Damping optical fiber composite overhead ground wire

An overhead ground wire and optical fiber composite technology, applied in the field of overhead transmission lines, can solve the problems of communication interruption, strand fatigue breaking, wire breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

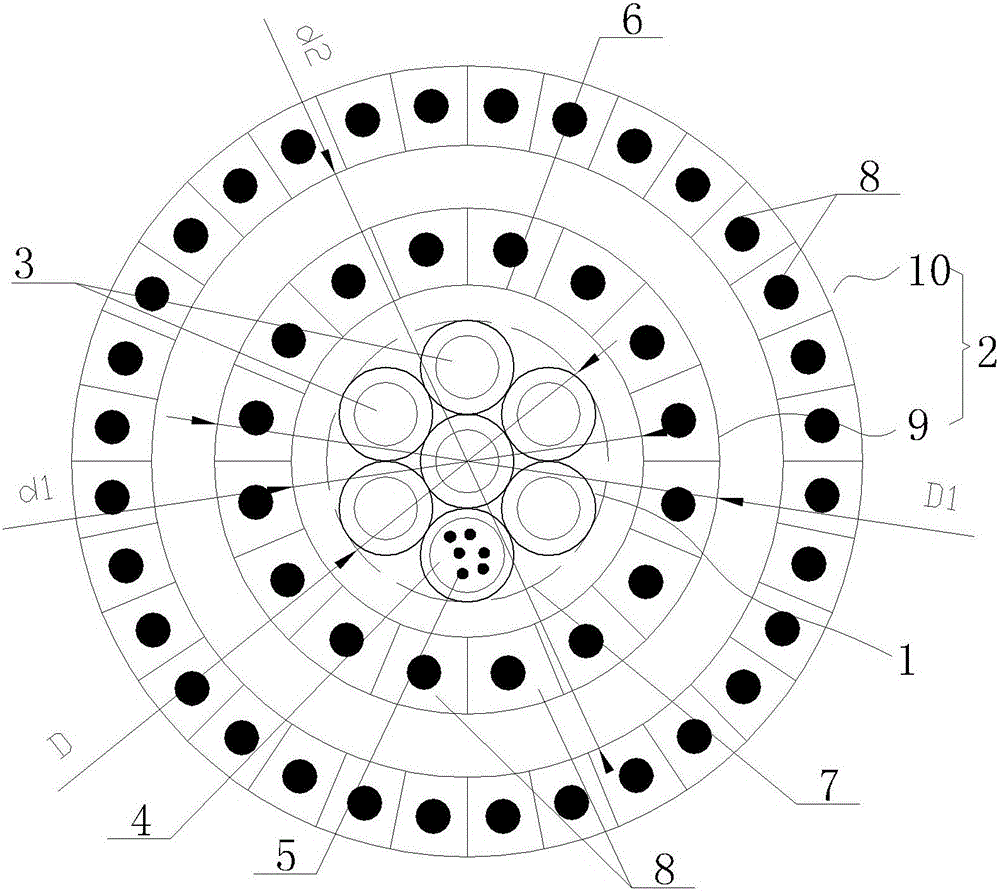

[0021] Specific embodiment one, see figure 1 : The outer conductor 2 has two layers, the first outer conductor 9 and the second outer conductor 10 respectively. The outer conductor opposite to the outer layer is specifically the second outer conductor 10, which is composed of a closed The inner diameter of the toroidal structure is d2, and the outer conductor opposite to the inner layer is the first outer conductor 9. The outer diameter of the closed toroidal structure formed by the first outer conductor 9 is D1, and the inner diameter is d1, D1: d2=0.85 , D: d1=0.85, the outer conductor of each layer is formed by combining several sections of aluminum clad steel wire with the same arc with a circular cross section. The first outer conductor 9 is composed of sixteen sections of the first aluminum clad with the same arc. The steel wire is combined to form a corresponding closed first torus structure, and the second outer conductor 10 is composed of thirty-two sections of second a...

specific Embodiment 2

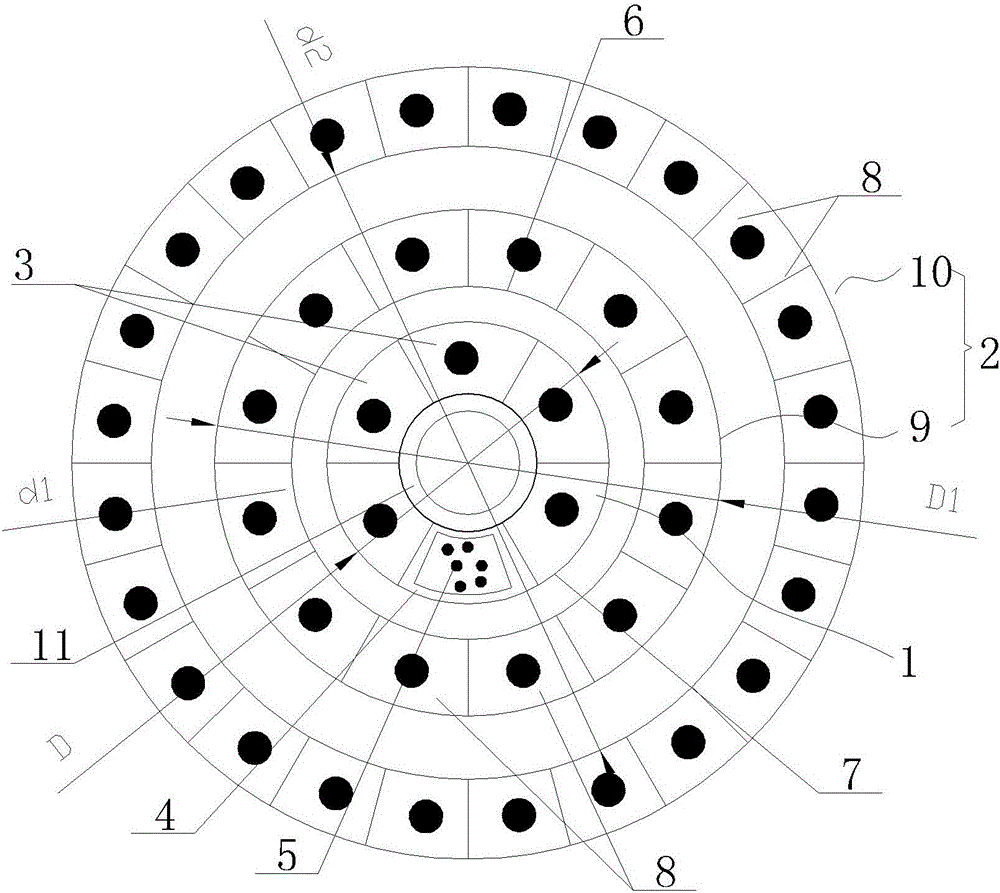

[0022] Specific embodiment two, see figure 2 : The outer conductor 2 has two layers, the first outer conductor 9 and the second outer conductor 10 respectively. The outer conductor opposite to the outer layer is specifically the second outer conductor 10, which is composed of a closed The inner diameter of the toroidal structure is d2, and the outer conductor opposite to the inner layer is the first outer conductor 9. The outer diameter of the closed toroidal structure formed by the first outer conductor 9 is D1, and the inner diameter is d1, D1: d2 = 0.9 , The outer conductor 2 of each layer is formed by combining several sections of aluminum clad steel wire 8 with the same arc with a circular cross section, and the first outer conductor 9 is formed by combining twelve sections of the first aluminum clad steel wire with the same arc. Corresponding to the closed first torus structure, the second outer conductor is composed of twenty-four segments of the second aluminum-clad st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com