High temperature insulated aluminum conductor

A technology of conductors and electric conductors, applied in the field of high-temperature insulated aluminum conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

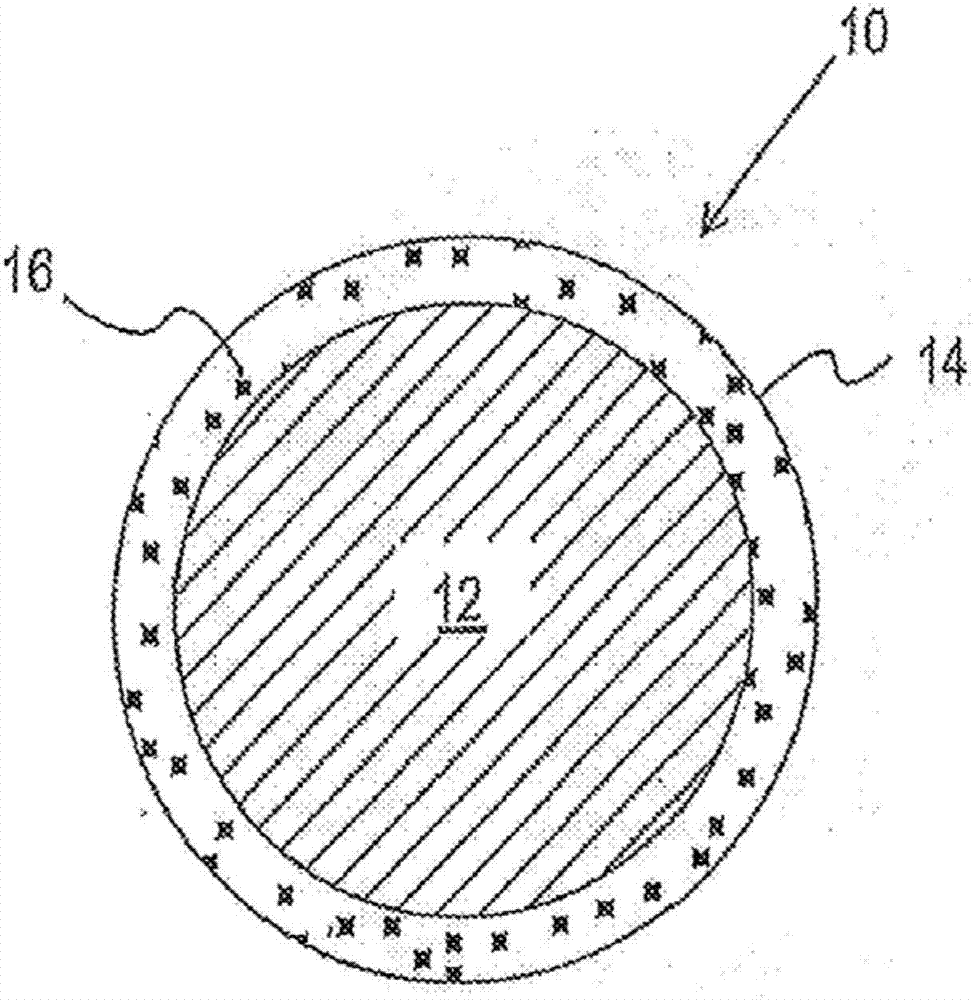

Embodiment 1

[0084] Aluminum wires are immersed in an electrolyte containing dissolved Ti, phosphate and etchant. The diameter of the aluminum wire was 0.76 mm and its residence time in the bath was 10 seconds at 490 volts (peak voltage) and 185 amperes. Remove the wire from the electrolyte bath and measure the coating thickness and contents. There is about 10 microns of titanium dioxide-containing electroceramic coating.

[0085] The titanium dioxide coated wires were tested in comparison to two commercially available reference copper wires conventionally coated by the manufacturer with an insulating coating. Copper Wire Reference 1 is a 0.74 mm diameter copper magnet wire coated with an organic insulating coating. Wires were removed from the coils of the electric drill motor of an 18V cordless Craftsman brand drill available from Sears. Copper Wire Reference 2 is a commercially available copper magnet wire with a diameter of 0.66 mm coated with an organic insulating coating. Wires ar...

