A kind of carbon nanotube reinforced multilayer aluminum matrix composite material and its preparation method and application

A technology of aluminum-based composite materials and carbon nanotube layers, which is applied in the direction of carbon-silicon compound conductors, equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, etc., can solve problems such as difficulty in achieving uniform powder formation, Achieve the effects of improving mechanical properties and electrical conductivity, improving microscopic texture, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

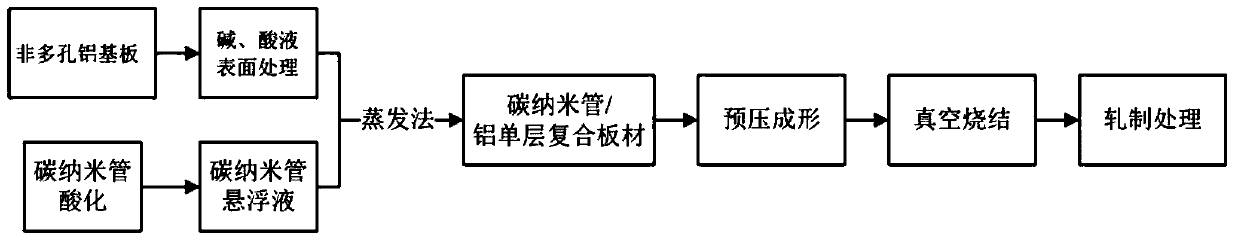

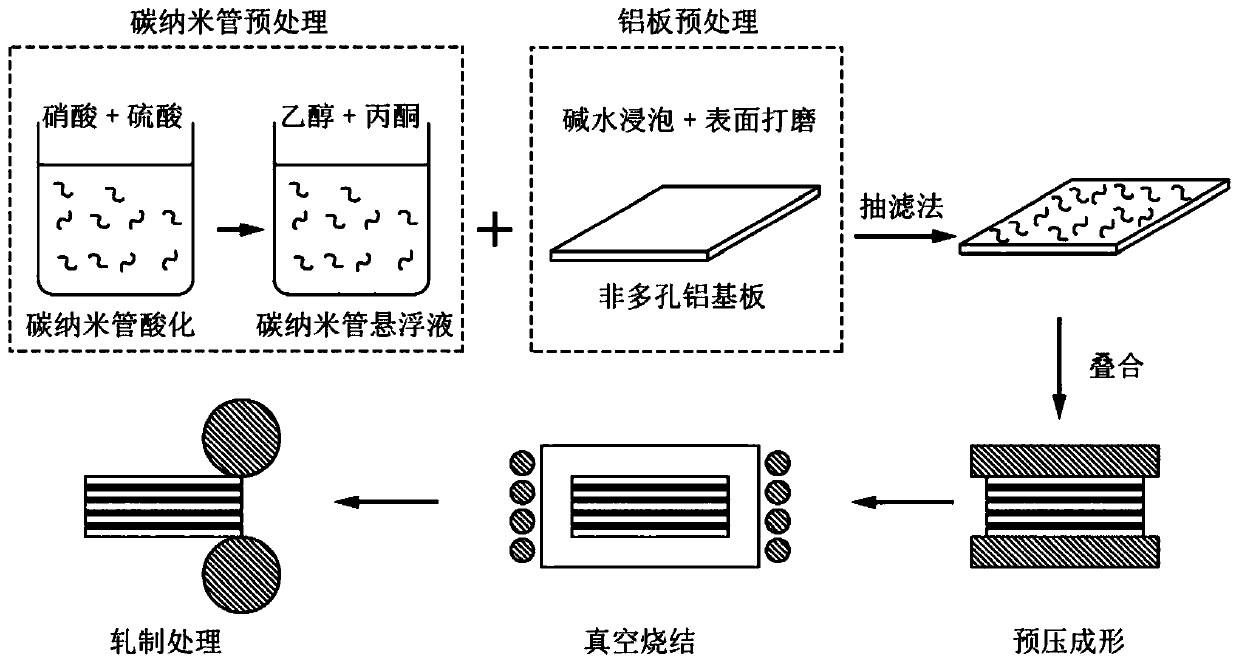

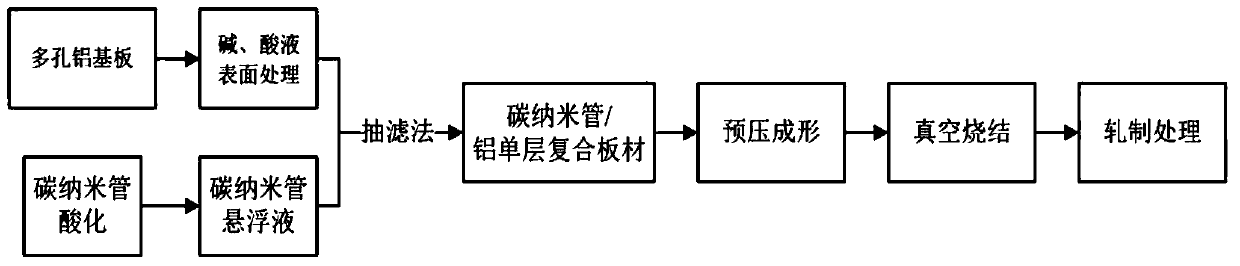

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0048] (1) Soak the 6063 aluminum alloy plate with length, width and thickness of 60, 30 and 0.1mm in 50g / ml sodium hydroxide solution for 5min, rinse with 68% nitric acid after taking it out, and finally Rinse with deionized water and dry;

[0049] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0050] (3) Put 0.05g of carbon nanotubes (30 μm in length and 20 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 2:1 for acidification treatment for 6 hours, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidification t...

Embodiment 2

[0057] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0058] (1) Soak the 6063 aluminum alloy plates with length, width and thickness of 60, 30 and 2 mm in 50 g / ml sodium hydroxide solution for 5 minutes, rinse with 68% nitric acid after removal, and finally remove After washing with ionized water, dry;

[0059] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0060] (3) Put 0.05g of carbon nanotubes (10 μm in length and 8 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:1 for acidification treatment for 10 h, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidifica...

Embodiment 3

[0067] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0068] (1) Soak the 6063 aluminum alloy plate with length, width and thickness of 60, 30 and 1mm in 50g / ml sodium hydroxide solution for 5min, rinse with 68% nitric acid after taking it out, and finally remove After washing with ionized water, dry;

[0069] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0070] (3) Put 0.05g of carbon nanotubes (25 μm in length and 50 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 4:1 for acidification treatment for 2 hours, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com