High-strength aluminum-clad steel wire and production method thereof

An aluminum-clad steel wire, high-strength technology, applied in the direction of rod/rod/wire/strip conductor, auxiliary non-insulated conductor, cable/conductor manufacturing, etc. The problem of high production cost, to achieve the effect of high production efficiency, enhanced corrosion resistance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

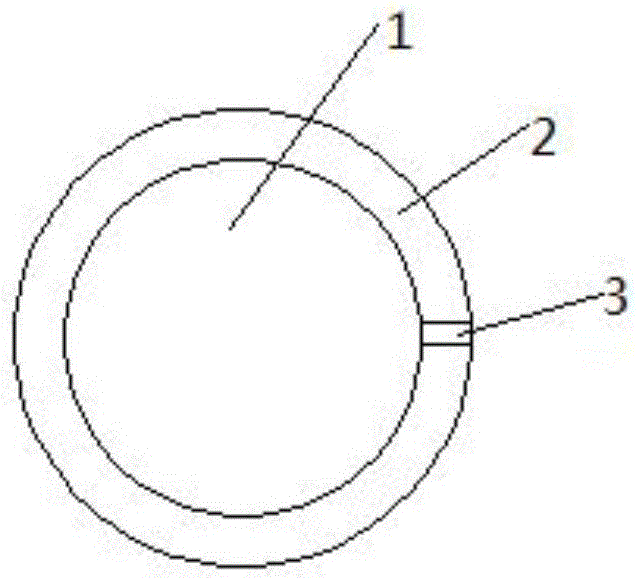

[0021] A high-strength aluminum-clad steel wire, comprising a steel core 1 and an aluminum layer 2 coated on the outer surface of the steel core 1, two opposite sides of the aluminum layer are welded and connected, and a weld 3 is formed at the weld;

[0022] The steel core 1 is prepared by the following method:

[0023] (1) Vacuum smelting is carried out with alloy steel as the blank, and the components in the alloy steel are calculated by mass percentage: carbon 0.65%, silicon 0.2%, manganese 0.3%, chromium 1.3%, nickel 1.4%, molybdenum 0.5%, Rare earth element 0.04%, the rest is Fe;

[0024] (2) Heating the semi-finished steel wire finished rolling to the required size, the heating temperature is 850°C;

[0025] (3) Pass the steel wire semi-finished product through a heat treatment furnace for lead bath quenching treatment. The heat treatment line temperature is 900°C, the lead bath temperature is about 550°C, and the time in the furnace is 200S; The surface oxide skin is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com