Electrical contact element with cover layer having chemical reducing agent, electrical contact arrangement and methods for manufacturing electrical contact element and for reducing oxidization of contact section of electrical contact element

A technology of contact elements and covering layers, which is applied in the direction of contact manufacturing, contact parts, electrical components, etc., can solve the problems of contact surface damage, restriction, and reduced conductivity, and achieve the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

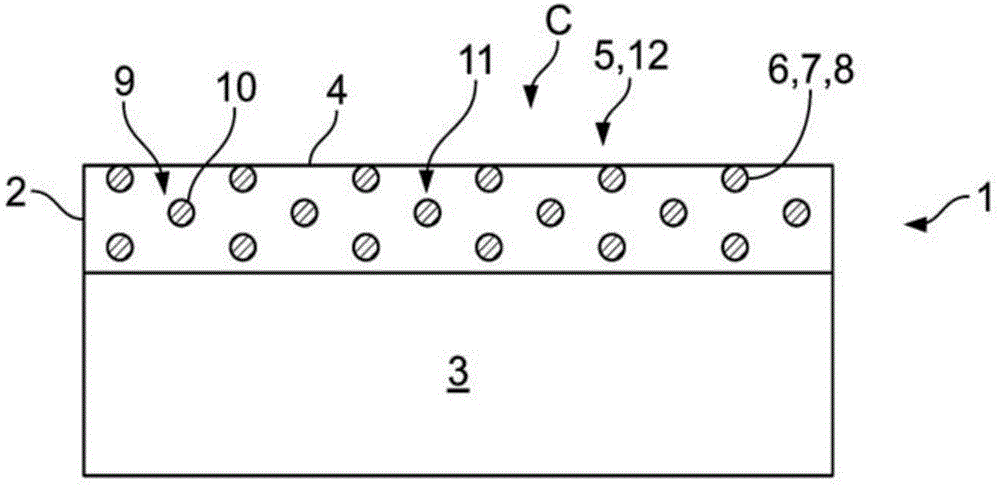

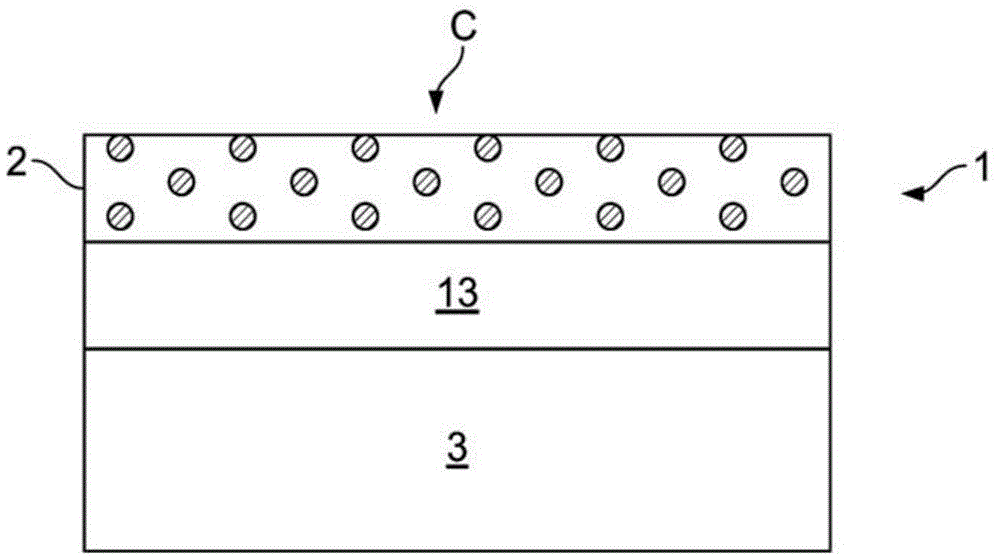

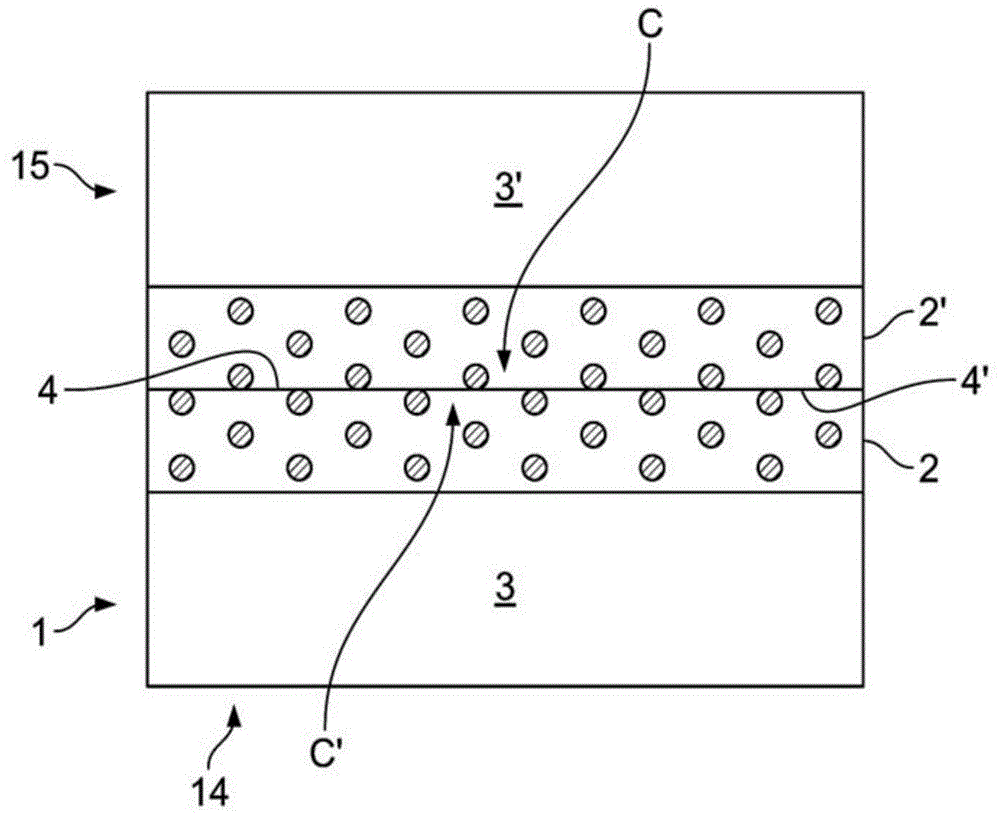

[0044] first refer to figure 1 An electrical contact element 1 with a cover layer 2 is described. The contact element 1 may comprise a core body 3 on which a cover layer 2 may be arranged in at least the contact portion C of the contact element 1 . The core body 3 may be electrically conductive and may be made of metal, such as copper, silver or alloys.

[0045] The cover layer 2 can also be electrically conductive. The contact surface 4 of the cover layer 2 may form the contact surface 4 of the contact element 1 , which may be exposed to air or another gas comprising oxygen. Thus, the contact surface 4 may become oxidized after a period of time, the oxidized material of the contact surface 4 potentially affecting the conductivity of the contact surface 4 . The cover layer 2 may comprise a chemical reducing agent 5 suitable for reducing oxidation of the metal.

[0046] During operation of the contact element 1 the contact surface 4 can be damaged by contact or non-contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com