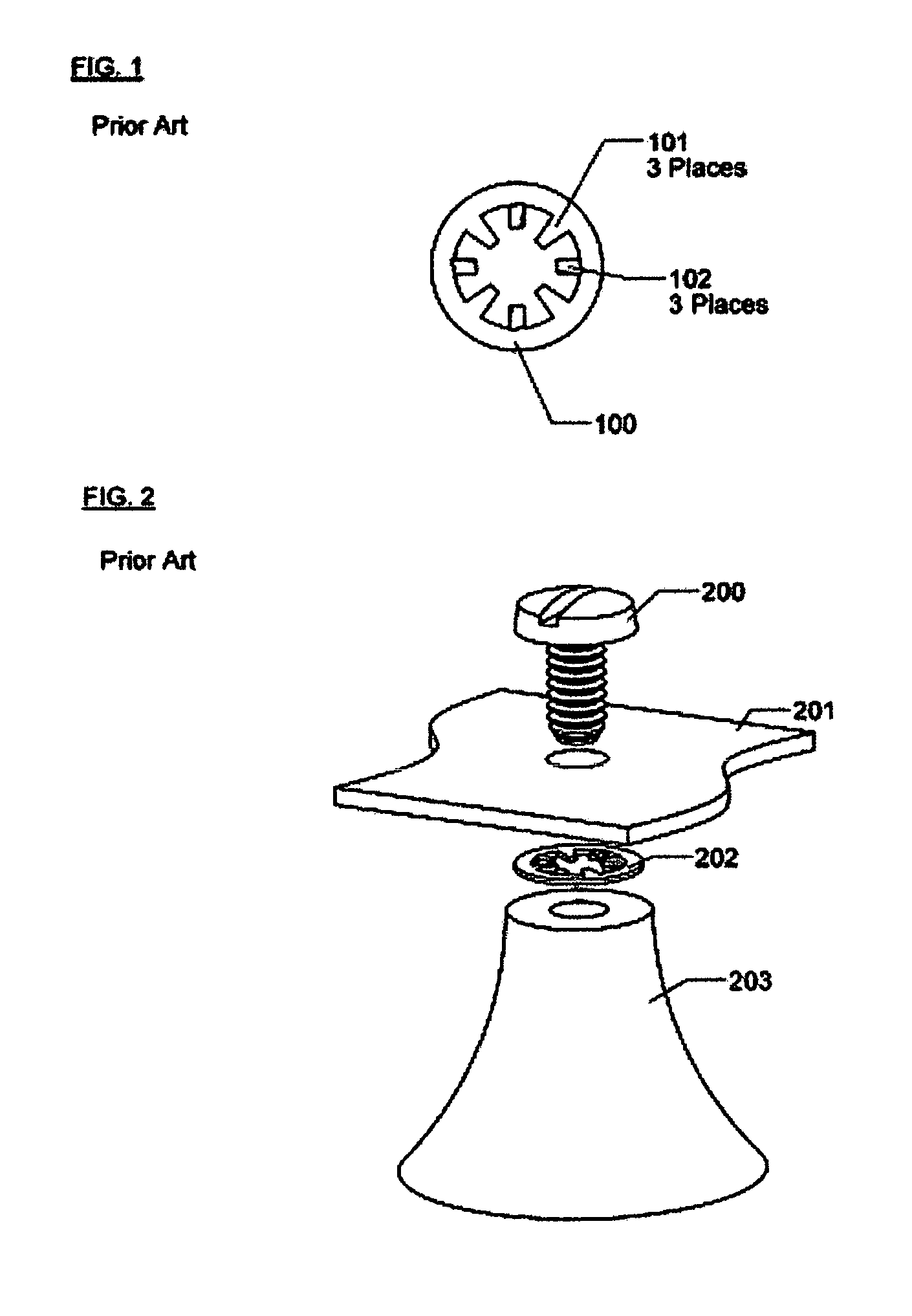

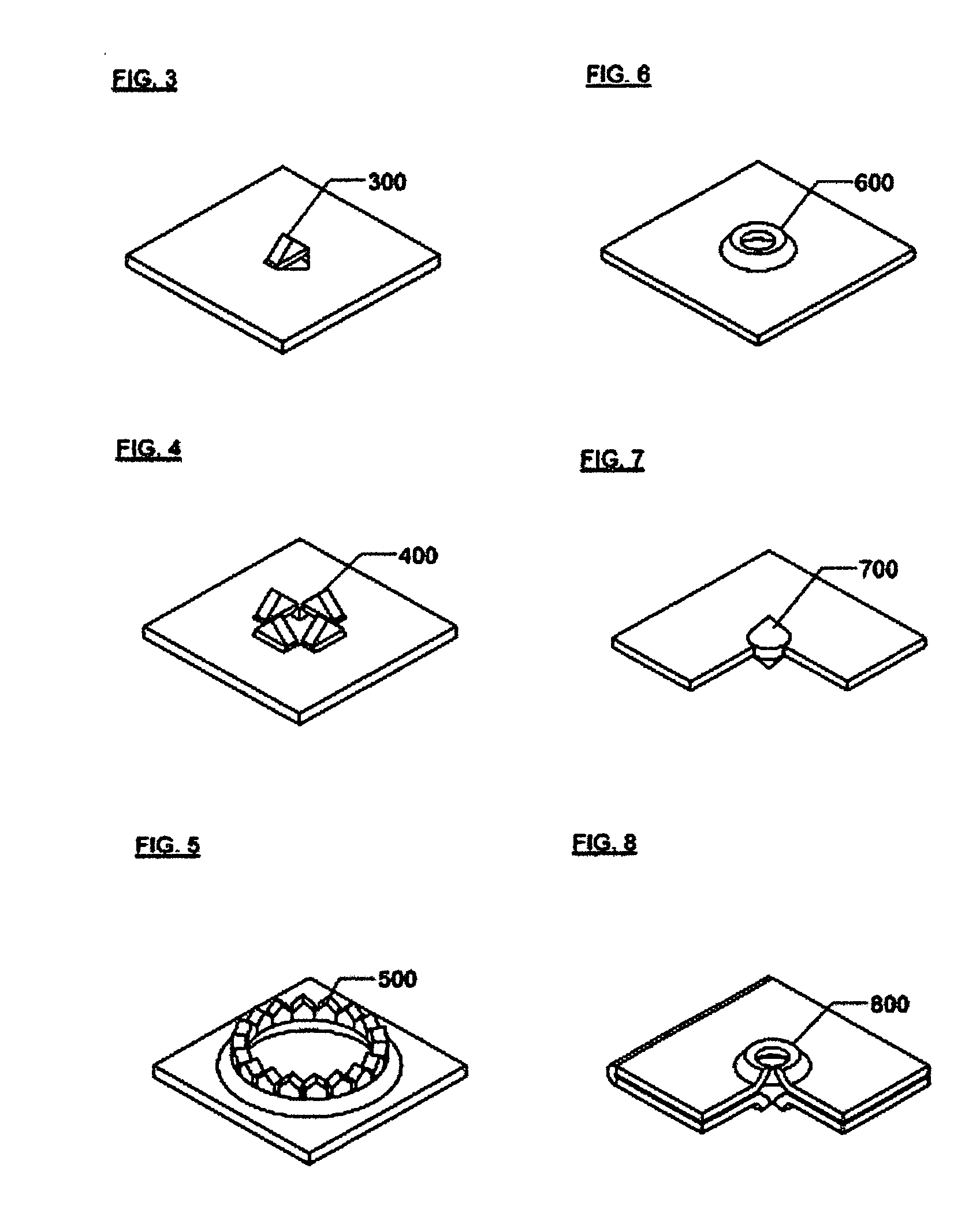

ActiveUS20070248434A1Maintain electrical connectionElectrically conductive connectionsWashersElectrical connectionEngineering

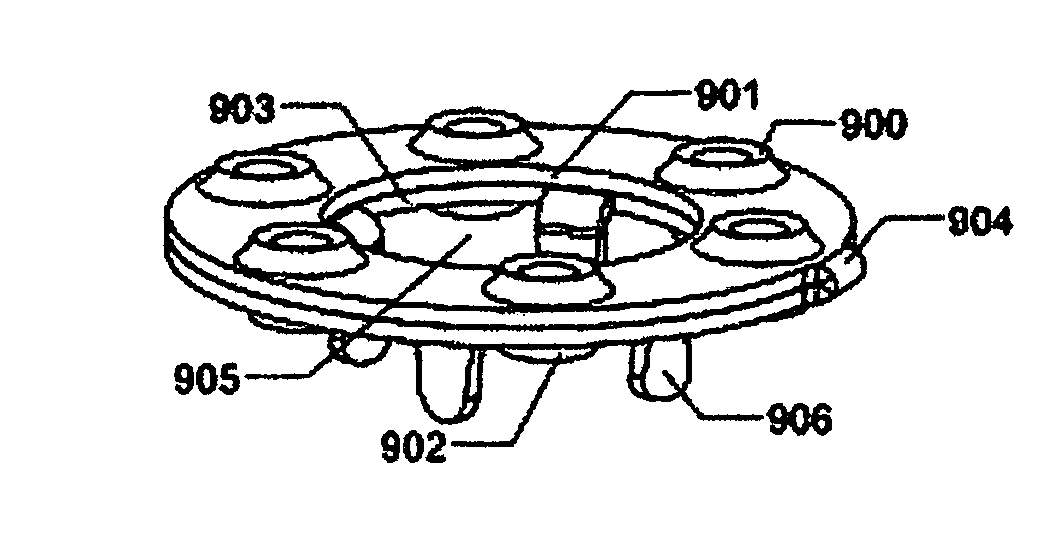

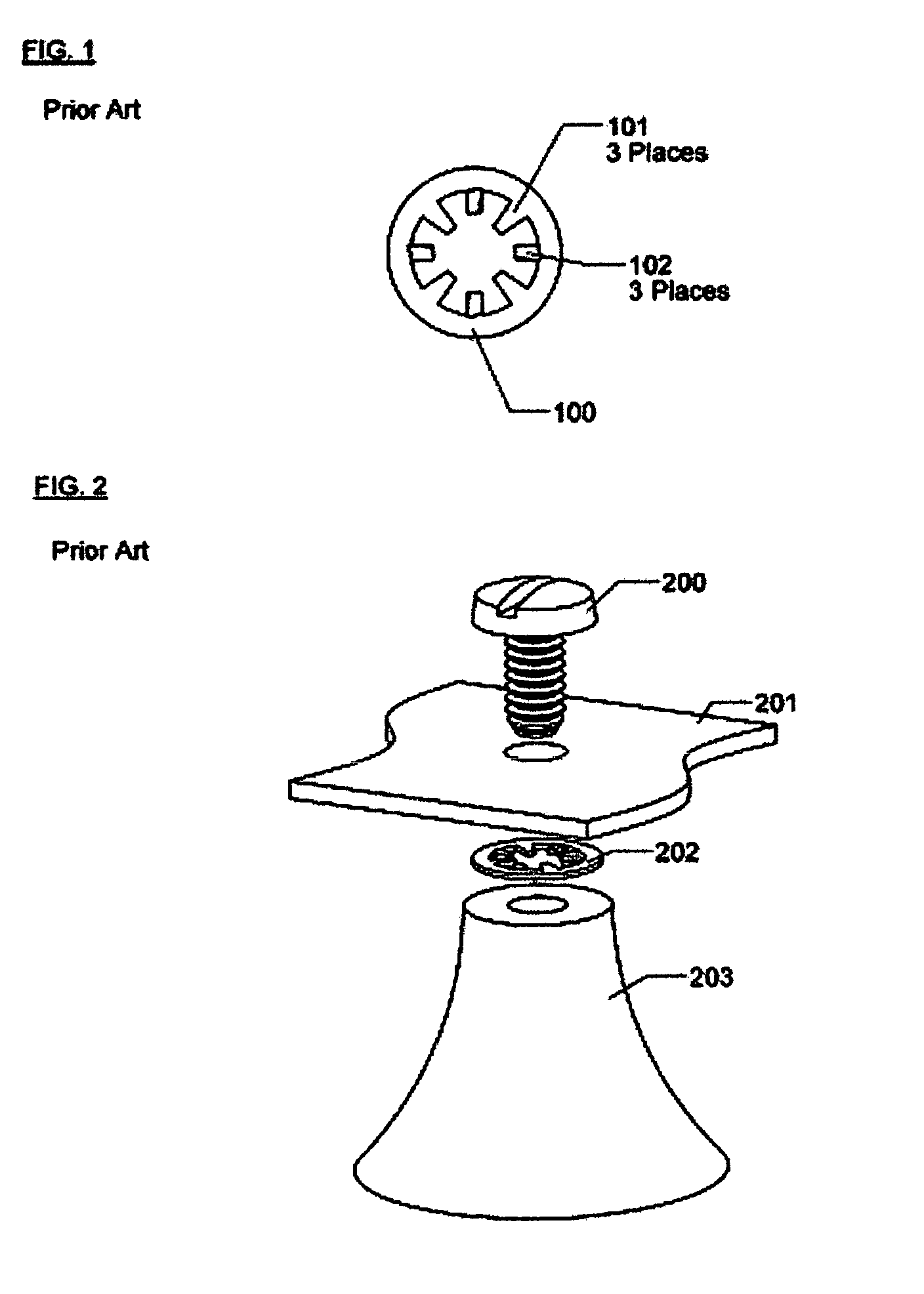

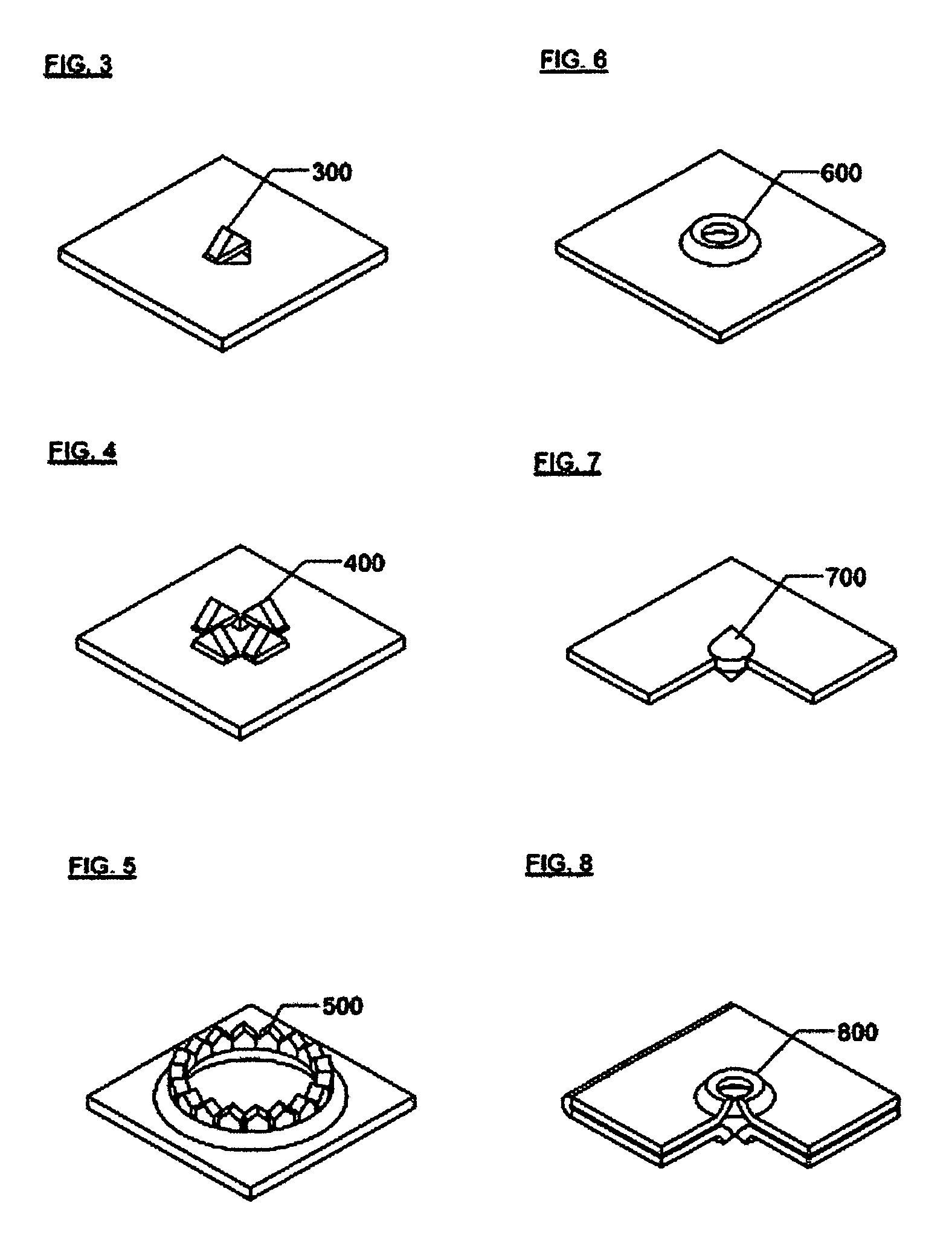

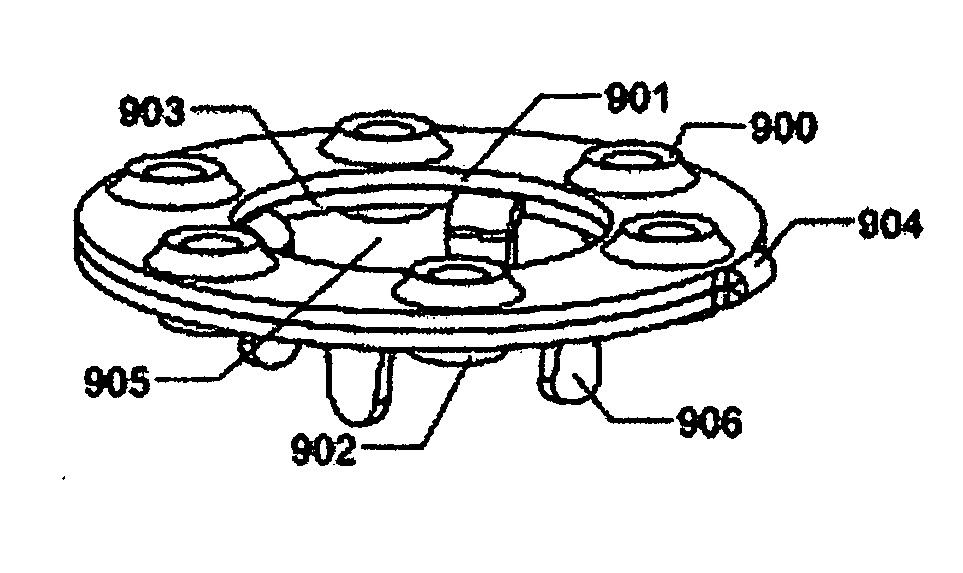

A bonding washer for making electrical connection between two metal pieces that are to be mechanically fastened together. The washer, to be interposed between the two metal pieces, is constructed so as to fasten to one of the pieces before the two pieces are joined. Teeth on the washer, positioned at right angles to the plane of the washer, are forced into each of the two metal pieces when the fastener is tightened, making electrical connection between the two metal pieces.

Owner:HUBBELL INC

Surface modified overhead conductor

ActiveUS20150235739A1Lower operating temperaturePlastic/resin/waxes insulatorsAuxillary non-insulated conductorsElectrical conductorSolar absorptivity

The present invention relates to a surface modified overhead conductor with a coating that allows the conductor to operate at lower temperatures. The coating is an inorganic, non-white coating having durable heat and wet aging characteristics. The coating preferably contains a heat radiating agent with desirable properties, and an appropriate binder / suspension agent. In a preferred embodiment, the coating has L* value of less than 80, a heat emissivity of greater than or equal to 0.5, and / or a solar absorptivity coefficient of greater than 0.3.

Owner:GENERAL CABLE TECH CORP

Method for Nanowire Cluster Formation

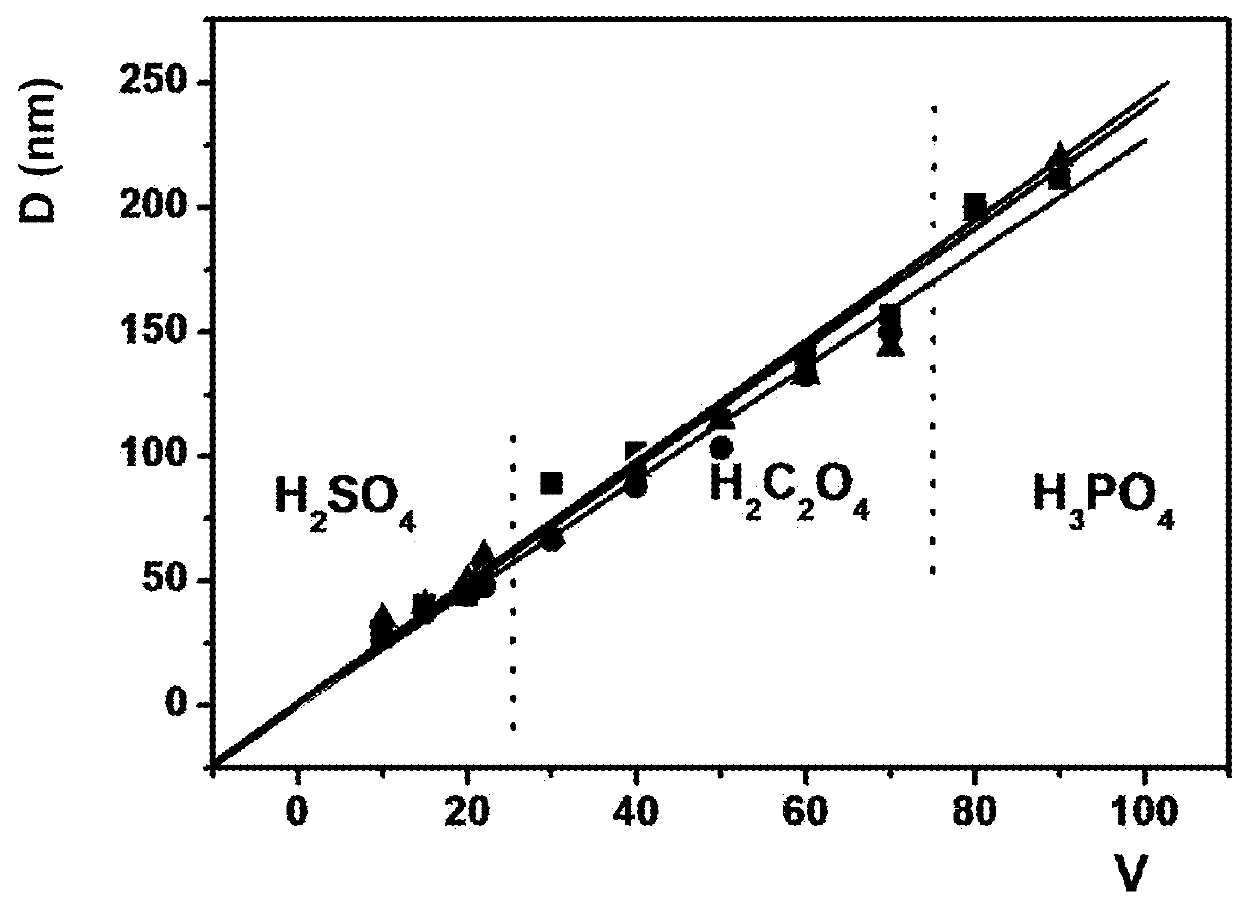

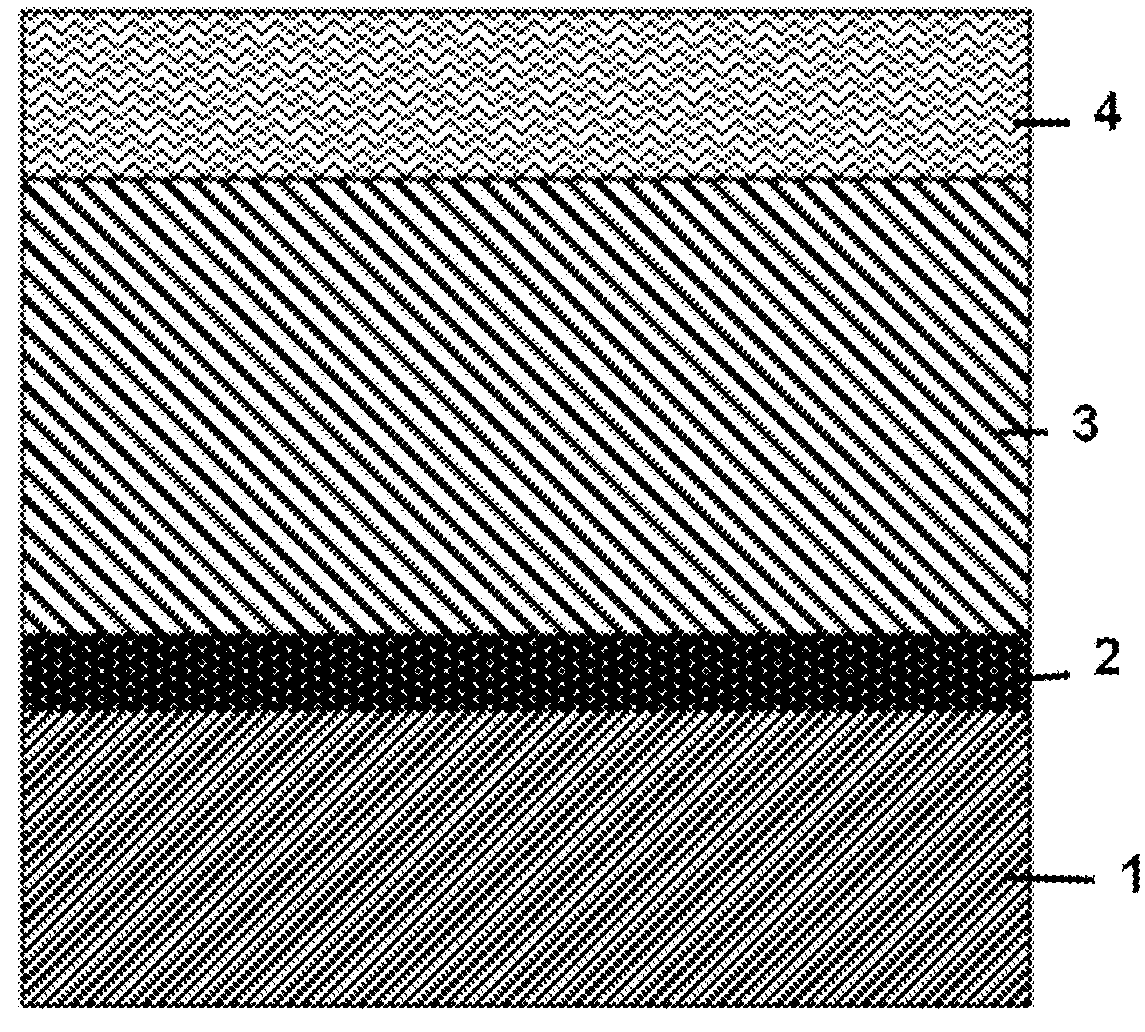

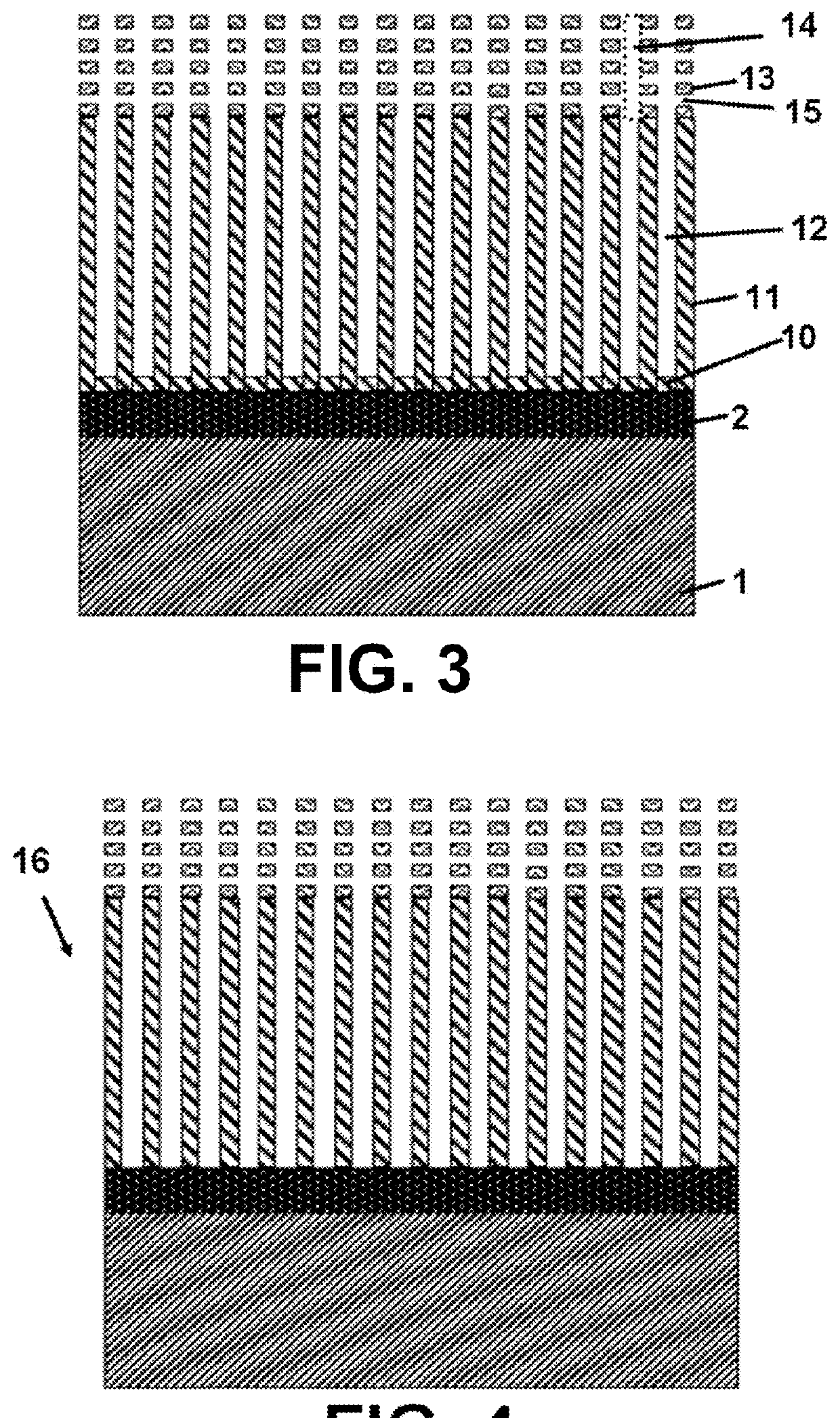

ActiveUS20160032475A1Inexpensive productionConvenient coatingTransistorAnodisationNanowireInterconnection

