Vibration reduction wire formed by combining aluminum clad steel cores and aluminum-alloy twisted wires

A technology of aluminum clad steel core and aluminum alloy wire, applied in the field of overhead transmission lines, can solve the problems of unfavorable stability, asymmetry, and long vibration duration of the power system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

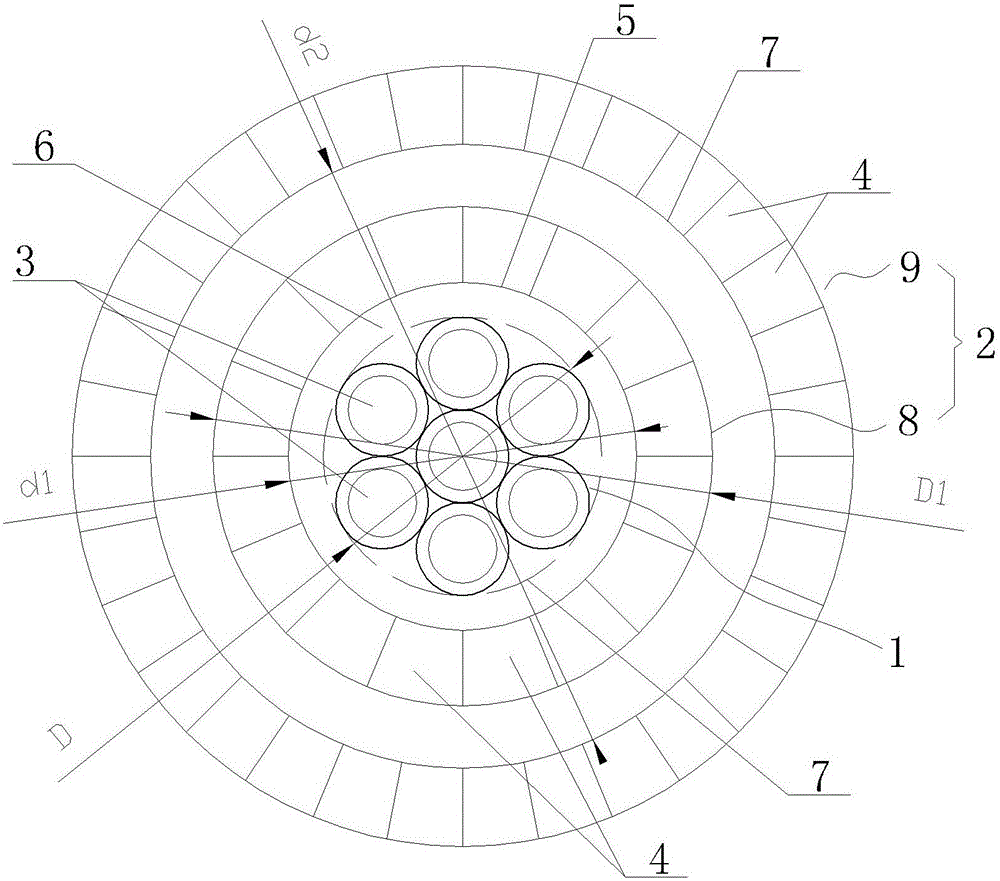

[0024] Specific embodiment one, see figure 1 : The aluminum alloy wire 4 is specifically an aluminum alloy wire with an arc-shaped cross-section, and several sections of the same arc-shaped aluminum alloy wire with an arc-shaped cross-section are combined to form an outer layer conductor of a corresponding layer, and the outer layer conductor is two layers. At this time, N = 2, the outer layer conductor opposite to the outer layer is specifically the second outer layer conductor 9, the inner diameter of the closed torus structure formed by the second outer layer conductor 9 is d2, and the outer layer conductor relative to the inner layer is the first outer layer conductor 8 , the outer diameter of the closed torus structure composed of the first outer conductor 8 is D1, the inner diameter is d1, the aluminum alloy wire is made of super heat-resistant aluminum alloy, the continuous working temperature of the aluminum alloy wire 4 is 210°C, D1:d2 =0.8, D: d1=0.85, due to the hig...

