Patents

Literature

35results about How to "Increase the compression factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Fe-Cu alloy material and preparation method thereof

The invention particularly relates to an Al-Fe-Cu alloy material and a preparation method thereof. The Al-Fe-Cu alloy material comprises the following components in percentage by weight: 0.20-1.30 wt% of Fe, 0.01-0.08 wt% of Cu, 0.06-0.15 wt% of Si, 0.02-0.10 wt% of rare-earth element and the balance of Al and unavoidable impurities. The aluminum alloy is prepared by casting and semi-annealing raw materials. When the aluminum alloy is prepared, the alloy material is semi-annealed, and thus, the adverse effects of stress on a conductor structure in the process of drawing and twisting are reduced, the electric conductivity reaches and even exceeds 61% of IACS (International Annealed Copper Standard) (the electric conductivity standard of an aluminum conductor for a general electrician is 61% of IACS), and the performances of elongation and the flexibility of the aluminum alloy are improved greatly by annealing. The performances of the elongation of a cable made of the aluminum alloy wire can reach 30%, the flexibility is 25% higher than that of a copper cable, and the resistivity maintains in a lower level.

Owner:安徽省惠尔电气有限公司

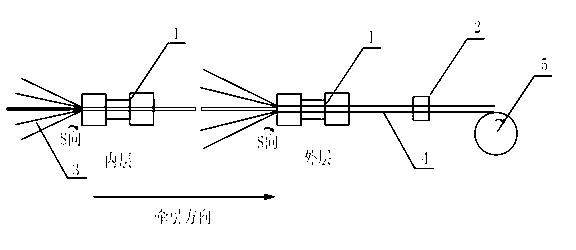

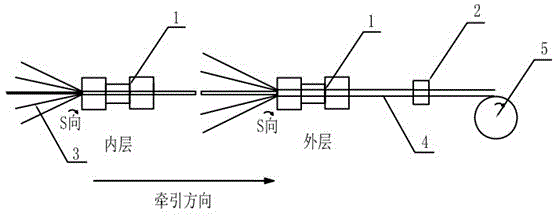

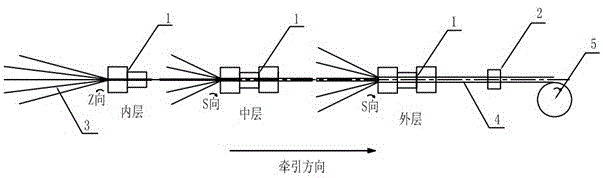

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

Rare-earth aluminum alloy conductor for cable and manufacturing method thereof

InactiveCN102864344AHigh tensile strengthHigh elongationMetal/alloy conductorsRare-earth elementElectrical conductor

The invention discloses a rare-earth aluminum alloy conductor for a cable and a manufacturing method thereof. The rare-earth aluminum alloy conductor comprises the following components in percentage by weight: 0.05 to 0.15 percent of copper, 0.40 to 1.0 percent of ferrum, 0.03 to 0.15 percent of silicon, 0.02 to 0.12 percent of rare-earth elements and the balance of aluminum. The prepared rare-earth aluminum alloy conductor is subjected to tempering, the stress effect in the processes of drawing and stranding and the adverse effect of strain hardening on an organization structure of the conductor are improved, so that electric conductivity reaches and even exceeds 61 percent International annealed copper standard (IACS); and the elongation and flexibility of rare-earth aluminum alloy can be improved greatly, and the resistance of the conductor can be reduced by annealing treatment. According to the aluminum alloy conductor for the cable, the strength is improved 10 percent compared with pure aluminum, the elongation is 30 percent, the flexibility is 25 percent higher than that of a copper cable, and the resistance of the conductor is kept at a low level.

Owner:ANHUI PACIFIC CABLE GROUP

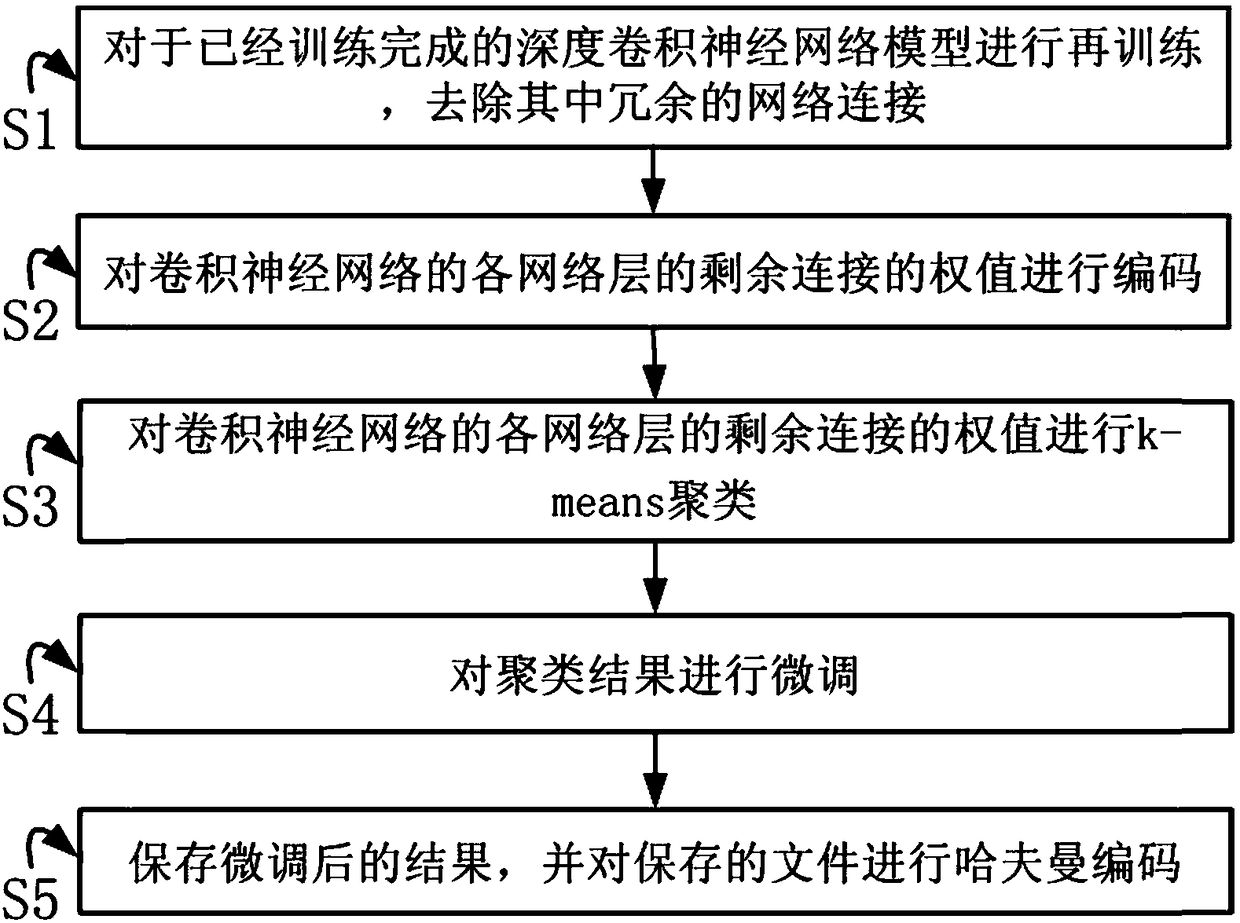

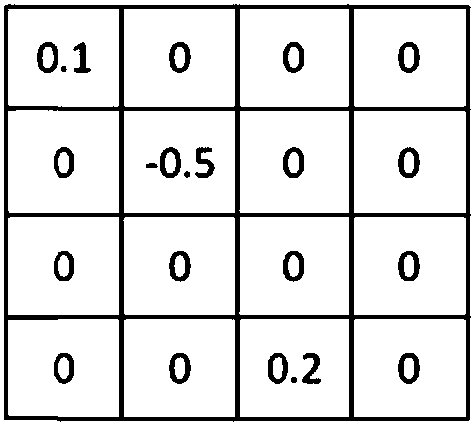

Method for deep convolutional neural network model compression

InactiveCN108322221AStable removalIncrease the compression factorCode conversionCharacter and pattern recognitionNetwork connectionData mining

The invention discloses a method for deep convolutional neural network model compression. The method comprises the steps that a trained deep convolutional neural network model is retrained to remove redundant network connections; weights of remaining connections of various network layers of a convolutional neural network are coded; the weights of the remaining connections of the various network layers of the convolutional neural network are subjected to k-means clustering; clustering results are subjected to fine tuning; and results after fine tuning are saved, and a saved file is subjected toHuffman coding. According to the method, by setting a dynamic threshold, the connections in the network can be gently removed to enable the network to be recovered from the unfavorable condition thatthe connections are removed, and therefore the effect that the compression multiples is high under the condition of the same accuracy rate loss can be achieved; and in the coding process of the remaining connections, the bit number needed for representing an index value can be decreased by means of the used improved CSR coding method, therefore, the size of the compressed file can be decreased, and the compression ratio is increased.