A cluster of non-collapsed nanowires, a template to produce the same, methods to obtain the template and to obtain the cluster by using the template, and devices comprising the cluster are described. The cluster and the template both have an interconnected region and an interconnection-free region.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

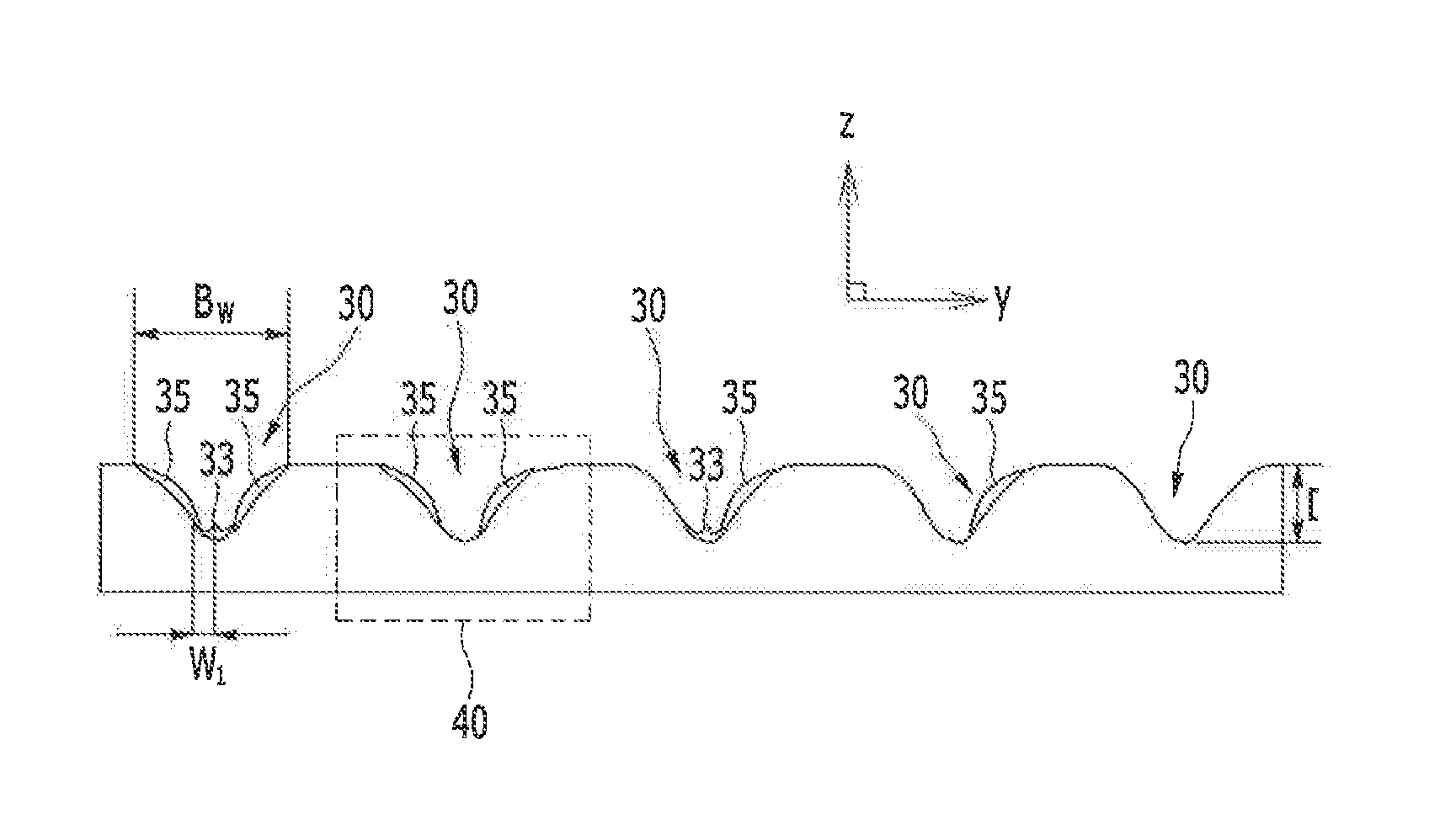

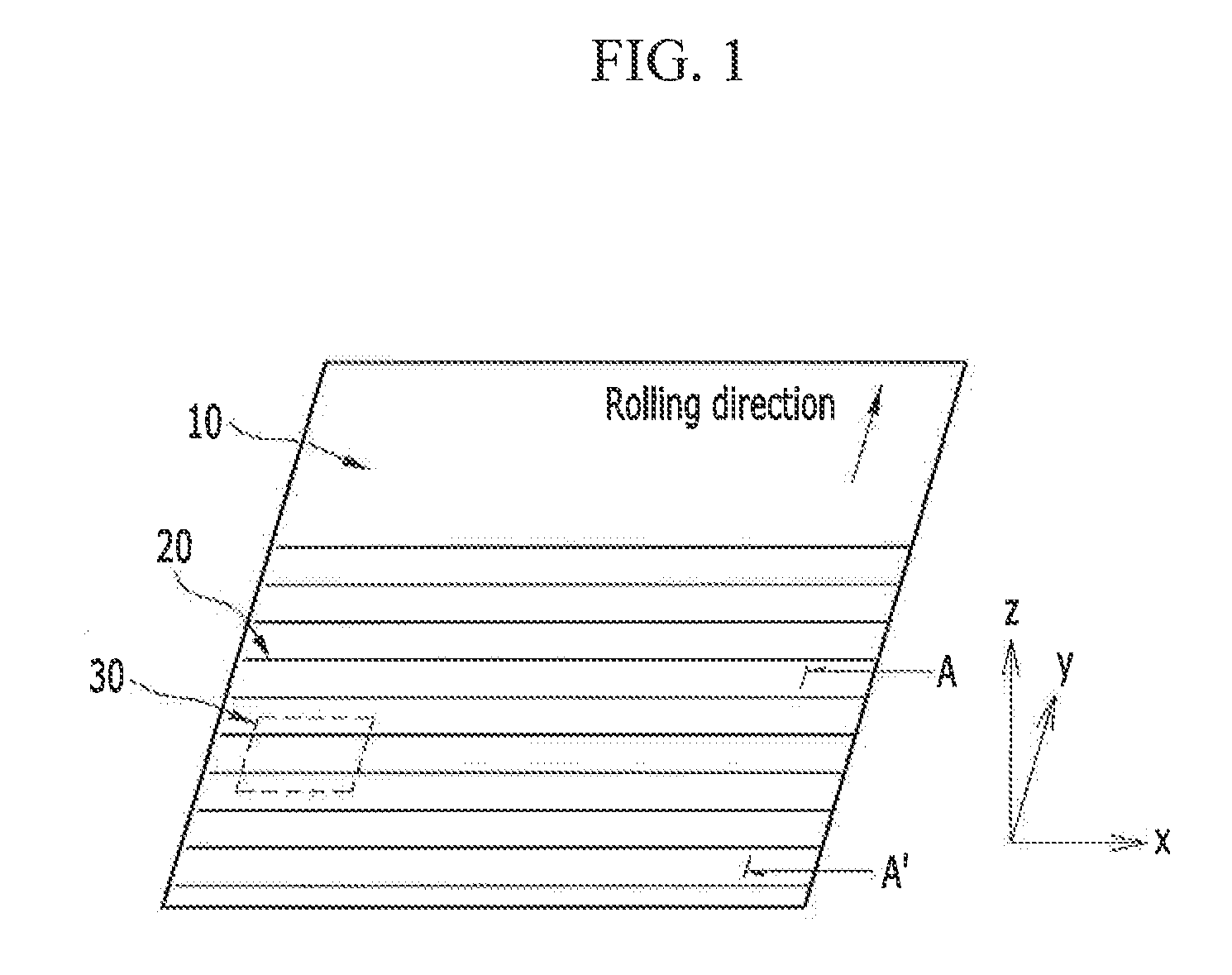

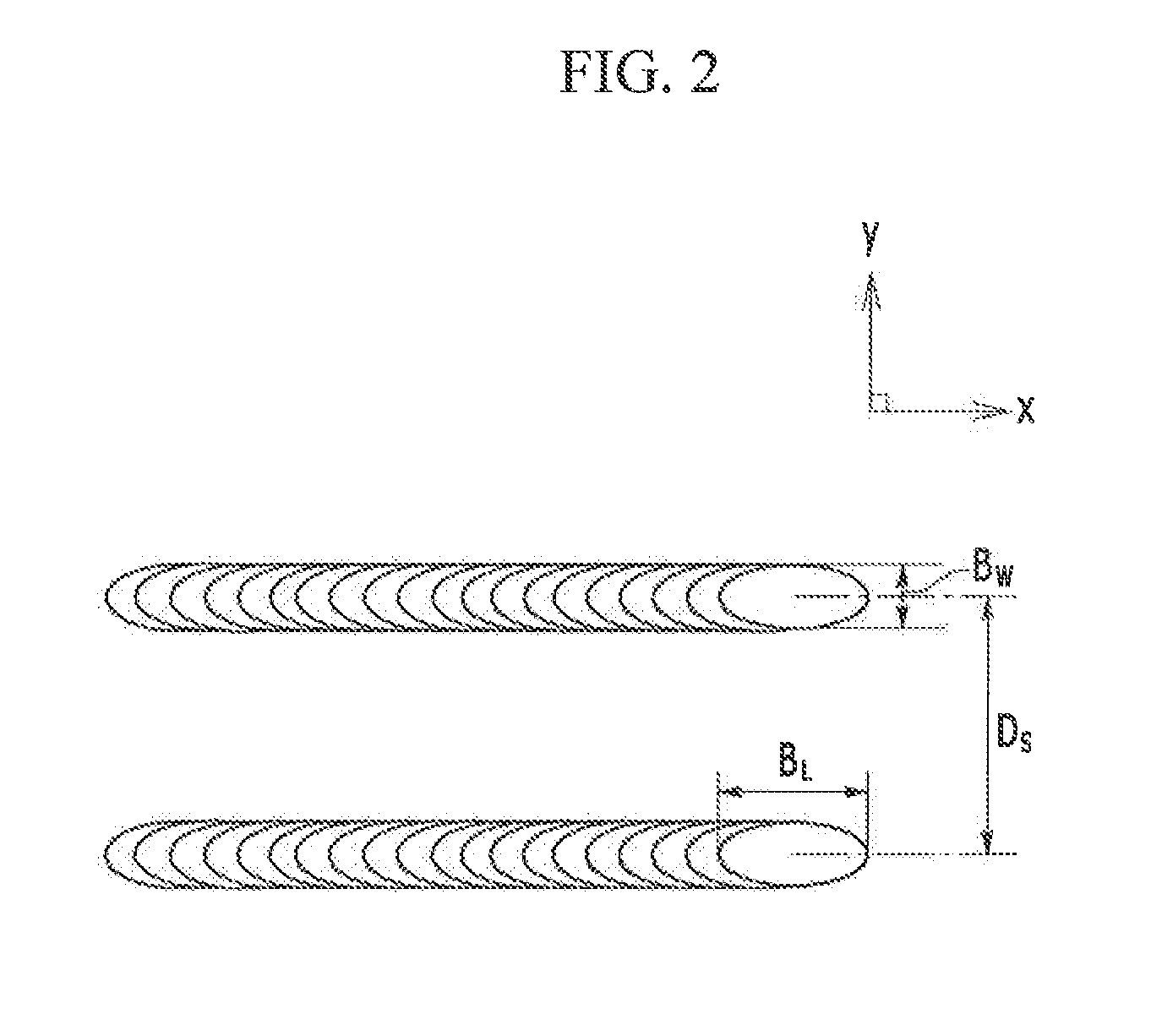

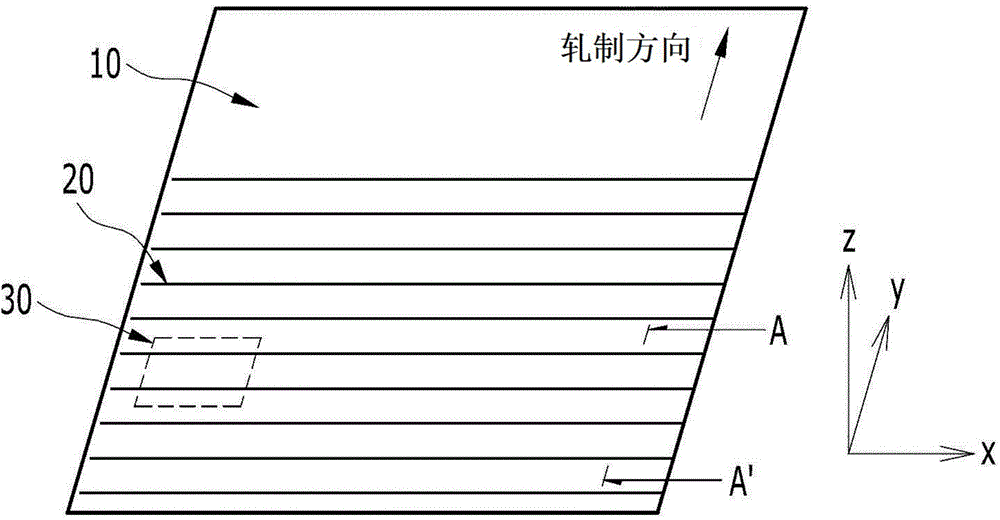

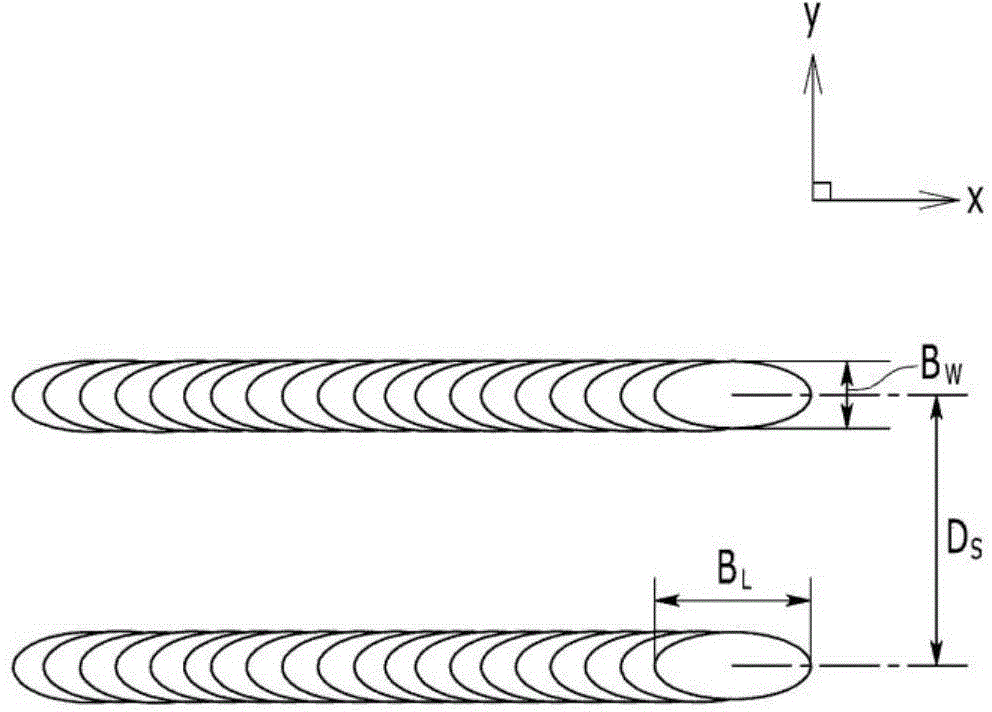

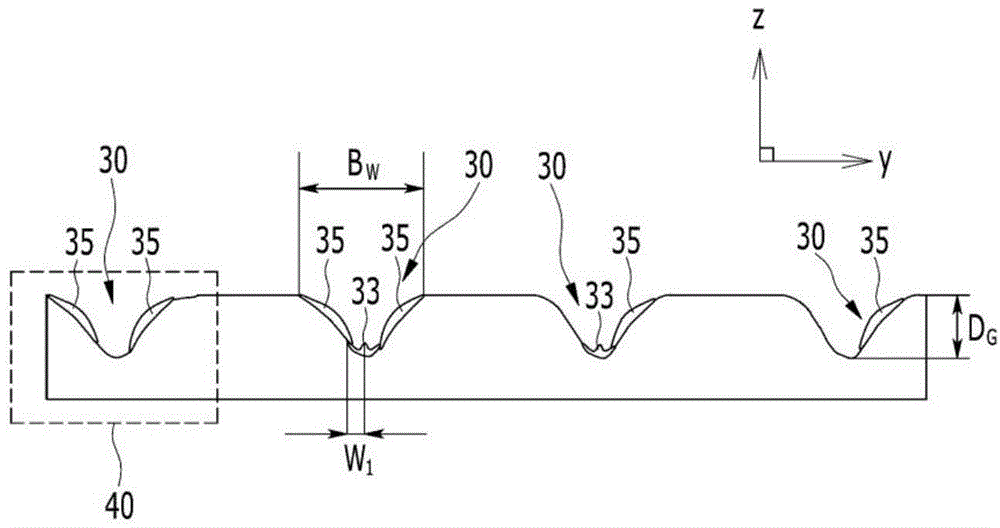

Electrical Steel Sheet and Method for Manufacturing the Same

InactiveUS20140374137A1Maximize magnetic domain miniaturizing effectMaximize the effectAuxillary non-insulated conductorsMetal/alloy conductorsElectrical steelSheet steel

A method for manufacturing an electrical steel sheet is provided. The method for manufacturing an electrical steel sheet includes forming a groove having first and second side surfaces and a bottom surface by melting a surface of a steel sheet by laser irradiation, and forming an opening by removing melted byproducts of the steel sheet formed on the first and second side surfaces and the bottom surface through air blowing or suctioning to expose at least one surface of the first side surface, the second side surface, and the bottom surface in the forming of the groove.

Owner:POHANG IRON & STEEL CO LTD

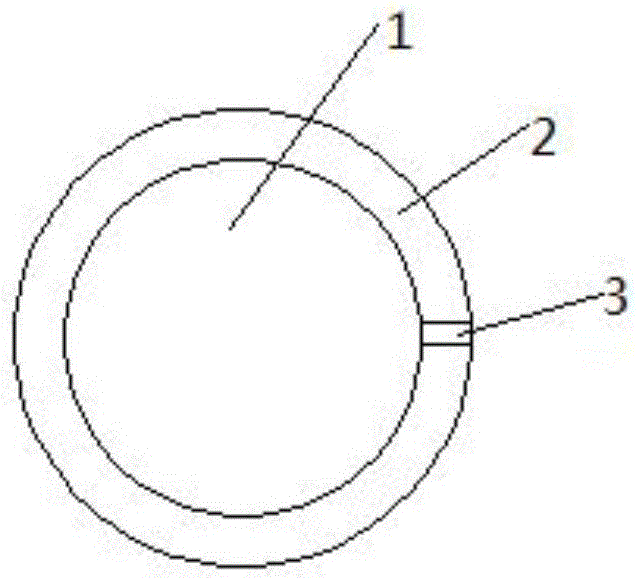

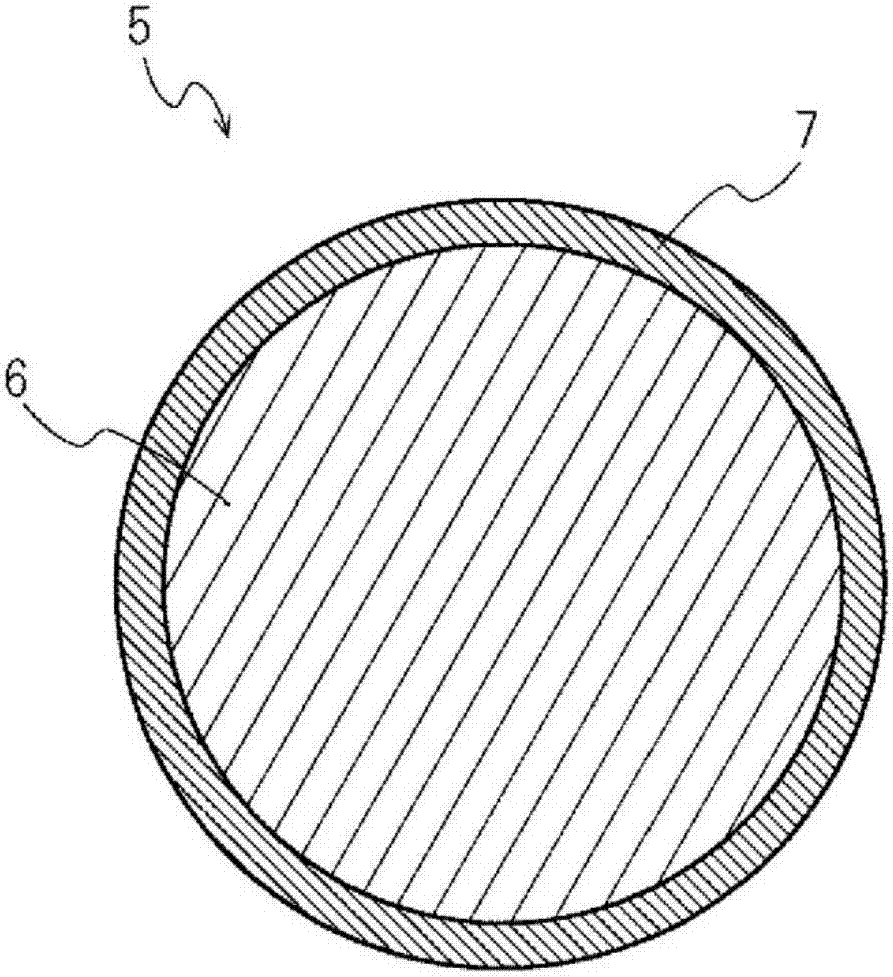

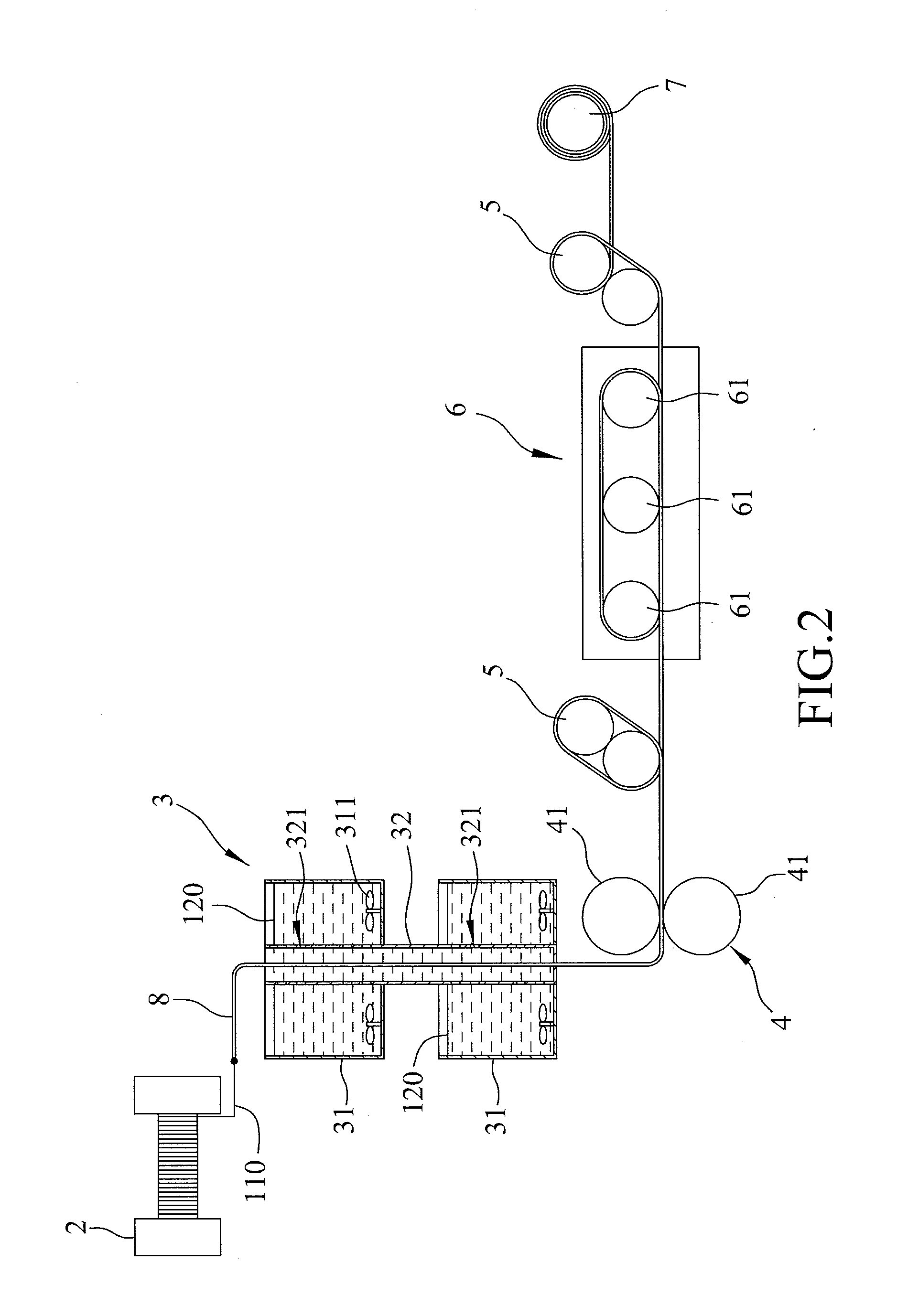

High-strength aluminum-clad steel wire and production method thereof

InactiveCN106653154AImprove conductivityImprove heat resistanceSingle bars/rods/wires/strips conductorsAuxillary non-insulated conductorsRare-earth elementHeat resistance

The invention discloses a high-strength aluminum-clad steel wire and a production method thereof. The high-strength aluminum-clad steel wire comprises a steel core and an aluminum layer clad on the outer surface of the steel core; two opposite edges of the aluminum layer are welded and connected, and a welding line is formed at the welding point; and the steel core comprises the following components in percentages by weight: 0.58% to 0.78% of carbon, 0.1% to 0.3% of silicon, 0.2% to 0.4% of manganese, 1.2% to 1.5% of chromium, 1.2% to 1.5% of nickel, 0.4% to 0.6% of molybdenum, 0.03% to 0.05% of rare earth elements and the balance of Fe. The high-strength aluminum-clad steel wire disclosed by the invention has the performances of high conductivity, high heat resistance and low creep deformation.