specific Embodiment 2

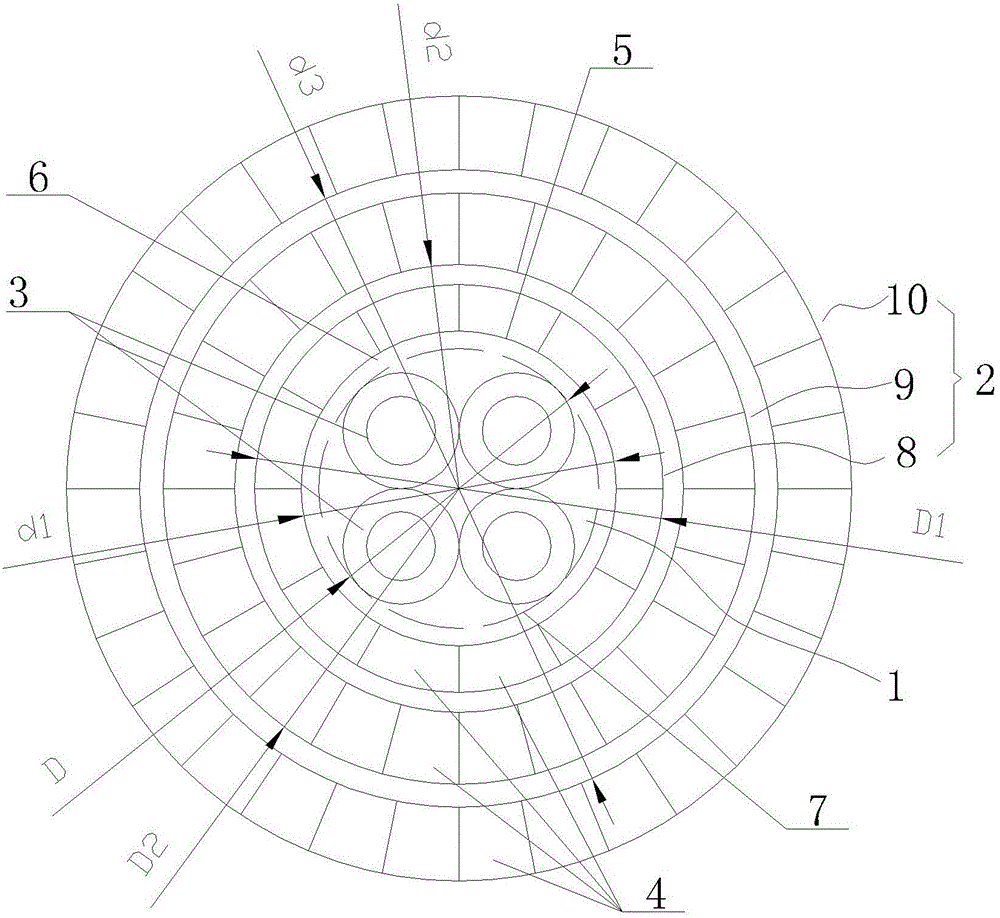

[0025] Specific embodiment two, see figure 2 : The aluminum alloy wire 4 is specifically an aluminum alloy wire with an arc-shaped cross-section, and a plurality of aluminum alloy wires with the same arc-shaped cross-section are combined to form an outer layer conductor of a corresponding layer, and the outer layer conductor is three layers. At this time, N =3, including the first outer layer conductor 8, the second outer layer conductor 9, the third outer layer conductor 10, the inner diameter of the third closed ring structure formed by the third outer layer conductor 10 is d3, the second outer layer conductor The inner diameter of the second closed torus structure composed of 9 is d2 and the outer diameter is D2, the inner diameter of the first closed torus structure formed by the first outer conductor 8 is d1, and the outer diameter is D1, and the aluminum alloy wires are all heat-resistant Aluminum alloy material, its continuous working temperature is 150°C, D3: d2 = D1:...