Owner:SOUTH CHINA UNIV OF TECH +1

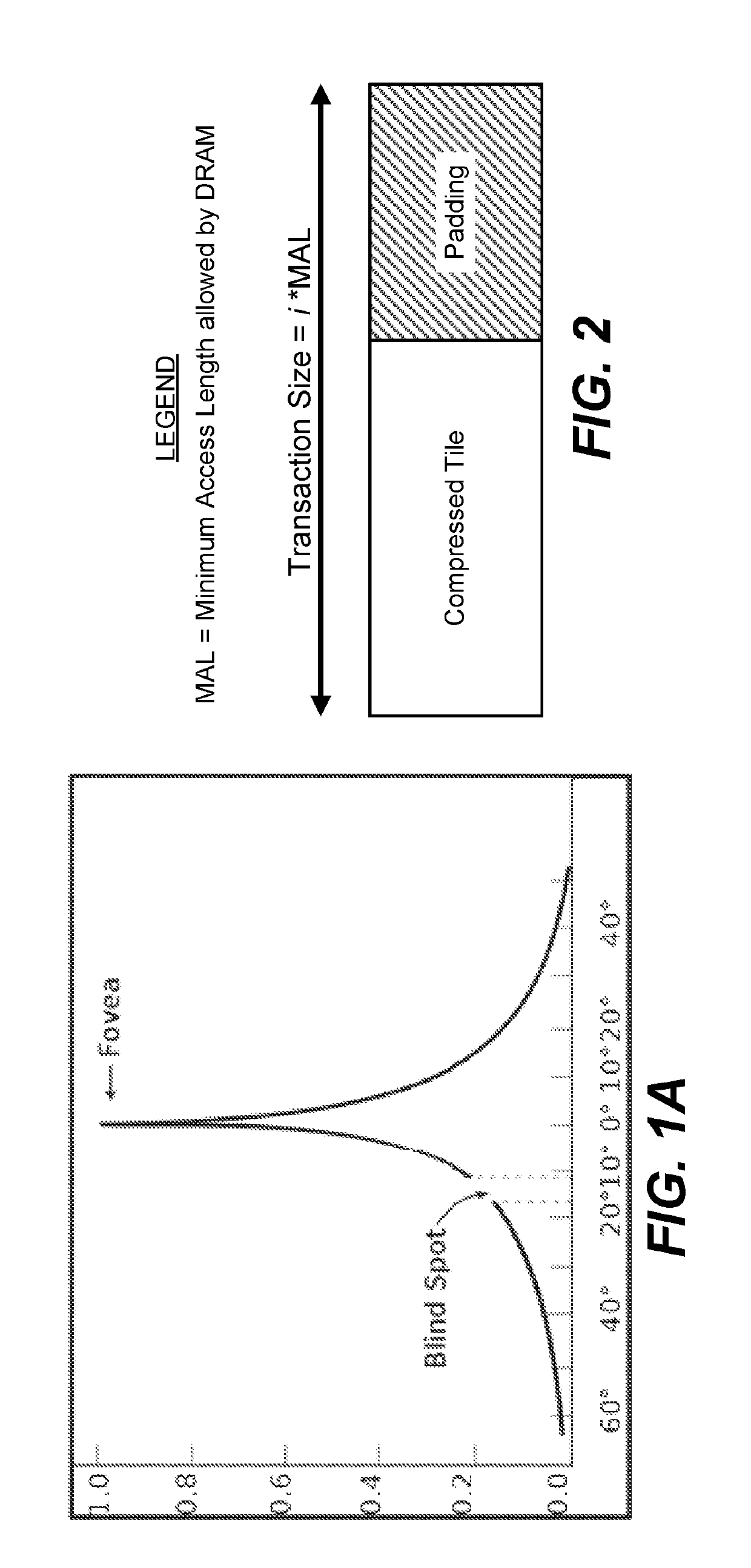

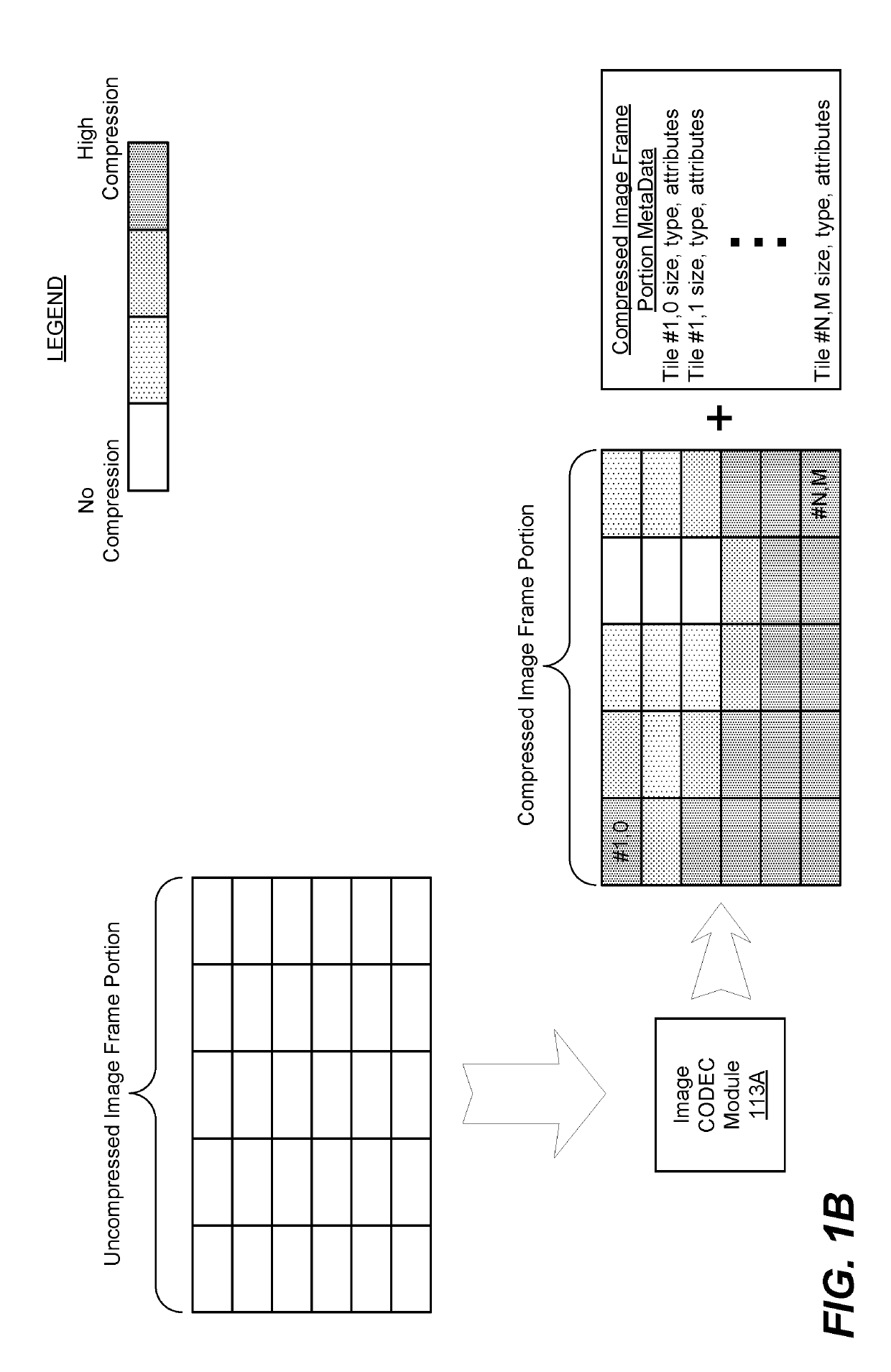

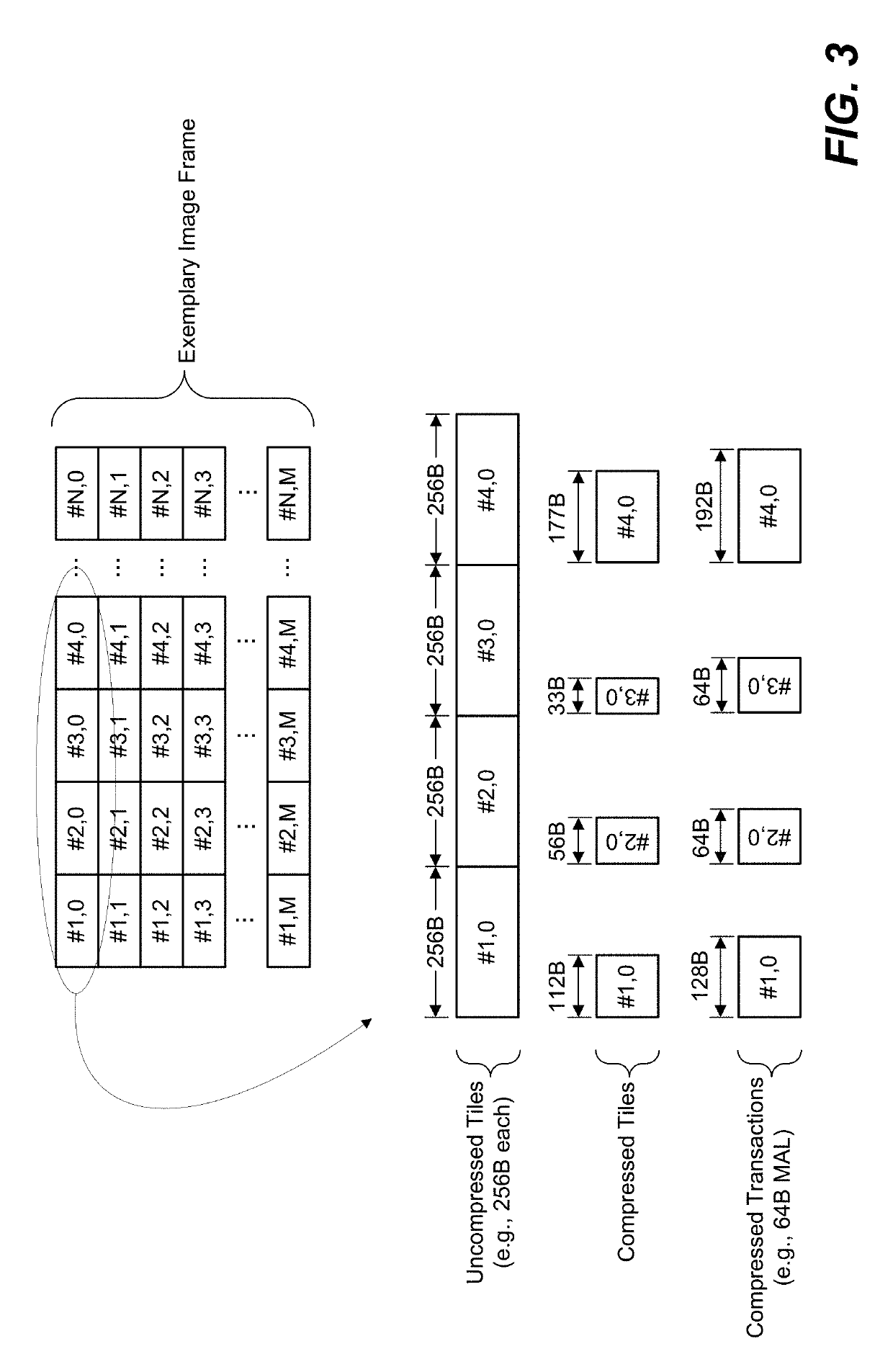

System and method for foveated compression of image frames in a system on a chip

ActiveUS20190110053A1Increase the compression factorCompression can be losslessMemory architecture accessing/allocationTelevision system detailsFixation pointLossless compression algorithm

An exemplary method for intelligent compression uses a foveated-compression approach. First, the location of a fixation point within an image frame is determined. Next, the image frame is sectored into two or more sectors such that one of the two or more sectors is designated as a fixation sector and the remaining sectors are designated as foveation sectors. A sector may be defined by one or more tiles within the image frame. The fixation sector includes the particular tile that contains the fixation point and is compressed according to a lossless compression algorithm. The foveation sectors are compressed according to lossy compression algorithms. As the locations of foveation sectors increase in angular distance from the location of the fixation sector, a compression factor may be increased.

Owner:QUALCOMM INC

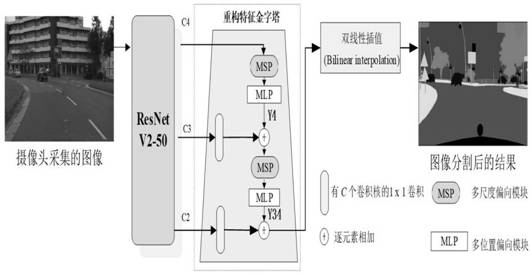

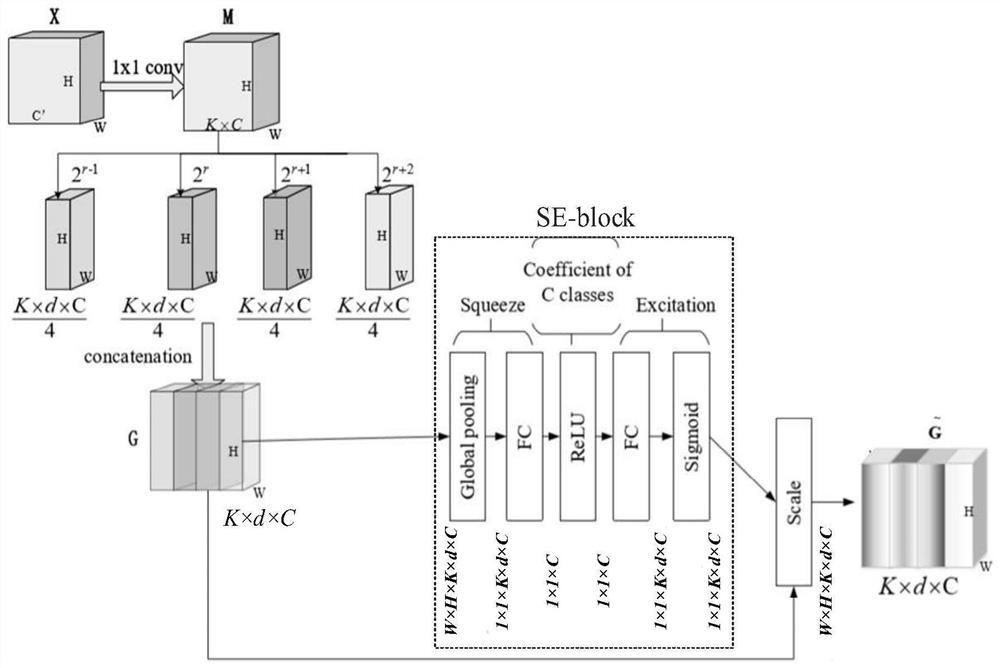

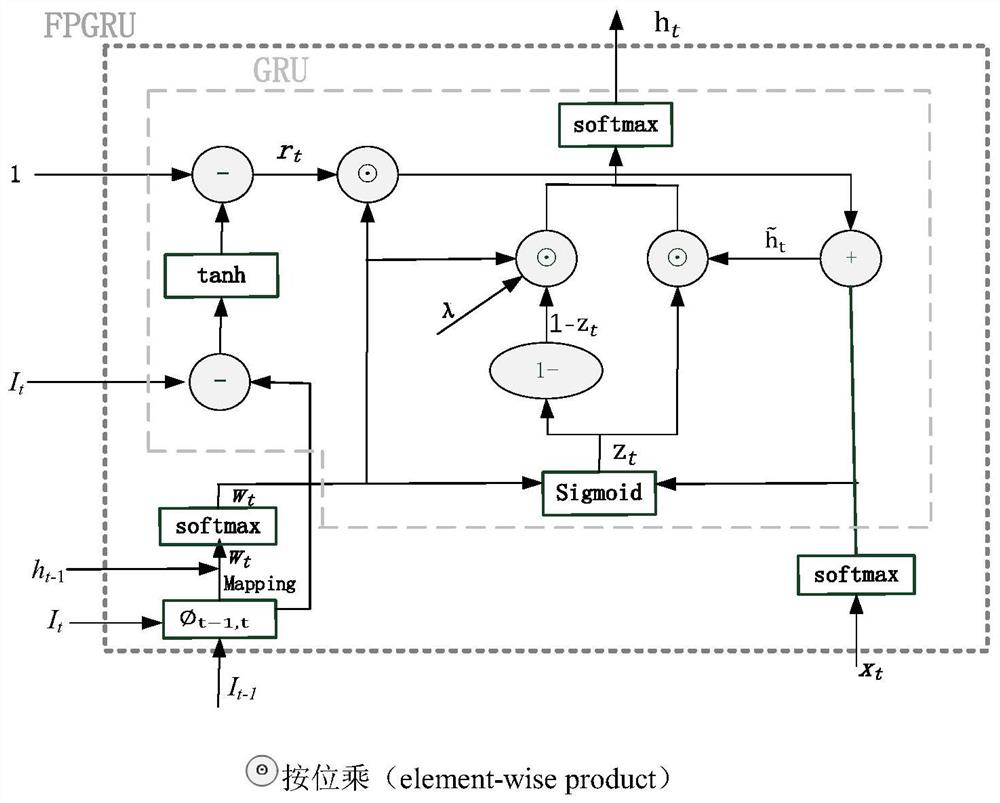

Method for guiding video coding by utilizing scene semantic segmentation result

ActiveCN112004085AIncrease the compression factorReduce storage consumptionImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention provides a method for guiding video coding by utilizing a semantic segmentation result. Firstly, on the basis of an image semantic segmentation result, inter-frame optical flow estimation is combined, semantic segmentation of a video flow sequence is achieved in a mode that a plurality of flow propagation gating circulation units are connected in series, and the precision and speed of video semantic segmentation are improved. Furthermore, the video semantic segmentation result is applied to adaptive video coding under the guidance of scene content classification;, the target category and motion characteristics in the video content can be effectively utilized to realize self-adaptive quantization, low-rate compression is carried out on key objects and motion targets, high-ratecompression is carried out on non-key objects, the storage consumption and bandwidth occupation of the video are reduced, and effective reference is provided for video coding compression, especiallyapplication in the monitoring field.