Owner:ANHUI TIANYUAN CABLE

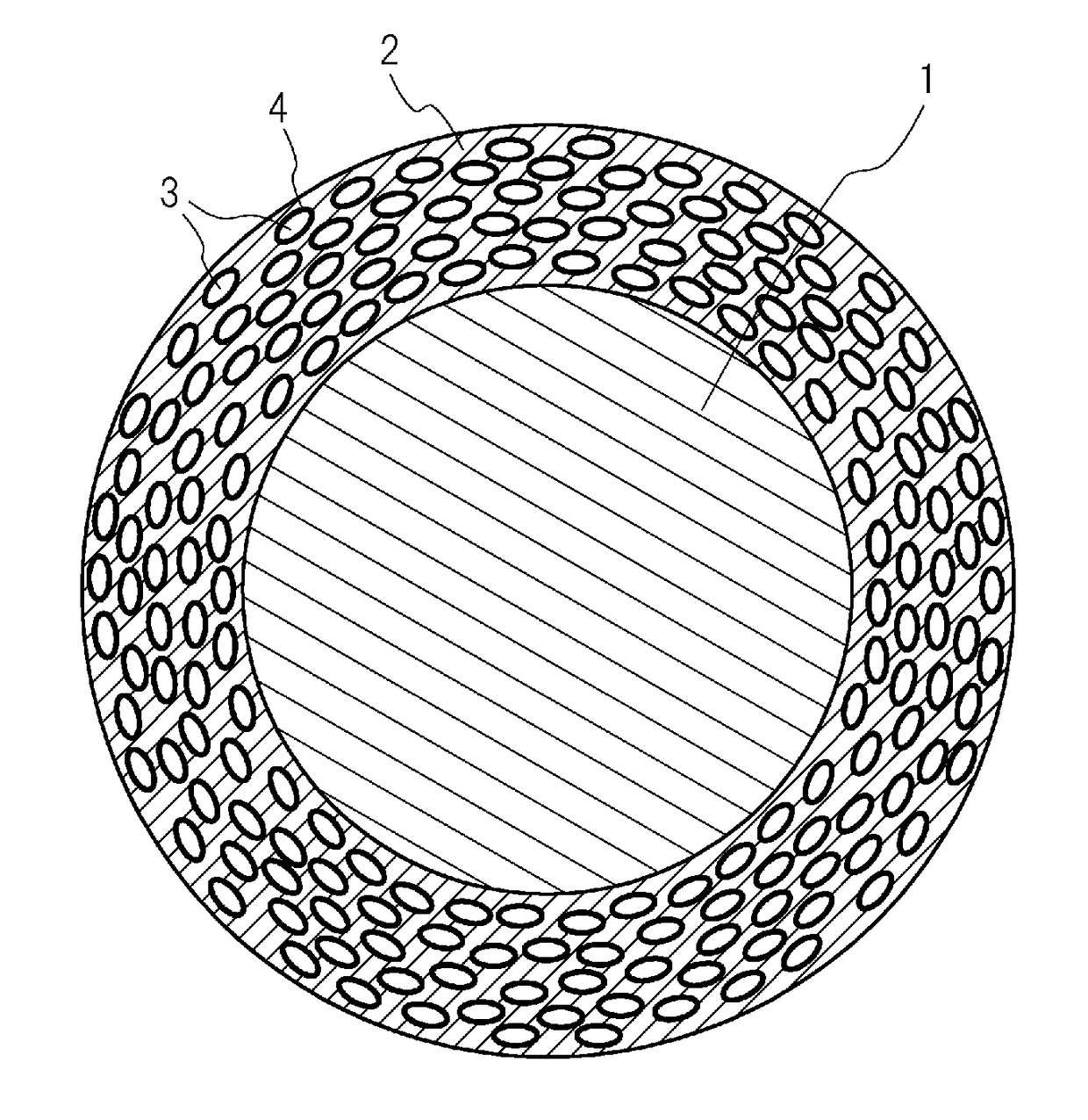

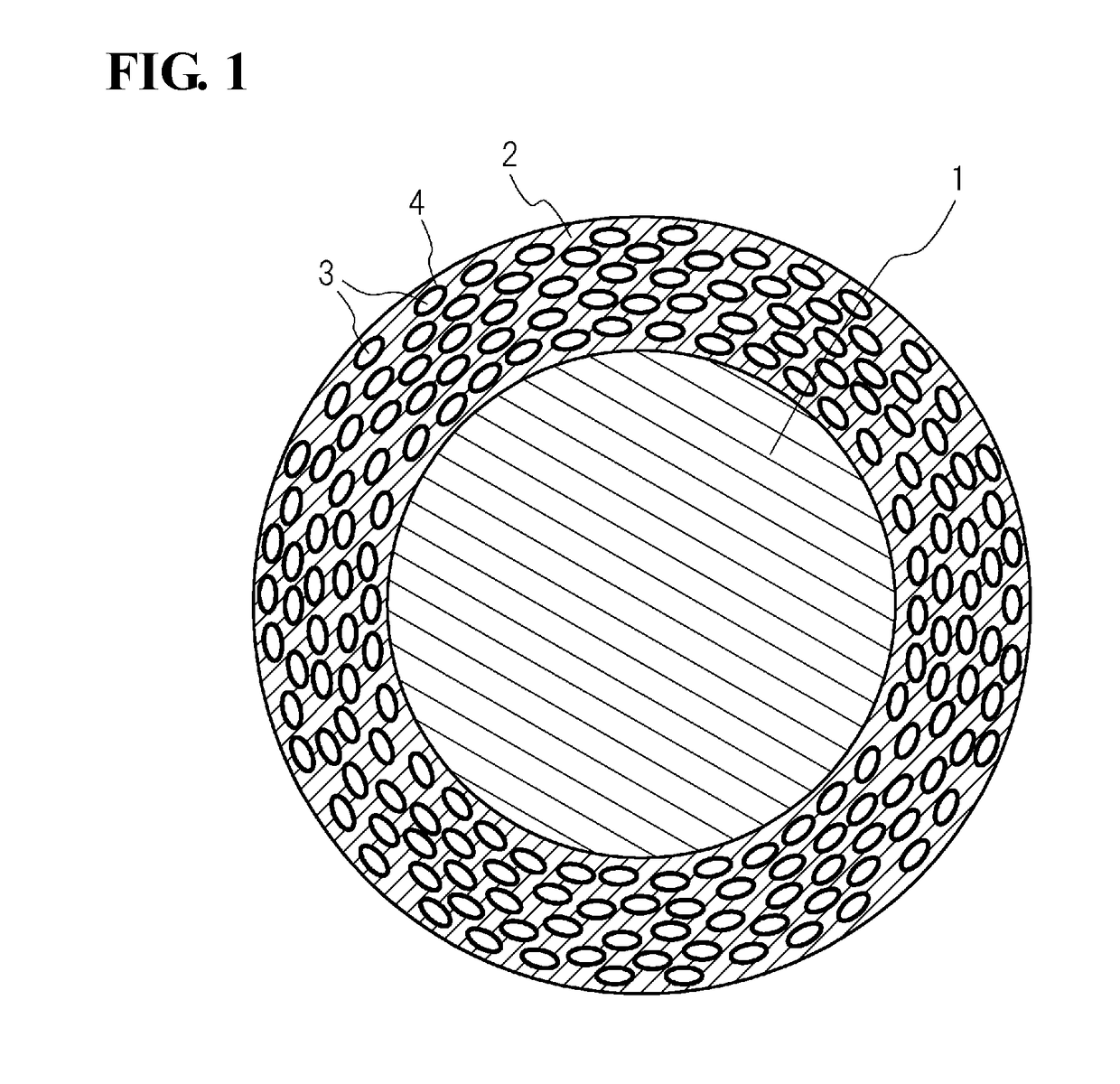

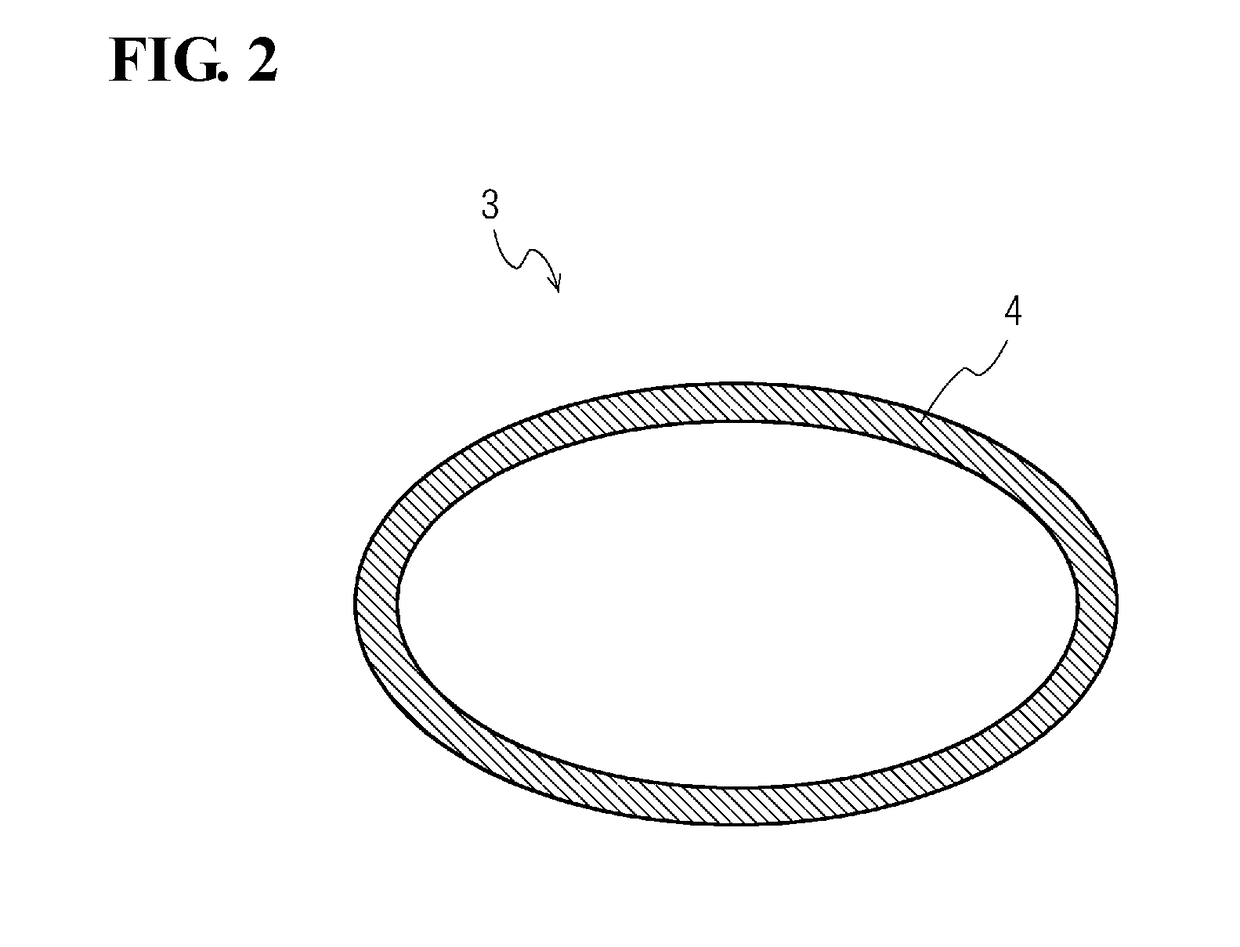

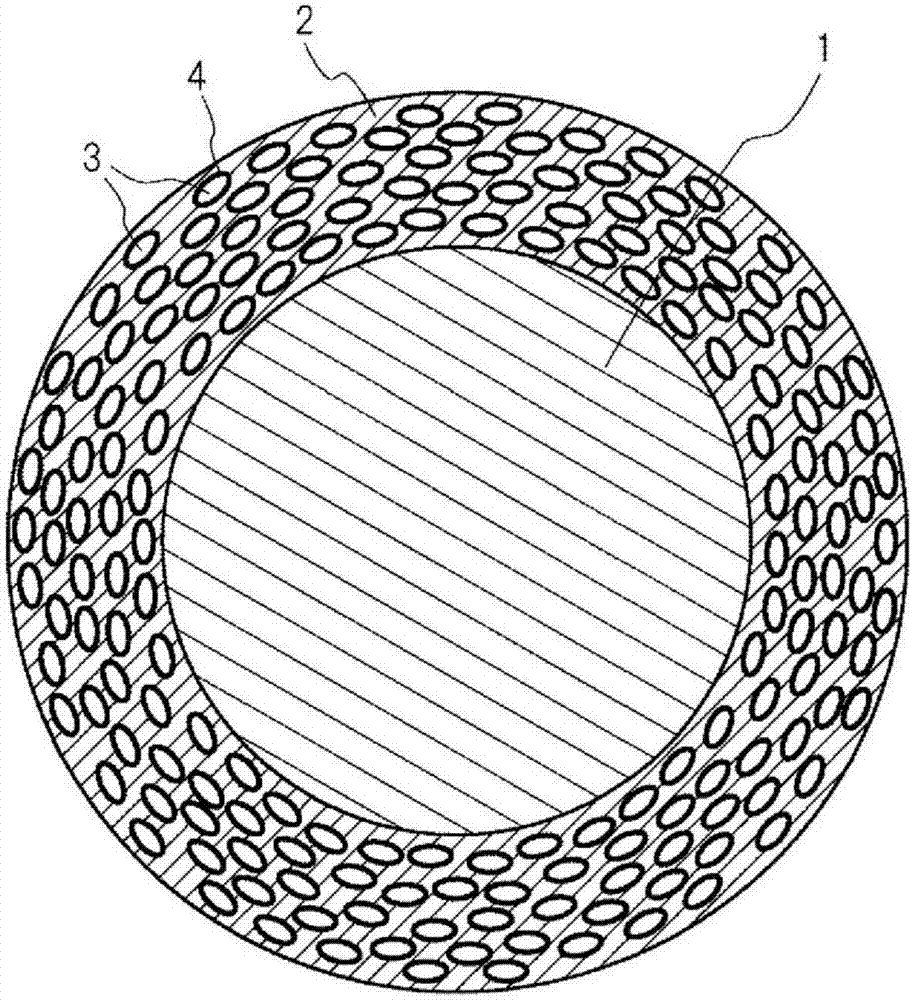

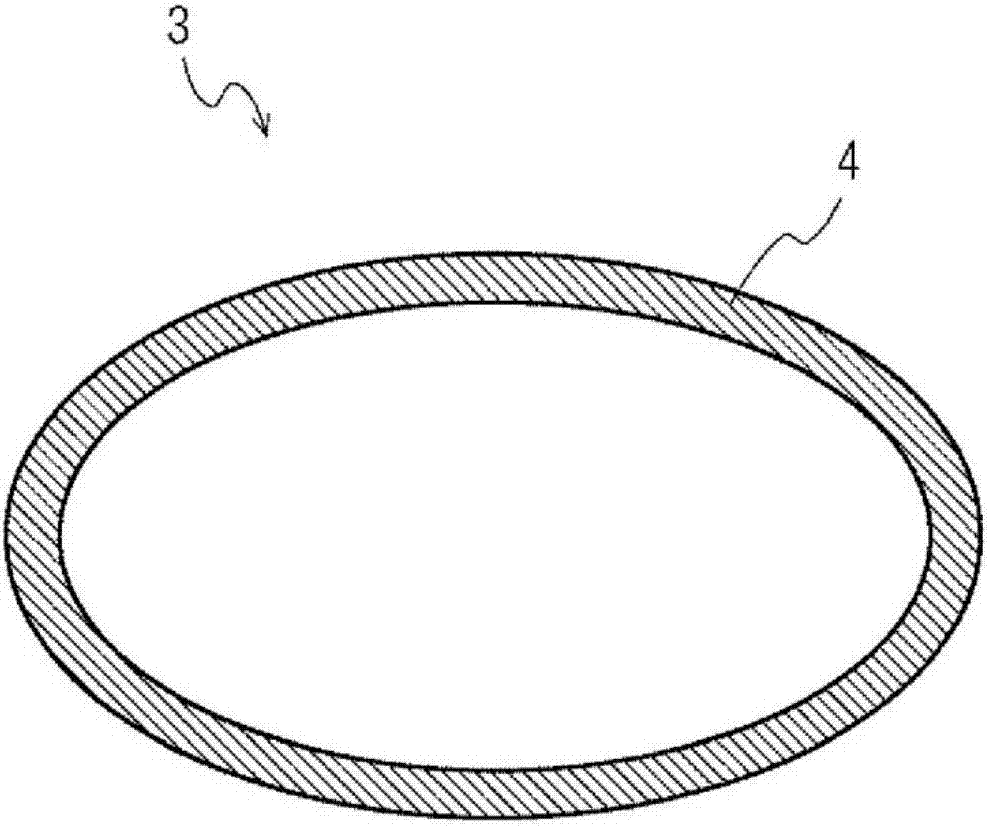

Insulated electric wire and varnish for forming insulating layer

ActiveUS20180033518A1Decrease propertyDecrease solvent resistancePlastic/resin/waxes insulatorsAuxillary non-insulated conductorsElectrical conductorEngineering

An insulated electric wire includes a linear conductor and one or a plurality of insulating layers formed on an outer peripheral surface of the conductor. At least one of the one or plurality of insulating layers contains a plurality of pores, outer shells are disposed on peripheries of the pores, and the outer shells are derived from shells of hollow-forming particles having a core-shell structure. A varnish for forming an insulating layer contains a resin composition forming a matrix and hollow-forming particles having a core-shell structure and dispersed in the resin composition. In the varnish, cores of the hollow-forming particles contain a thermally decomposable resin as a main component, and shells of the hollow-forming particles contain a main component having a higher thermal decomposition temperature than the thermally decomposable resin.

Owner:SUMITOMO ELECTRIC IND LTD +1

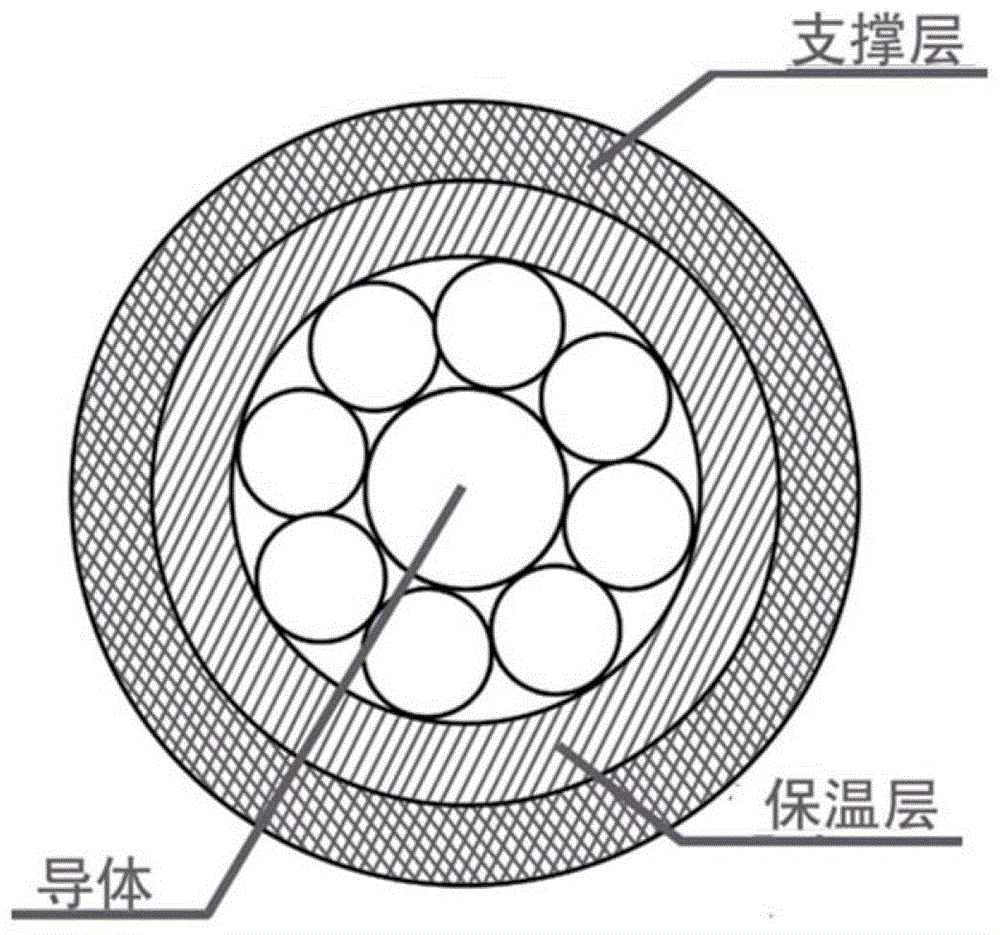

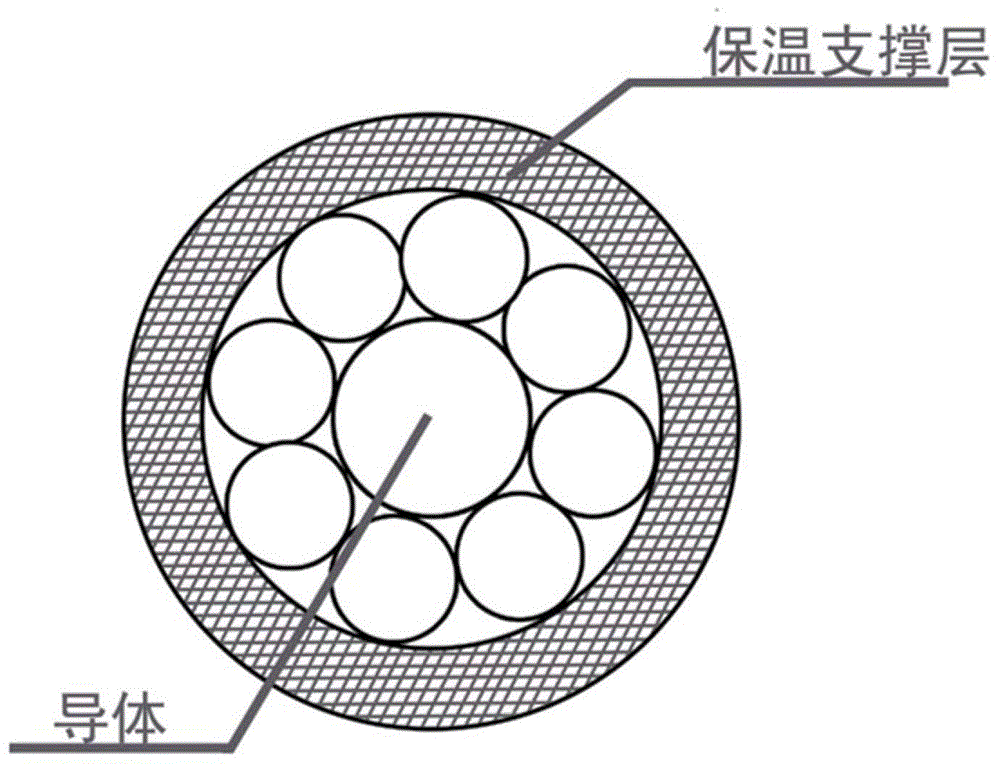

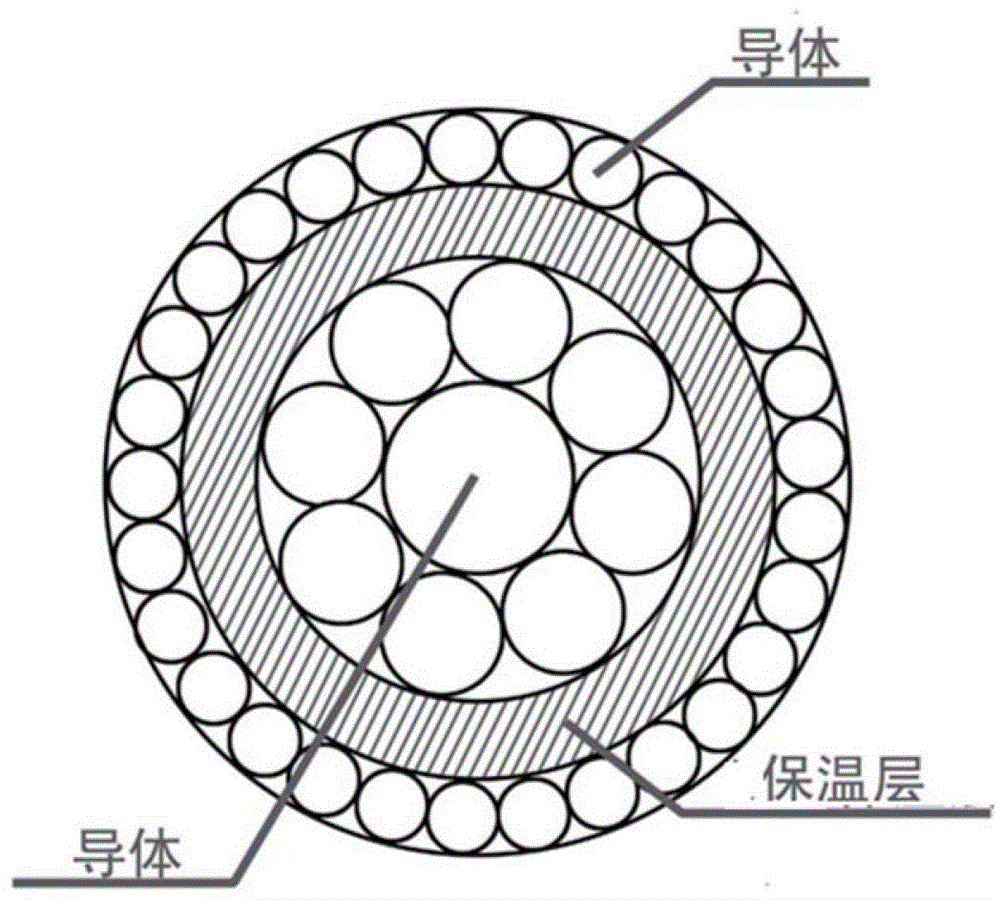

Transmission line to prevent snow and ice disaster

InactiveCN103337295AChange in thermal conductivityChange the convective heat transfer processAuxillary non-insulated conductorsInsulated cablesTransmission lineEngineering

The invention provides a transmission line to prevent a snow and ice disaster. The transmission line is provided with, from inside to outside, a conductor, an insulation layer and a support layer. The support layer contains rubber. By adding of the insulation layer and the insulating support layer around the surface of the conductor, heat loss of the transmission line, and a heat conduction process and a convective heat exchange process between the transmission line and the transmission line surrounding environment are changed; and an artificial "diffusing heat dam" which can overflow is produced, so that temperature field distribution of the transmission line, of the insulation layer, of the support layer, of a thin contacting layer between the transmission line and surrounding air, and of a transmission line surrounding air environment layer is changed. Accordingly, the probability of the glaze, snow rime and the like to form the snow and ice disaster of the transmission line is eliminated; and the effect of preventing the snow and ice disaster of the transmission line is realized.

Owner:STATE GRID CORP OF CHINA +1

Electric mattress and method for manufacturing same

ActiveCN104039988ASegmentation effect improvedEnsure the static magnetic effectAuxillary non-insulated conductorsMetal/alloy conductorsEngineeringLaser beams

Provided is a method for manufacturing an electric mattress. The method for manufacturing the electric mattress includes: a step of melting the surface of a steel plate by irradiating a laser beam to form a groove having first and second side surfaces and a bottom surface; and a step of air-blow or suction molding the steel plate byproduct formed on the first and second side surfaces and the bottom surface of the groove in the groove formation step to form an opening part through which at least one surface of the first and second side surfaces and the bottom surface is exposed.

Owner:浦项股份有限公司

Insulating electric wire and varnish for forming insulating layers

ActiveCN107112084APlastic/resin/waxes insulatorsAuxillary non-insulated conductorsElectrical conductorDecomposition

An insulating electric wire according to one embodiment of the present invention is provided with a linear conductor and one or more insulating layers layered on the outer circumferential surface of the conductor, wherein at least one of the one or more insulating layers includes a plurality of pores, an outer shell is provided on the circumferential edge portion of the pores, and the outer shell is derived from particles forming the hollow of a core-shell structure. Varnish for forming insulating layers according to one embodiment of the present invention is used for forming an insulating layer included in an insulating electric wire, and contains a resin composition forming a matrix and particles which are dispersed in the resin composition and which form the hollow of a core-shell structure, wherein the core of the hollow-forming particles contains a heat decomposable resin as a main component, and the heat decomposition temperature of the main component of the shell of the hollow-forming particles is higher than the heat decomposition temperature of the heat decomposable resin.

Owner:SUMITOMO ELECTRIC IND LTD +1

Electrodes and applications

InactiveUS20130233595A1Lamination ancillary operationsHybrid capacitor electrodesCapacitanceCarbon nanotube

Disclosed herein is an electrode comprising, a capacitive carbon material located on at least one surface of a thin. The capacitive carbon material typically comprises functionalized ultra-long carbon nanotubes and optionally another carbon allotrope or mixture of carbon allotropes with sufficiently high active surface area. . Methods of forming such electrodes are also disclosed.

