Insulating electric wire and varnish for forming insulating layers

一种绝缘电线、绝缘层的技术,应用在绝缘电缆、绝缘体、绝缘导体等方向,能够解决温度升高、产生离子、介质击穿等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

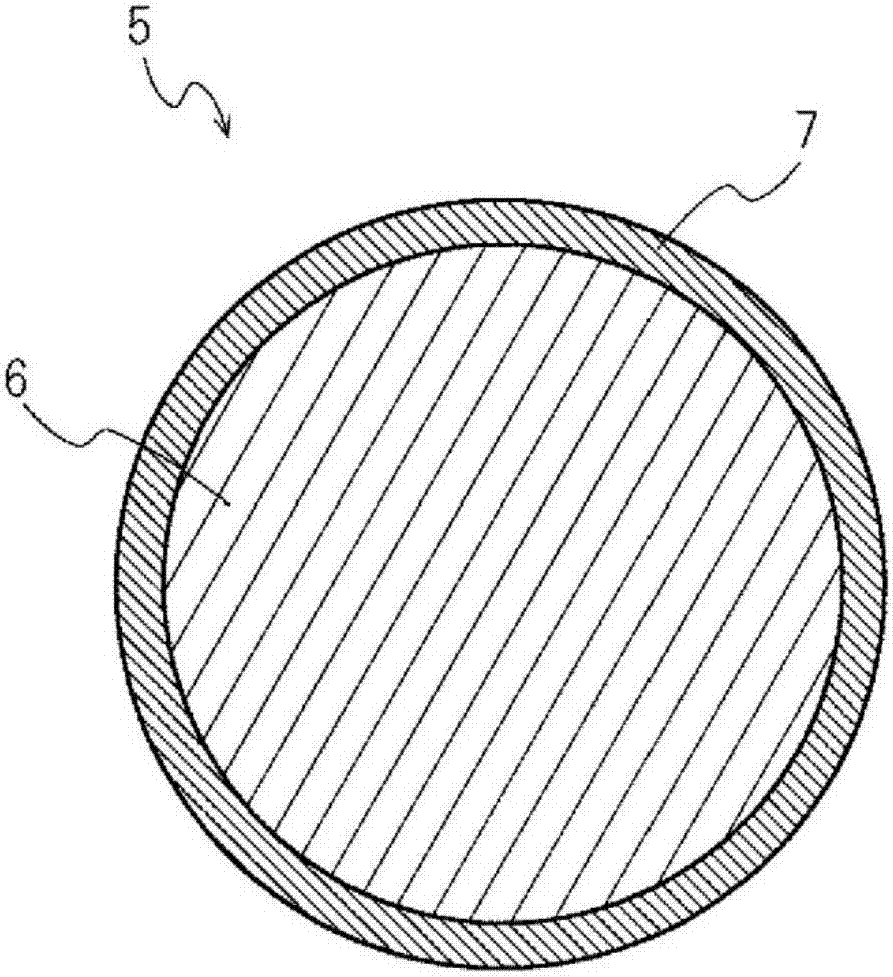

[0060] The varnish for forming the insulating layer is a varnish for forming the insulating layer 2 of the insulated electric wire. The varnish for forming an insulating layer according to the first embodiment includes a matrix-forming resin composition, and hollow-forming particles 5 having a core-shell structure dispersed in the resin composition. In the varnish, the core 6 of the hollow-forming particle 5 contains a pyrolytic resin as a main component, and the shell 7 of the hollow-forming particle 5 contains a main component whose thermal decomposition temperature is higher than that of the pyrolytic resin.

[0061] (resin composition)

[0062] The resin composition is a composition containing, for example, a main polymer, a solvent for dilution, and a hardener. The main polymer is not particularly limited. When a thermosetting resin is used, examples of the host polymer include polyvinyl formal precursors, thermosetting polyurethane precursors, thermosetting acrylic res...

no. 2 Embodiment approach

[0082] The insulating layer forming varnish according to the second embodiment is a varnish for forming an insulating layer of an insulated electric wire like the varnish for forming an insulating layer in the first embodiment. The varnish used to form the insulating layer of the second embodiment includes a matrix-forming resin composition, and hollow particles dispersed in the resin composition. In this varnish, the outer shell of the hollow particles contains resin as a main component.

[0083] The resin composition of the varnish forming the insulating layer may be the same as that of the varnish forming the insulating layer of the first embodiment.

[0084] Examples of the resin as the main component of the hollow particles include polystyrene, silicone, fluororesin, and polyimide. Among these resins, silicone is preferable from the viewpoint of imparting elasticity to the casing and improving insulation performance and heat resistance performance.

[0085] The lower li...

specific Embodiment approach

[0103] It should be understood that the specific embodiments disclosed herein are only illustrative and non-restrictive in every respect. The scope of the invention is not limited to the configuration of the specific embodiments, but is defined by the following claims. The scope of the present invention covers all modifications within the equivalent meaning and scope of the claims.