Owner:BEIHANG UNIV

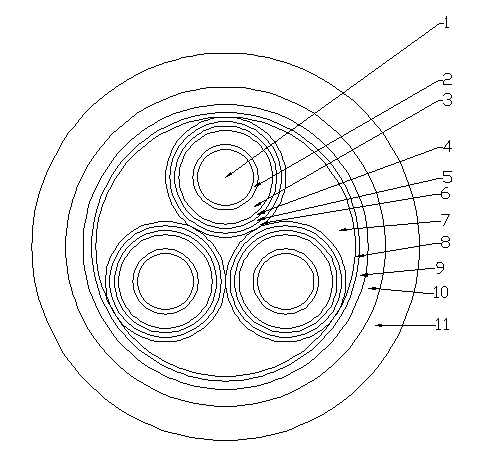

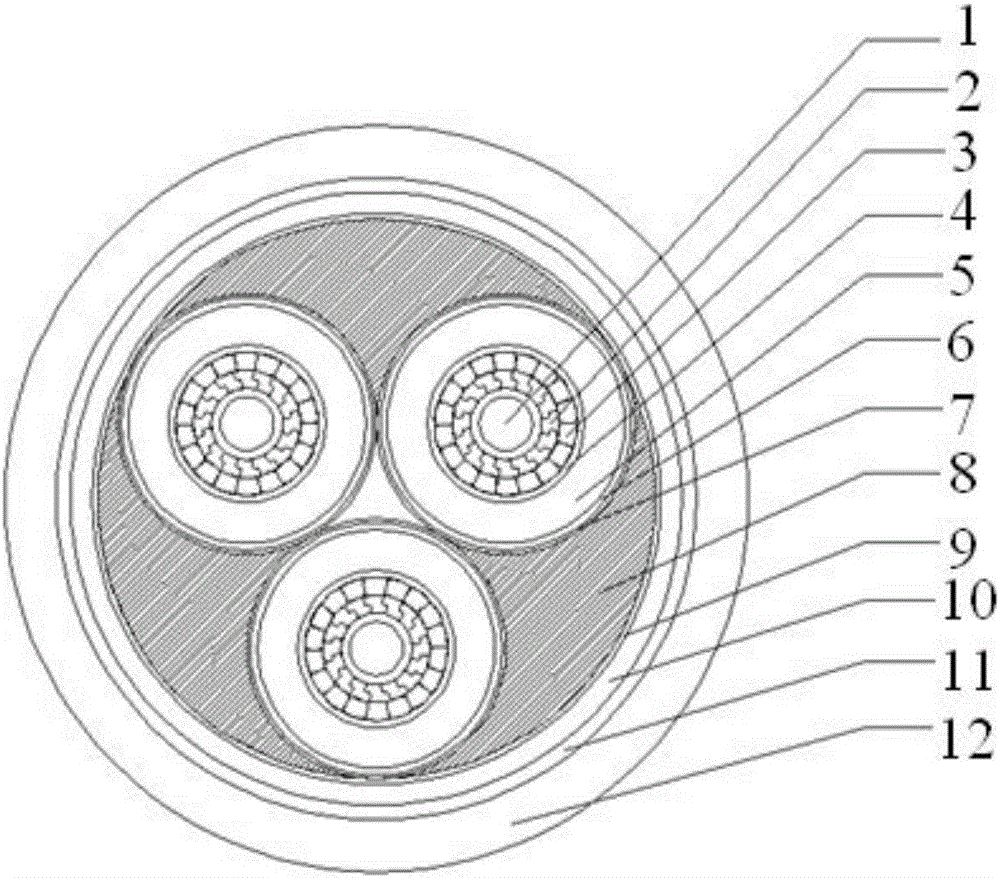

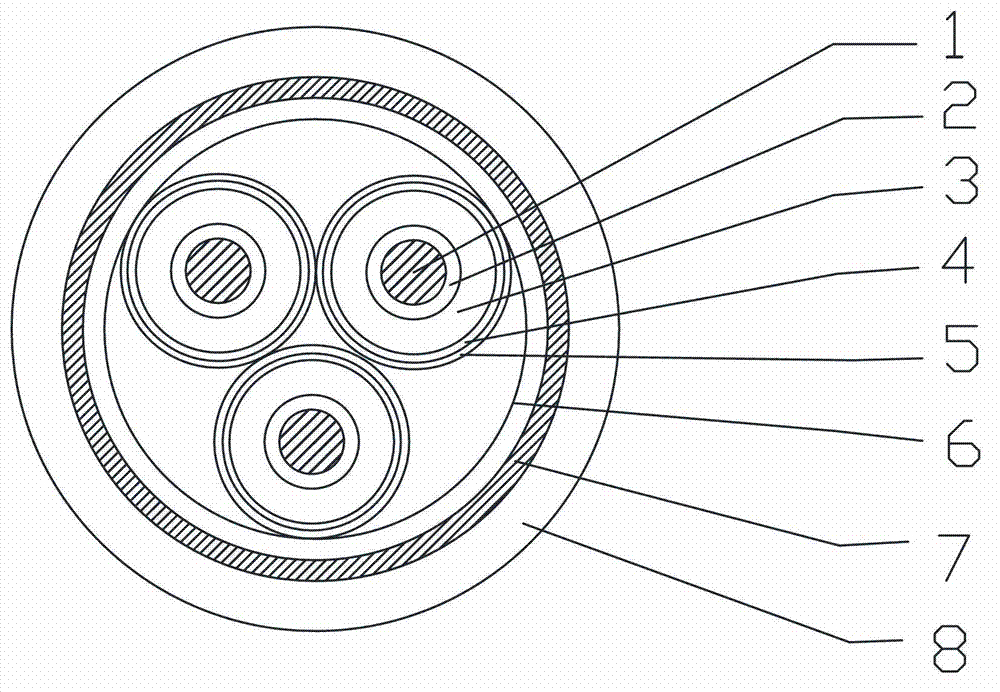

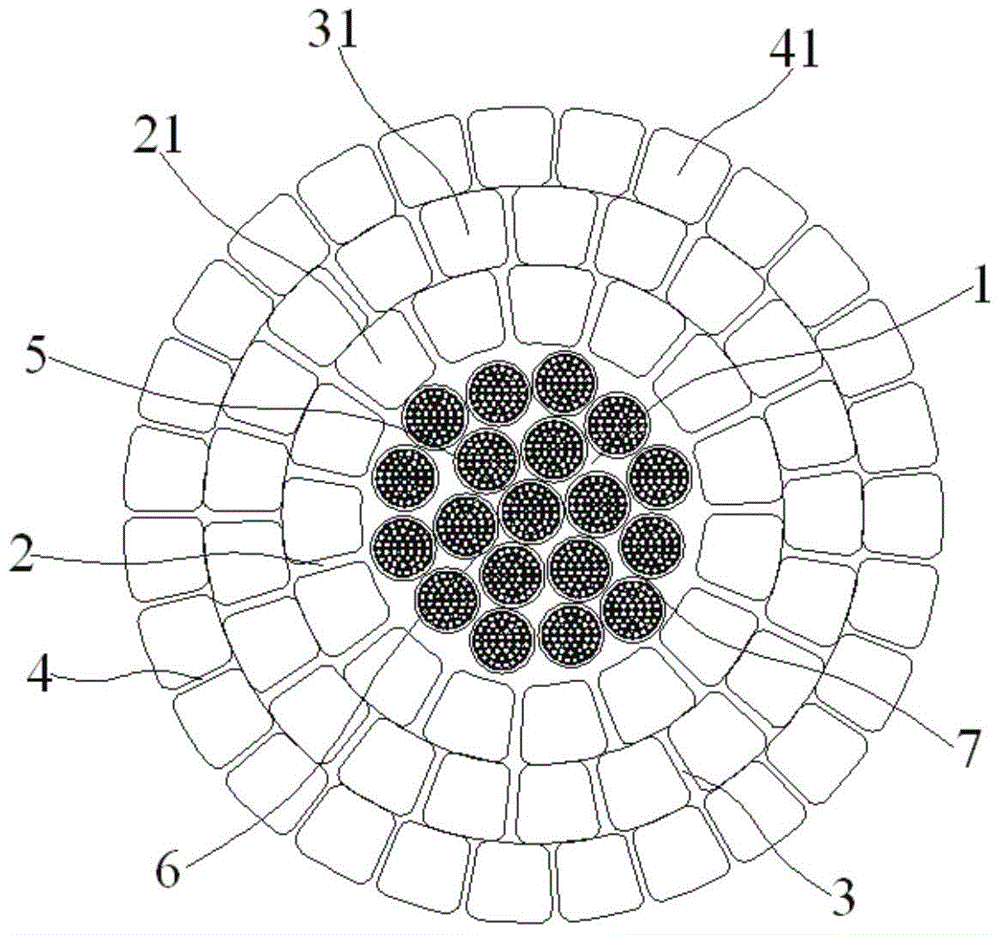

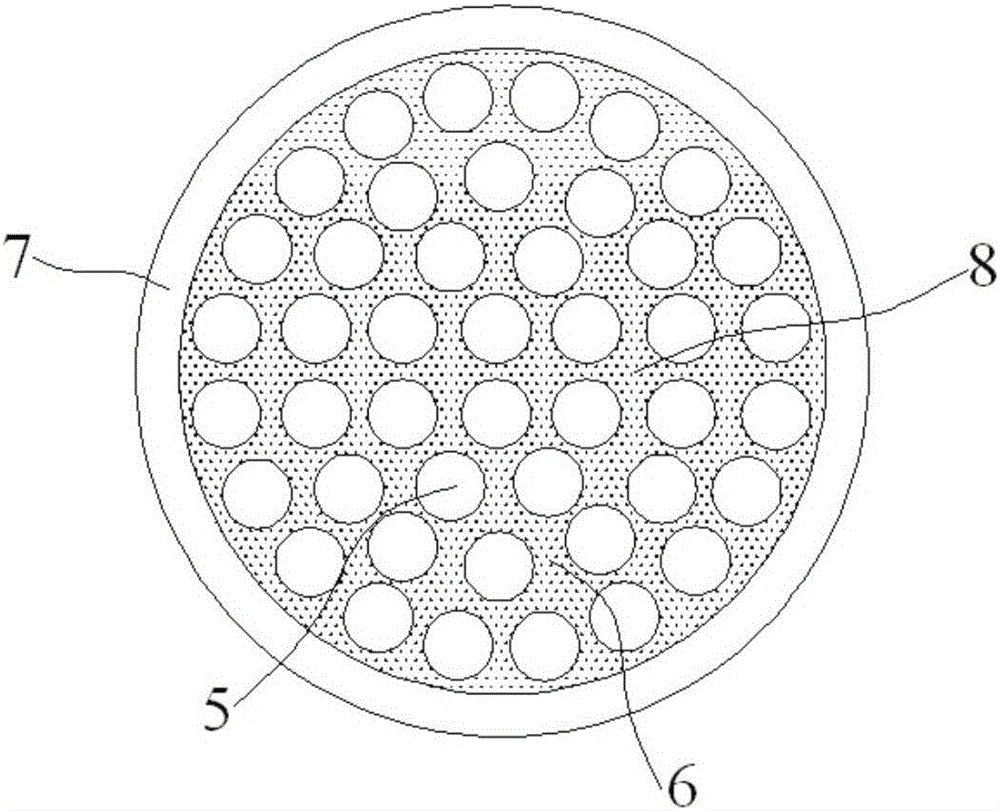

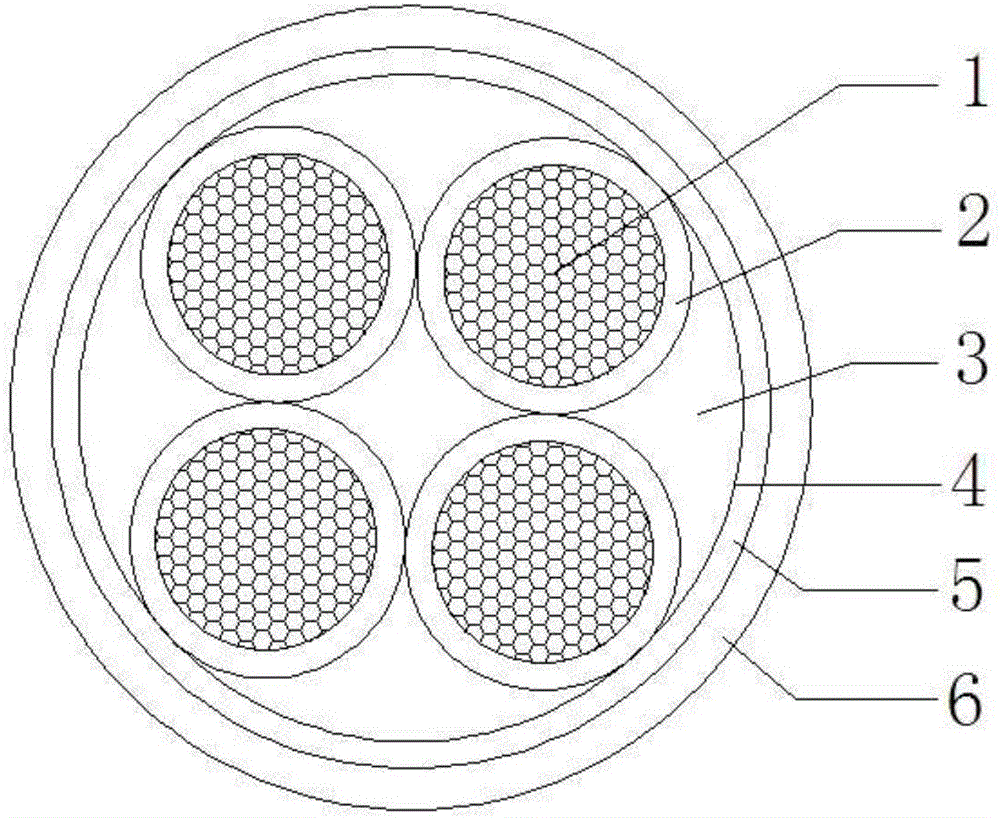

Water tight cable for beach

InactiveCN103400646AIncrease the compression factorEnsure vertical waterproof performanceInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a water tight cable for a beach, which comprises a cable core positioned in the middle of the cable, the cable core is formed by hinging a plurality of wire cores, and each wire core is composed of a conductor and a conductor screen layer, an insulating layer, an insulating screen layer, a semi-conductive belting layer and a metal screen layer arranged outside the conductor in sequence; a packing layer is arranged between the cable cores, and a belting layer, a metal armor layer, a water proof inner protecting sleeve and a water proof outer protecting sleeve are arranged outside the cable core in sequence. The cable adopting the structure provided by the invention is provided with better water blocking performance, better corrosion resisting performance, and higher safety performance, and the cable is used for power transporting line in beach area.