Owner:MULTIPURE INT

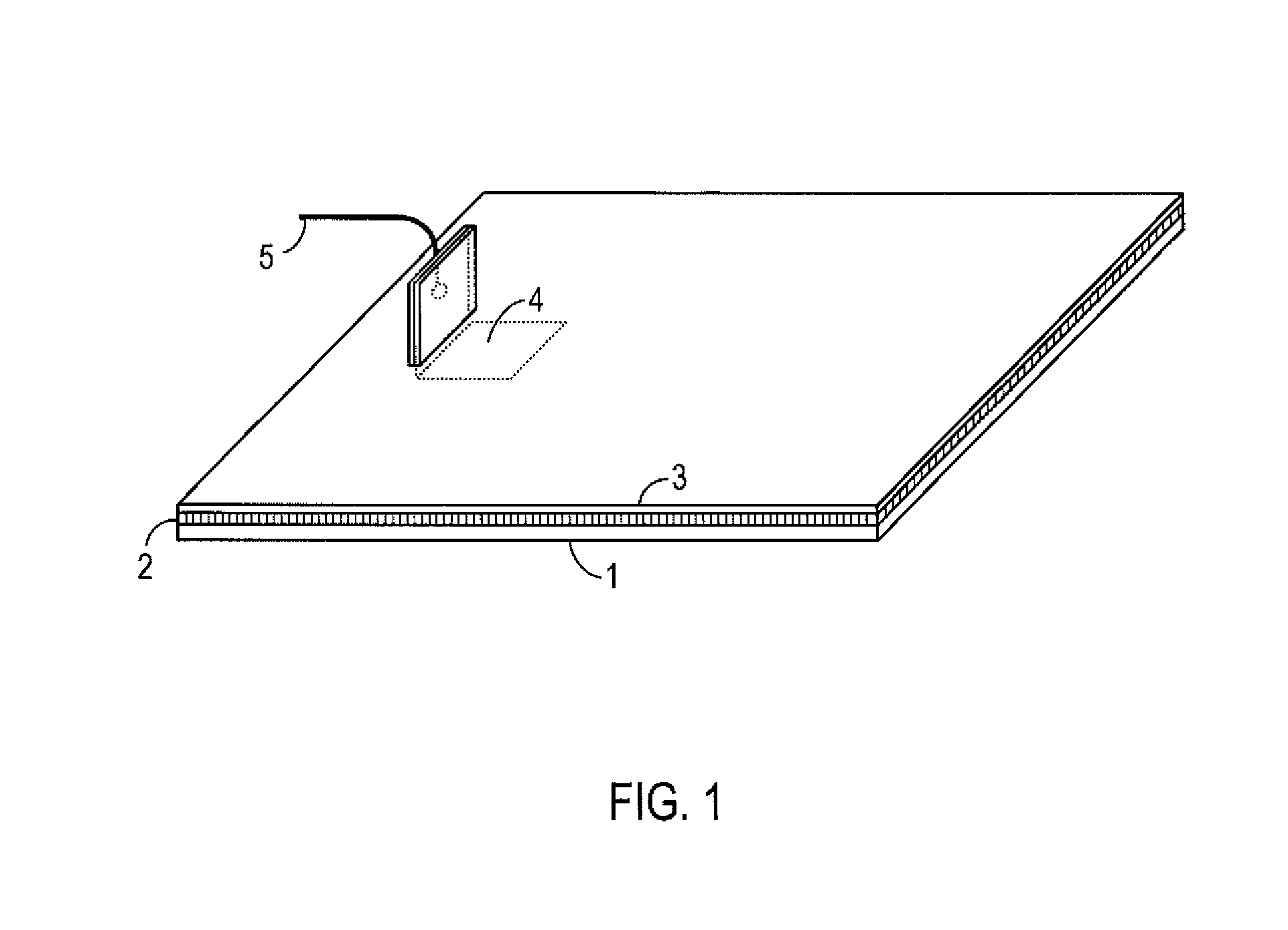

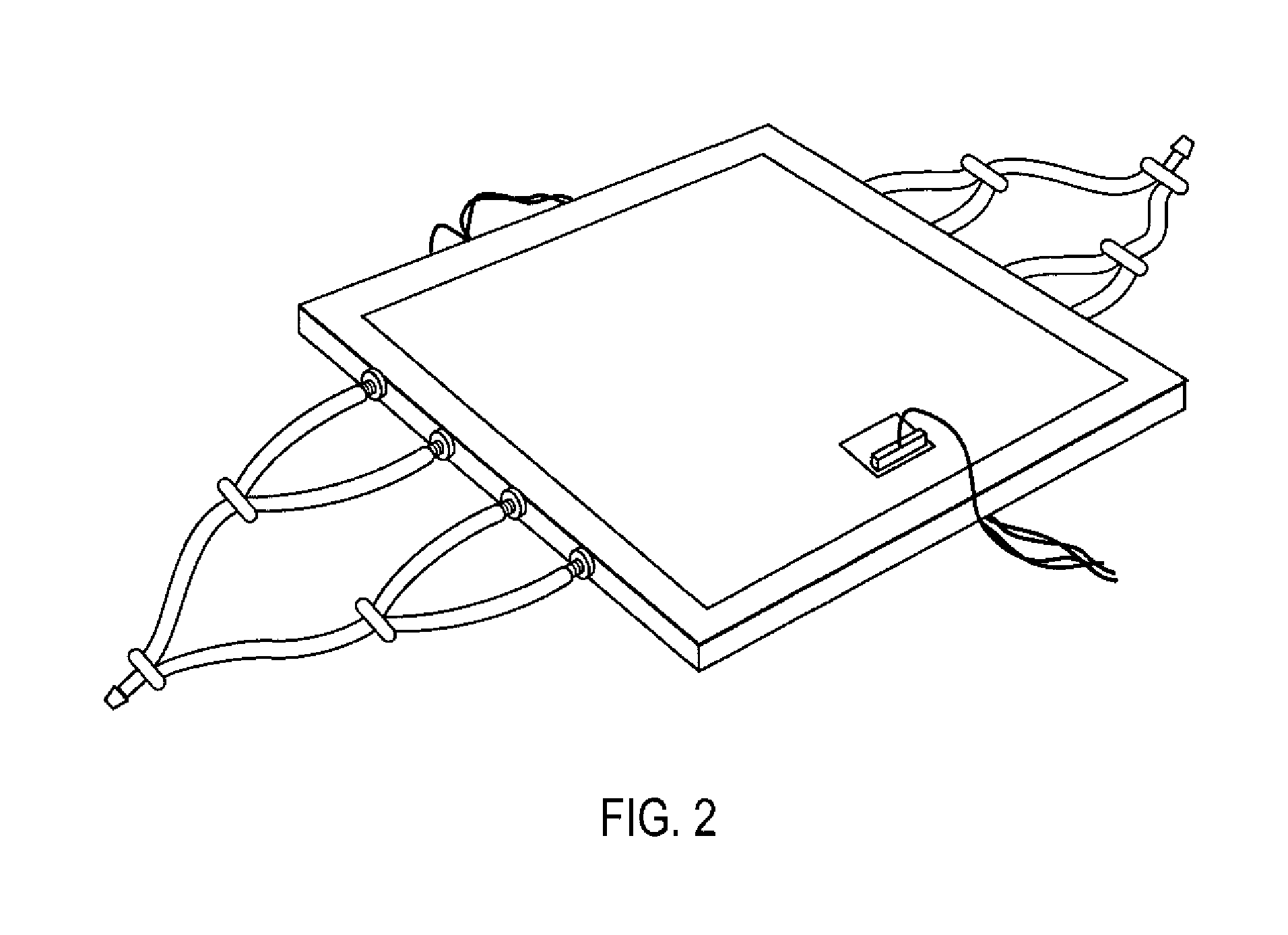

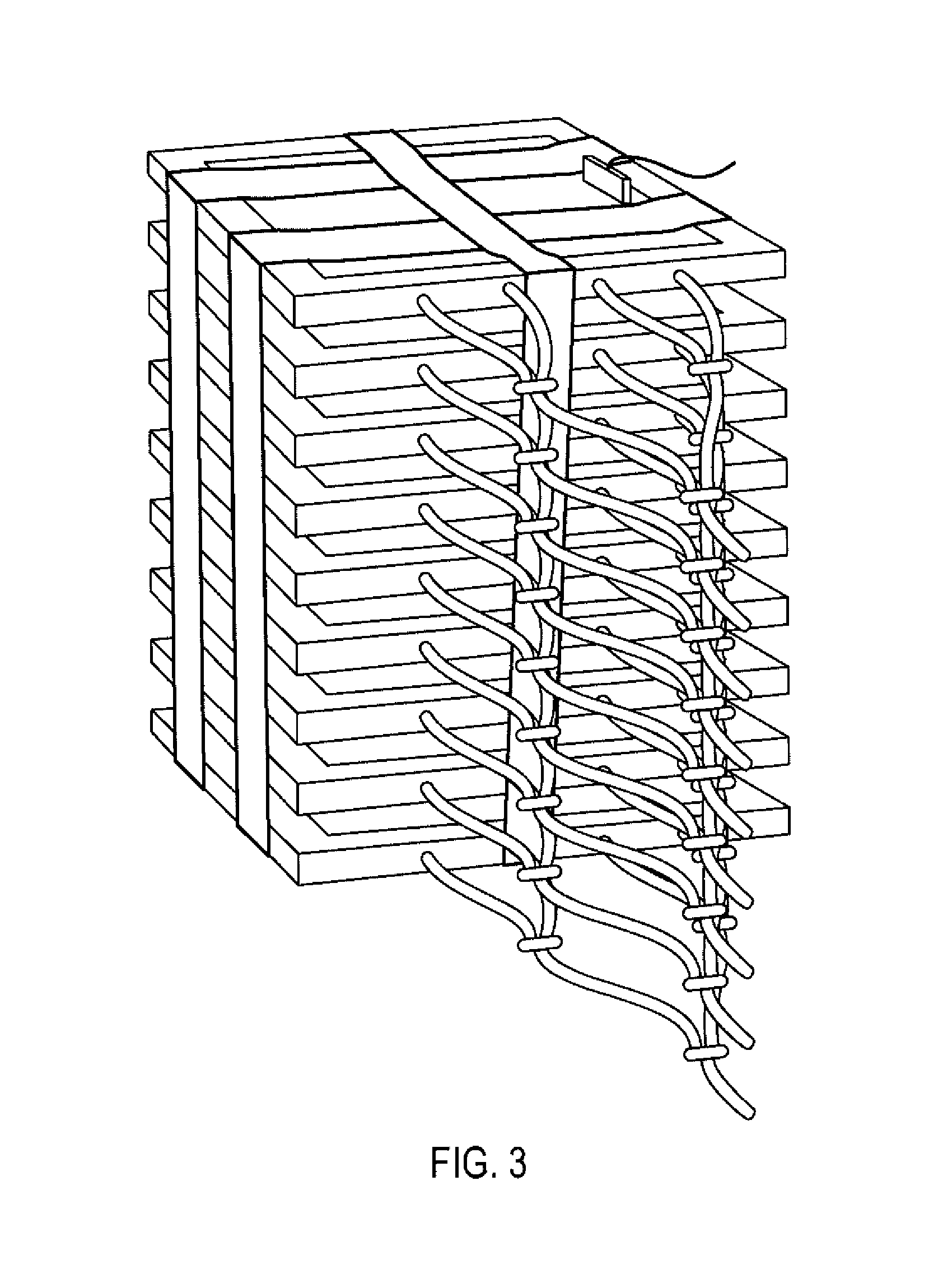

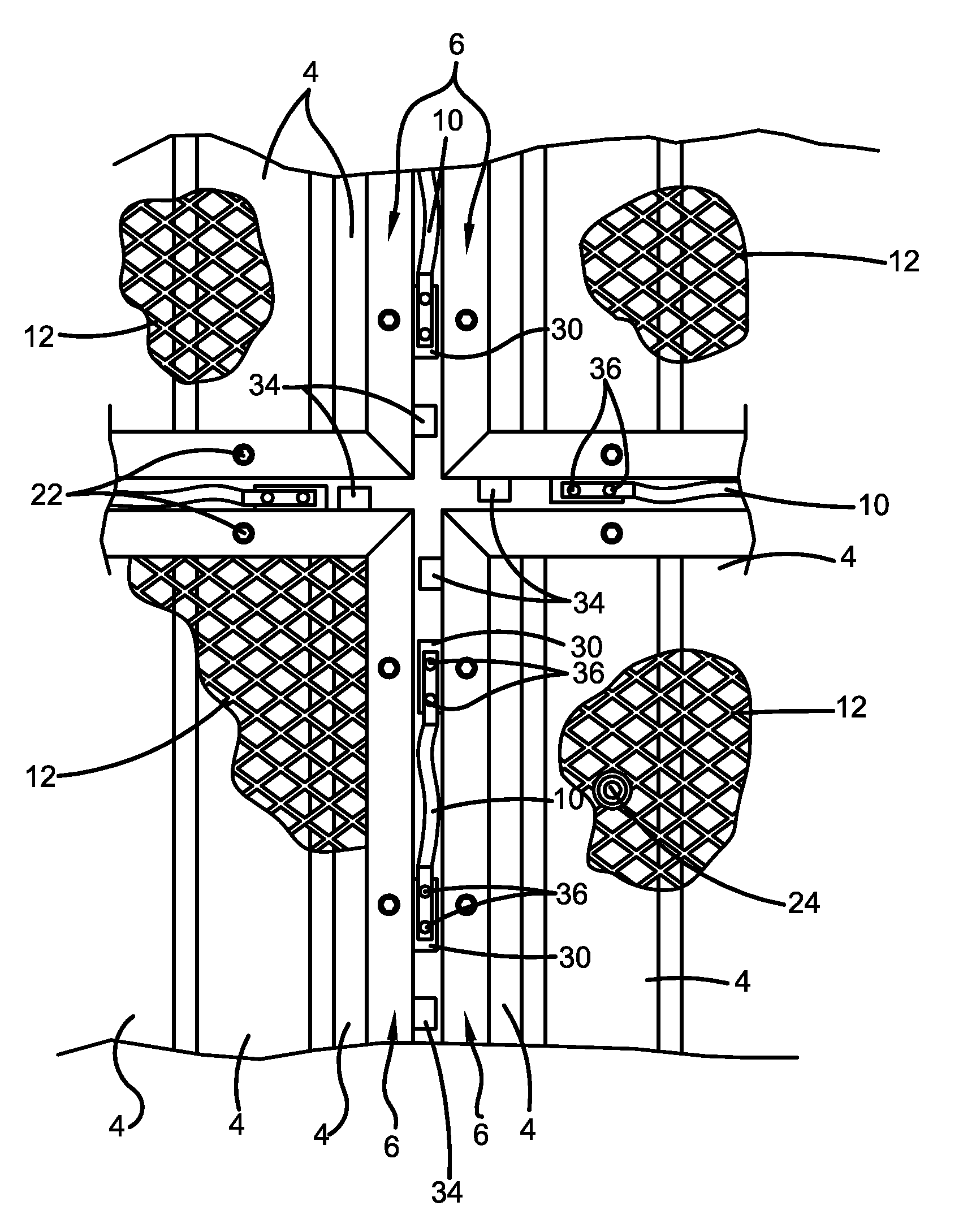

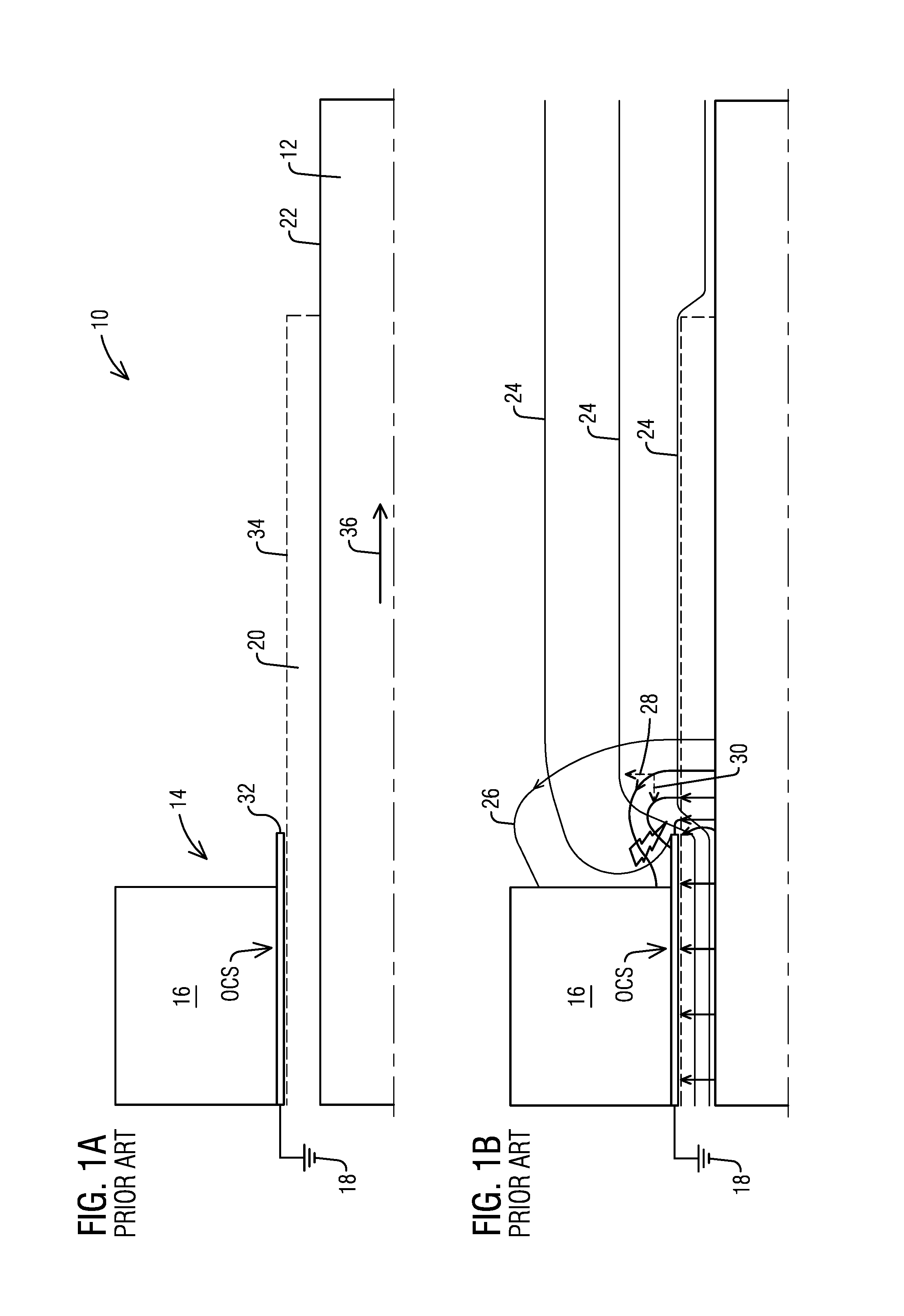

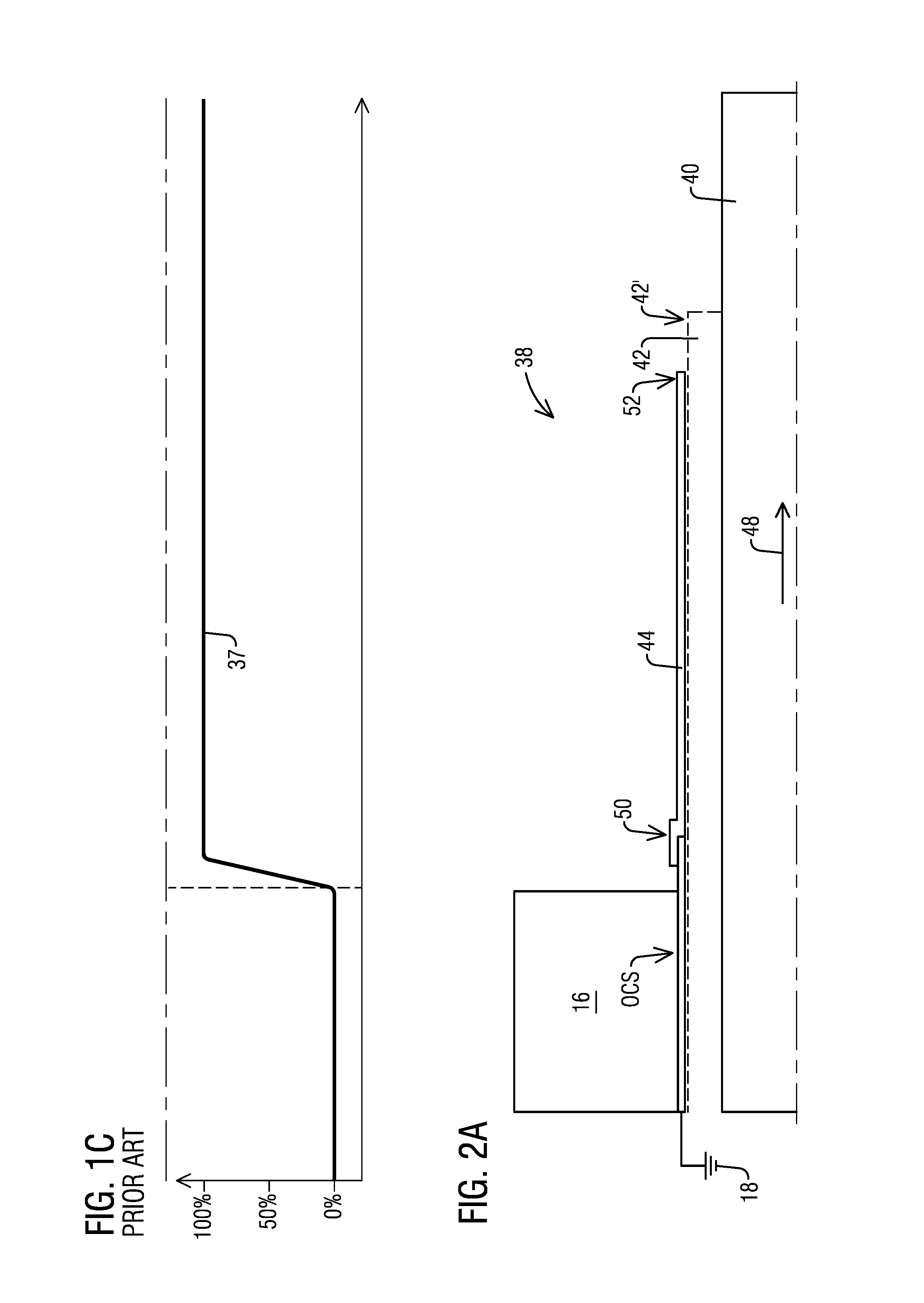

Timber access mat with grounding

A timber access mat having an electrical grounding feature includes an electrically conductive cover layer that is removably carried over the top of the body of the timber access mat. The electrically conductive cover layer can be formed from one or more sheets of expanded metal such as expanded steel. The layer is joined to a perimeter frame that includes offset connector tabs that allow mats to be positioned side-by-side. The connector tabs are paired with cable guides to protect the cable leads that connect the mats. The perimeter frame and conductive cover layer can be added to traditional timber access mats when electrical grounding is required and then removed and stored when not required.

Owner:KLEIN PARENT LLC

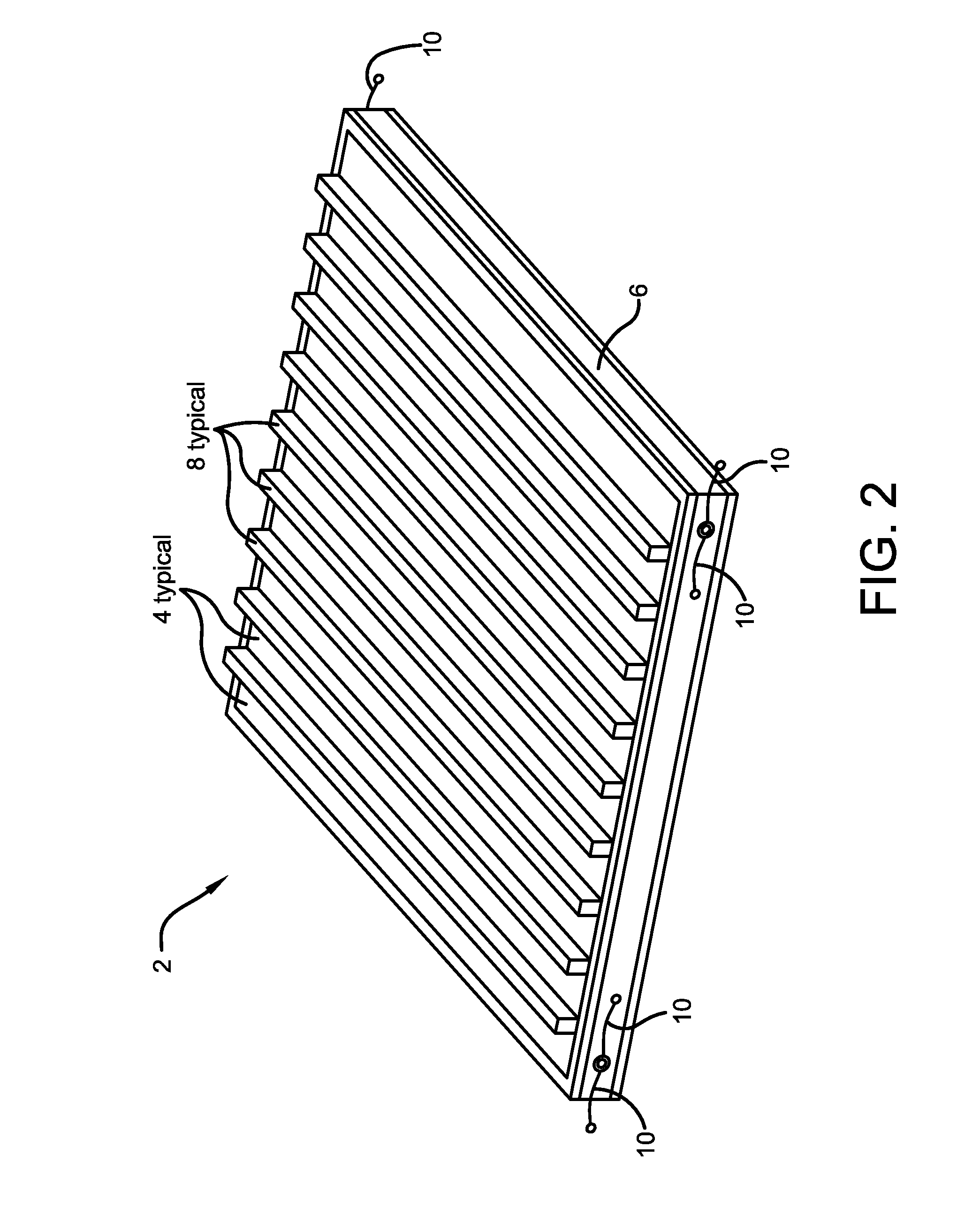

Electric conductor with graphene core and preparation method of electric conductor with graphene core

ActiveCN106128545AReduces total mechanical loadReduce skin effectSingle bars/rods/wires/strips conductorsAuxillary non-insulated conductorsElectrical conductorSkin effect

The invention discloses an electric conductor with a graphene core and a preparation method of the electric conductor with the graphene core. The electric conductor with the graphene core comprises the graphene core surrounded by a sheath, wherein the graphene core is formed by compressing graphene particles. By the electric conductor with the graphene core, the skin effect can be reduced to the maximal extent; the conductivity can be improved; the transmission loss is reduced; and the total mechanical load of a transmission line is reduced.

