Carbon nanotube reinforced multilayer aluminum-based composite material as well as preparation method and application thereof

A technology of aluminum-based composite materials and carbon nanotube layers, which is applied in the direction of carbon-silicon compound conductors, equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, etc., can solve problems such as difficulty in achieving uniform powder formation, Achieve high strength, improve performance, and promote alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

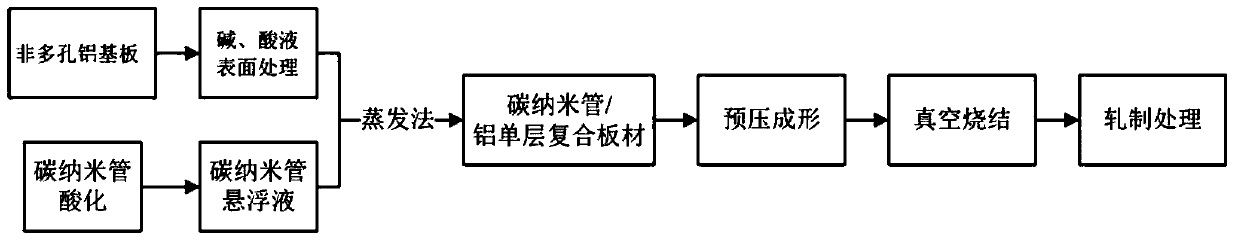

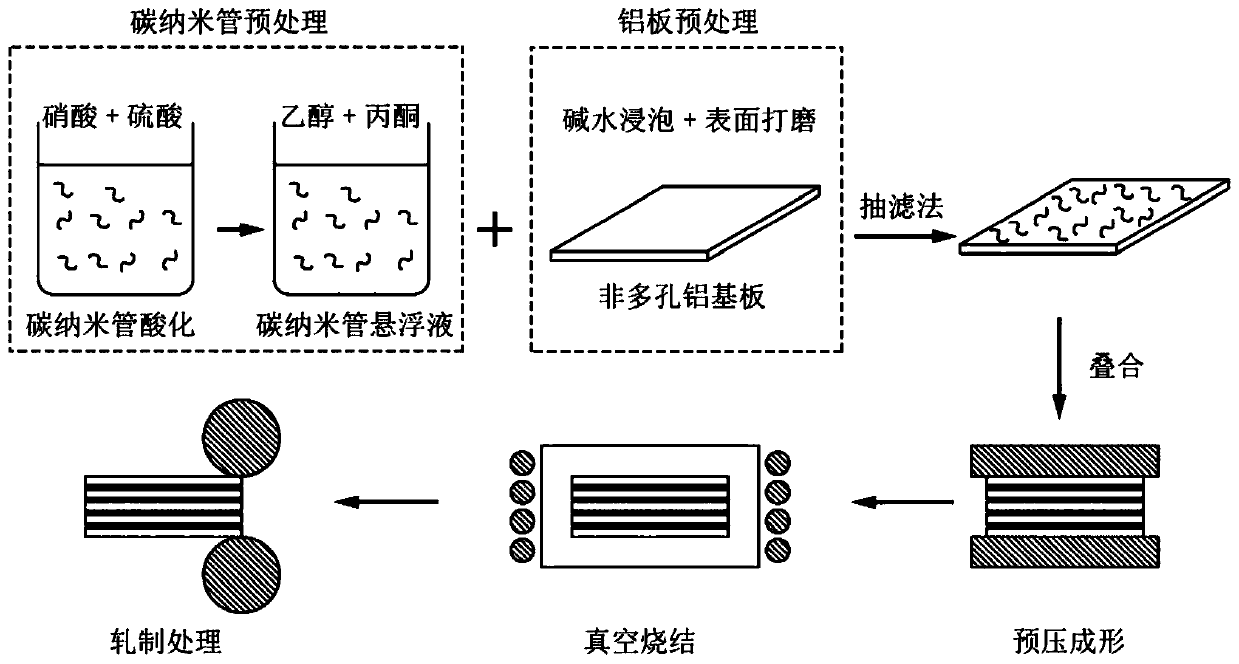

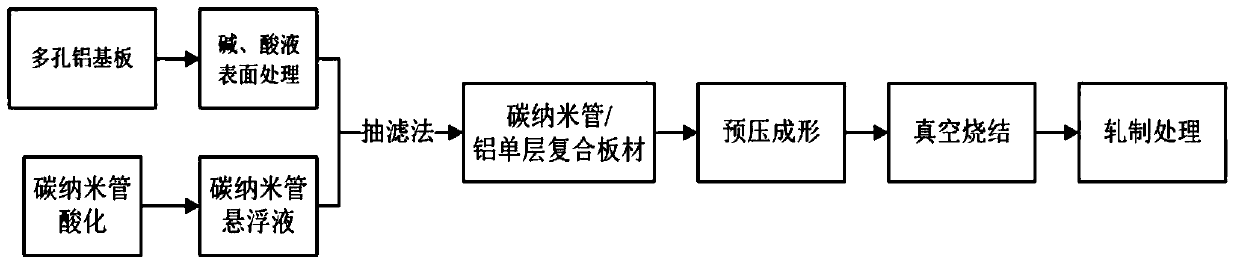

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0048] (1) Soak the 6063 aluminum alloy plate with length, width and thickness of 60, 30 and 0.1mm in 50g / ml sodium hydroxide solution for 5min, rinse with 68% nitric acid after taking it out, and finally Rinse with deionized water and dry;

[0049] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0050] (3) Put 0.05g of carbon nanotubes (30 μm in length and 20 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 2:1 for acidification treatment for 6 hours, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidification t...

Embodiment 2

[0057] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0058] (1) Soak the 6063 aluminum alloy plates with length, width and thickness of 60, 30 and 2 mm in 50 g / ml sodium hydroxide solution for 5 minutes, rinse with 68% nitric acid after removal, and finally remove After washing with ionized water, dry;

[0059] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0060] (3) Put 0.05g of carbon nanotubes (10 μm in length and 8 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:1 for acidification treatment for 10 h, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidifica...

Embodiment 3

[0067] A method for preparing a carbon nanotube-reinforced multilayer aluminum-based composite material. In this embodiment, a non-porous aluminum substrate (6063 aluminum alloy) is used as the aluminum substrate, comprising the following steps:

[0068] (1) Soak the 6063 aluminum alloy plate with length, width and thickness of 60, 30 and 1mm in 50g / ml sodium hydroxide solution for 5min, rinse with 68% nitric acid after taking it out, and finally remove After washing with ionized water, dry;

[0069] (2) The 6063 aluminum alloy plate obtained in step (1) is polished with 2000# sandpaper, then rinsed with deionized water and dried, and set aside;

[0070] (3) Put 0.05g of carbon nanotubes (25 μm in length and 50 nm in diameter) in a mixed acid prepared by concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 4:1 for acidification treatment for 2 hours, then dilute to neutral, and Carry out centrifugation treatment, obtain the carbon nanotube of acidifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com