Owner:夏航

Tensile aluminum stranded wire for electric power transmission

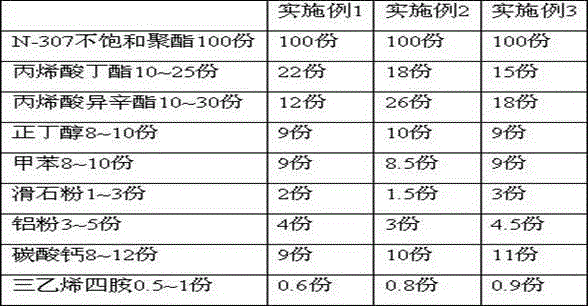

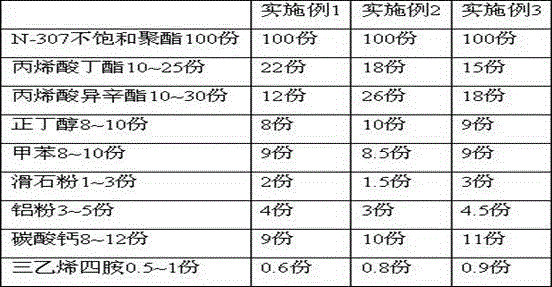

ActiveCN104538101AAvoid damageAvoid defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersElectric power transmissionPolyester

The invention discloses a tensile aluminum stranded wire for electric power transmission. The tensile aluminum stranded wire comprises a center stressed unit, a first aluminum alloy conducting layer and a second aluminum alloy conducting layer, wherein the first aluminum alloy conducting layer and the second aluminum alloy conducting layer are sequentially stranded on the outer surface of the stressed unit; an aluminum conductor wrapping layer is formed by stranding 19-21 Z-shaped aluminum alloy conductors with Z-shaped sections; the stressed unit comprises a first carbon fiber single wire located at the center and six second carbon fiber single wires stranded on the outer surface of the first carbon fiber single wire; the first carbon fiber single wire and each second carbon fiber single wire are each formed by stranding a plurality of carbon fiber precursors; a polyester adhesive filling part is formed by mixing a first component and a second component, and the first component is composed of, by weight, N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butyl alcohol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. It is guaranteed that the carbon fiber precursors in the aluminum layers are round and normal, damage of the aluminum layers in subsequent use is avoided, reliability of electrical property is guaranteed, and the bending radius is lowered to be six times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

A-class fire-retardant water-proof rat-proof ant-proof intermediate-voltage special cable for rail traffic

InactiveCN108091443AIncrease the compression factorConductor roundingNon-insulated conductorsPower cables with screens/conductive layersBlocking layerVoltage

The invention relates to an A-class fire-retardant water-proof rat-proof ant-proof intermediate-voltage special cable for the rail traffic. The cable comprises a conductor; a conductor shielding layer, an insulation layer, an insulation shielding layer, a wrapping layer, a metal shielding layer, a water blocking layer, a flame-retardant layer, an inner sheath, a metal armored layer, and an outer sheath are arranged successively outside the conductor, wherein the conductor shielding layer, the insulation layer, and the insulation shielding layer re in a three-layer co-extruded manner. The innersheath is an extruded halogen-free low-smoke flame-retardant oxygen barrier layer formed by wrapping of two alkali-free glass tapes. The outer sheath is formed by extruding an optical cement by a low-smoke halogen-free fire-retardant rat-proof ant-proof high-polymer material; and the optical cement has the thickness of 10 to 20 microns. The outer sheath is a polyvinyl chloride outer sheath; and awhite-ant-proof plant additive that is non-toxic and is harmless to the human body and the environment is added into the outer sheath. The cable has characteristics of excellent environmental protection effect and good low-smoke, halogen-free, flame-retardant, waterproof, anti-ultraviolet radiation, rat-proof, and ant-proof performances and the like.

Owner:YANGZHOU SHUGUANG CABLE

Double-volume medium-voltage cable

PendingCN106782856AIncrease ampacityReduce usageSingle bars/rods/wires/strips conductorsPower cables with screens/conductive layersCarrying capacityElectrical conductor

The invention relates to a double-volume medium-voltage cable which comprises an inner support interlocking tube (1) and a conductive insulated wire core, an inner protective layer (10), an armor layer (11) and an outer protective layer (12) which are sequentially lapped on the periphery of the inner support interlocking tube (1). The inner interlocking tube (1) is of an aluminum or steel interlocking sleeve; the conductive insulated wire core sequentially comprises a lead, a lead shielding layer (4) and an insulting layer (5) from inside to outside. Under the same level condition, carrying capacity can be increased by 20%-30%; under the same cross section condition, 10%-20% of a conductor can be saved; double-volume medium-voltage cable has fire retardant and environmental performance.

Owner:BEIJING TIANCHENG RUIYUAN CABLE

Novel fireproof cable

InactiveCN106205765ALow costSolve easy oxidationConductive materialInsulated cablesLow smoke zero halogenPolyolefin

The invention relates to a novel fireproof cable which comprises a cable core. The cable core is made by twisting a plurality of conductors; each conductor comprises an aluminium alloy conductor; a ceramic low-smoke zero-halogen polyolefin fire-retardant insulating layer is extruded outside each aluminium alloy conductor; a gap of the cable core adopts a zero-halogen low-smoke fire-retardant filling layer; and a ceramic fire-retardant fireproof silicon gel composite tape, a metal fireproof layer and a ceramic low-smoke zero-halogen polyolefin fire-retardant outer protection layer are sequentially lapped outside the cable core. The novel fireproof cable is reasonable in structure and convenient to manufacture, has a good energy-saving effect, excellent fireproof performance, shock resistance and spraying resistance and is environmental-friendly.