Owner:HANGZHOU CABLE +1

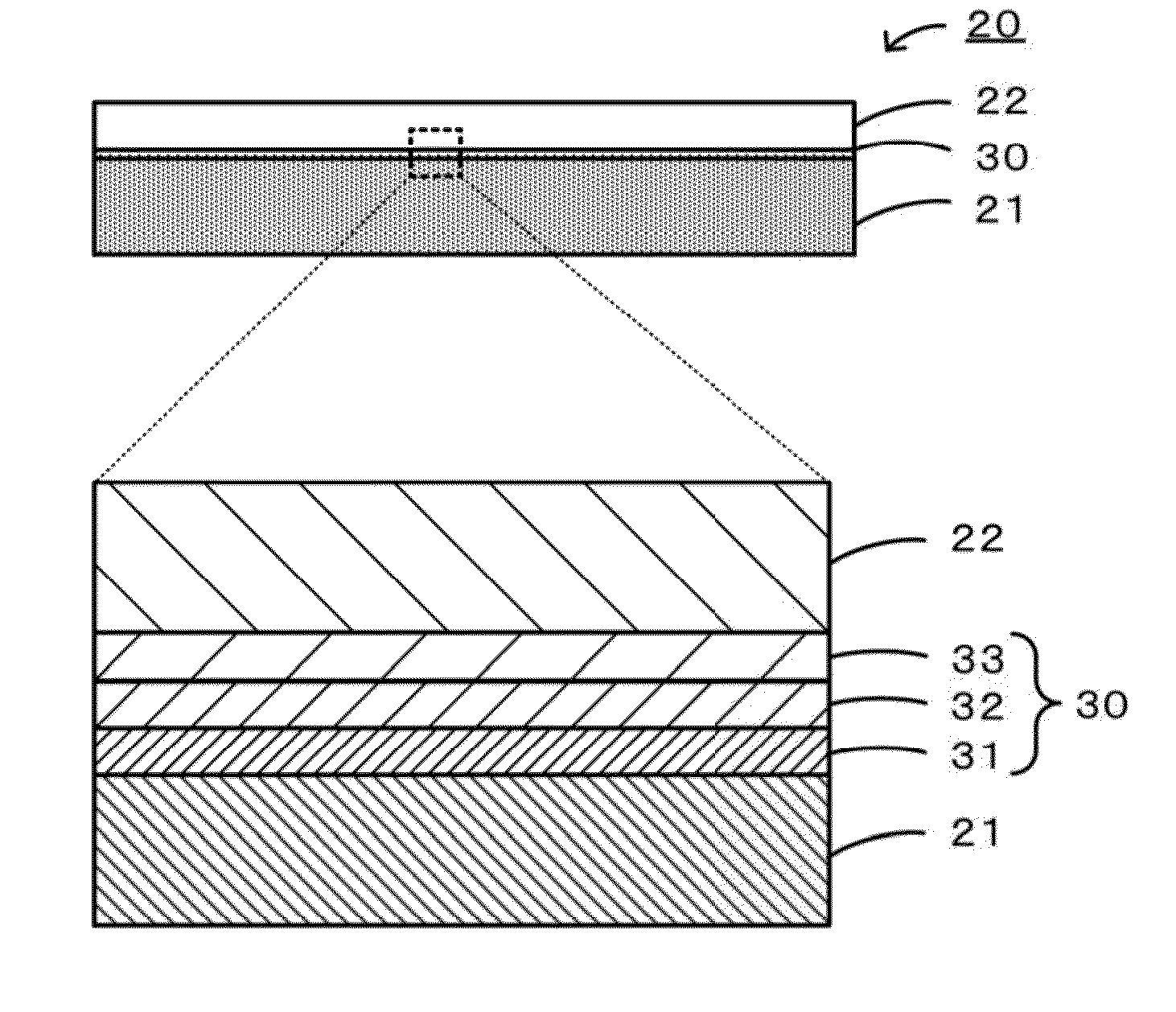

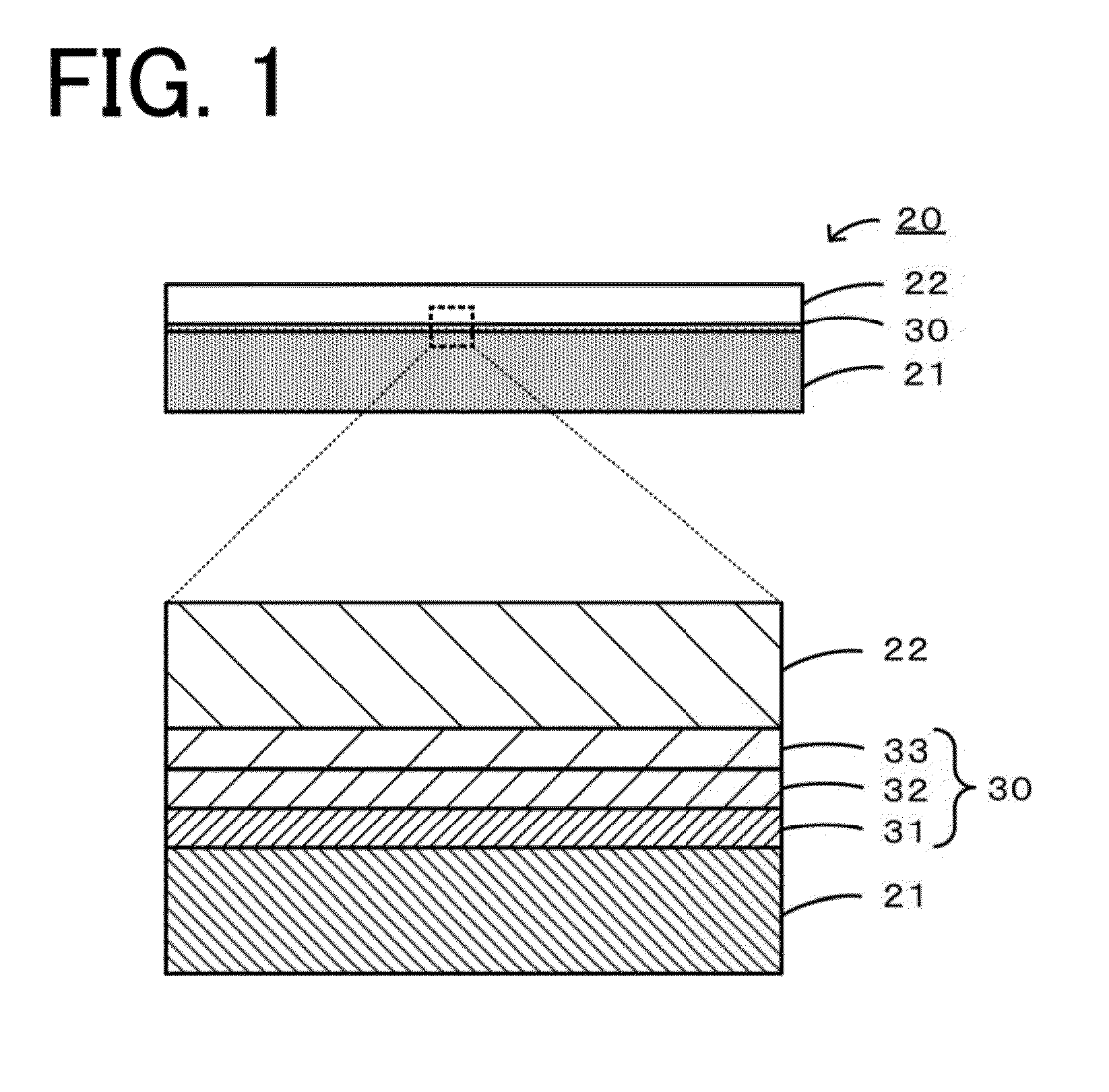

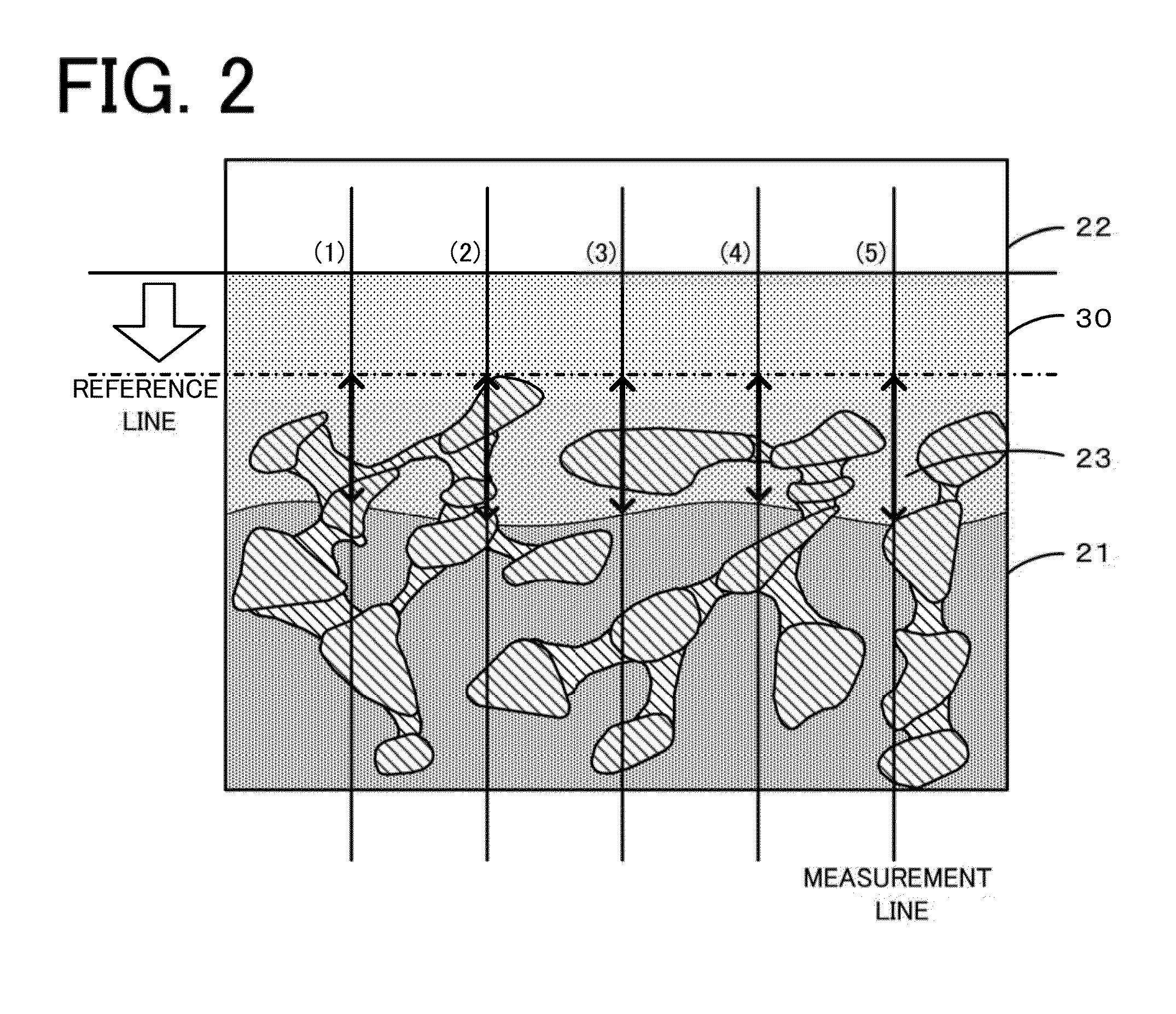

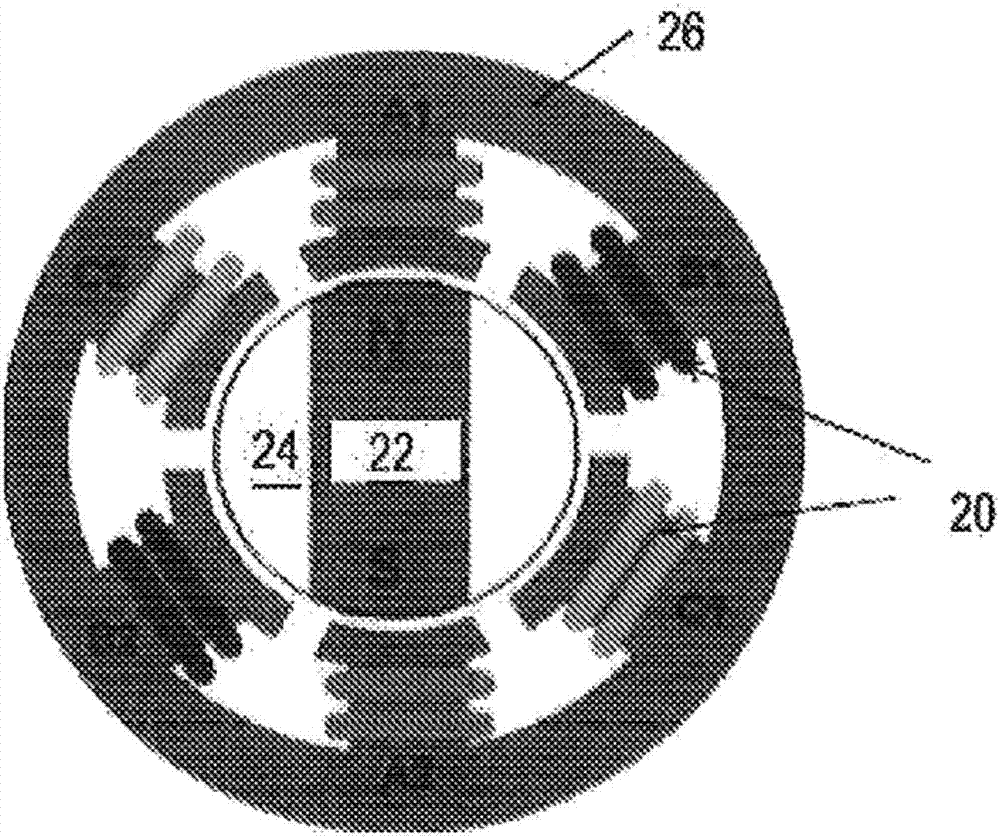

Joined body and method for manufacturing the same

ActiveUS20160099089A1Improve the immunityFirmly connectedExhaust apparatusApparatus for heat treatmentThermal expansionMetal

A joined body 20 includes comprises a first member 21, a second center 22 having a high coefficient of thermal expansion as compared to that of the first member 21, and a joint portion 30 which at least partially includes a mixed layer 33 containing metal of a transition metal and an oxide of the transition metal and which joins the first member 21 and the second member 22. In this joint portion 30, a first layer 31 containing a first oxide of a transition metal, a second layer 32 containing a second oxide of a transition metal having a low valence as compared to that of the first oxide, and the mixed layer 33 metal of a transition metal and an oxide thereof preferably are formed so as to form a multilayer structure.

Owner:NGK INSULATORS LTD

Coated overhead conductor

InactiveCN106062896AAuxillary non-insulated conductorsPretreated surfacesMechanical engineeringPolymer coating

A polymeric coating can be applied to an overhead conductor. The overhead conductor includes one or more conductive wires, and the polymeric coating layer surrounds the one or more conductive wires. The overhead conductor can operate at a lower temperature than a bare overhead conductor with no polymeric coating layer when tested in accordance with ANSI C119.4 method. Methods of applying a polymeric coating layer to an overhead conductor are also described herein.

Owner:GENERAL CABLE TECH CORP

High temperature insulated aluminum conductor

InactiveCN107112088AWindings insulation materialElectrolysis componentsElectrical conductorAluminum metal

The present invention relates to an aluminum or aluminum alloy metal electrical conductor having a high temperature resistant electrically insulating metal oxide coating layer including at least one non-aluminum metal oxide chemically bonded thereto and methods of making and using same.

Owner:HENKEL KGAA

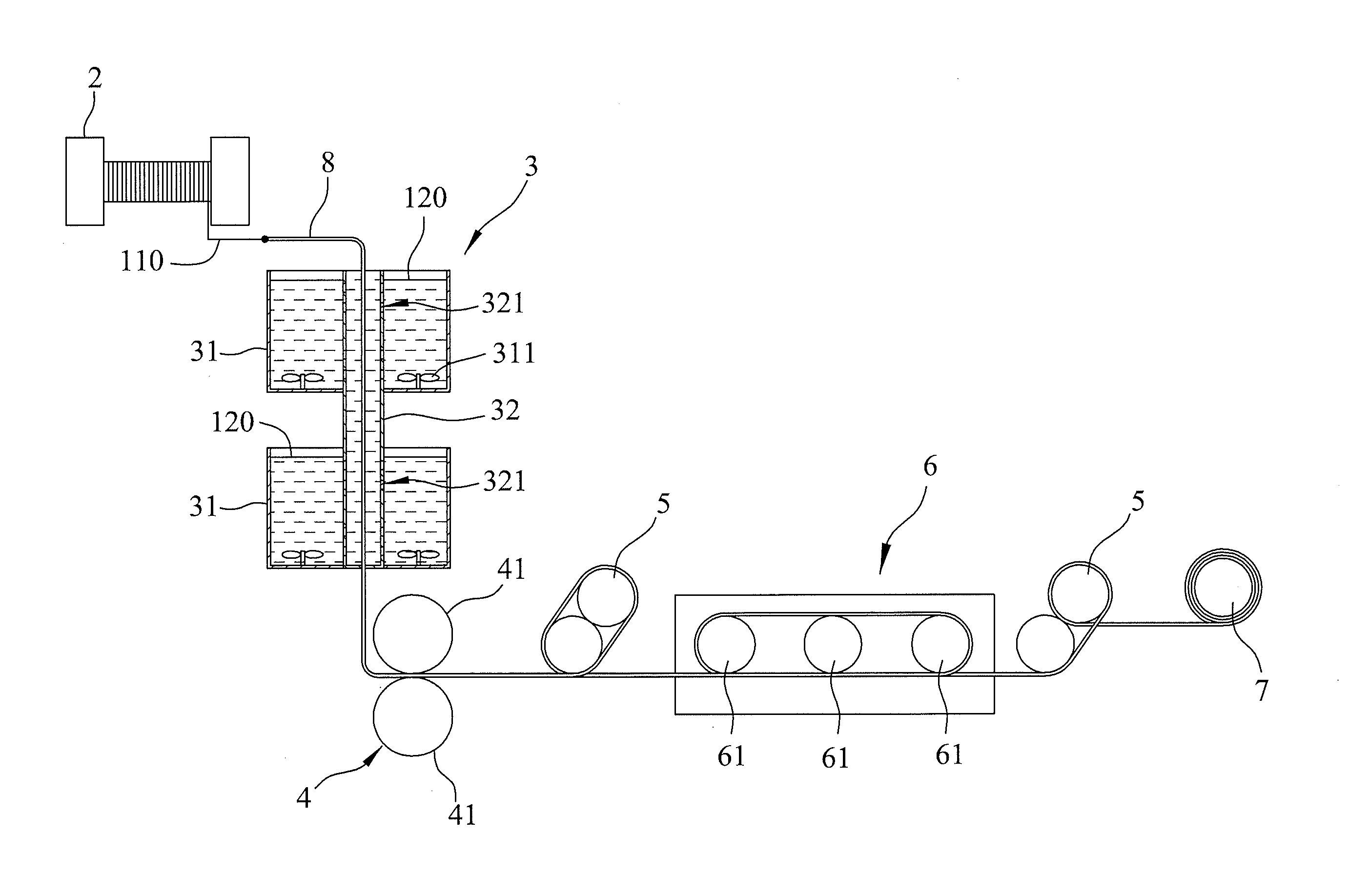

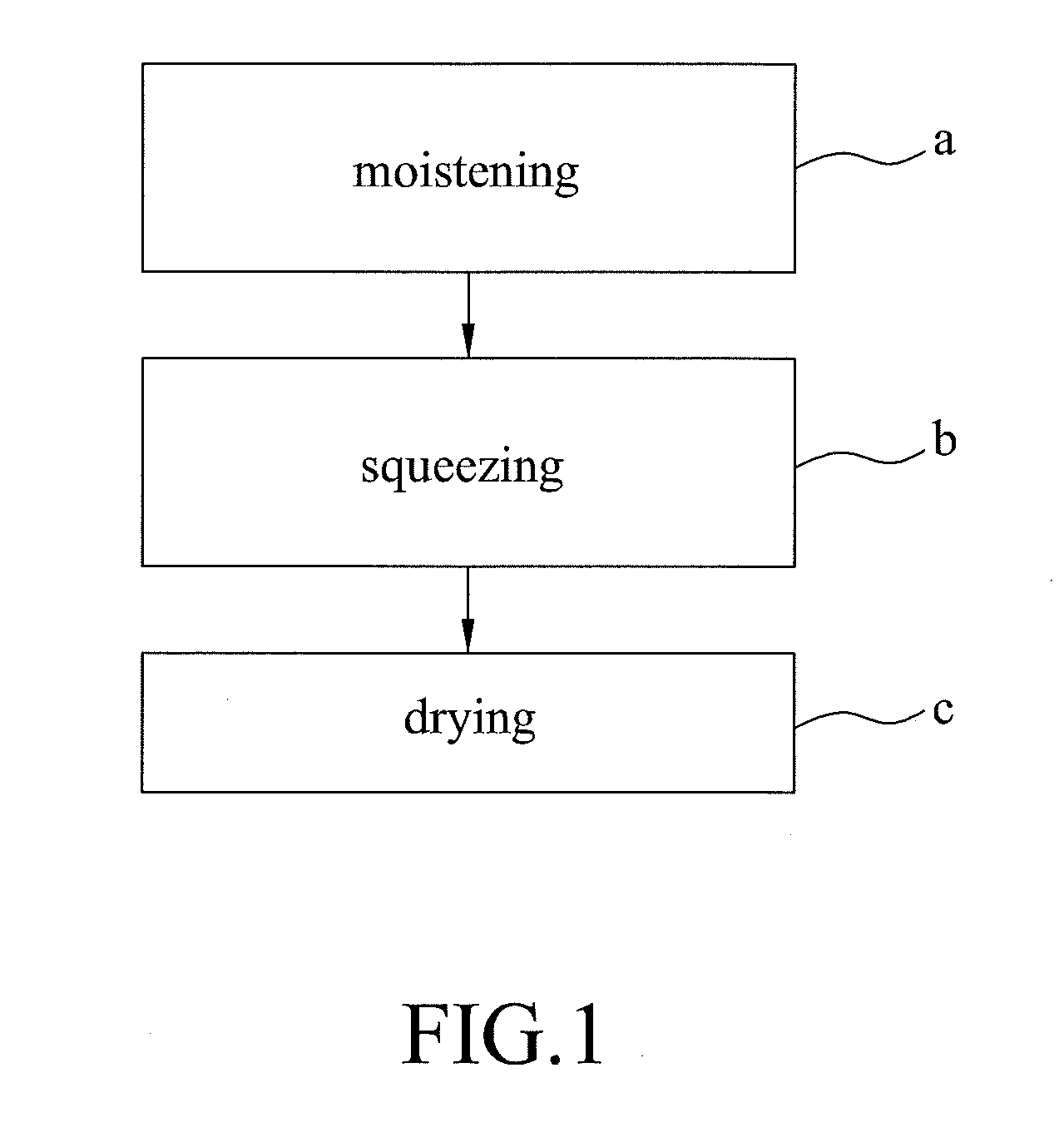

Method for fabricating a conductive yarn and conductive yarn fabricated by the method

InactiveUS20140318857A1Improve conductivityShorten the processing periodMaterial nanotechnologyLubricating devicesPolymer scienceElectrically conducting yarn

A method for fabricating a conductive yarn includes the steps of: moistening a preformed yarn with a conductive slurry to prepare the preformed yarn absorbed with the conductive slurry; and drying the preformed yarn absorbed with the conductive slurry. The conductive slurry includes a conductive nanometer structure, a solvent, and a resin component. The conductive nanometer structure has an aspect ratio sufficient to permit binding of the conductive nanometer structure to the preformed yarn.

Owner:ASIATIC FIBER CORP

Copper strip flexible connection part facilitating heat dissipation

InactiveCN107481782AIncrease cooling areaImprove cooling effectSingle bars/rods/wires/strips conductorsAuxillary non-insulated conductorsCopper foilTin

The invention discloses a copper strip flexible connection part facilitating heat dissipation, and the connection part comprises a copper strip, projections, a heat dissipation hole, a first copper foil piece, a second copper foil piece, a third copper foil piece, a convex block, and a tin-coated heat dissipation layer. The external surfaces of the two sides of the copper strip are provided with projections, thereby increasing the heat dissipation area of the surface of the copper strip, and enabling the copper strip to be easier to cool. A connection fixing part is provided with a connection fixing hole, and the side surface, perpendicular to the connection fixing hole, of the connection fixing part is provided with a heat dissipation hole, thereby solving a problem that a large amount of heat is liable to be generated at a copper strip flexible connection point, and achieving the timely and effective heat dissipation function. The external surfaces of the convex blocks on the first and second copper foil pieces and the external surface of the convex block on the third copper foil piece are welded together, thereby achieving the forming of through holes between the internal convex blocks of the copper strip flexible connection part, and facilitating the heat dissipation. The copper strip is provided with the tin-coated heat dissipation layer, and the tin-coated heat dissipation layer is good in heat dissipation effect, thereby facilitating the heat dissipation of the copper strip, and solving a problem that a conventional large-current copper strip flexible connection part is difficult to cool.

Owner:湖北华品科技发展有限公司

Corrosion-resistant anti-creeping copper core conductor

ActiveCN106205763ANot easily oxidizedImprove compatibilitySingle bars/rods/wires/strips conductorsConductive materialPotassiumElectrochemical corrosion

The invention discloses a corrosion-resistant anti-creeping copper core conductor. The copper core conductor is composed of a copper core conductor main body, a buffer layer sputtered on the copper core conductor main body and a silicon thin layer evaporated on the buffer layer; a small amount of elements of boron, silicon, phosphorous, sulfur, magnesium, silver, potassium and molybdenum are added on the copper core conductor main body, the buffer layer is an aluminum nitride layer; one layer of buffer layer is firstly sputtered on the surface of the copper core conductor and then one layer of silicon thin layer is evaporated on the buffer layer, so that the copper core conductor and the silicon thin layer have good compatibility, the lattice mismatching and like defects of the metal copper and the silicon are overcome; the outer surface of the copper core conductor is hard to oxidize through the adoption of the silicon thin layer, thereby avoiding the electrochemical corrosion; and meanwhile, the structure design of the traditional power transmission conductor is broken through, one layer of semiconductor layer is covered on the outer surface of the copper core conductor and then an insulating layer is used for wrapping on the semiconductor layer; the electricity loss produced in power transmission is less, the electric creepage or the electric shock accident can be avoided even if the insulating outer layer is damaged.

Owner:安徽樵森电气科技股份有限公司

Electrical conduction device, overhang corona shielding arrangement and method for producing an overhang corona shielding

InactiveUS20140345907A1High dielectric strengthWindings insulation shape/form/constructionSingle bars/rods/wires/strips conductorsEngineeringElectrical conduction

An electrical conduction device is provided having an electrically conductive conduction element and an electrically insulating sheathing surrounding said conduction element at least in regions. An overhang corona shielding in the form of a coating composed of a material having a resistivity that increases towards an end of the sheathing is arranged on the sheathing at an outer side. An overhang corona shielding arrangement and a method for producing an overhang corona shielding are also provided.

Owner:SIEMENS AG

Electrical conduction device, overhang corona shielding arrangement and method for producing an overhang corona shielding

InactiveUS9396837B2High dielectric strengthWindings insulation shape/form/constructionSingle bars/rods/wires/strips conductorsEngineeringElectrically conductive

An electrical conduction device is provided having an electrically conductive conduction element and an electrically insulating sheathing surrounding said conduction element at least in regions. An overhang corona shielding in the form of a coating composed of a material having a resistivity that increases towards an end of the sheathing is arranged on the sheathing at an outer side. An overhang corona shielding arrangement and a method for producing an overhang corona shielding are also provided.