Embodiment 2

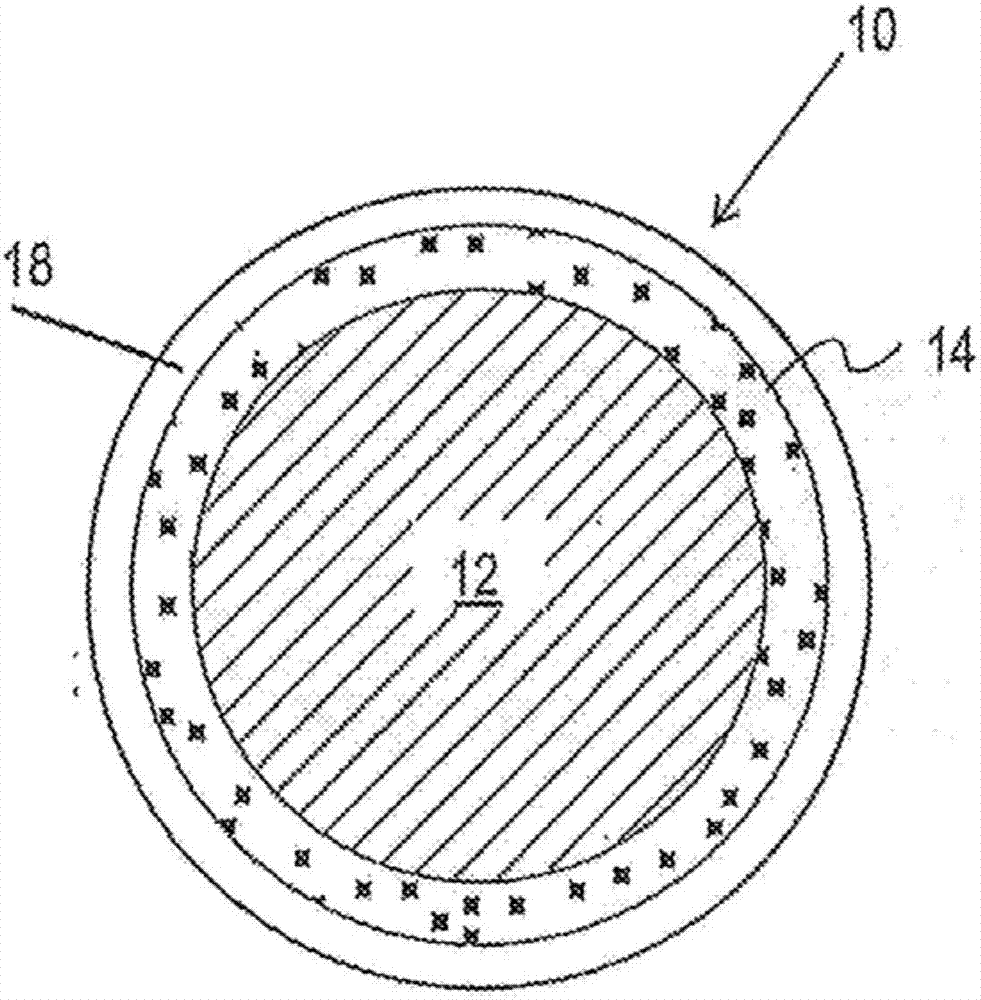

[0092] Insulation tests and hot spot tests were performed on electrical conductors with coatings of the present disclosure, wherein a second insulating organic layer was applied to the outer surface of the electroceramic coating; The electrical conductors of the layers are subjected to insulation tests and hot spot tests.