Owner:JIANGSU CHANGFENG CABLE

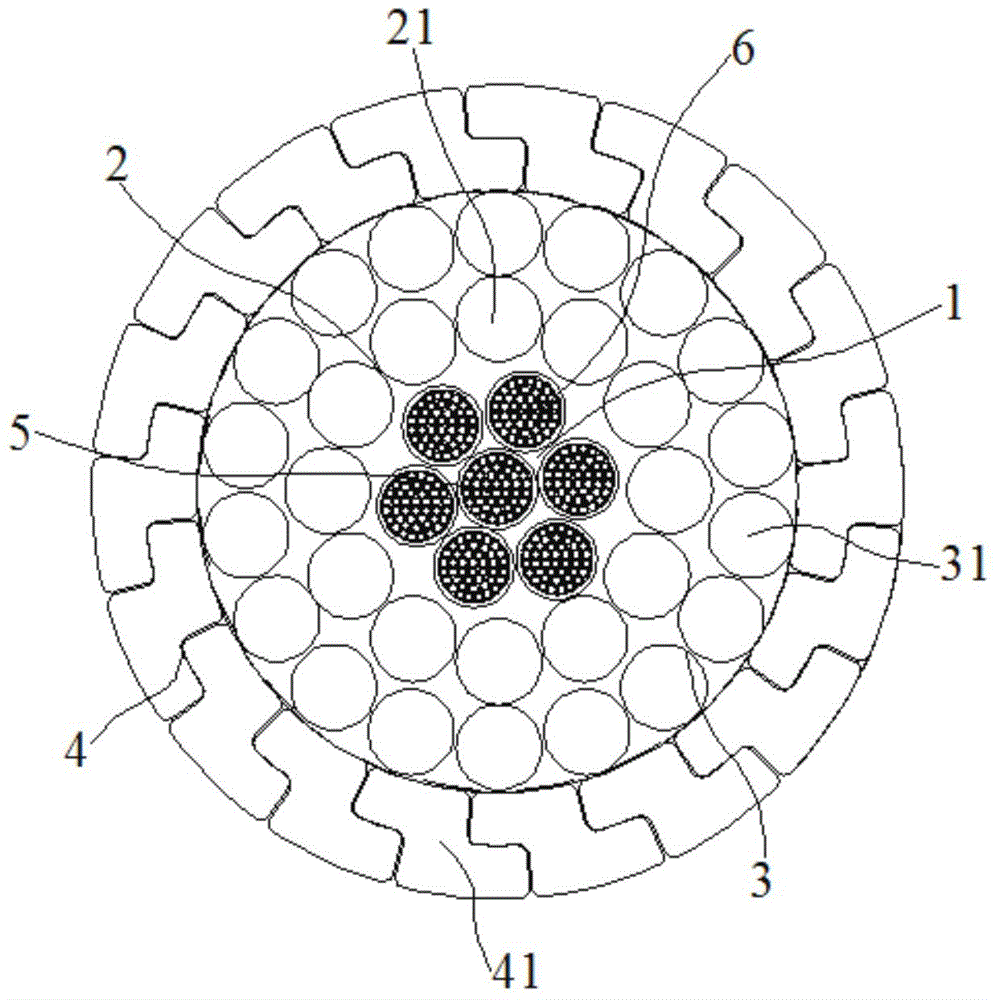

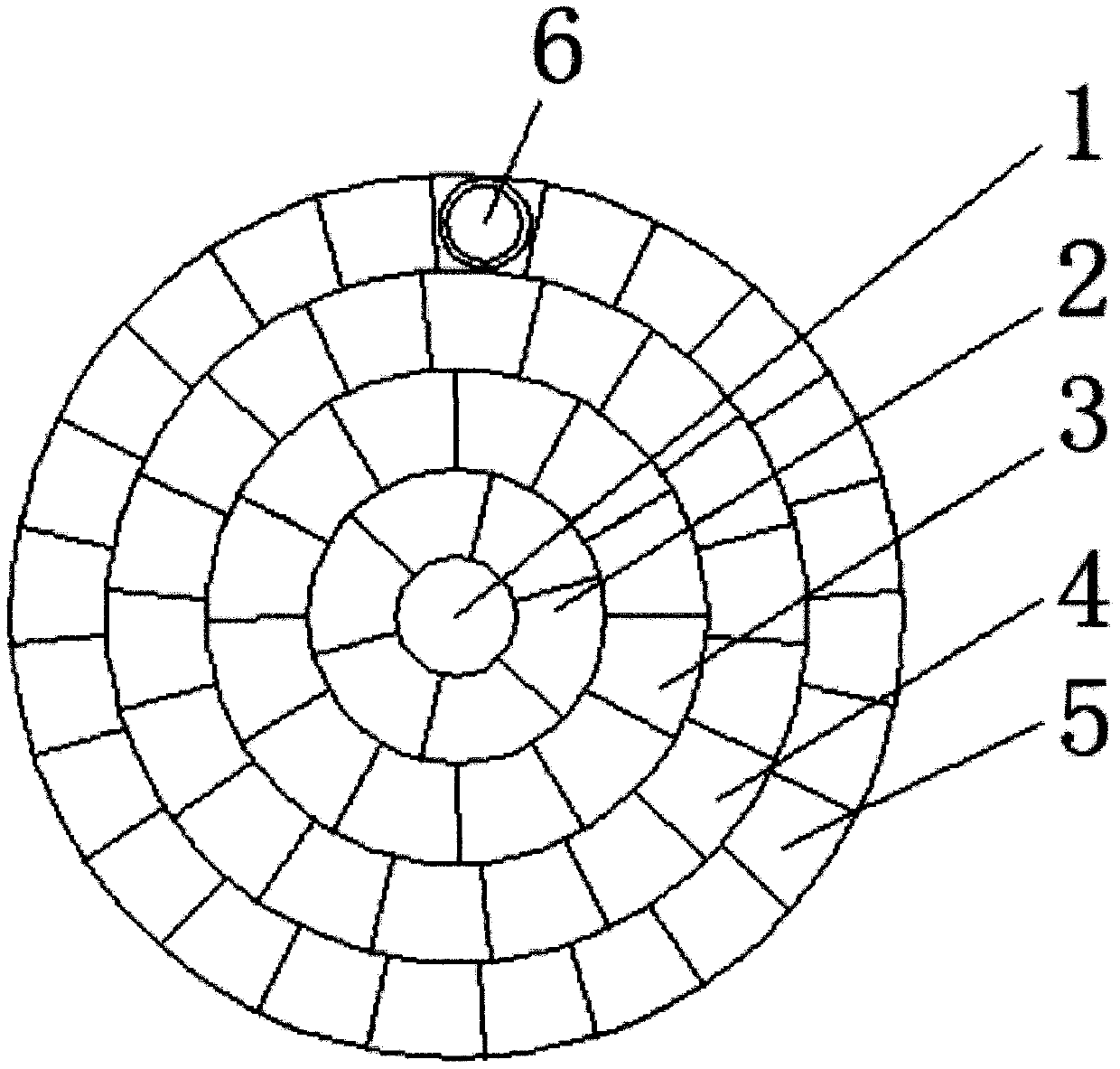

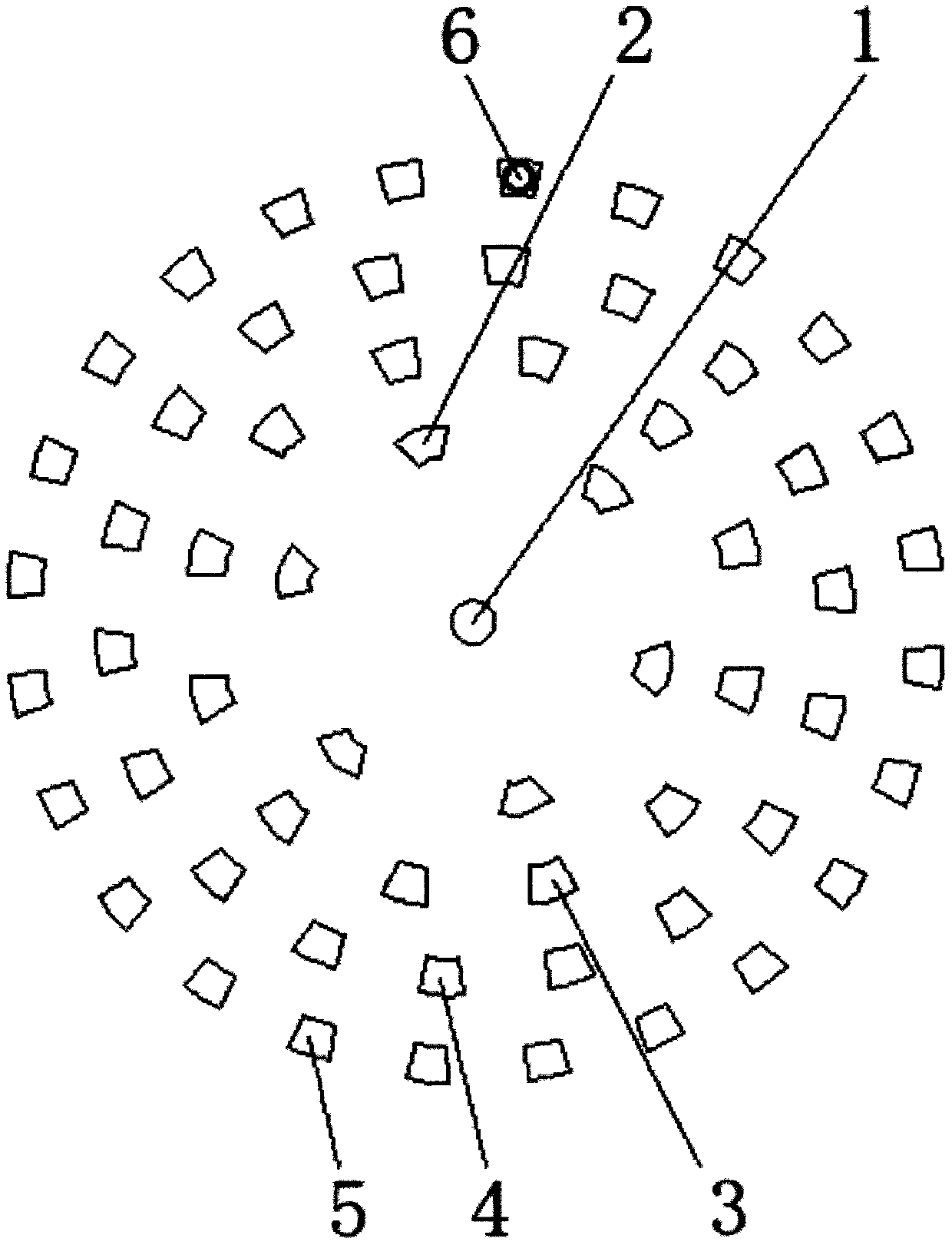

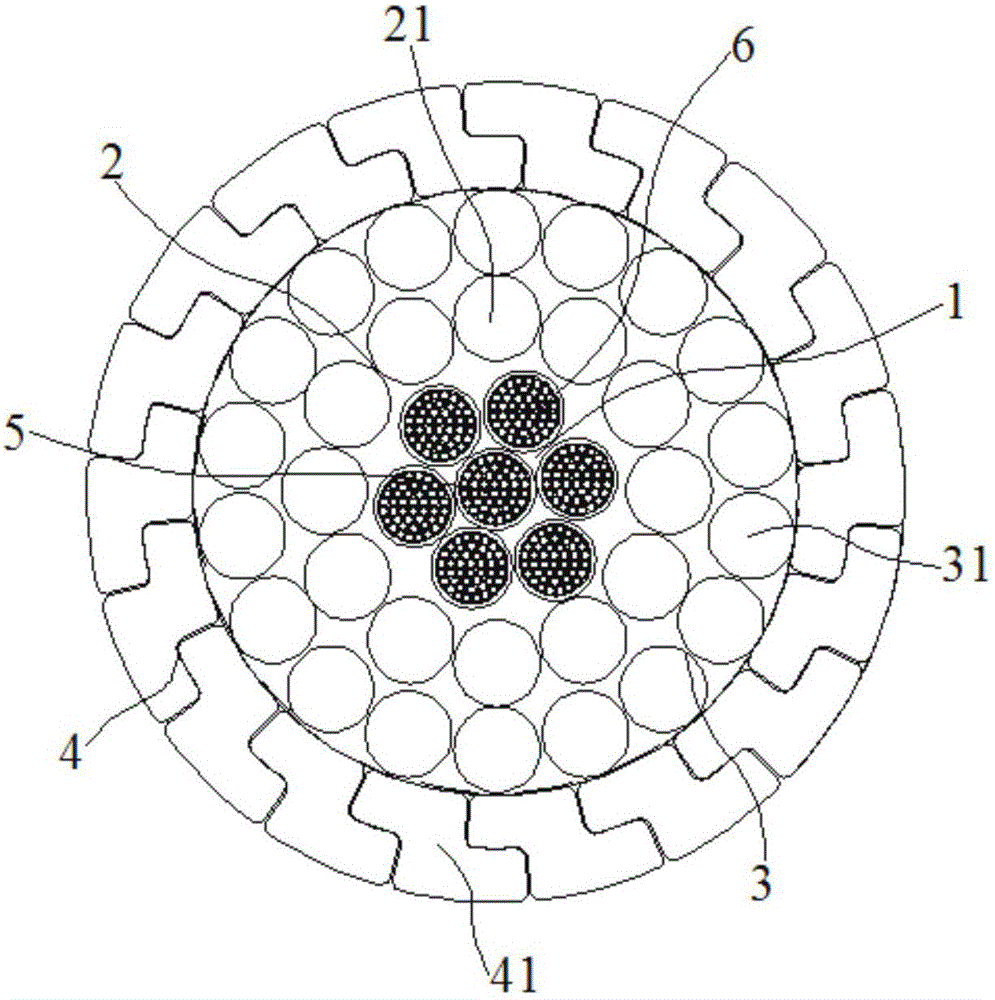

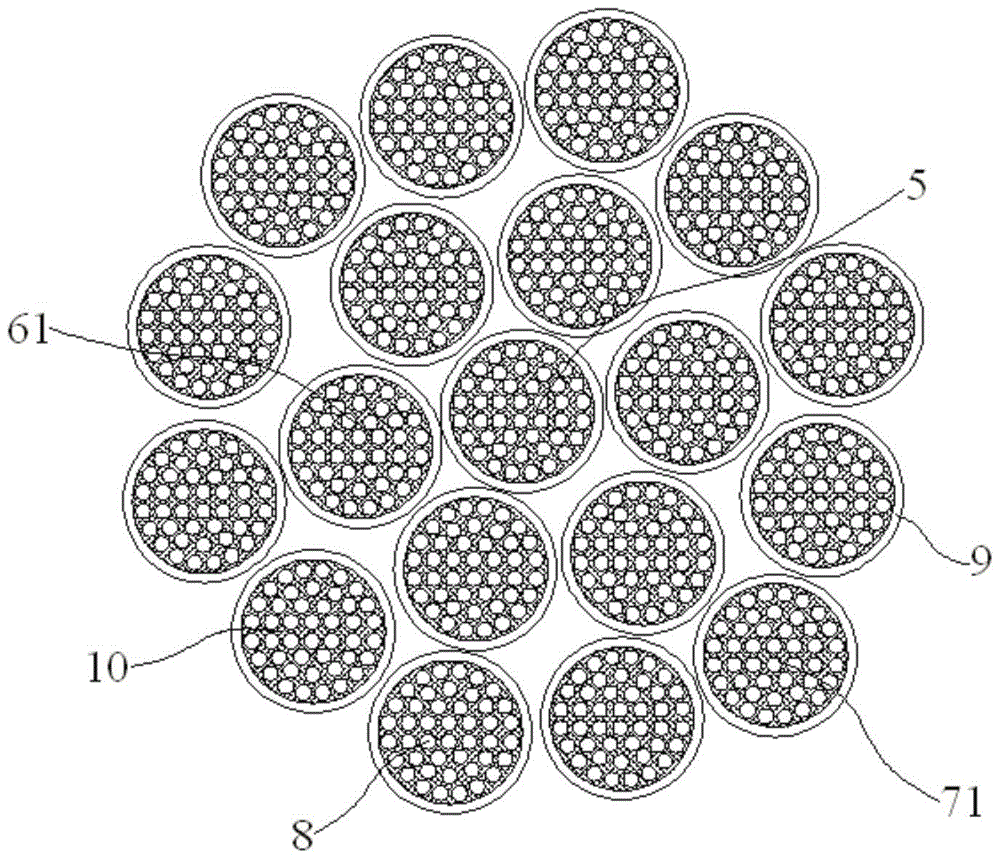

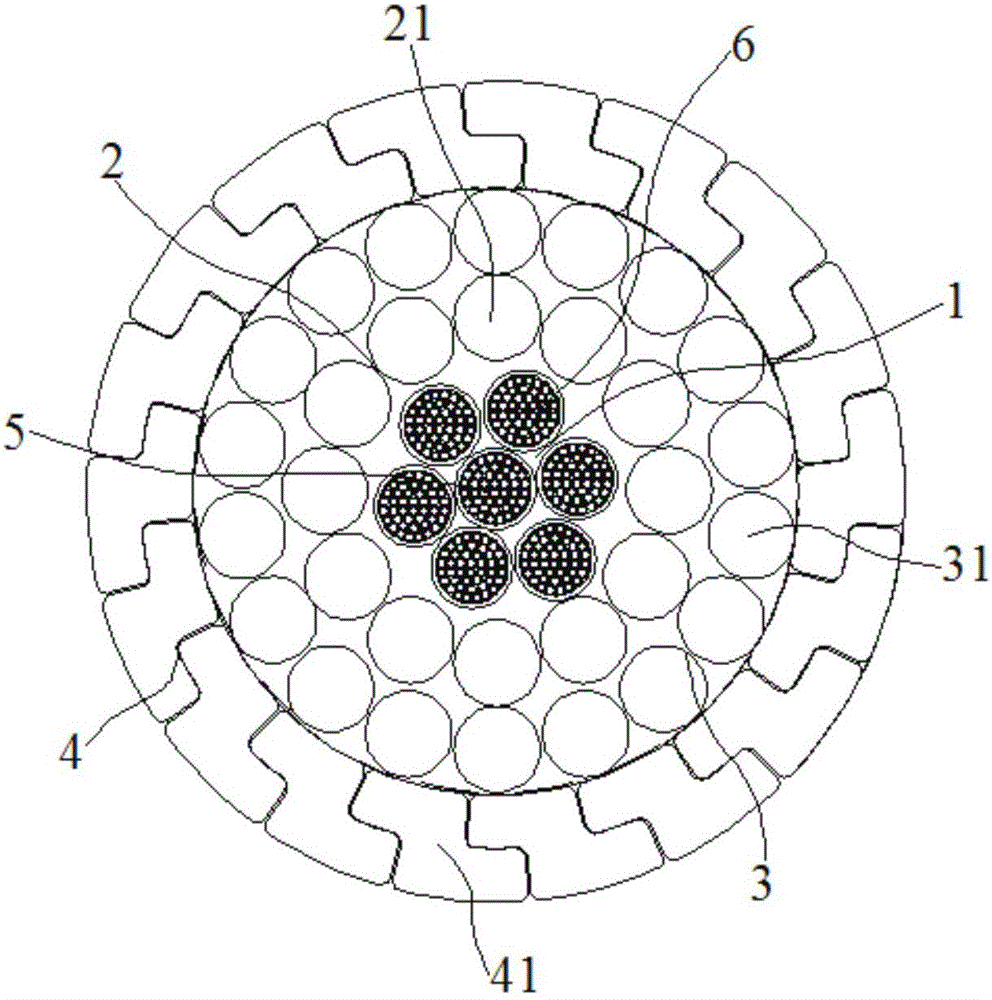

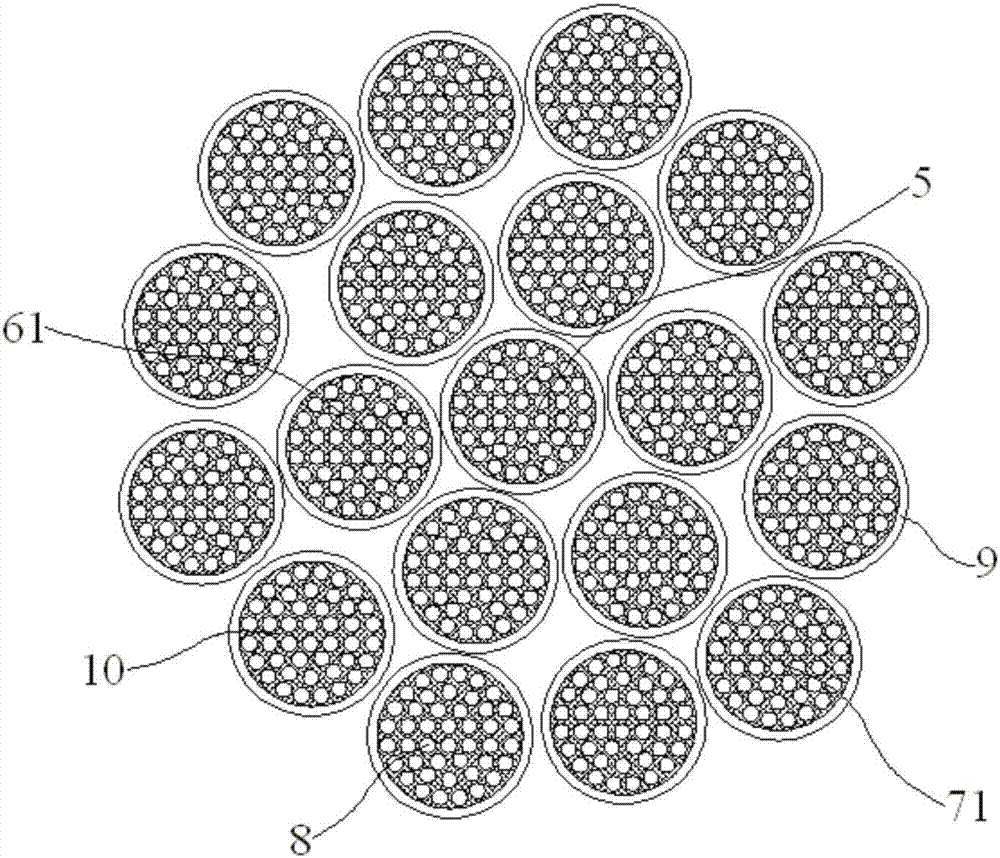

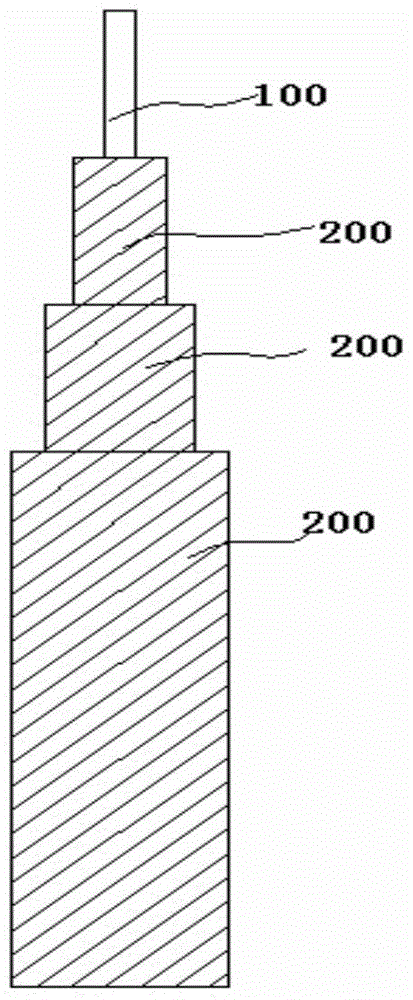

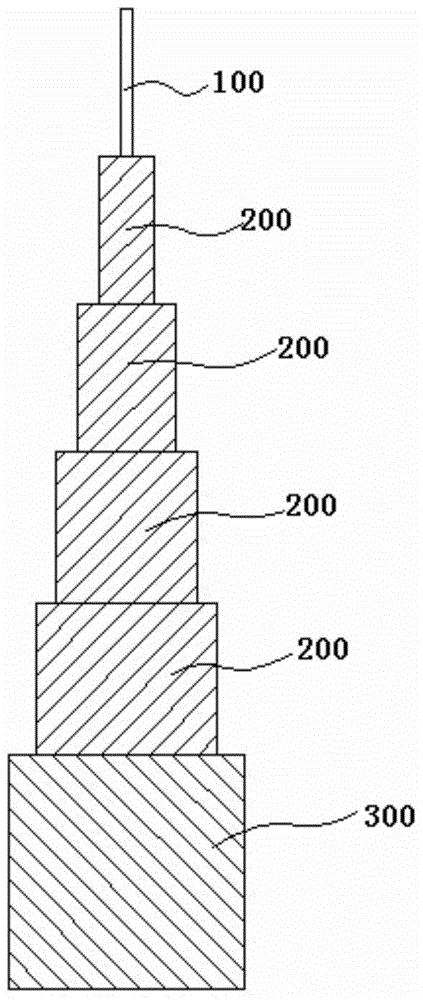

Special-shaped monofilament intelligent conductor structure

PendingCN110517807AIncrease the compression factorSmall outer diameterAuxillary non-insulated conductorsElectrical conductorFiber optic sensor

The invention relates to the technical field of cables, in particular to a special-shaped monofilament intelligent conductor structure comprising a conductor center line, a first layer of conductor special-shaped monofilament, a second layer of conductor special-shaped monofilament, a third layer of conductor special-shaped monofilament and a fourth layer of conductor special-shaped monofilament.The first layer of conductor special-shaped monofilament is twisted on the outer side of the conductor center line. An optical fiber sensor is twisted between the sides of the fourth layer of conductor special-shaped monofilament. The special-shaped monofilament intelligent conductor structure is enabled to have the advantages of improving the compaction coefficient of the conductor, realizing real-time