Owner:SIEMENS AG

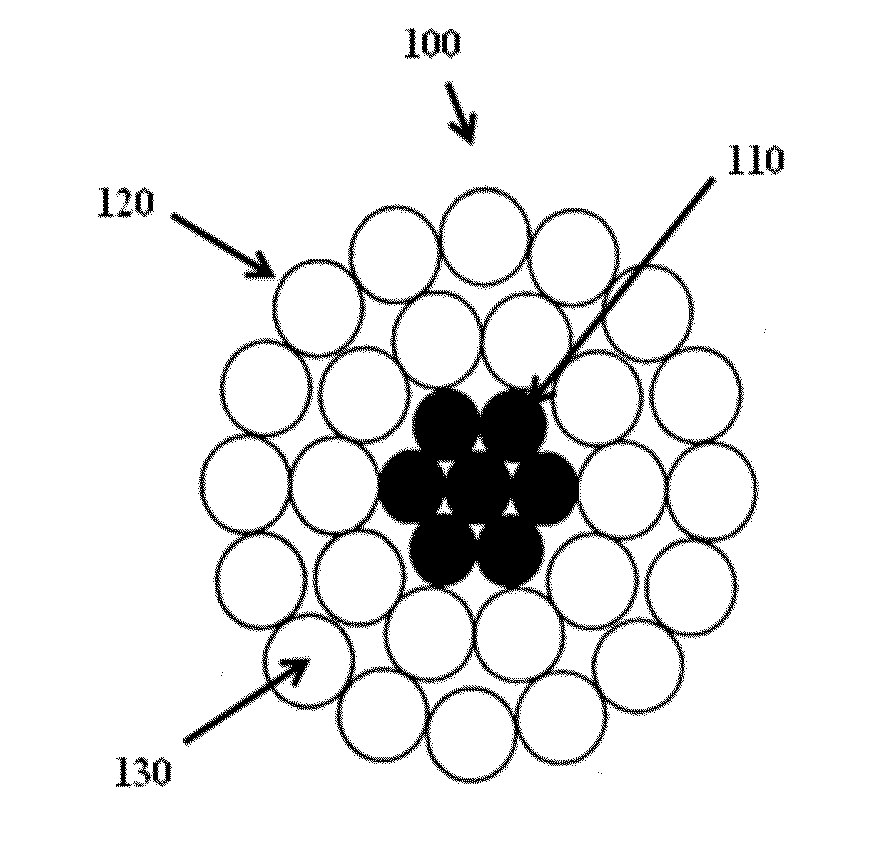

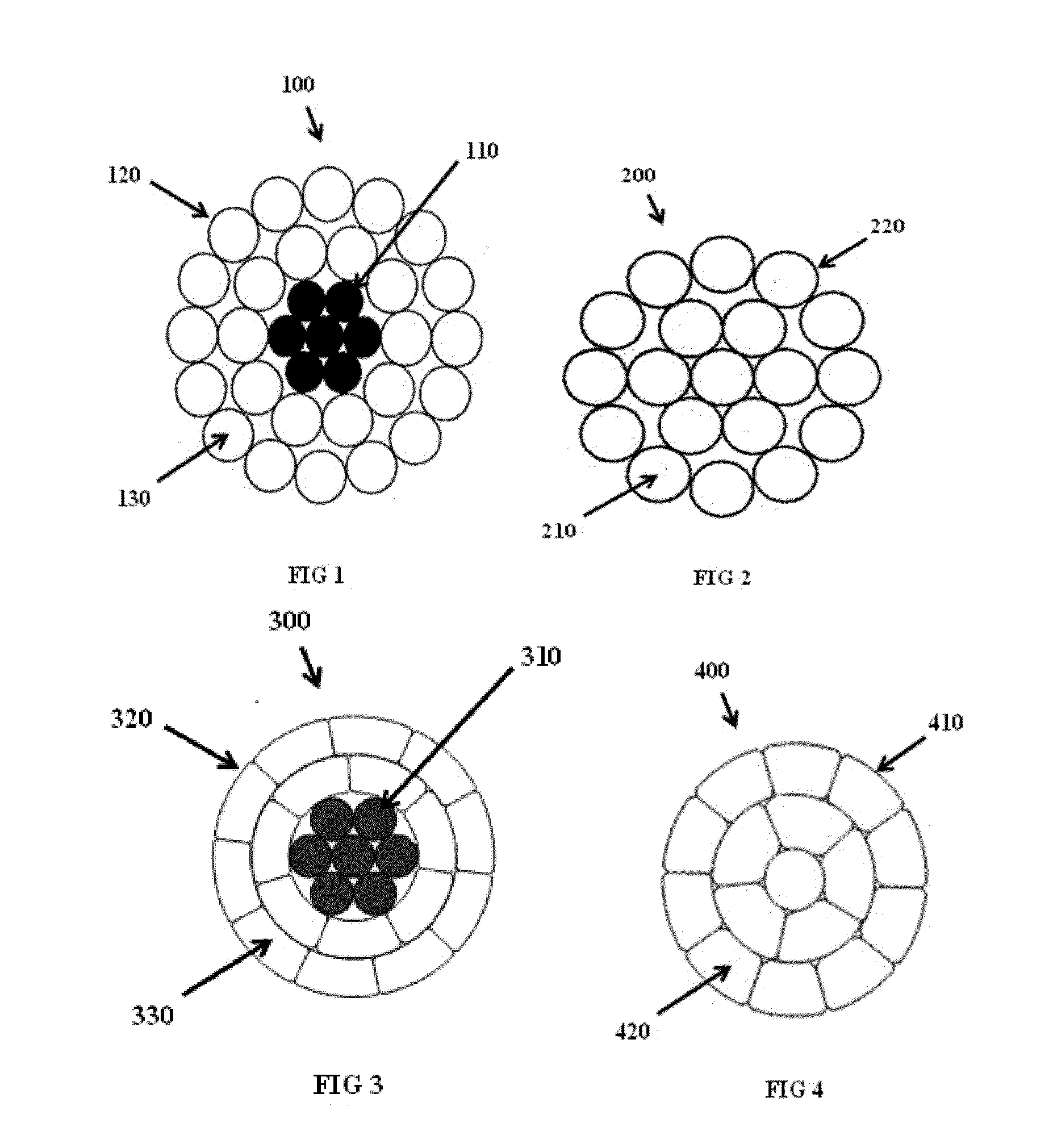

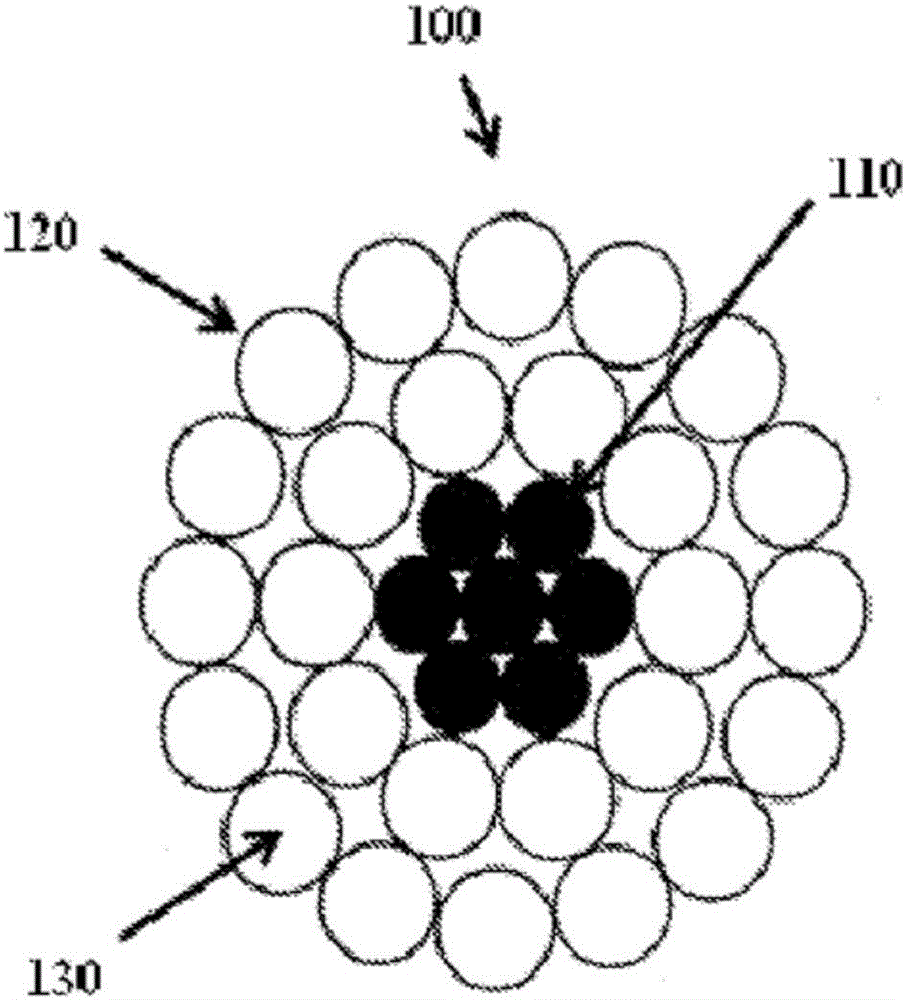

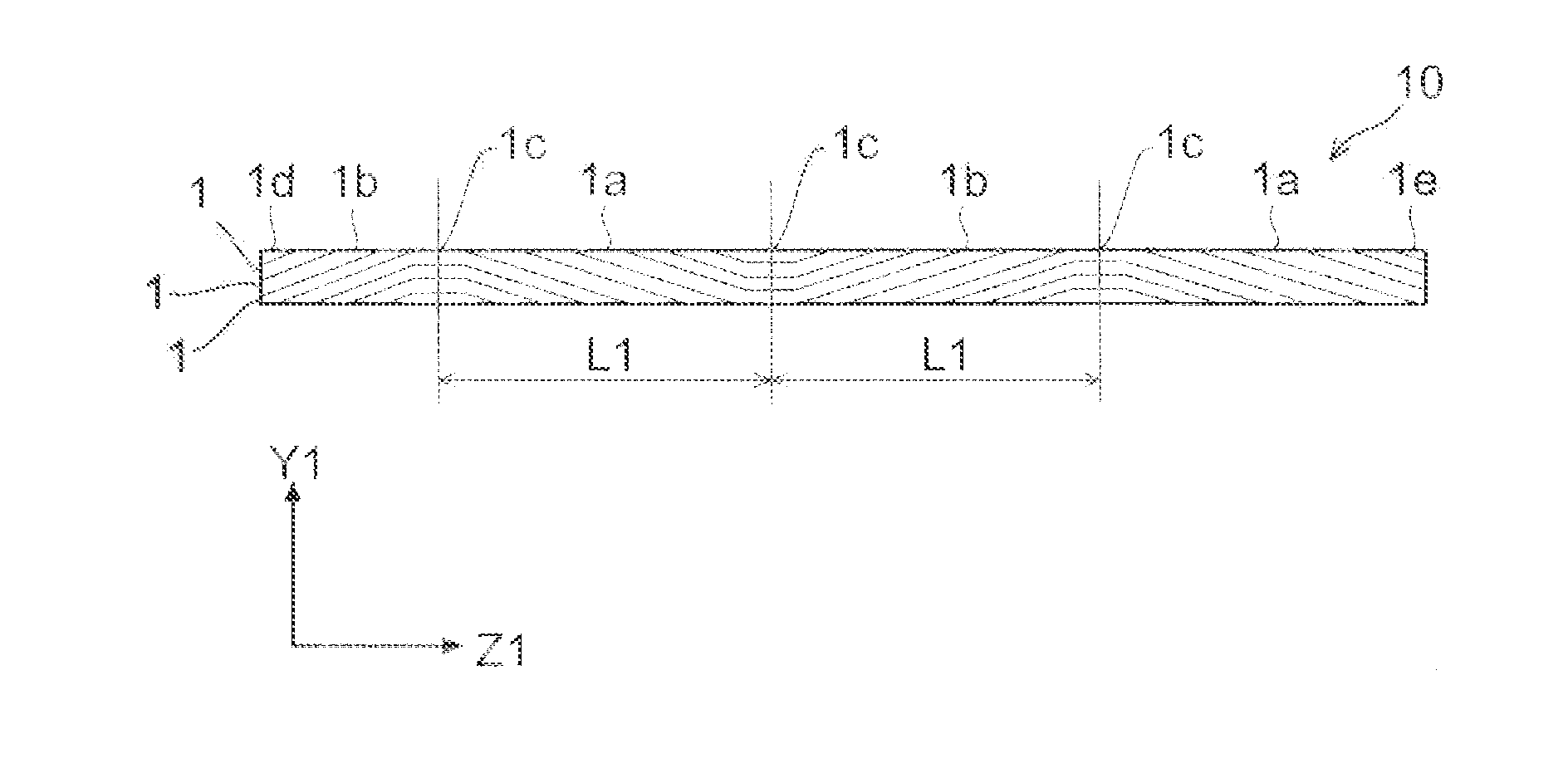

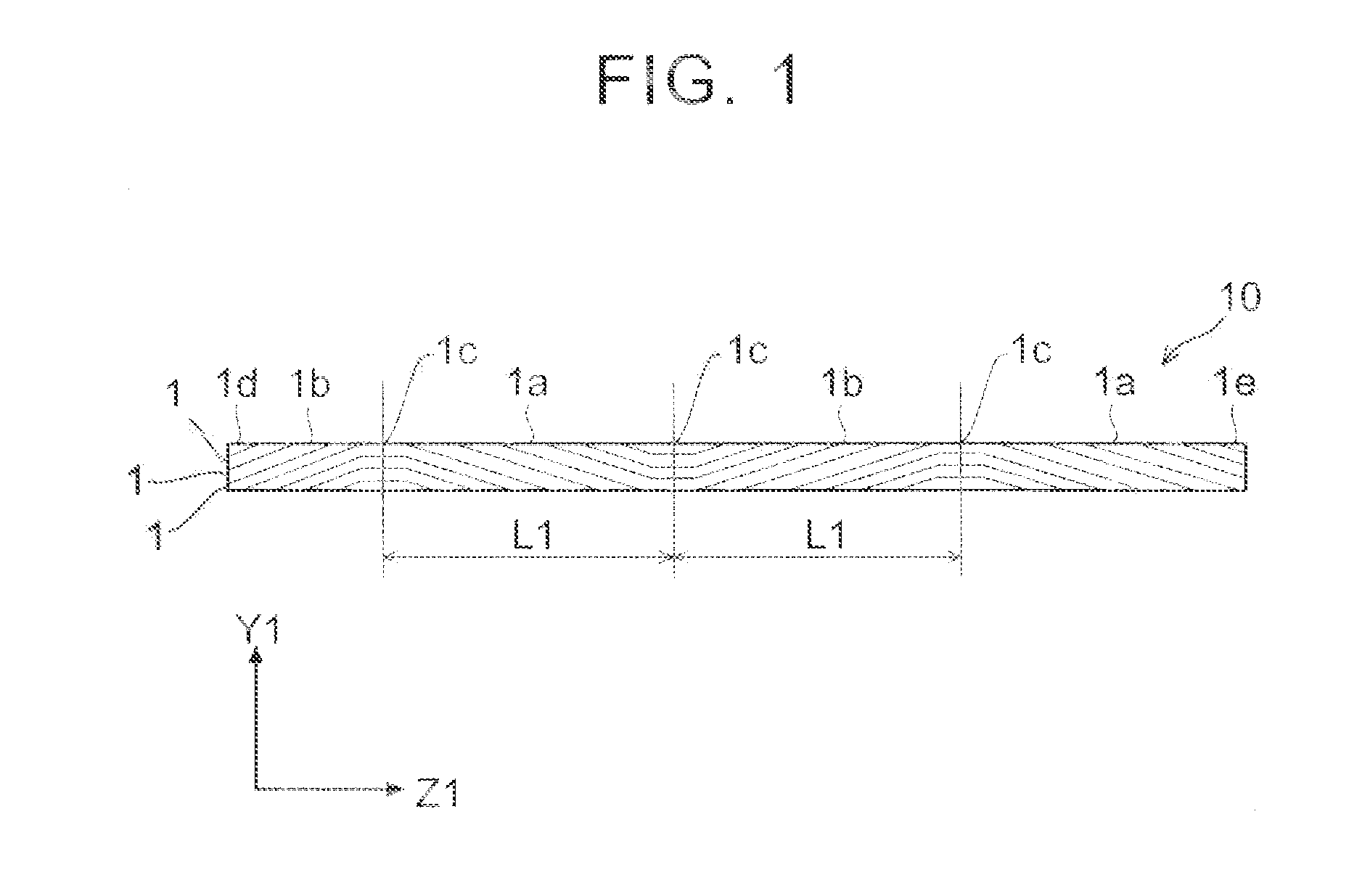

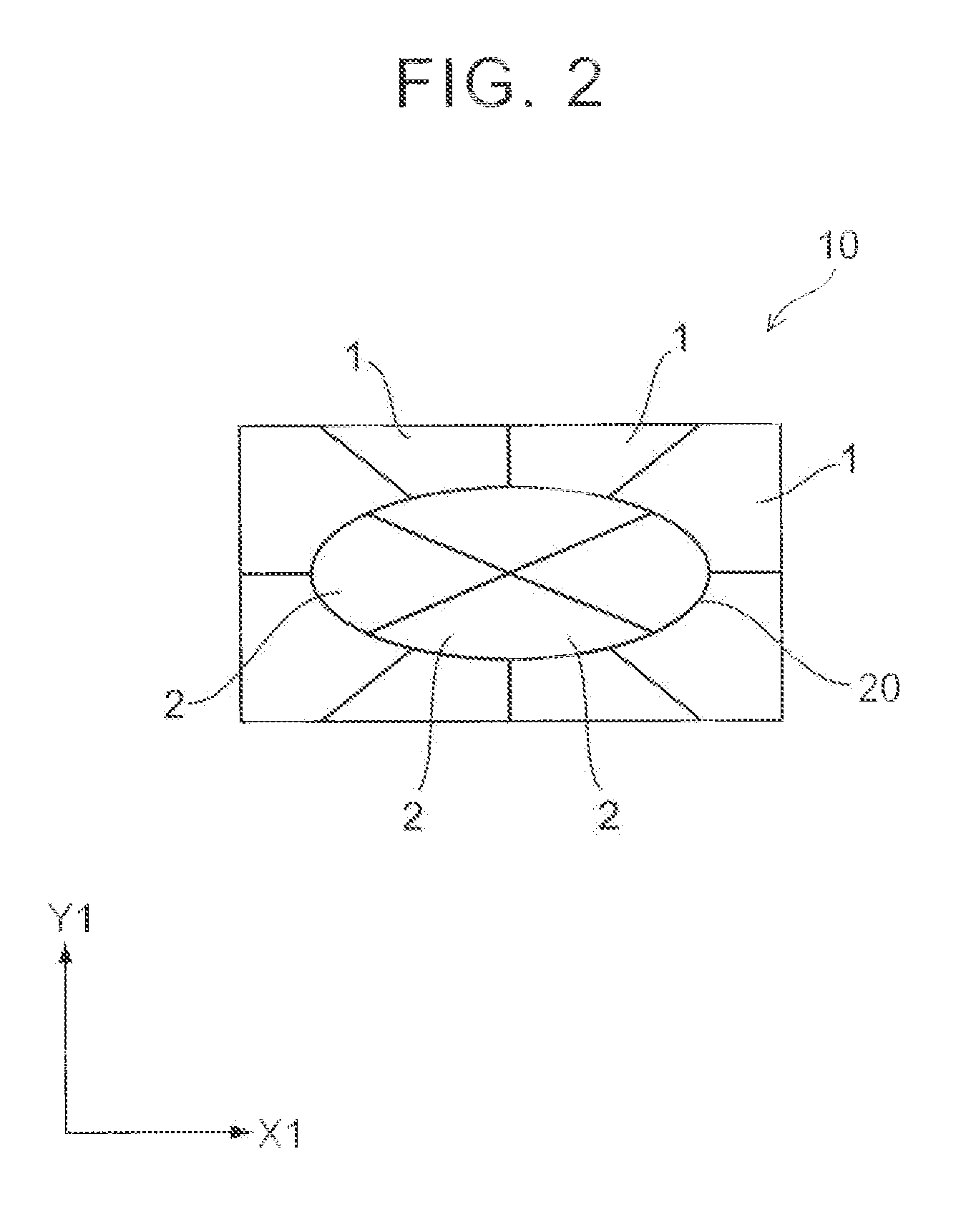

Assembled conductor and manufacturing method for assembled conductor

InactiveUS20160027551A1Restraint torsionSuppression of distortionLine/current collector detailsAuxillary non-insulated conductorsElectrical conductorEngineering

The invention provides an assembled conductor, which is formed by rolling a conductor bundle including a central conductor and a peripheral conductor arranged around the central conductor. The central conductor has a shape in which a right-twisted portion of the central conductor and a left-twisted portion of the central conductor are arranged alternately in predetermined intervals. The right-twisted portion of the central conductor extends from one end side of the central conductor to the other end side of the central conductor and is twisted in a clockwise direction, and the left-twisted portion of the central conductor extends from the one end side of the central conductor to the other end side of the central conductor and is twisted in a counterclockwise direction. The peripheral conductor is arranged around the central conductor so that a twist direction of the peripheral conductor becomes opposite to a twist direction of the central conductor.

Owner:TOYOTA JIDOSHA KK

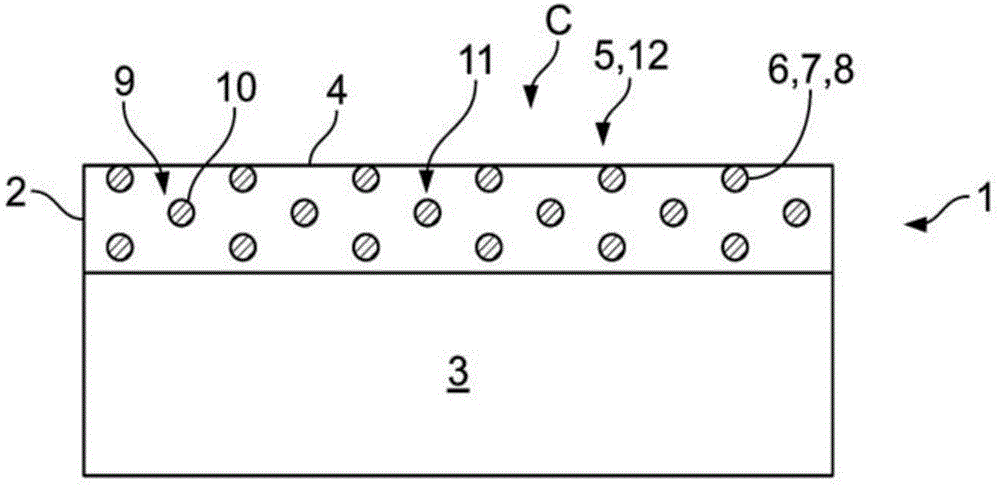

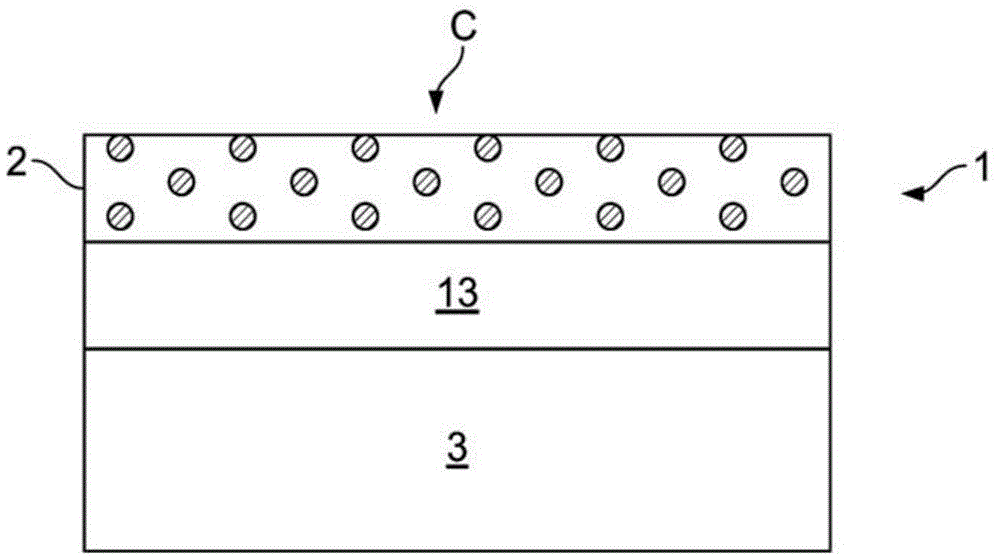

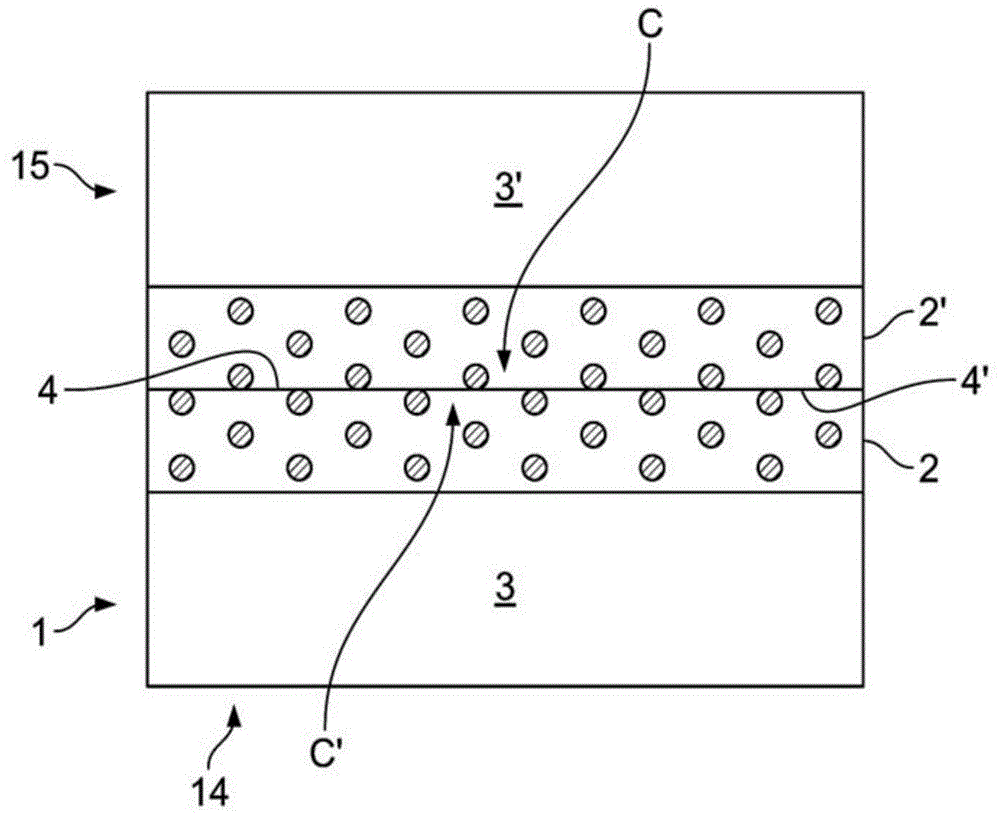

Electrical contact element with cover layer having chemical reducing agent, electrical contact arrangement and methods for manufacturing electrical contact element and for reducing oxidization of contact section of electrical contact element

ActiveCN103563180AFull chemical resistanceContact materialsContact member manufacturingElectricityContact element

The invention relates to an electrical contact element (1, 1', 15), an electrical contact arrangement (14) and methods for manufacturing an electrical contact element (1, 1', 15) and for reducing oxidization of a contact section (C, C') of an electrical contact element (1, 1', 15). In order to avoid that the durability of the contact element (1, 1', 15) and therefore of the contact arrangement (14) is negatively influenced by growing oxide layers on contact surfaces (4, 4'), the contact element (1, 1', 15) is provided with a cover layer (2, 2') with a chemical reducing agent (5) that can be activated by frictional forces.