[0093] Aluminum wires are immersed in an electrolyte containing dissolved Ti, phosphate and etchant. The diameter of the aluminum wire was 0.76 mm and its residence time in the bath was 10 seconds at 410 volts (peak voltage). Remove the wire from the electrolyte bath and measure the coating thickness and contents. There was about 10 microns of an electroceramic coating containing titanium dioxide on the aluminum conductor lines. An additional outer insulating organic sheath having a thickness of 0.36 mm was provided on the outer surface of the titanium dioxide-containing coating. The outer insulating organic sheath is ethylene-chlorotrifluoroethylene (EC...

Embodiment 3

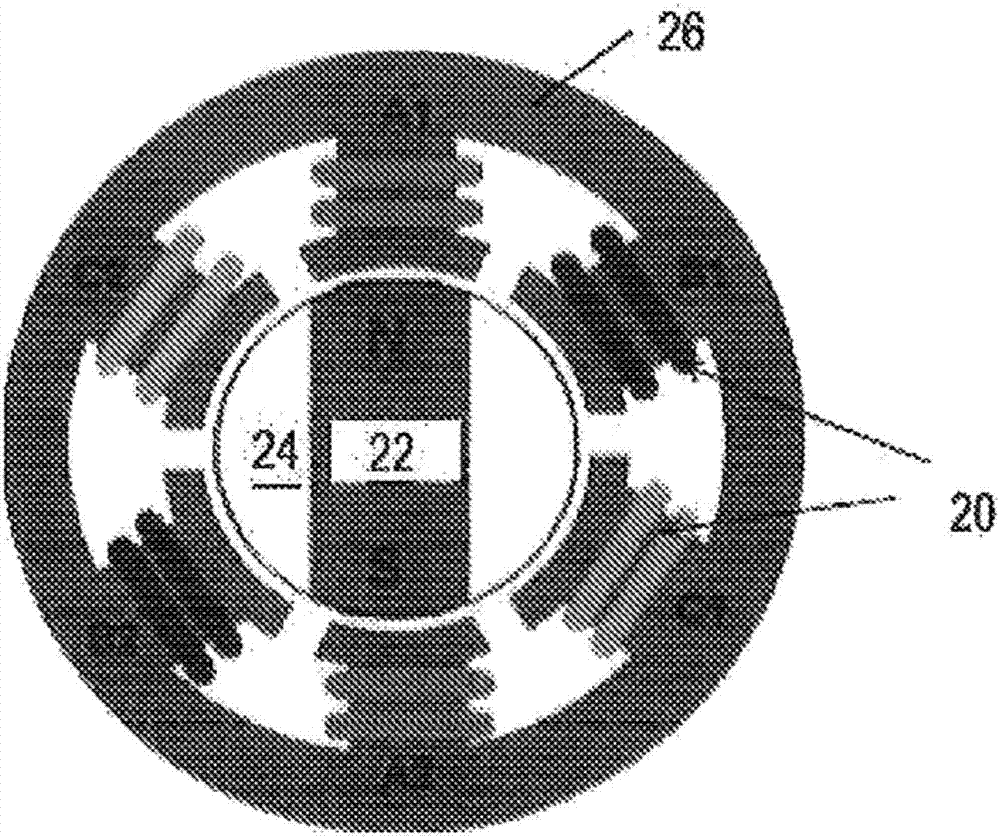

[0100] Thermal shock tests were performed on samples of the disclosed coated aluminum alloy conductors having metal oxide coatings comprising titania and alumina and samples of conventional anodized aluminum alloy conductors. A conventional anodized aluminum alloy conductor was anodized in a stage 1 sulfuric acid anodizing process, and the resulting oxide layer had a thickness of about 18 microns on the sample of Comparative Example 3.

[0101] Samples of aluminum alloy wires were immersed in an electrolyte containing dissolved Ti, phosphate and etchant. The aluminum alloy wire samples were 0.76 mm in diameter and had a residence time in the bath of 10 seconds at 410 volts (peak voltage). The aluminum alloy wire samples were removed from the electrolyte bath and the coating thickness and content were measured. On the aluminum alloy wire sample of Example 3, there was about 10 microns of an electroceramic coating containing titanium dioxide.

[0102] The initial resistance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com