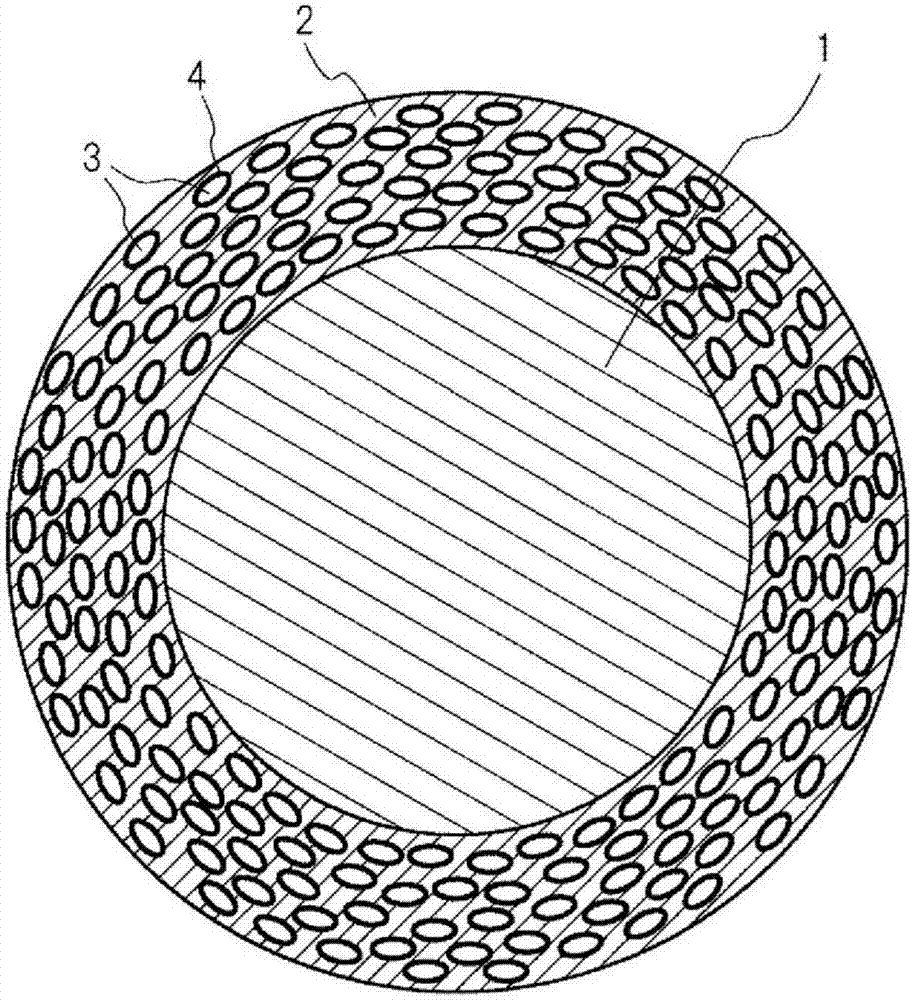

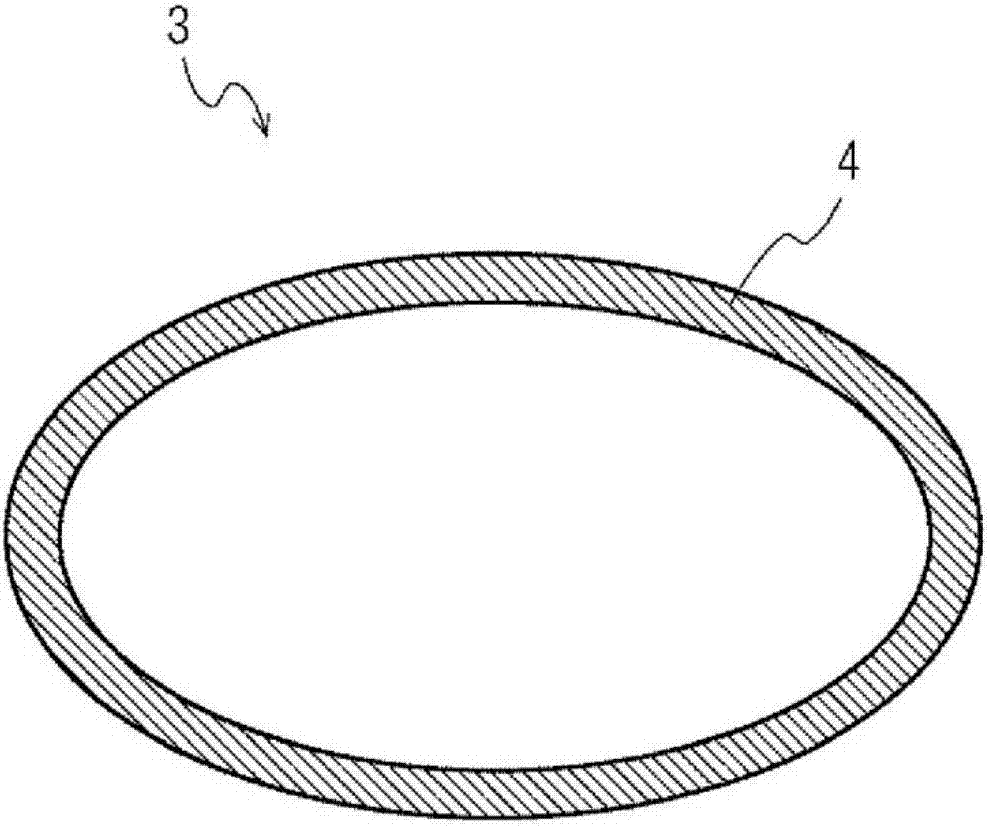

[0104] In a specific embodiment, an insulated wire is described in which a single insulating layer is formed on the outer peripheral surface of a conductor. Alternatively, the insulated wire may have a structure in which multiple insulating layers are formed on the outer peripheral surface of the conductor. Specifically, one or more insulating layers may be placed between conductor 1 and include figure 1 Air holes 3 in the insulating layer 2 are formed. Alternatively, one or more insulating layers may be formed over the figure 1 The outer peripheral surface of the insulating layer 2 in the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com