Owner:TE CONNECTIVITY GERMANY GMBH +1

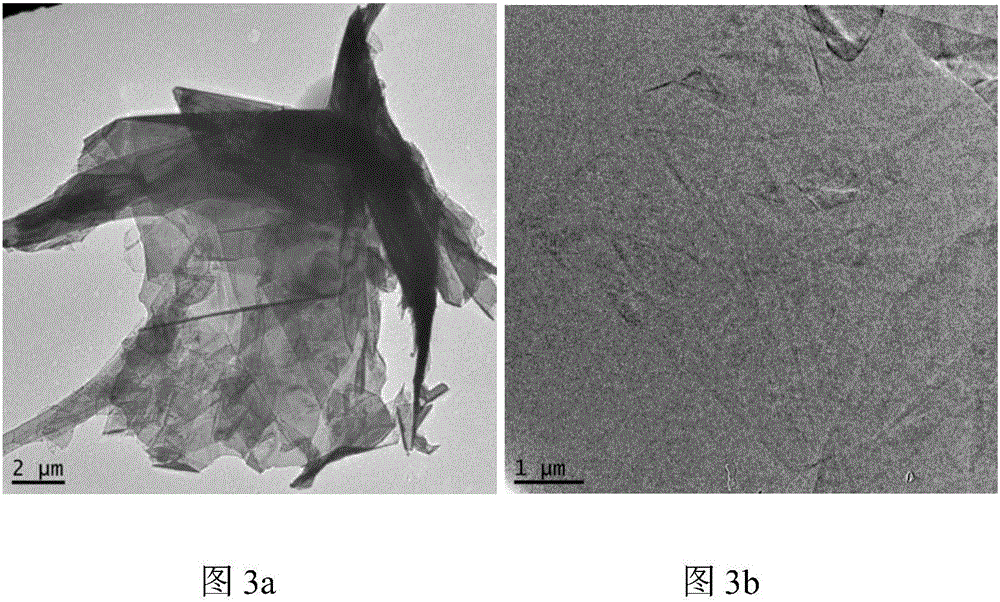

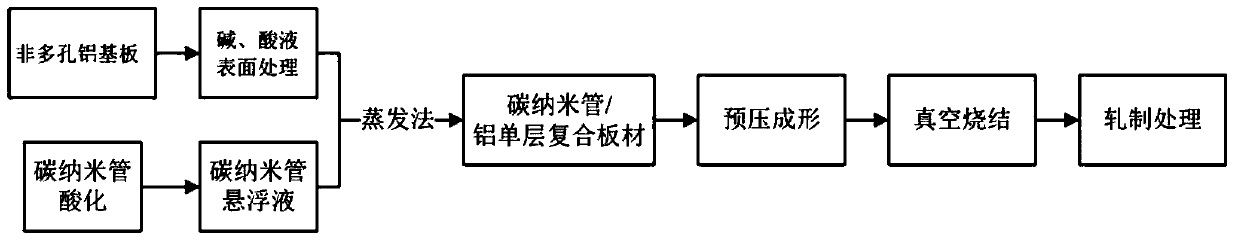

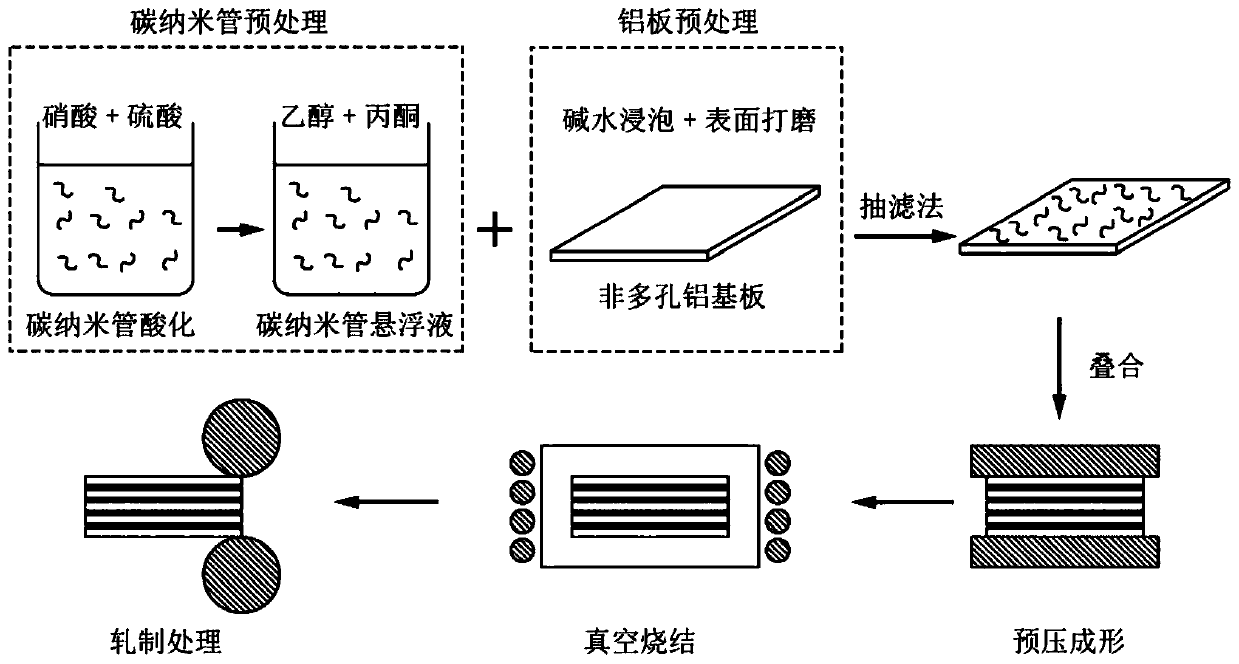

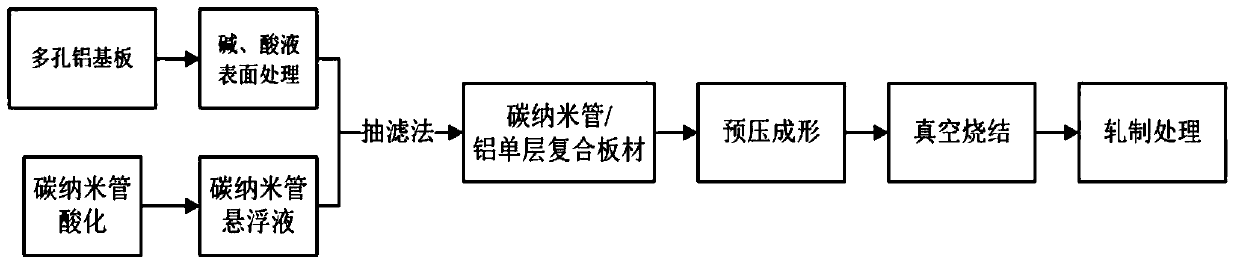

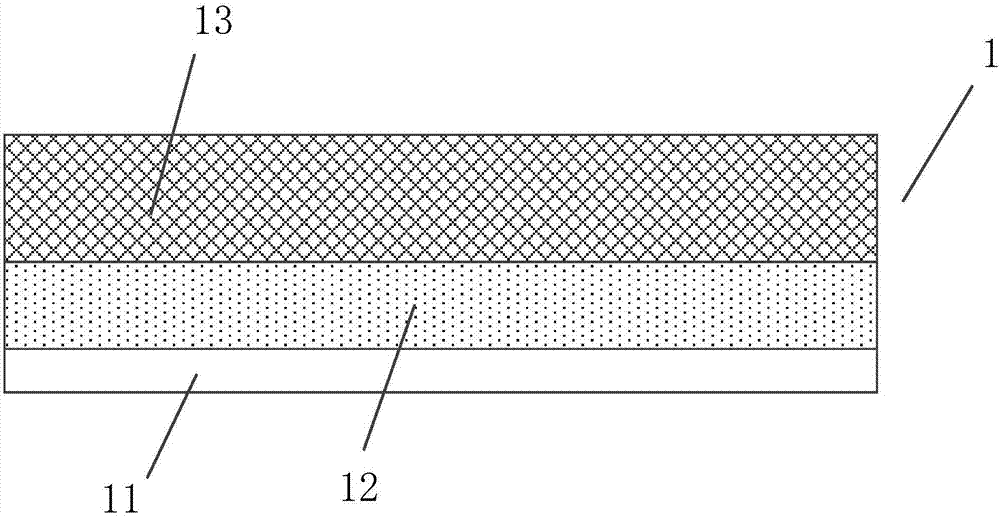

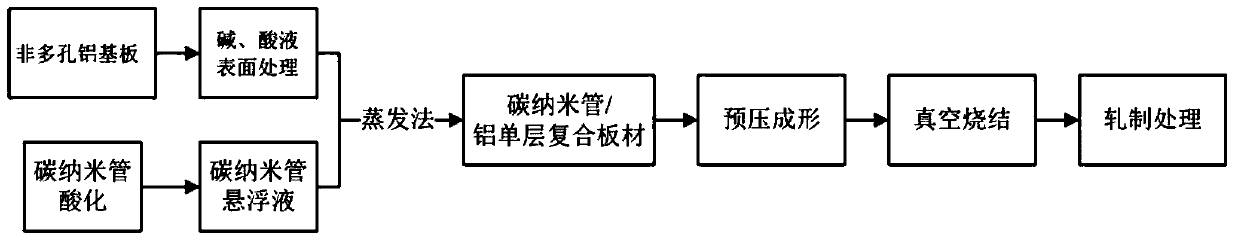

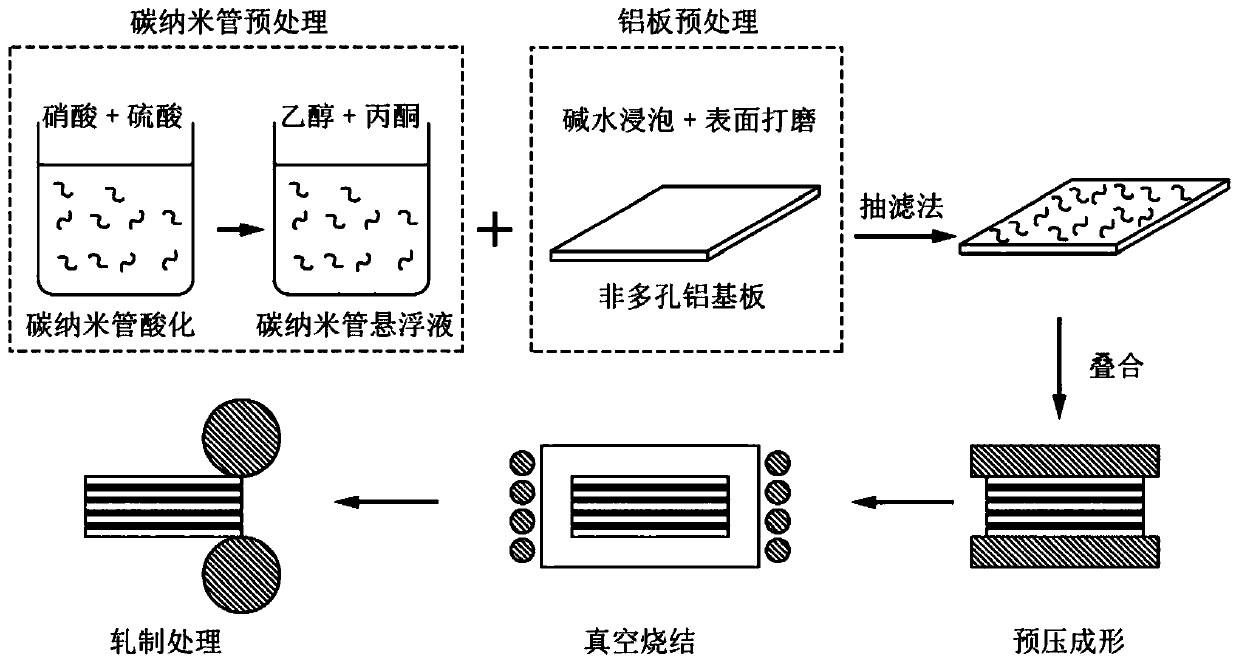

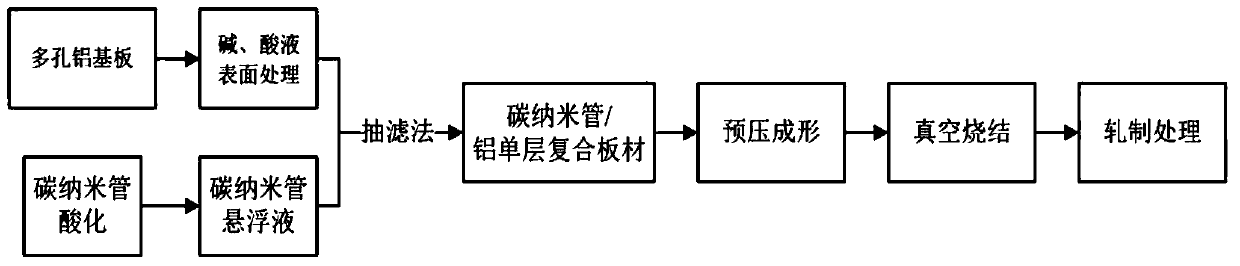

Carbon nanotube reinforced multilayer aluminum-based composite material as well as preparation method and application thereof

ActiveCN110322987AImprove microstructureEnhanced interface bindingApparatus for heat treatmentApparatus for manufacturing conducting/semi-conducting layersCarbon nanotubeAluminum substrate

The invention relates to the technical field of aluminum-based composite materials, in particular to a carbon nanotube reinforced multilayer aluminum-based composite material as well as a preparationmethod and application thereof. The method comprises the following steps: 1) treating the surface of an aluminum substrate with alkaline liquor and acid liquor, cleaning, drying and then performing grinding pretreatment on the surface of the aluminum substrate; 2) acidifying a carbon nanotube with mixed acid, and then preparing the acidified carbon nanotube into a carbon nanotube suspension; 3) placing the carbon nanotube suspension prepared in the step 2) on the surface of the aluminum substrate ground in the step 1), and drying to obtain a carbon nanotube / aluminum single-layer composite plate; 4) piling the composite plate obtained in the step 3) alternatively, performing prepressing forming, and then performing vacuum sintering; and 5) rolling the product obtained after vacuum sinteringin the step 4) to obtain the carbon nanotube reinforced multilayer aluminum-based composite material. The carbon nanotube is taken as a reinforced layer among multiple layers of aluminum substrates,so that the mechanical property and conductivity of the multilayer aluminum-based composite material can be enhanced effectively.

Owner:SHANDONG UNIV

Electromagnetic shielding film

InactiveCN107464602AShort curing timeLow curing temperatureAuxillary non-insulated conductorsInsulated cablesElectrical conductorElectromagnetic shielding

The embodiment of the invention discloses an electromagnetic shielding membrane, which relates to the field of wire material manufacturing and is used to solve the problems that the existing electromagnetic shielding membrane is easy to break and the preparation process consumes a lot of time and electric energy. The electromagnetic shielding film body for cables of the present invention includes a first metal layer, a conductive layer and a protective film; the first metal layer is covered on the outer cover of the conductor of the cable, and is used for shielding electromagnetic interference and as a medium; the conductive layer It is arranged on the first metal layer for shielding electromagnetic interference, and the conductive layer includes a curing agent, metal particles and polyurethane for carrying metal particles; the protective film is arranged on the conductive layer for protecting the electromagnetic shielding film body, The first metal layer is a metal film composed of at least one of gold, silver, copper, nickel and aluminum, or an alloy film of at least two of gold, silver, copper, nickel and aluminum, so that the first The metal layer shields electromagnetic interference and acts as a conductive medium at the same time.

Owner:SHENZHEN HUAHU TECH CO LTD

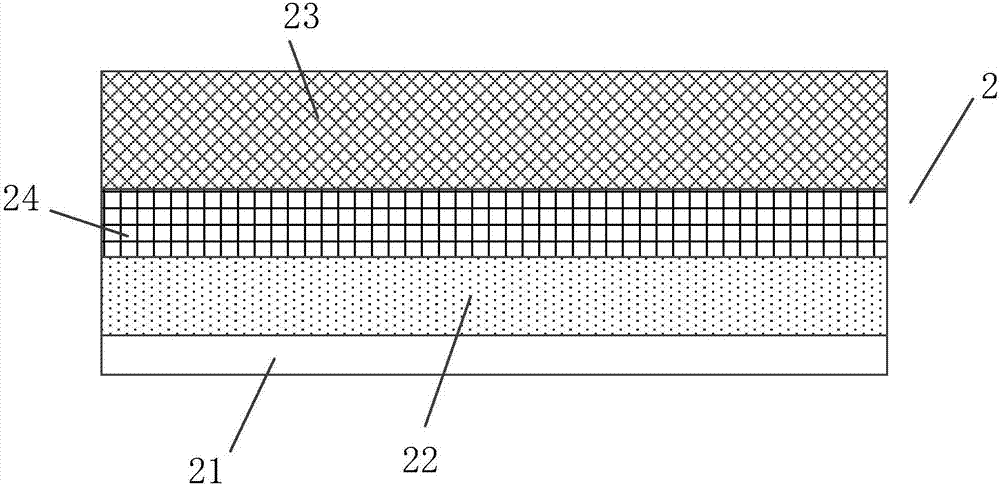

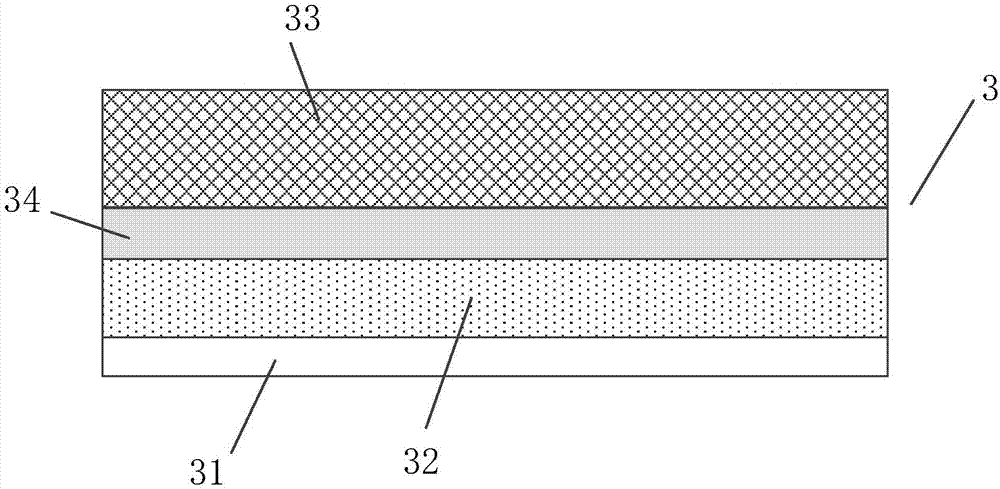

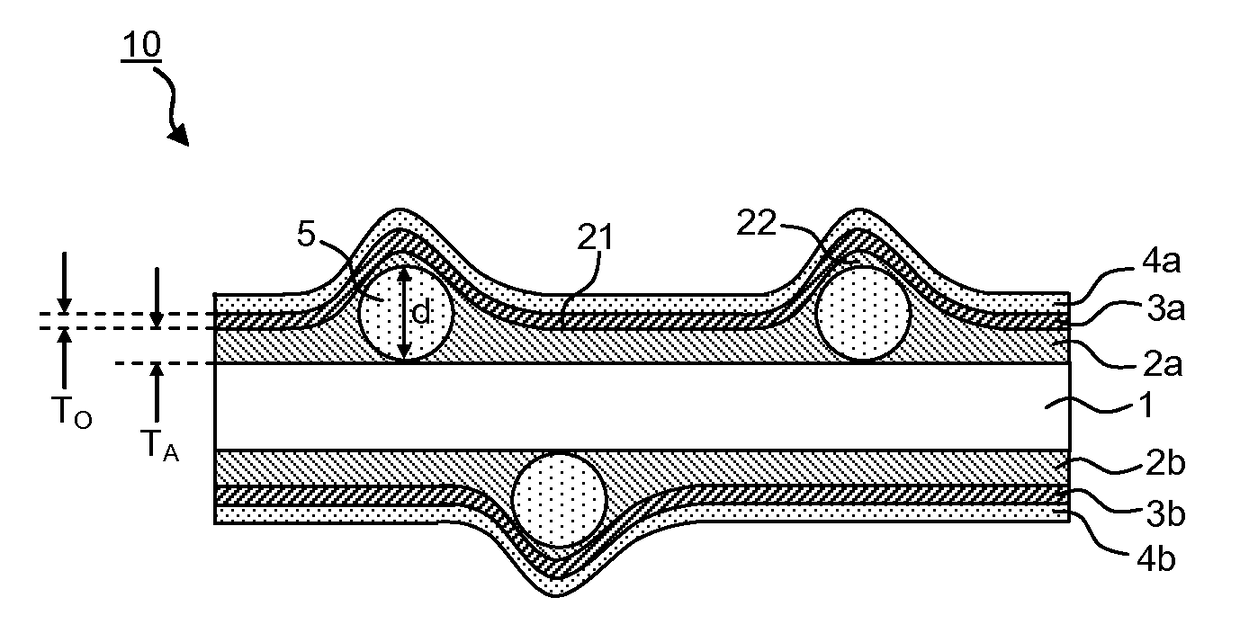

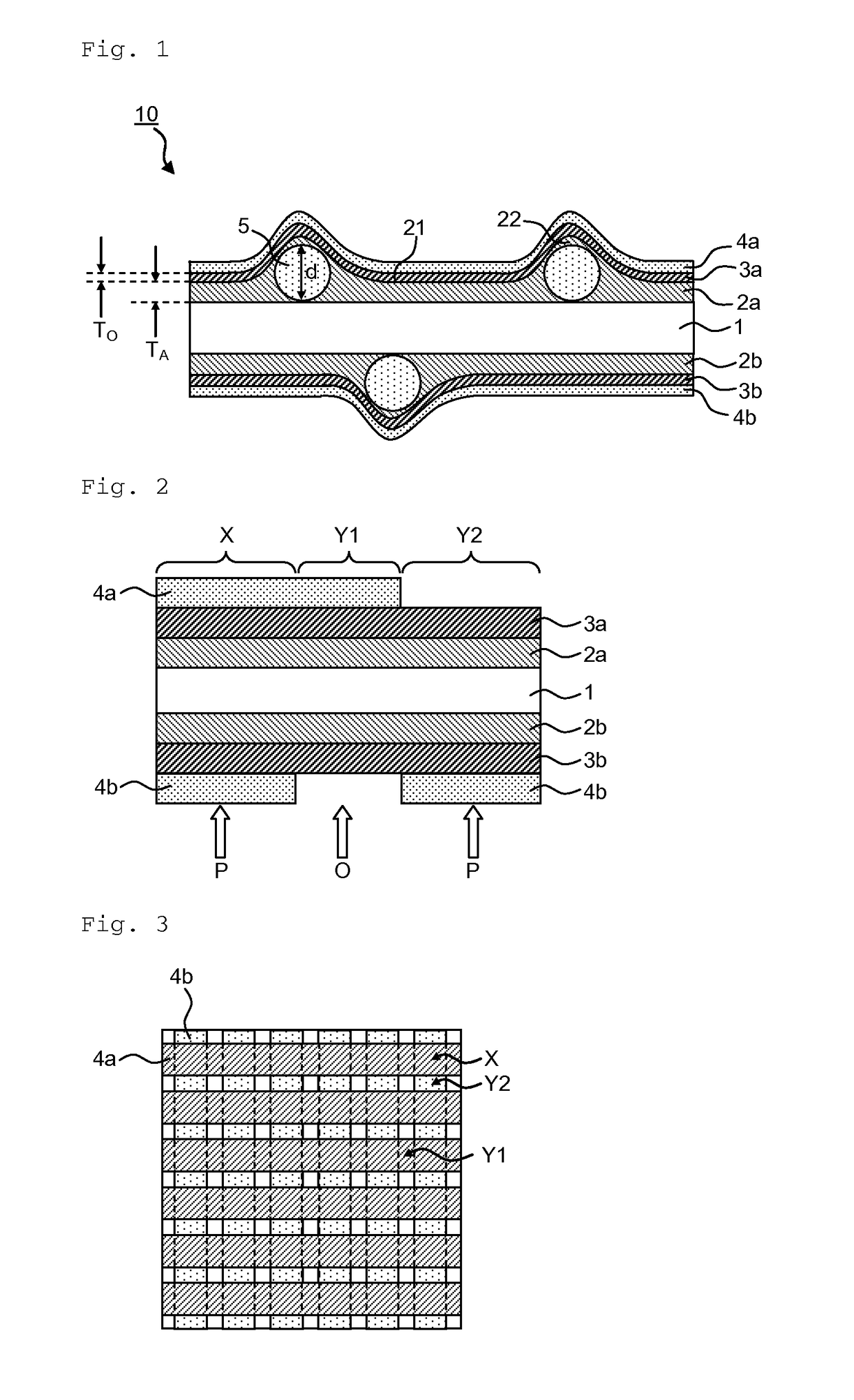

Double-sided transparent conductive film and touch panel

ActiveUS9607733B2Good anti-adhesionNot to damageConductive layers on insulating-supportsCircuit optical detailsTransparent conducting filmTouch panel

A double-sided transparent conductive film including a base material film, having an anti-blocking layer, an optical adjusting layer and a transparent conductive layer formed in this order on each of both sides of the base material film, wherein an anti-blocking layer containing particles is formed at least one of: a location between the base material film and one optical adjusting layer; and a location between the base material film and the other optical adjusting layer, the anti-blocking layer has a flat portion and protrusion portions caused by the particles, and a value obtained by subtracting a thickness of the flat portion of the anti-blocking layer from a mode diameter of the particles is larger than a thickness of the optical adjusting layer.

Owner:NITTO DENKO CORP

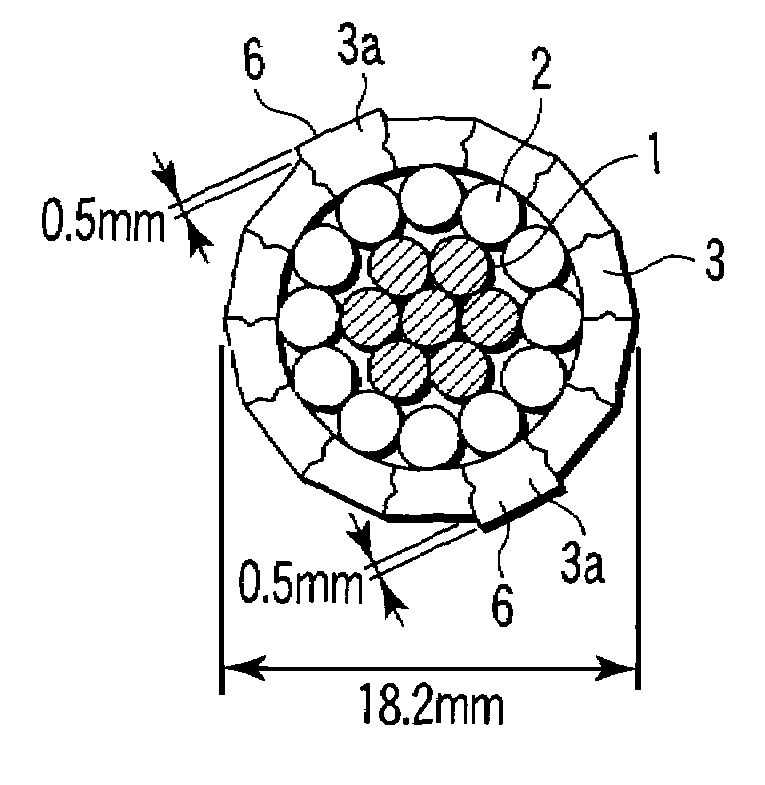

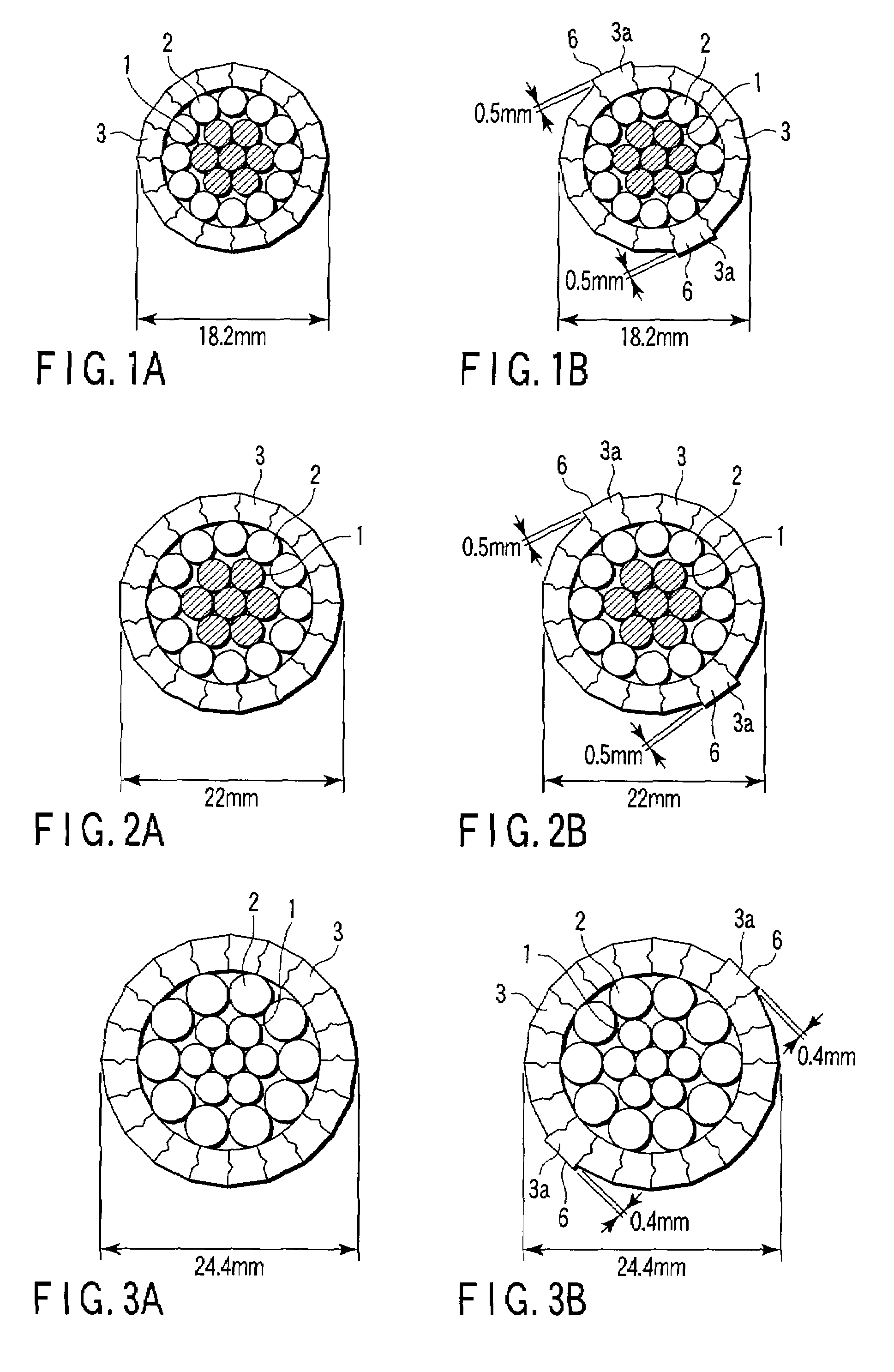

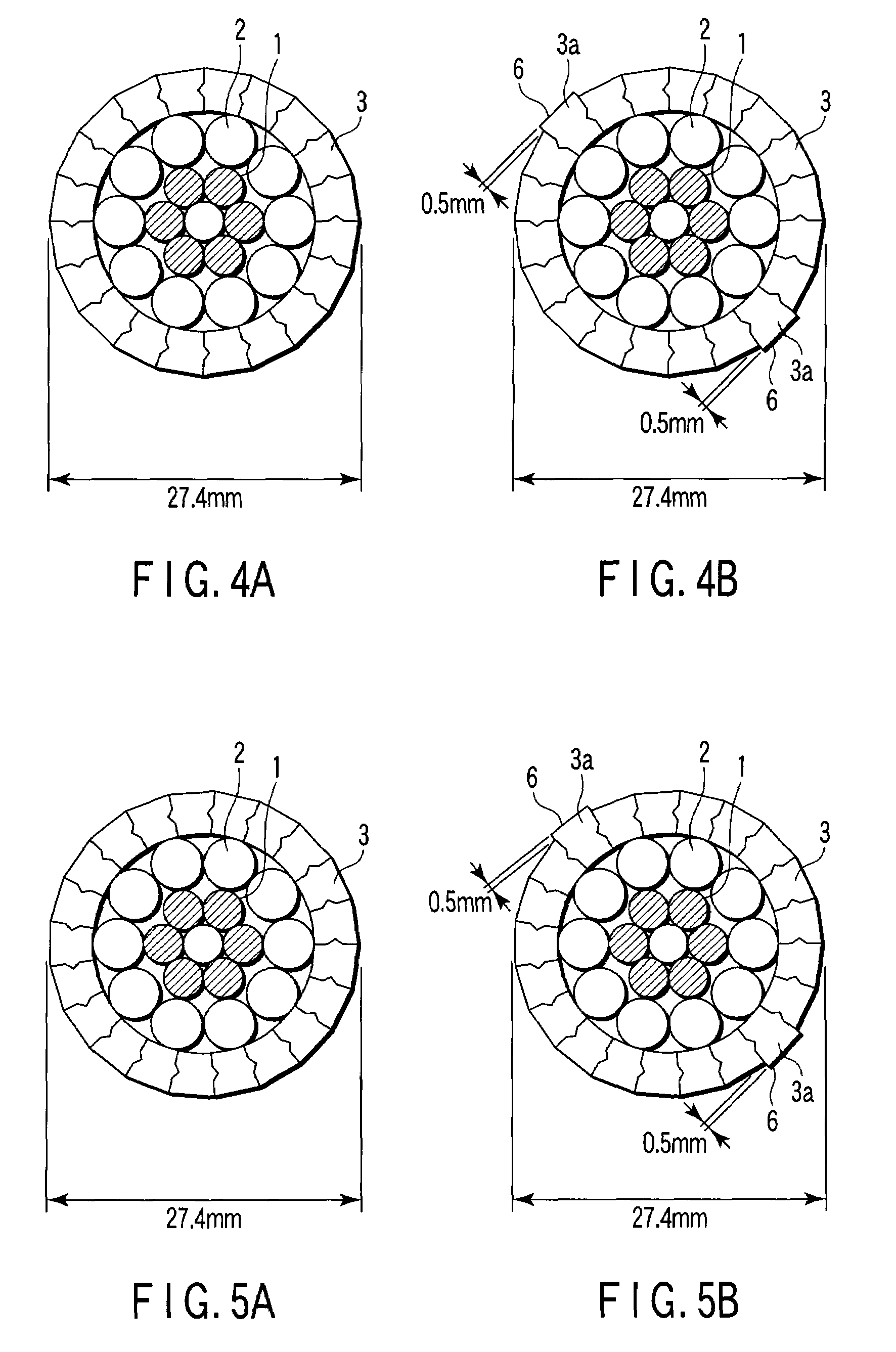

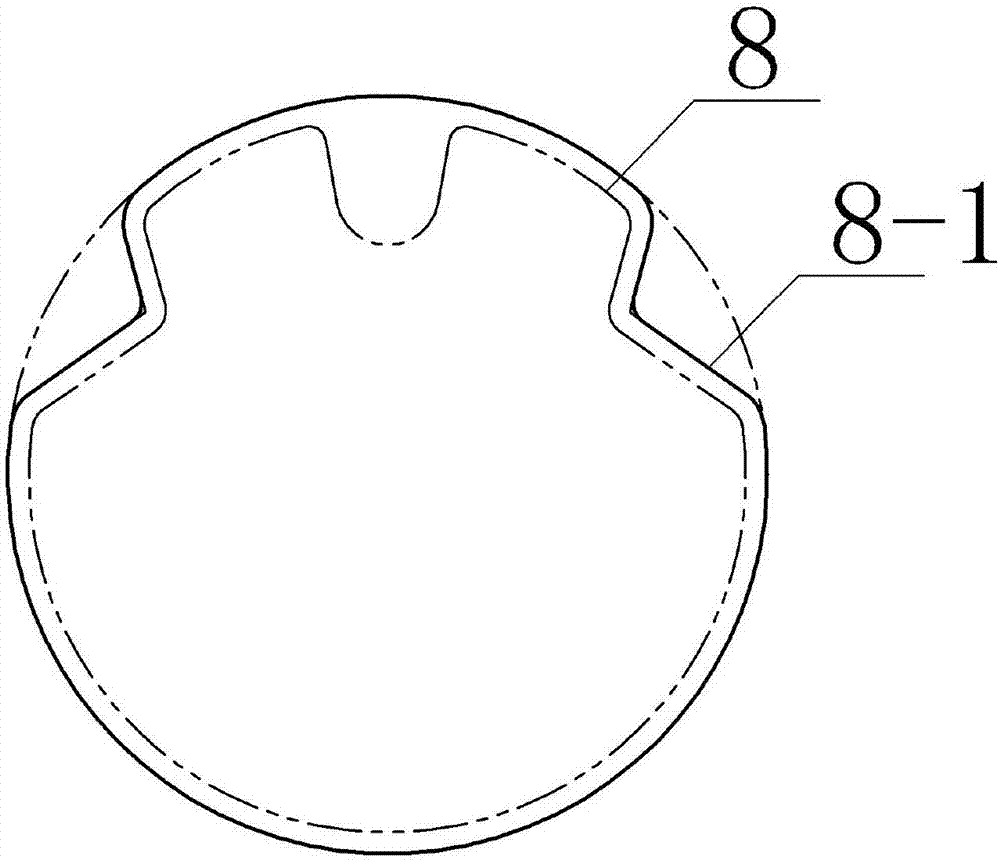

Polygonal overhead cable

ActiveUS7622681B2Subject to wind loadReduce wind noiseMaintaining distance between parallel conductorsSuspension arrangements for electric cablesEngineeringMechanical engineering

An overhead cable including a plurality of element wires stranded to form a naked stranded cable, which has a cross-sectional shape of an equilateral polygon inscribed in a circle having a diameter of 18.2 mm to 38.4 mm as a fundamental cross-sectional shape, in which two sides of this equilateral polygon that are located at positions farthest from each other are outwardly projected, has two flat-plate-shaped projections corresponding to the two sides, wherein the number of angles of the equilateral polygon is set depending to the diameter of the circle.

