Coated overhead conductor

An overhead wire, coating technology, applied to the surface coating liquid device, conductor, coating, etc., can solve the problems of damage, resistance increase, limited maximum safe operating temperature of bare wires, etc.

Inactive Publication Date: 2016-10-26

GENERAL CABLE TECH CORP

View PDF14 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such ampacity is limited by the maximum safe operating temperature of the bare wire carrying the current

Exceeding this temperature can cause damage to the conductor or other components of the transmission line

However, the resistance of a conductor increases as the temperature of the conductor or power load increases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0101] Table 2 depicts the temperature reduction of coated overhead wires with a polymer coating layer compared to uncoated bare wires. Polymer coating layers consisting of PVDF (sample 1) and XLPE (sample 2) were applied using melt extrusion. currently using Figure 6 The depicted experimental setup measures the temperature drop across a wire while applying a current.

[0102] Table 2

[0103] sample

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

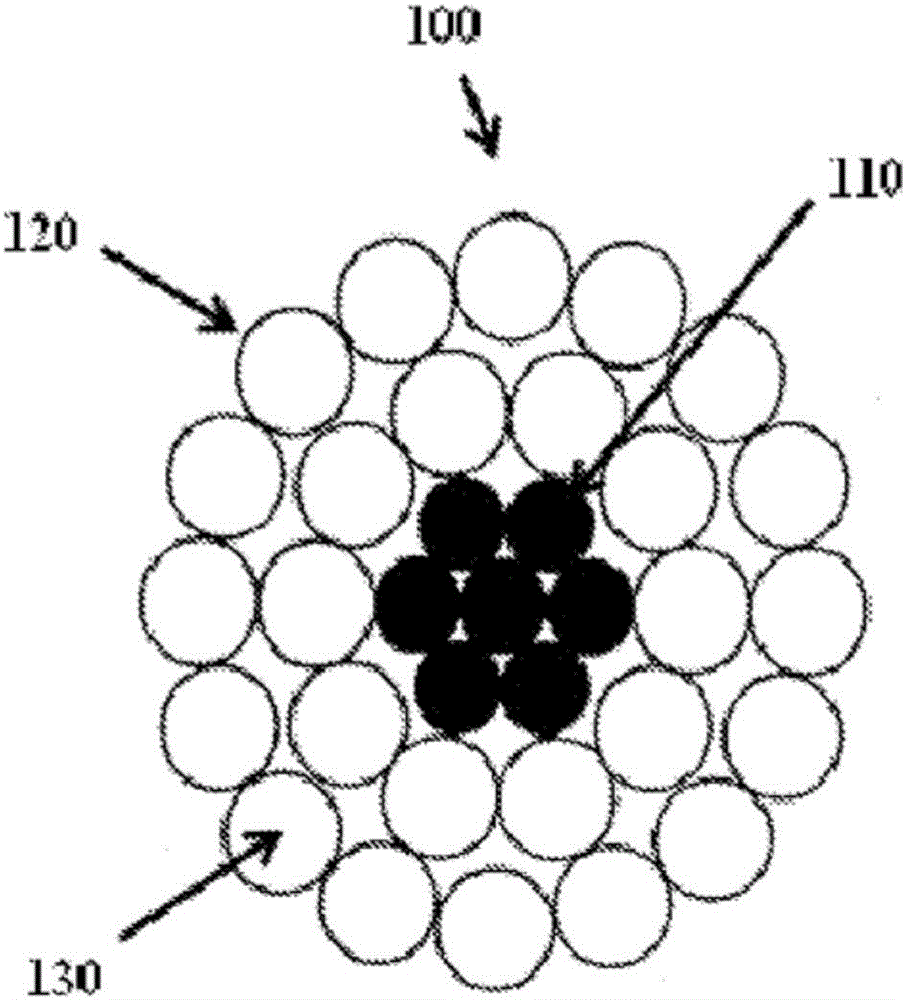

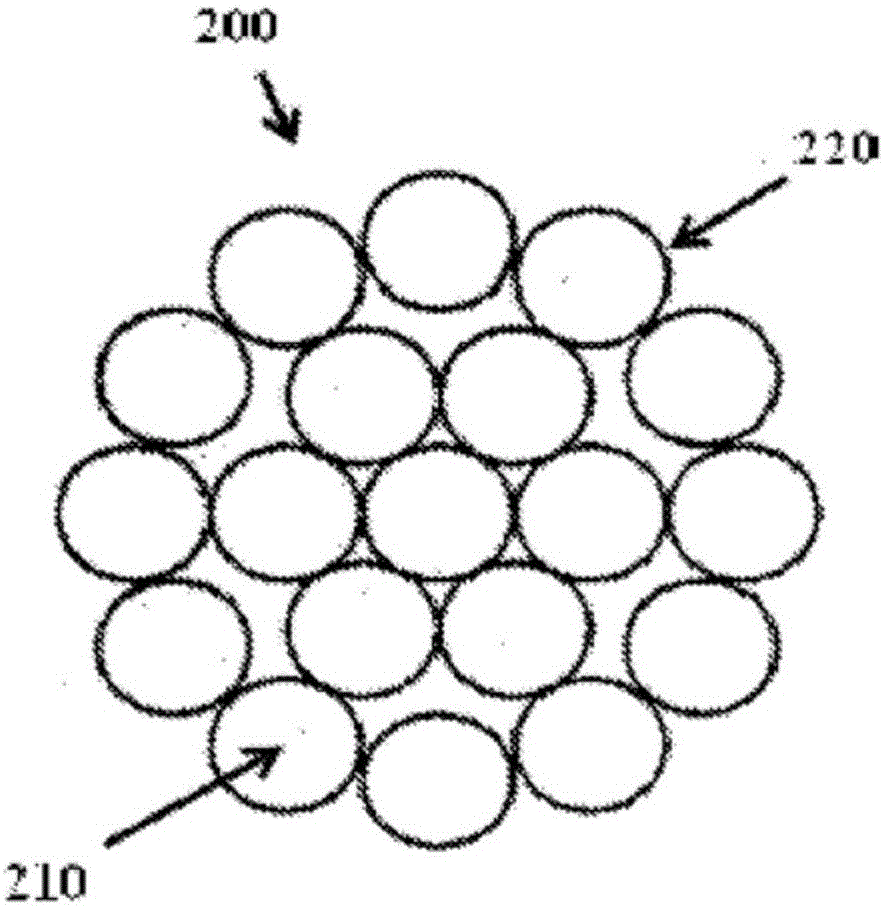

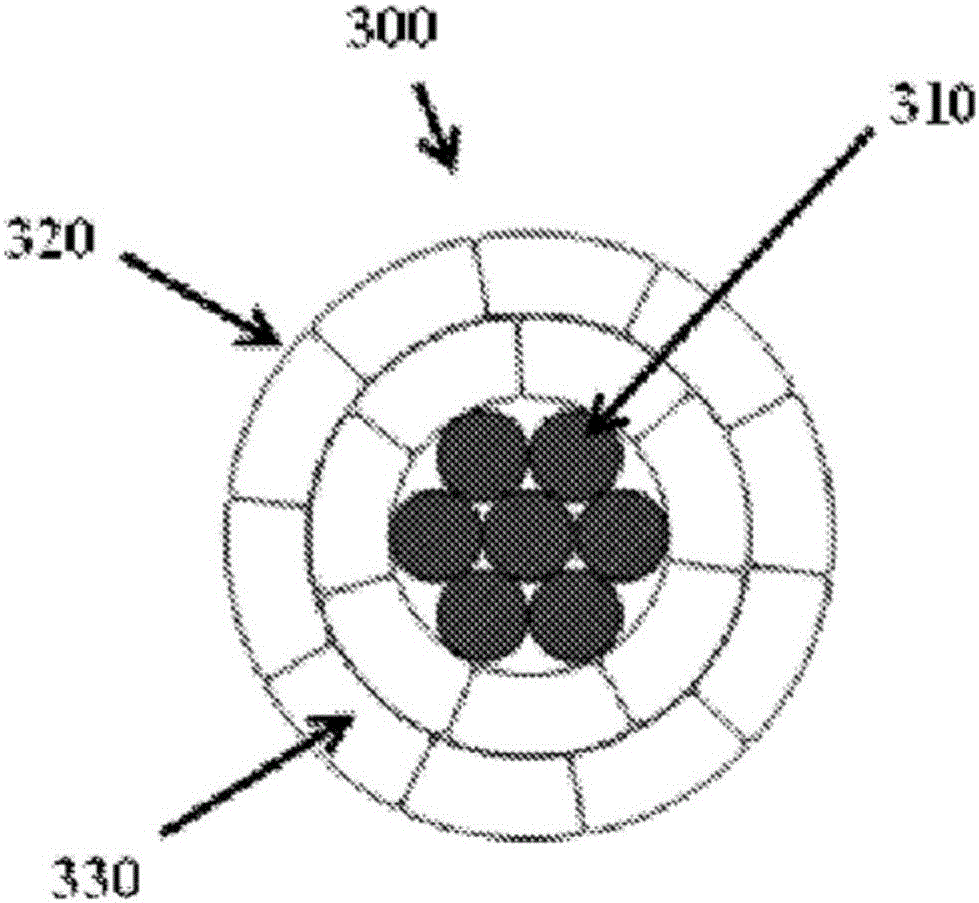

