Heatable copper alloy contact wire and manufacturing method thereof

A contact wire and copper alloy technology, applied in cable/conductor manufacturing, root rod/rod/wire/strip conductor, conductor, etc., can solve problems such as endangering the safety of locomotive operation, low deicing efficiency, and locomotive retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

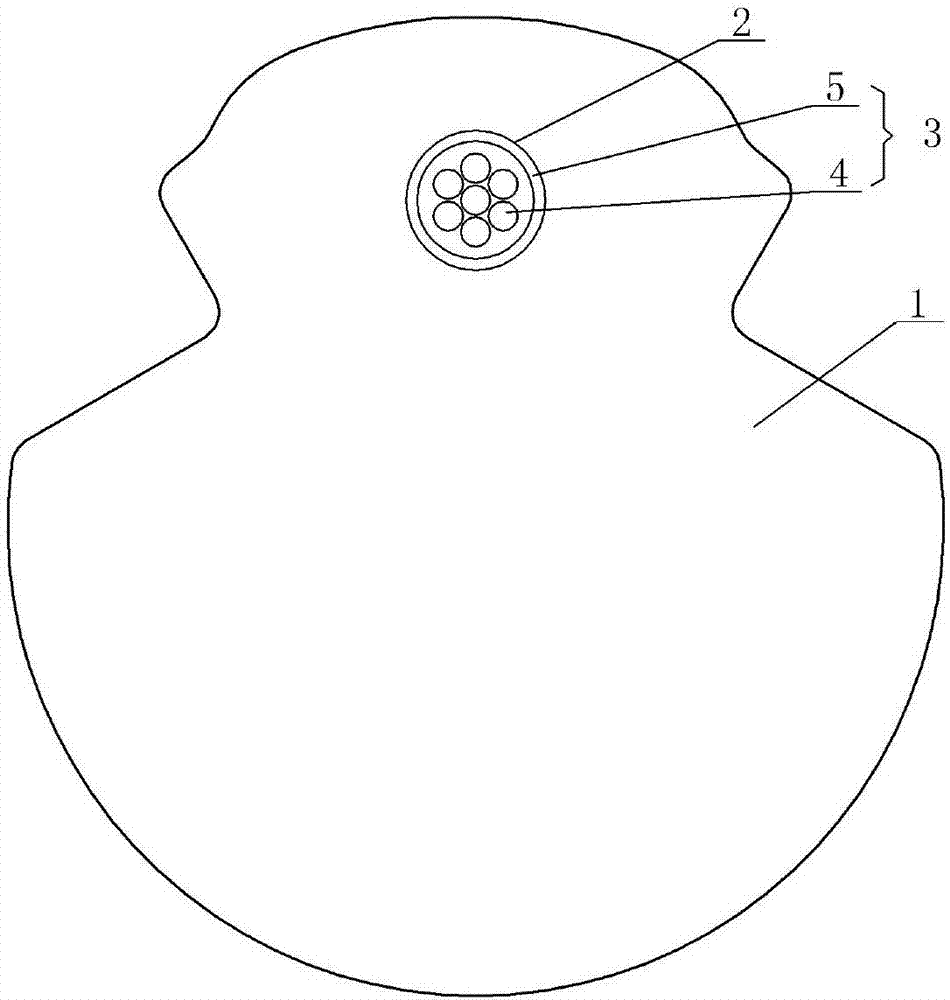

[0025] A heatable copper alloy contact wire, see figure 1 : It includes a contact wire body 1, a through hole 2 is arranged on the top of the contact wire body 1 in the length direction, and a heating wire 3 is arranged in the through hole 2, and the heating wire 3 includes an inner annealed copper stranded wire 4 and an outer insulating sheath 5.

[0026] The contact wire body 1 is obtained by drawing a material with a circular cross section through a tungsten steel mold;

[0027] The annealed copper stranded wire 4 of heating wire 3 is used for electrification;

[0028] The overall diameter of the heating wire 3 does not exceed 2mm.

[0029] When encountering low temperature weather, the ice coating detection sensor will transmit the line condition to the control center, and solve the ice coating problem of the external contact wire by energizing and heating the soft copper strand 4 . After testing, it only takes 20 minutes for the ice-coated contact wire to heat up from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com