temperature measurement of the conductor and avoiding connection pressure through the arrangement of the conductor center line, the first layer of the conductor special-shaped monofilament, thesecond layer of the conductor special-shaped monofilament, the third layer of the conductor special-shaped monofilament, the fourth layer of the conductor special-shaped monofilament and the opticalfiber sensor so that the problems that the current cable gap inside the conductor is large, the cable runs at high temperature, which affects the service life of the cable, and the temperature measurement optical fiber is placed inside the conductor and is subjected to connection pressure of the conductor can be solved.

Owner:广州岭南电缆股份有限公司

A special-shaped oxidation-resistant high-conductivity aluminum alloy carbon fiber wire and its manufacturing method

ActiveCN102903415BHigh tensile strengthHigh elongationNon-insulated conductorsMetal/alloy conductorsFiberRare-earth element

Owner:FOGANG XINYUAN HENGYE CABLE TECH CO LTD

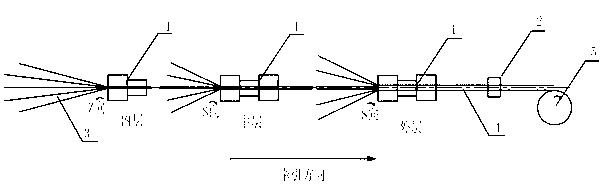

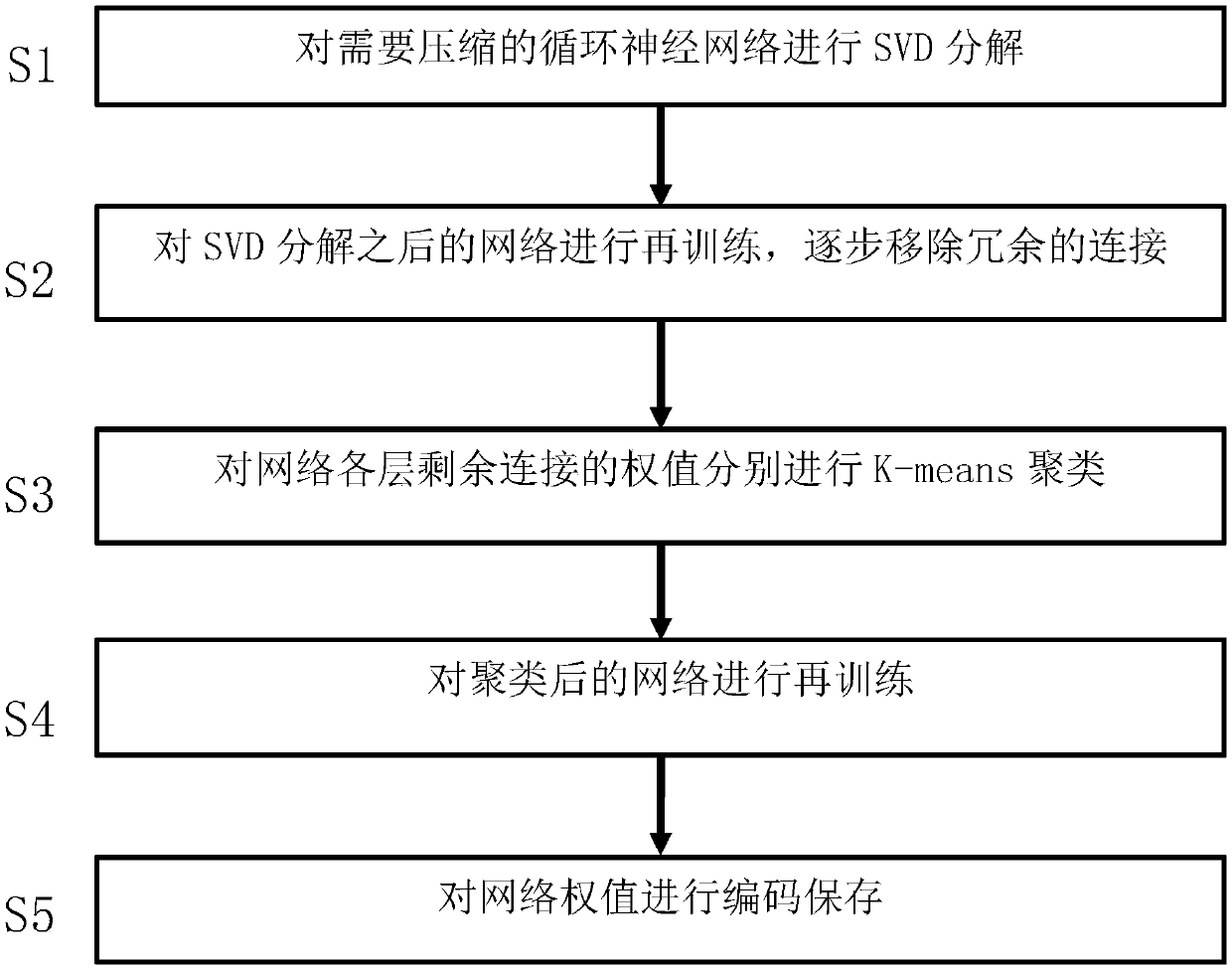

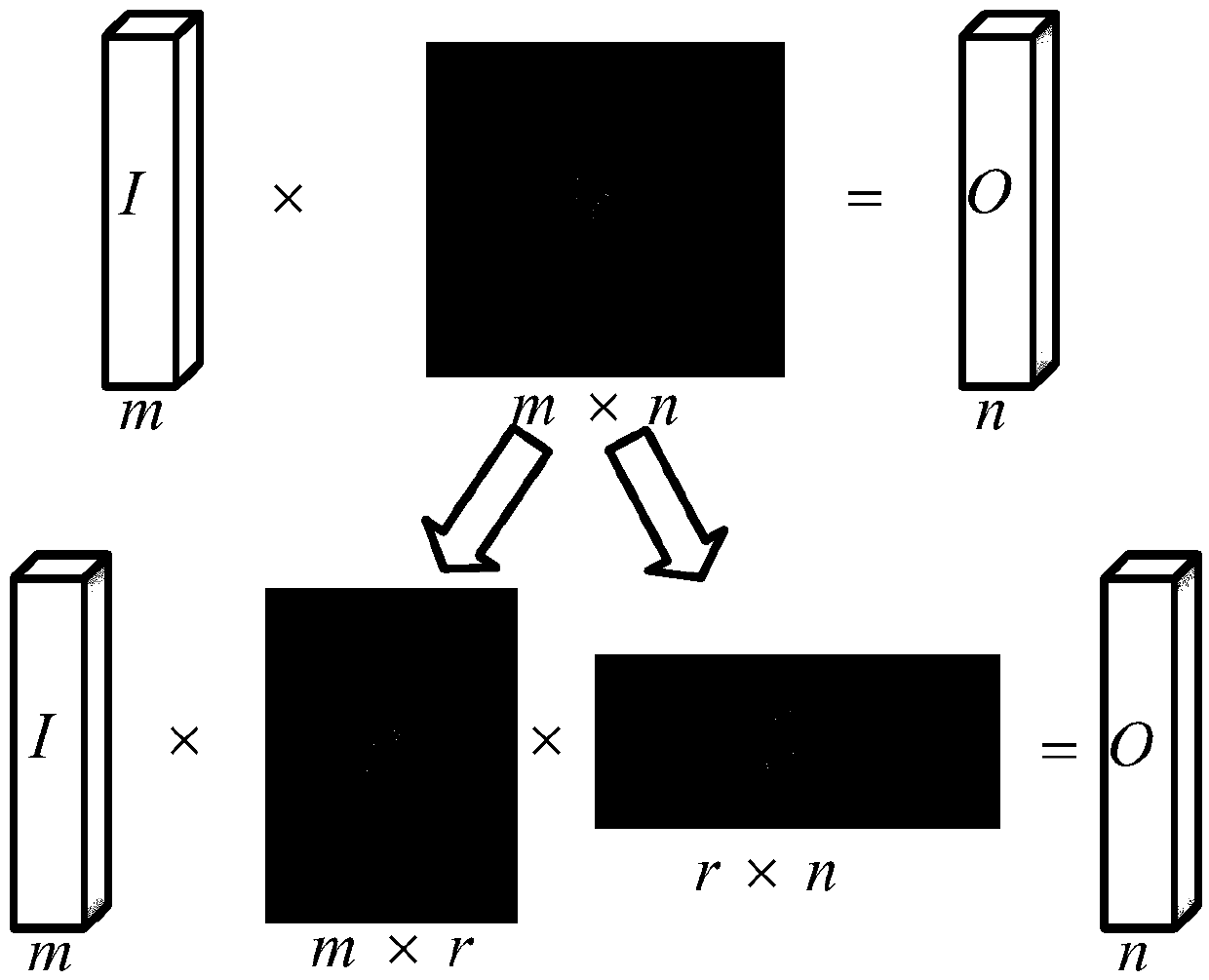

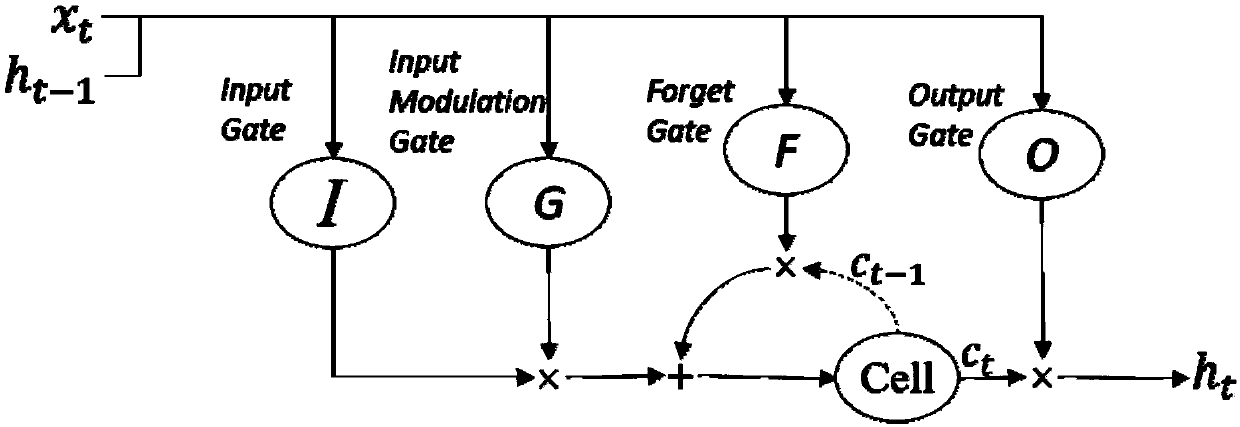

Compression method for deep recurrent neural network based on SVD and pruning

InactiveCN110533157AReduce the number of parametersGuaranteed performanceCharacter and pattern recognitionNeural architecturesDecompositionNetwork connection