A polymeric coating can be applied to an overhead conductor. The overhead conductor includes one or more conductive wires, and the polymeric coating layer surrounds the one or more conductive wires. The overhead conductor can operate at a lower temperature than a bare overhead conductor with no polymeric coating layer when tested in accordance with ANSI C119.4 method. Methods of applying a polymeric coating layer to an overhead conductor are also described herein.

Description

[0001] References to related applications [0002] This application claims priority to US Provisional Application No. 611925,053, filed January 8, 2014, entitled COATED HIGH VOLTAGE TRANSMISSIONOVERHEAD CONDUCTOR, which application is hereby incorporated by reference in its entirety. technical field [0003] In general, the present disclosure relates to polymer coatings that reduce the operating temperature of overhead high voltage electrical conductors. Background technique [0004] As electricity demand increases, the need for higher capacity electricity transmission and distribution lines increases. The power that a transmission line can deliver depends on the current-carrying capacity (carrying capacity) of the line. However, such ampacity is limited by the maximum safe operating temperature of the bare wire carrying the current. Exceeding this temperature can cause damage to the conductor or other components of the transmission line. However, the resistance of a cond...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B13/14H01B19/04C09D127/16

CPCB05B7/14B05D3/0218B05D7/20H01B5/002H01B7/292H01B13/14

Inventor S.K.兰加纳坦V.梅塔S.西里普拉普C.R.戴维斯F.E.克拉克

Owner GENERAL CABLE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com