Owner:FURUKAWA ELECTRIC CO LTD (25) +2

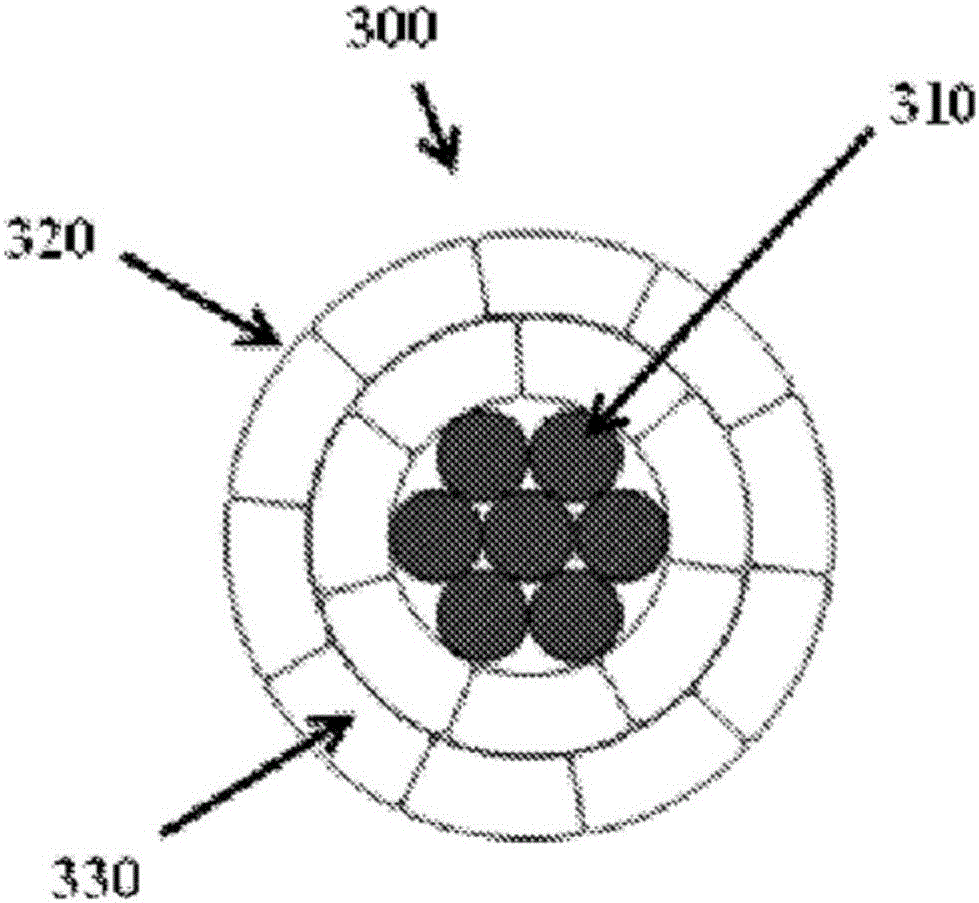

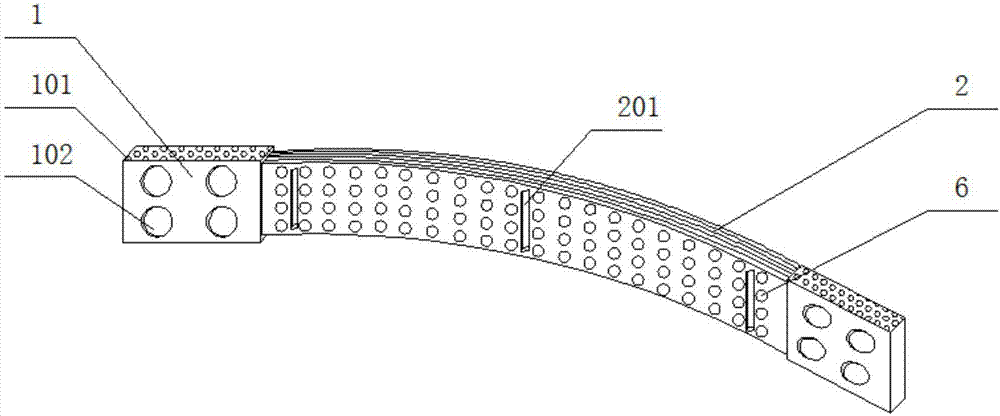

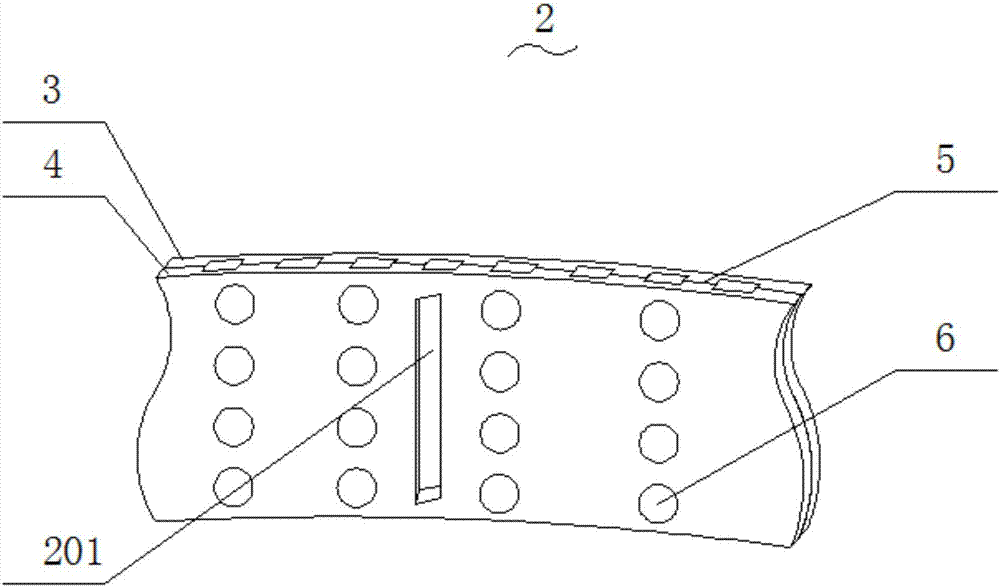

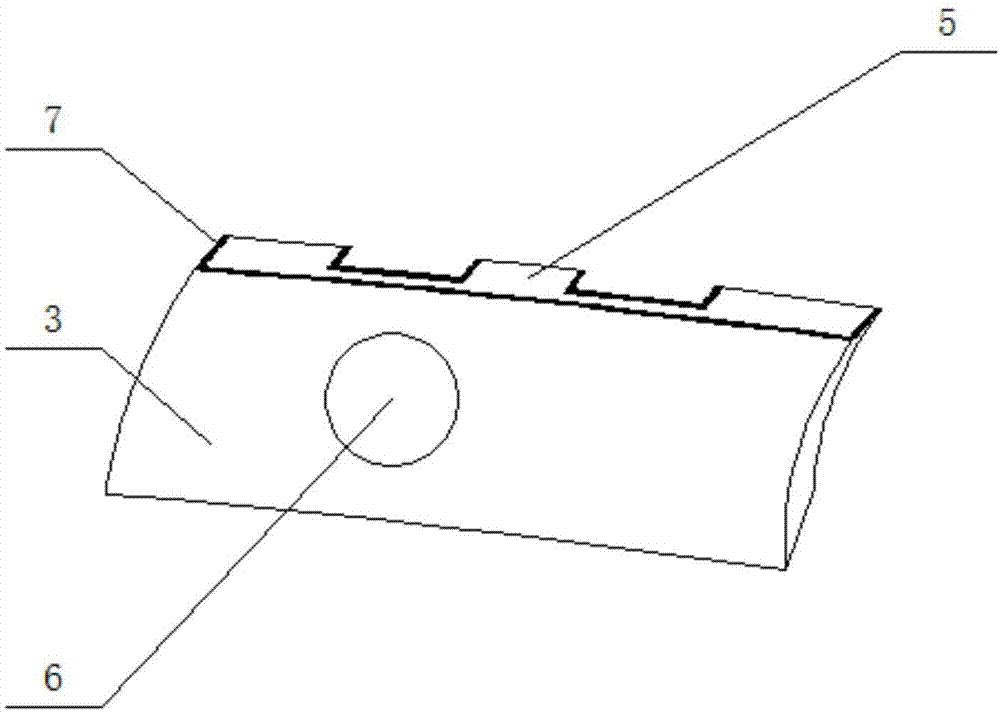

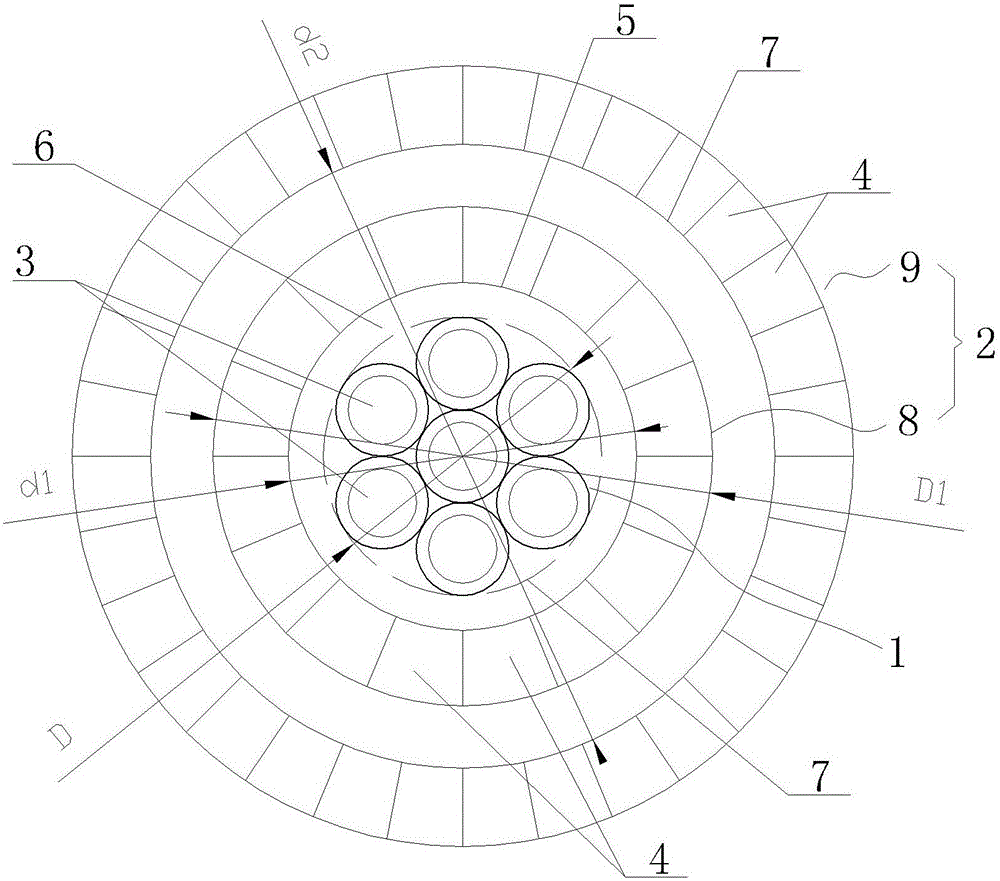

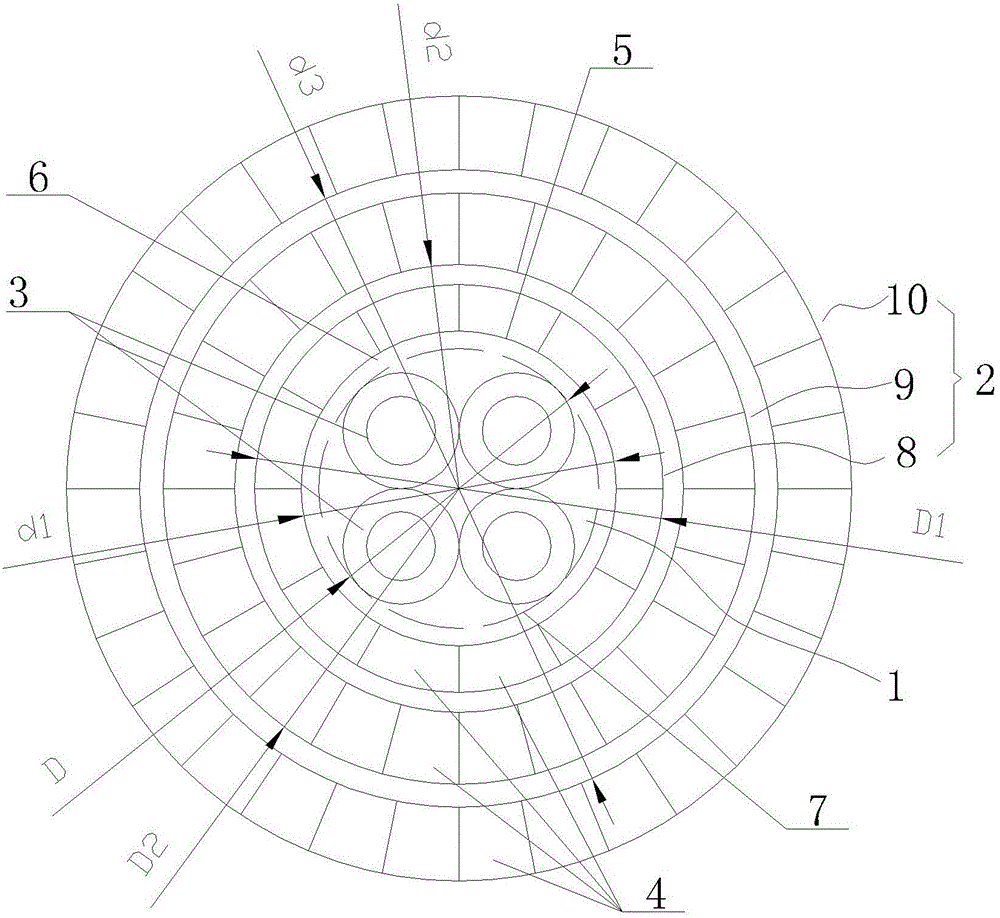

Vibration reduction wire formed by combining aluminum clad steel cores and aluminum-alloy twisted wires

InactiveCN105761783ATo achieve the effect of vibration reductionSingle bars/rods/wires/strips conductorsConductive materialElectrical conductorSurface structure

The invention provides a vibration reduction wire formed by combining aluminum clad steel cores and aluminum-alloy twisted wires.Natural vibration frequencies of all layers of the aluminum alloy wires and aluminum clad steel cores are different and are mutually interfered, and therefore aeolian vibration energy is automatically consumed, and the vibration reduction effect is achieved.The vibration reduction wire comprises an inner core conductor and outer layer conductors, the inner core conductor is formed by twisting multiple aluminum clad steel wires, the outer layer conductors comprise at least two layers, each layer of the outer layer conductors is formed by combining multiple sections of aluminum alloy wires with the same radian, the outer layer conductor on the innermost layer forms an enclosed first circular ring surface structure in a combined mode, each layer of the outer layer conductors forms the corresponding enclosed circular ring surface structure in a combined mode, the outer layer conductors of the relative-inner layer are arranged in a circular inner cavity formed by the enclosed ring surface structure composed of the outer layer conductors of the adjacent relative-outer layer, and the inner diameter of the enclosed ring surface structure composed of the outer layer conductors of the adjacent relative-outer layer is large than the outer diameter of the enclosed ring surface structure composed of the outer layer conductors of the relative-inner layer.

Owner:FUJIKURA HENGTONG AERIAL CABLE SYST

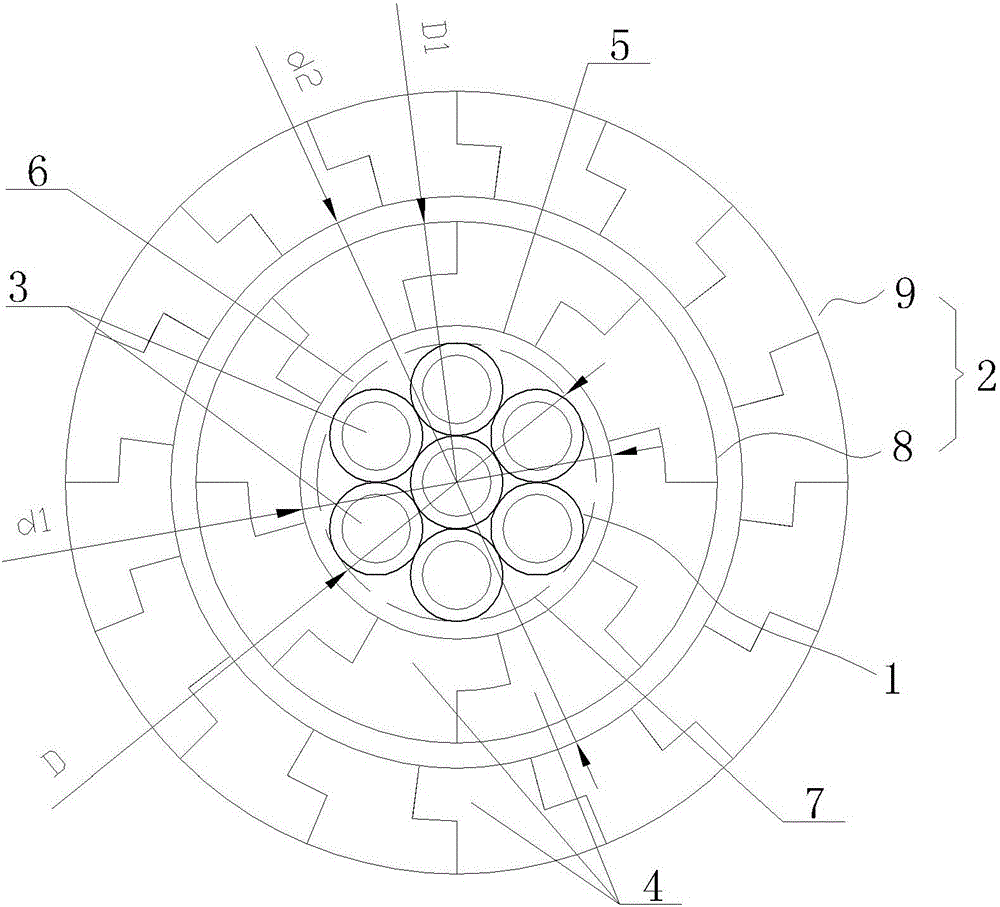

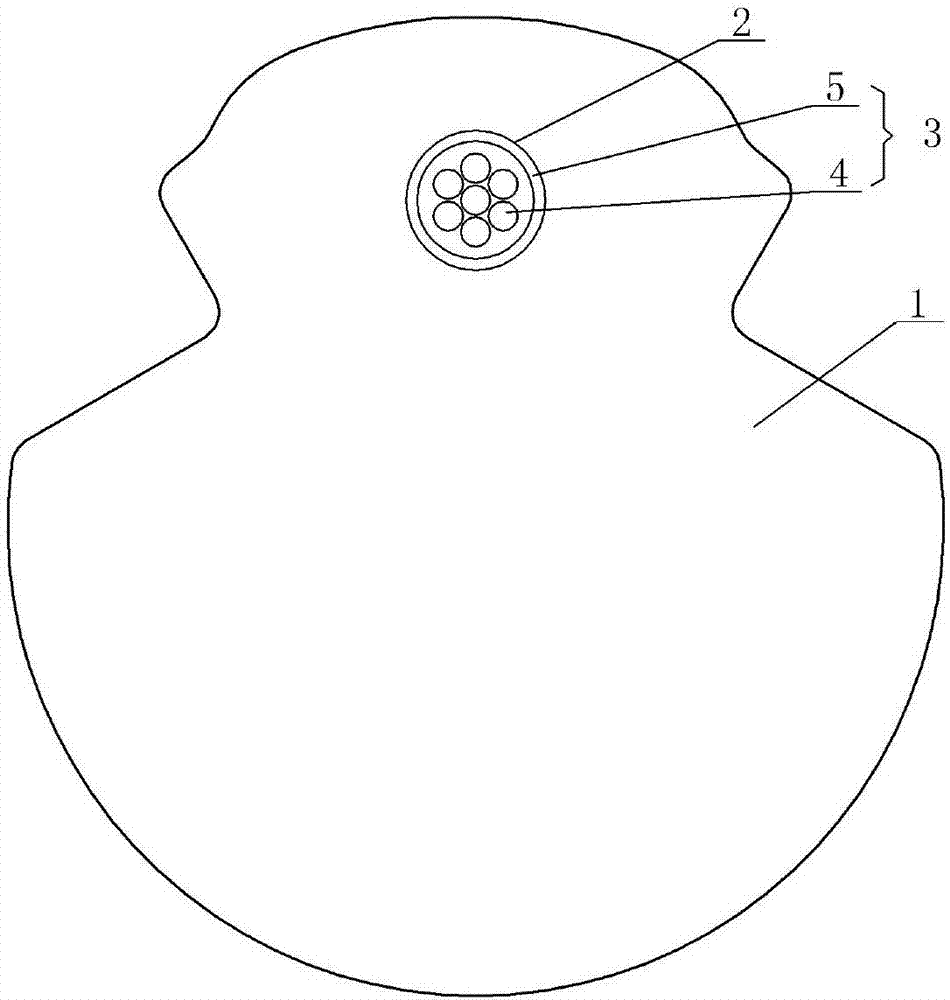

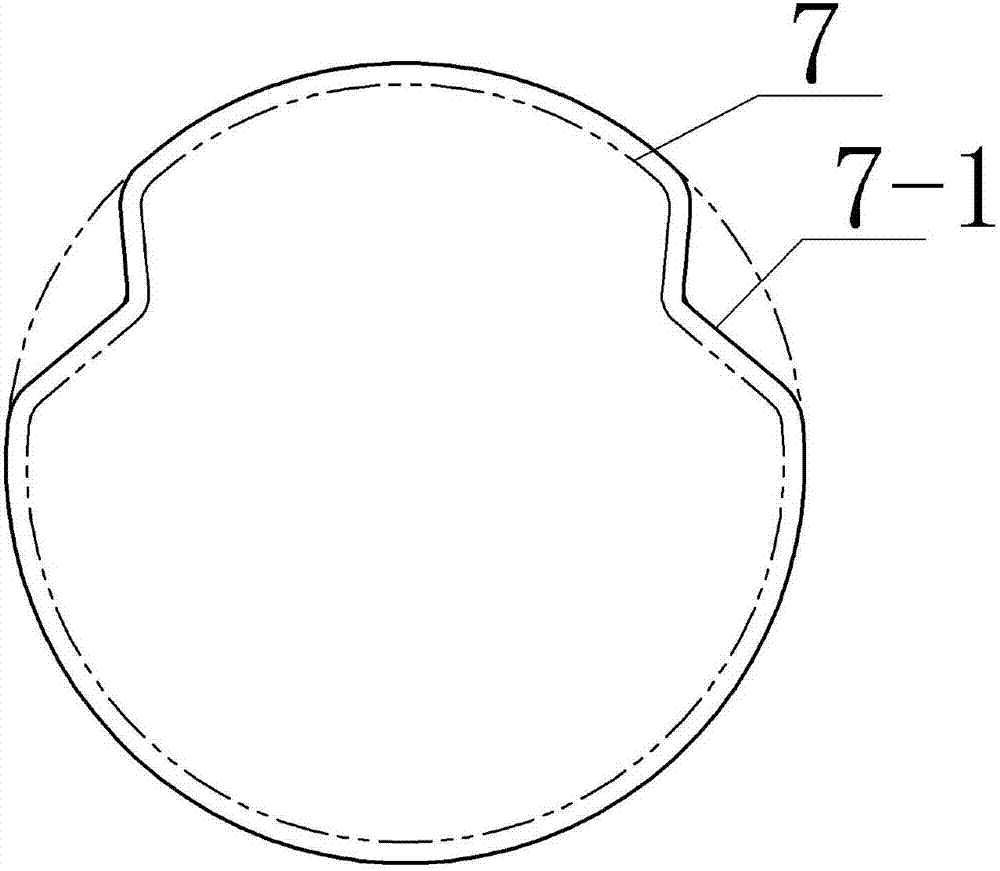

Heatable copper alloy contact wire and manufacturing method thereof

ActiveCN107039102ASolve the icingReduce power consumptionSingle bars/rods/wires/strips conductorsAuxillary non-insulated conductorsCopper alloyContact wire

The invention provides a heatable copper alloy contact wire. A heatable soft copper twisted wire is arranged in the heatable copper alloy contact wire, through electrifying and heating the soft copper twisted wire, an icing problem of the external contact wire is solved, and small power consumption and high icing efficiency are realized. The heatable copper alloy contact wire comprises a contact wire body and is characterized in that a top portion of the contact wire body in the length direction is provided with a penetration hole, the penetration hole is internally provided with a heating wire, and the heating wire comprises the internal soft copper twisted wire and an external insulation sheath.

Owner:FUJIKURA HENGTONG AERIAL CABLE SYST +2

A kind of carbon nanotube reinforced multilayer aluminum matrix composite material and its preparation method and application

ActiveCN110322987BImprove microstructureEnhanced interface bindingApparatus for heat treatmentApparatus for manufacturing conducting/semi-conducting layersComposite plateCarbon nanotube fet

The invention relates to the technical field of aluminum-based composite materials, in particular to a carbon nanotube reinforced multilayer aluminum-based composite material as well as a preparationmethod and application thereof. The method comprises the following steps: 1) treating the surface of an aluminum substrate with alkaline liquor and acid liquor, cleaning, drying and then performing grinding pretreatment on the surface of the aluminum substrate; 2) acidifying a carbon nanotube with mixed acid, and then preparing the acidified carbon nanotube into a carbon nanotube suspension; 3) placing the carbon nanotube suspension prepared in the step 2) on the surface of the aluminum substrate ground in the step 1), and drying to obtain a carbon nanotube / aluminum single-layer composite plate; 4) piling the composite plate obtained in the step 3) alternatively, performing prepressing forming, and then performing vacuum sintering; and 5) rolling the product obtained after vacuum sinteringin the step 4) to obtain the carbon nanotube reinforced multilayer aluminum-based composite material. The carbon nanotube is taken as a reinforced layer among multiple layers of aluminum substrates,so that the mechanical property and conductivity of the multilayer aluminum-based composite material can be enhanced effectively.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com