The invention relates to a compression method for a deep recurrent neural network based on SVD and pruning. The compression method comprises the steps of S1, performing SVD decomposition on a recurrent neural network needing to be compressed; s2, training the network after SVD decomposition again, and removing redundant connection step by step; s3, respectively performing K-means clustering on theweights of the remaining connections of each layer of the network; s4, training the clustered network again; and S5, encoding and storing the network weight. According to the invention, SVD and redundant network connection removing methods are combined; the number of parameters of the recurrent neural network is effectively reduced, the storage amount of the parameters is greatly reduced throughfurther K-means clustering and encoding storage of a sparse matrix, training of the network is combined in the series of processes, and it is guaranteed that a large compression multiple is achieved under the condition that the influence on the network performance is not large.

Owner:SOUTH CHINA UNIV OF TECH +1

Energy-saving overhead conductor used for high-voltage power transmission line

ActiveCN106057289AImprove anti-ice and snow abilityAvoid defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersFiberIsooctyl acrylate

The present invention discloses an energy-saving overhead conductor used for a high-voltage power transmission line. The energy-saving overhead conductor used for the high-voltage power transmission line is characterized in that an aluminum conductor cladding layer is orderly twisted on the outer surface of a second aluminum alloy conductive layer, and the aluminum conductor cladding layer is formed by twisting Z-shaped aluminum alloy conductors; a polyester adhesive filling part is filled between an aluminum layer and a plurality of carbon fiber precursors and is formed by mixing a first component and a second component according to a mass ratio of 1:2-4, and the first component is composed of the following weight parts of raw mateirals of N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butyl alcohol, methylbenzene, talcum powder, aluminite powder, calcium carbonate and triethylene tetramine. The energy-saving overhead conductor used for the high-voltage power transmission line of the present invention enables the conductive performance, the bending performance and the corrosion resistant of a cable to be improved and the cable calorific value to be reduced, and is widely used to improve the operation reliability and safety of a whole power transmission system substantially.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

