Toner and preparation method thereof

A technology of toner and isocyanate, applied in the direction of developer, electrography, optics, etc., can solve the problems of increased energy consumption, deterioration of fixtures, poor thermal efficiency, etc., to reduce caking, excellent weather resistance, and improve durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to a first aspect of the present invention, a kind of preparation method of isocyanate-styrene-acrylic composite resin emulsion is provided, comprising the following steps:

[0040] a) styrene monomer, acrylic acid and acrylic acid ester monomer carry out solution polymerization to obtain a solution containing styrene-acrylic resin;

[0041] Wherein, the acid value of styrene-acrylic resin is 30-50mg KOH / g, and the weight-average molecular weight of styrene-acrylic resin is 2000-10000g / mol;

[0042] b) adding isocyanate to the solution obtained in step a), reacting isocyanate with styrene-acrylic resin to obtain an isocyanate-styrene-acrylic composite resin solution, and then obtaining an isocyanate-styrene-acrylic composite resin emulsion through a phase inversion emulsification method;

[0043] Wherein, the acid value of the isocyanate-styrene-acrylic composite resin is 10-20mg KOH / g, and the weight average molecular weight of the isocyanate-styrene-acrylic ...

Embodiment 1

[0100] A preparation method of toner, comprising the following steps:

[0101] (1) Provide a 10-liter reactor equipped with a constant temperature oil bath, stirring device, thermometer, reflux condenser, nitrogen inlet pipe and dropping funnel, first feed nitrogen, fully replace the oxygen and water in the reactor, and then The temperature was raised to 50°C, 1100g of butanone was added, and the temperature was raised to 80°C.

[0102] Provide the monomer mixed solution that is made up of 180g butyl acrylate, 40g acrylic acid, 30g methyl methacrylate and 780g styrene, provide the initiator solution that 24g benzoyl peroxide is dissolved in the formation of 100g butanone; Monomer mixed solution Add it dropwise into the reactor simultaneously with the initiator solution, keep the temperature at 88° C. and stir for 4 hours, then lower the temperature to 40° C. to obtain a solution containing styrene-acrylic resin.

[0103] Determination of polymer molecular weight: Add deionize...

Embodiment 2-3

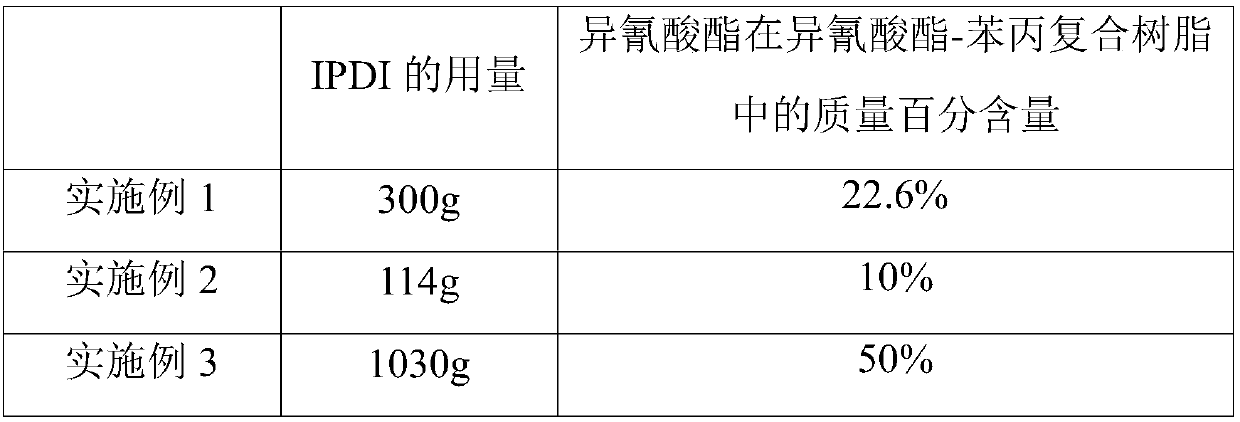

[0114] The only difference between Examples 2-3 and Example 1 is that the amount of isophorone diisocyanate (IPDI) in step (2) is changed. The details are shown in Table 1.

[0115] The consumption of different groups of isophorone diisocyanates in table 1

[0116]

[0117] Example 2 obtained an isocyanate-styrene-acrylic composite resin emulsion with a particle size of 176nm, a weight-average molecular weight (Mw)=32,000, a glass transition temperature (Tg)=70°C, and an acid value=13mgKOH / g.

[0118] Example 3 obtained an isocyanate-styrene-acrylic composite resin emulsion with a particle size of 170nm, a weight-average molecular weight (Mw)=37,000, a glass transition temperature (Tg)=65°C, and an acid value=20mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com