specific Embodiment 3

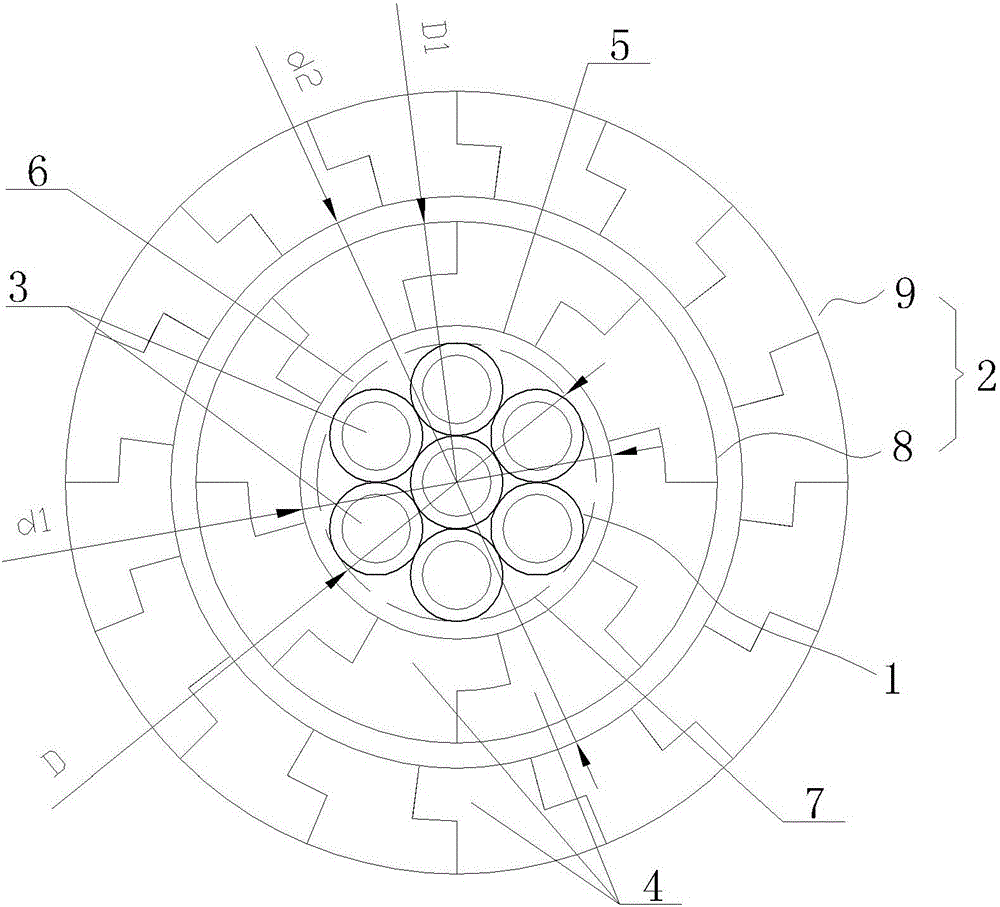

[0026] Specific embodiment three, see image 3 , Figure 4: The aluminum alloy wire is specifically a Z-shaped aluminum alloy wire, and the circumferential sides of the Z-shaped aluminum alloy wire are arc edges, including an outer arc edge 11, an inner arc edge 12, and an outer arc edge 12. The overlapping parts of the inner arc edge 11 are connected to form an overall structure, and the exposed inner end of the outer arc edge 12 is close to the exposed outer end of the inner arc edge 11 at the adjacent position to ensure the formation of a closed torus structure. Several sections of Z-shaped aluminum alloy wires with the same radian are combined to form the outer conductor of the corresponding layer. The outer conductor is two layers. At this time, N=2, and the outer conductor of the opposite outer layer is specifically the second outer conductor 9 , the inner diameter of the closed torus structure formed by the second outer conductor 9 is d2, the outer conductor of the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com