Electric mattress and method for manufacturing same

A manufacturing method and technology of electrical steel, applied in the direction of manufacturing tools, circuits, electrical components, etc., can solve problems such as unfavorable environmental protection, difficulty in ensuring the iron loss characteristics of the final product, mechanical processing stability, and reliability of complex processes, etc. , to achieve the effect of improving the subdivision effect of the magnetic region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The advantages and features of the present invention and methods for realizing them will become more apparent with reference to the accompanying drawings and detailed embodiments described later. However, the present invention is not limited to the embodiments disclosed below, but can be implemented in various forms different from each other, but this embodiment will make the disclosure of the present invention more complete, and will make people with ordinary knowledge in the technical field to which the present invention belongs A more complete understanding of the scope of the invention. The scope of the present invention is defined only by the claims. The same reference numerals denote the same structural elements throughout the specification.

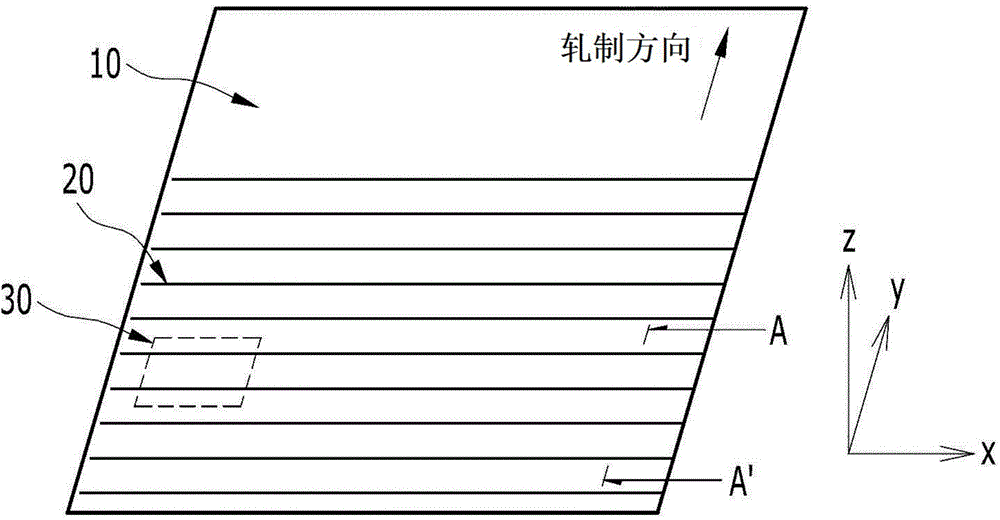

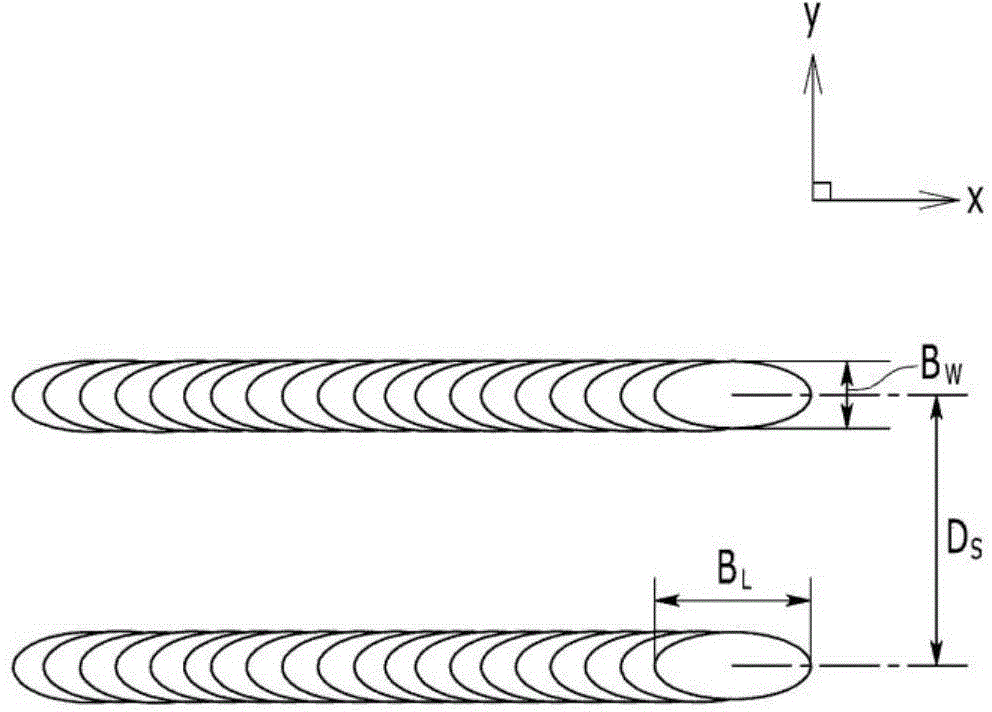

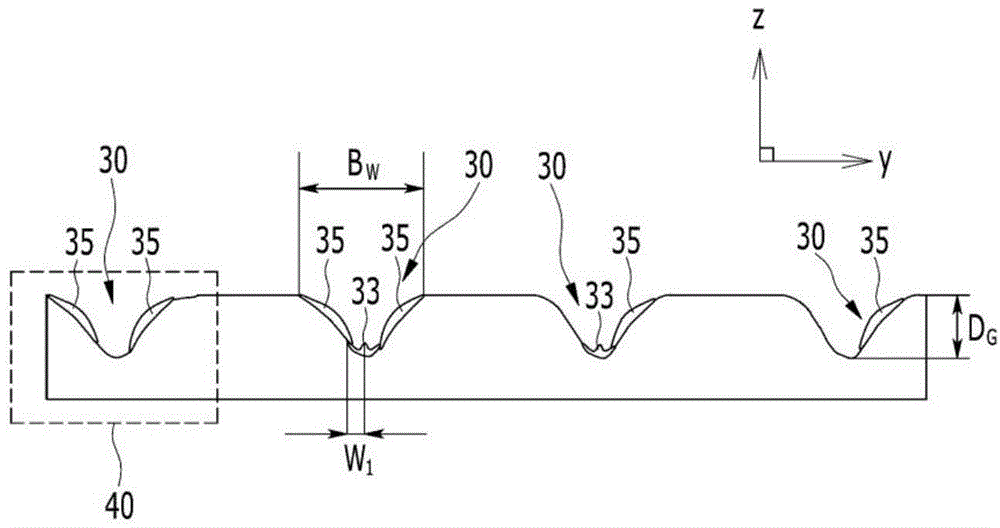

[0045] Next, an electrical steel sheet having grooves on the surface of the steel sheet for subdividing the magnetic domains will be described with reference to preferred embodiments of the present invention.

[0046] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com