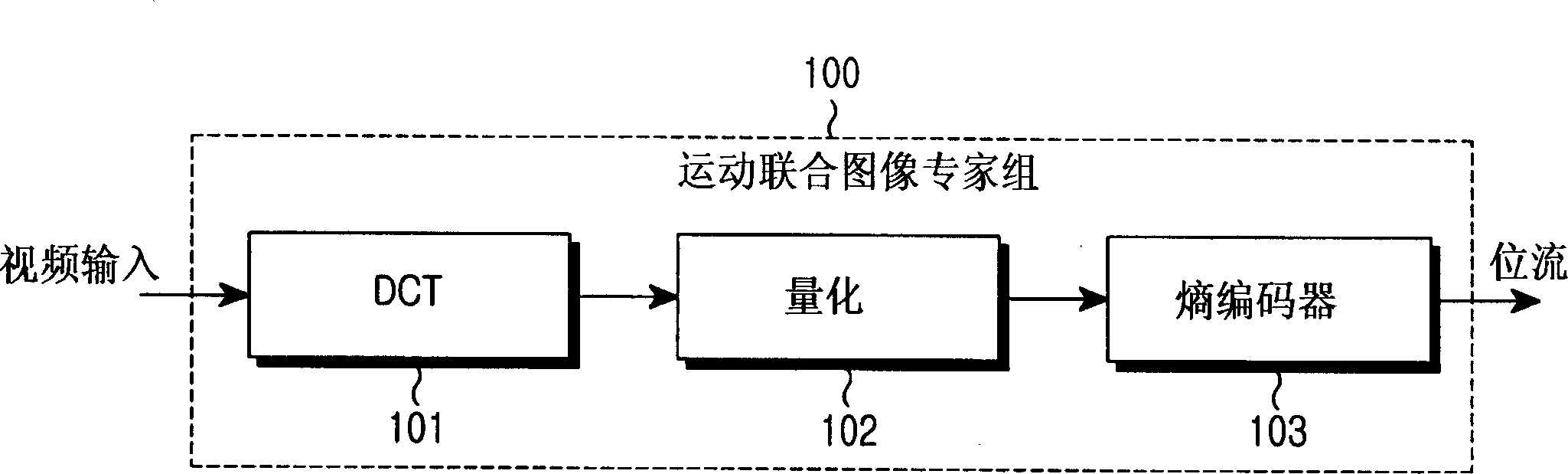

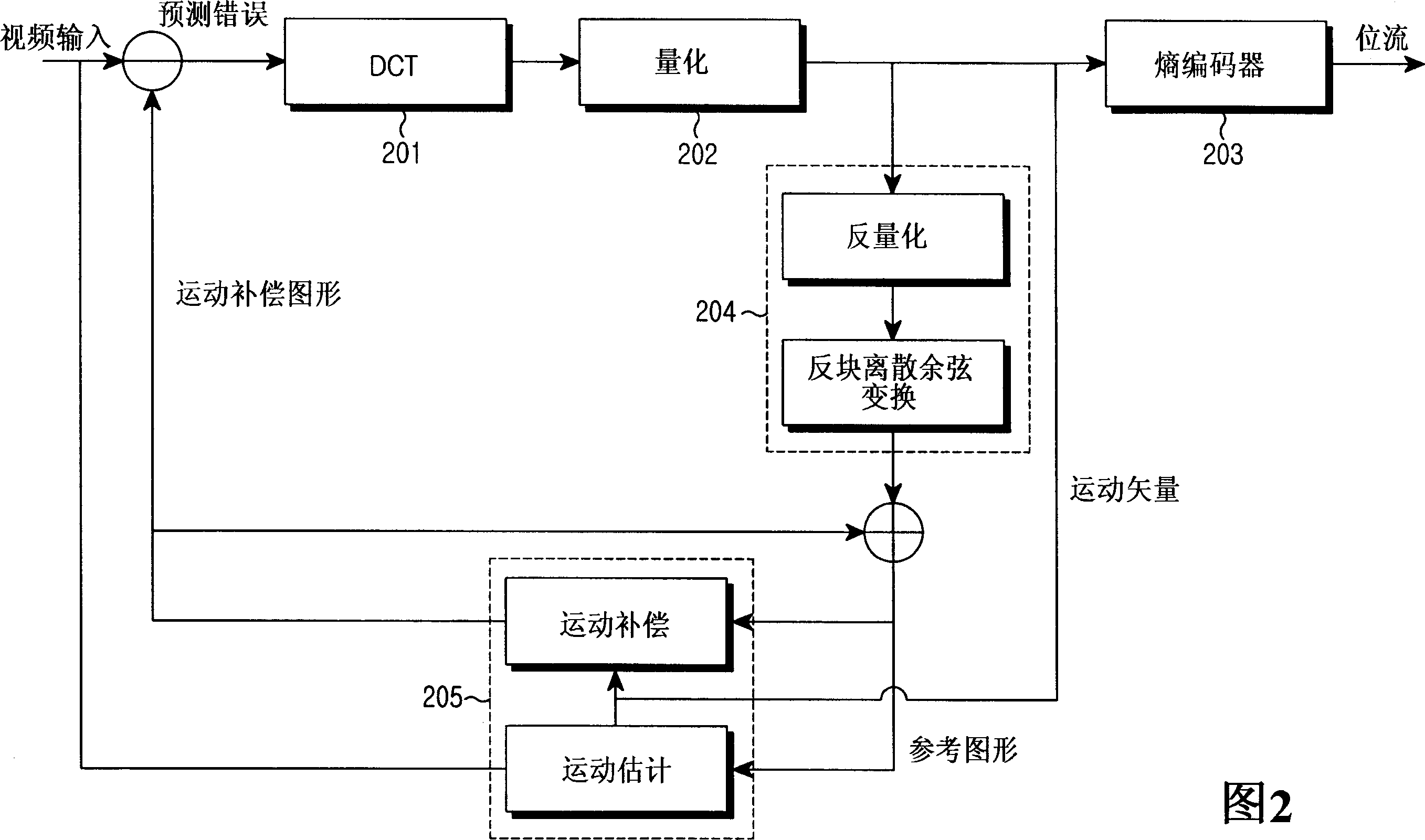

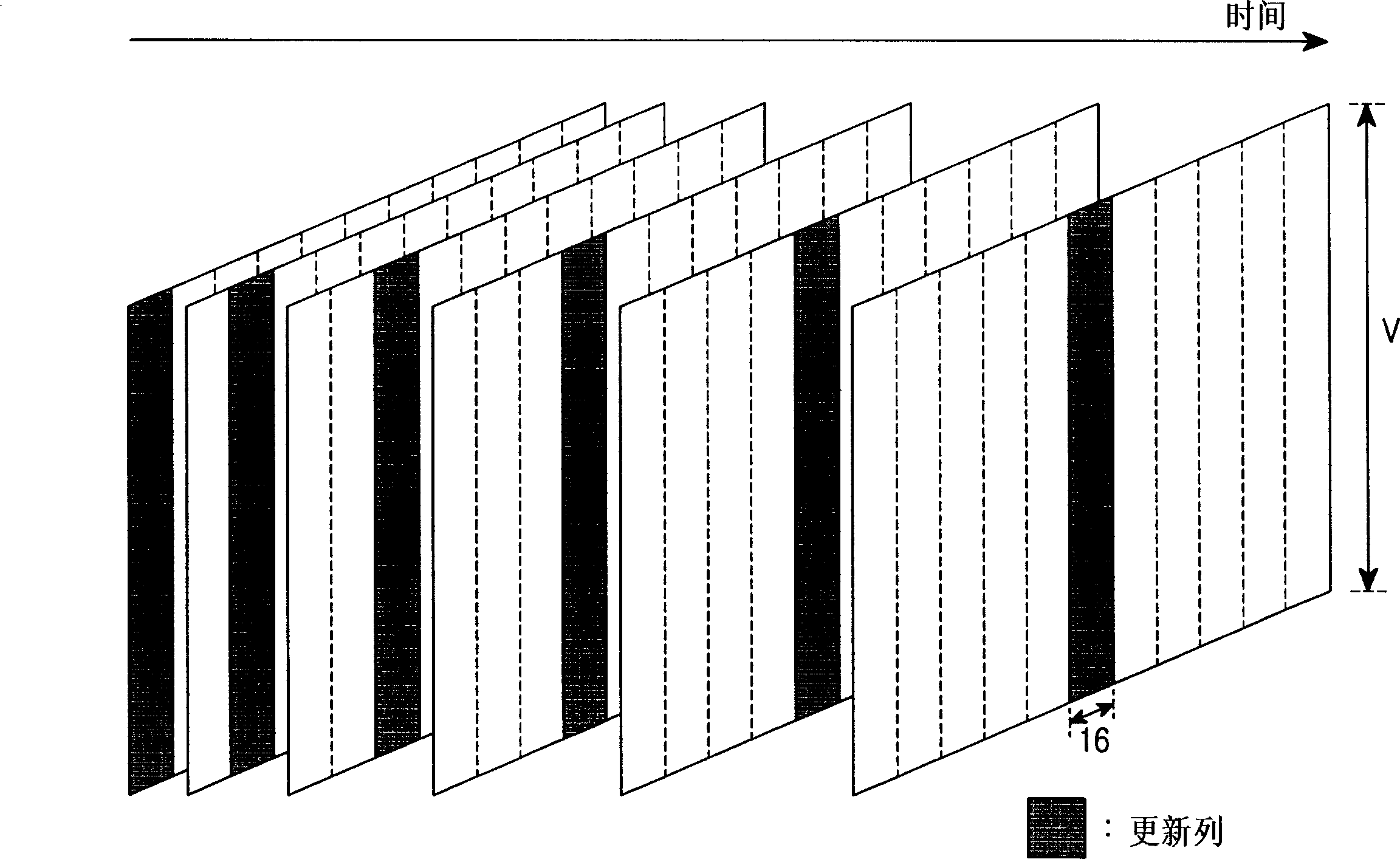

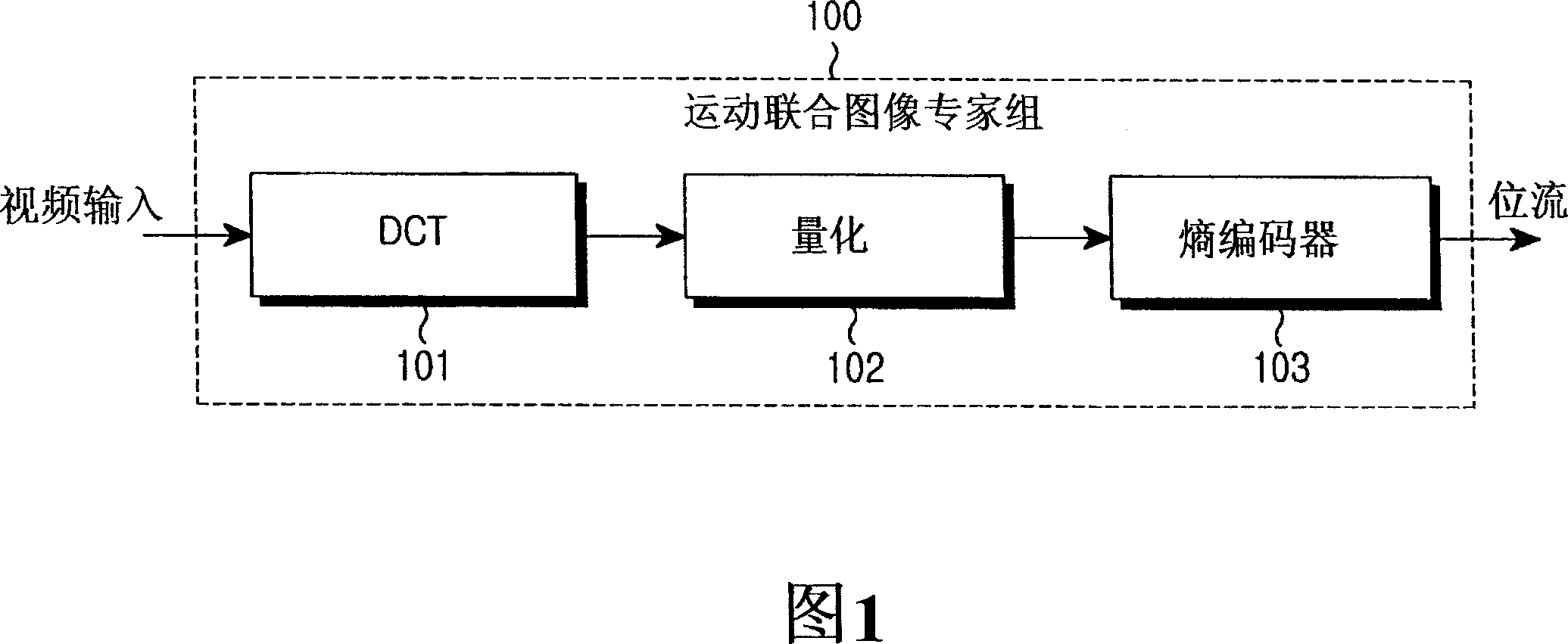

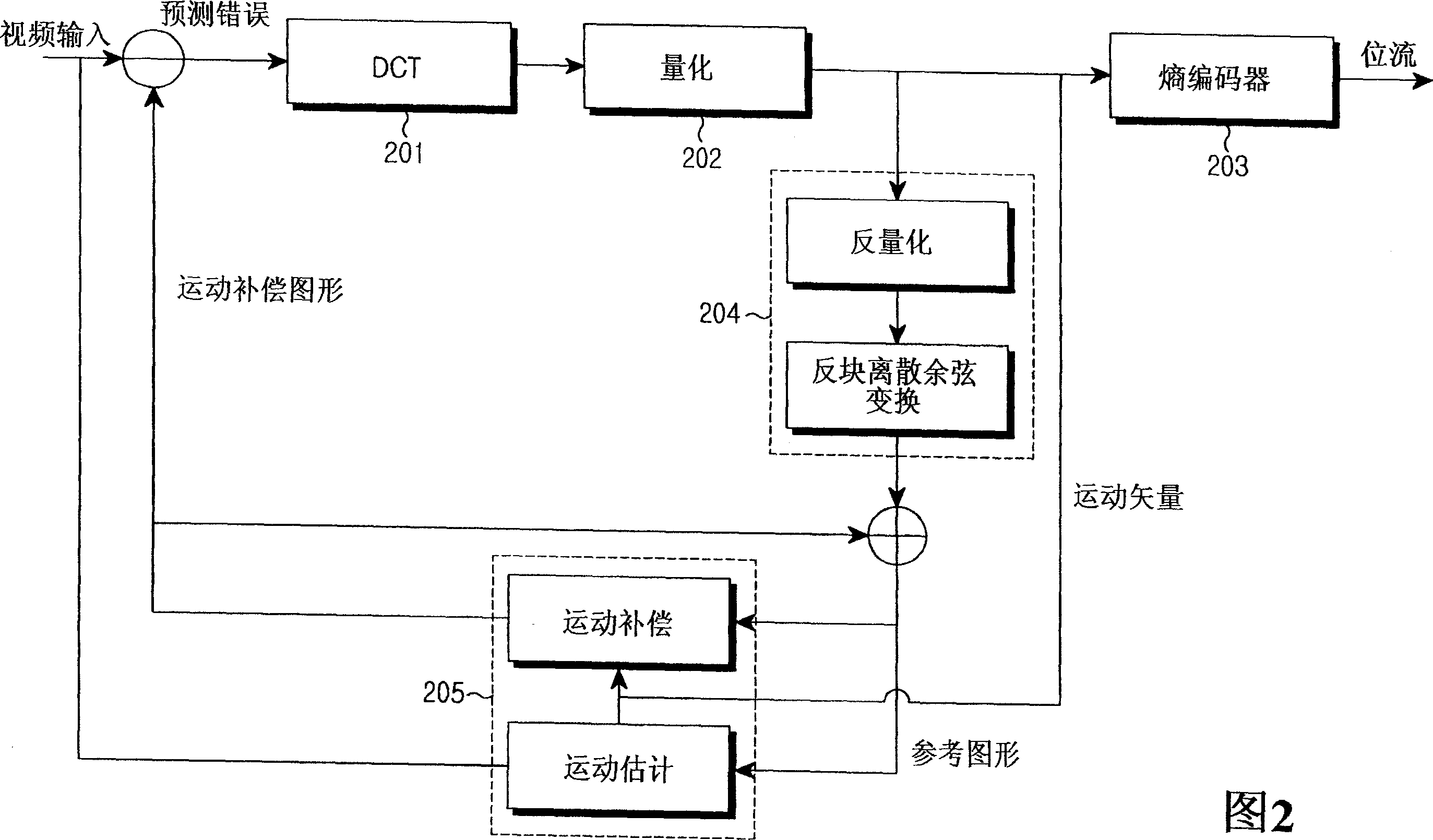

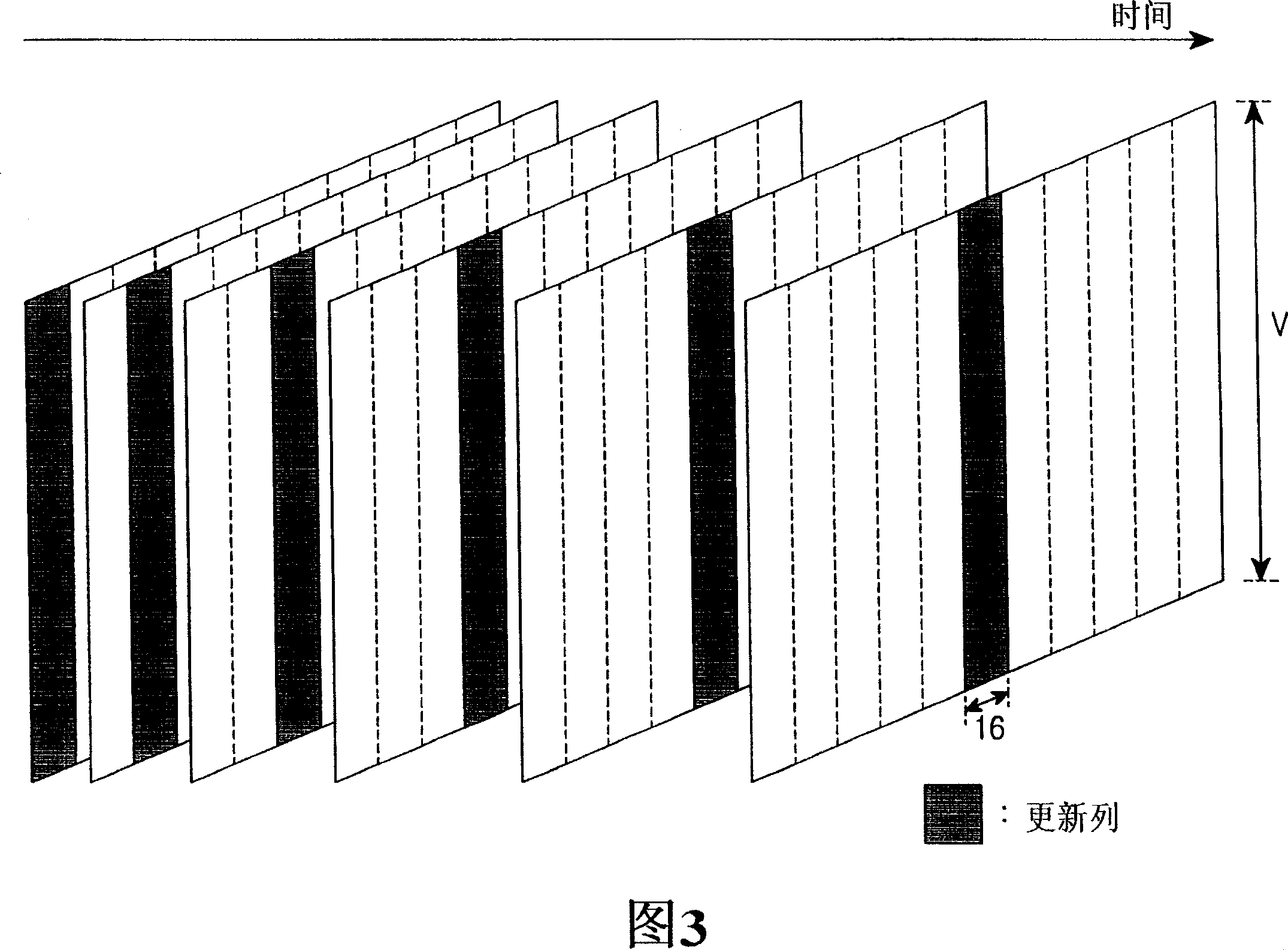

Method and device for compressing image data

InactiveCN1574964ASmall sizeAvoid error accumulationTelevision systemsDigital video signal modificationInter frameComputer science

Owner:SAMSUNG ELECTRONICS CO LTD

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437BReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

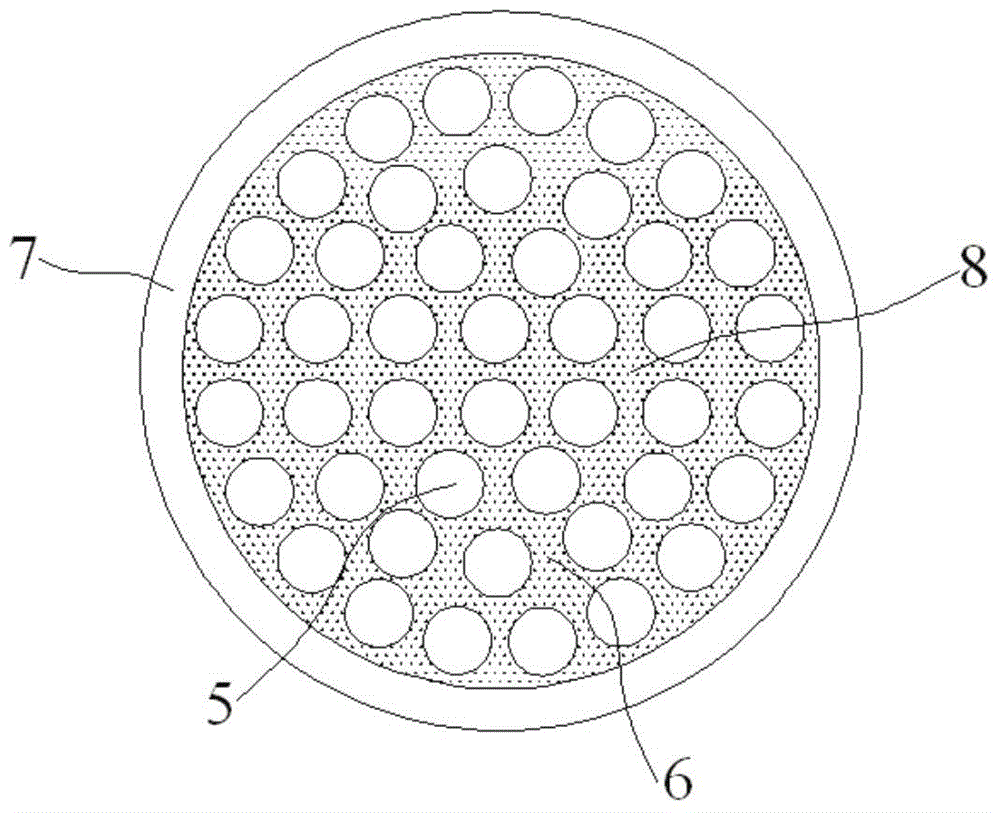

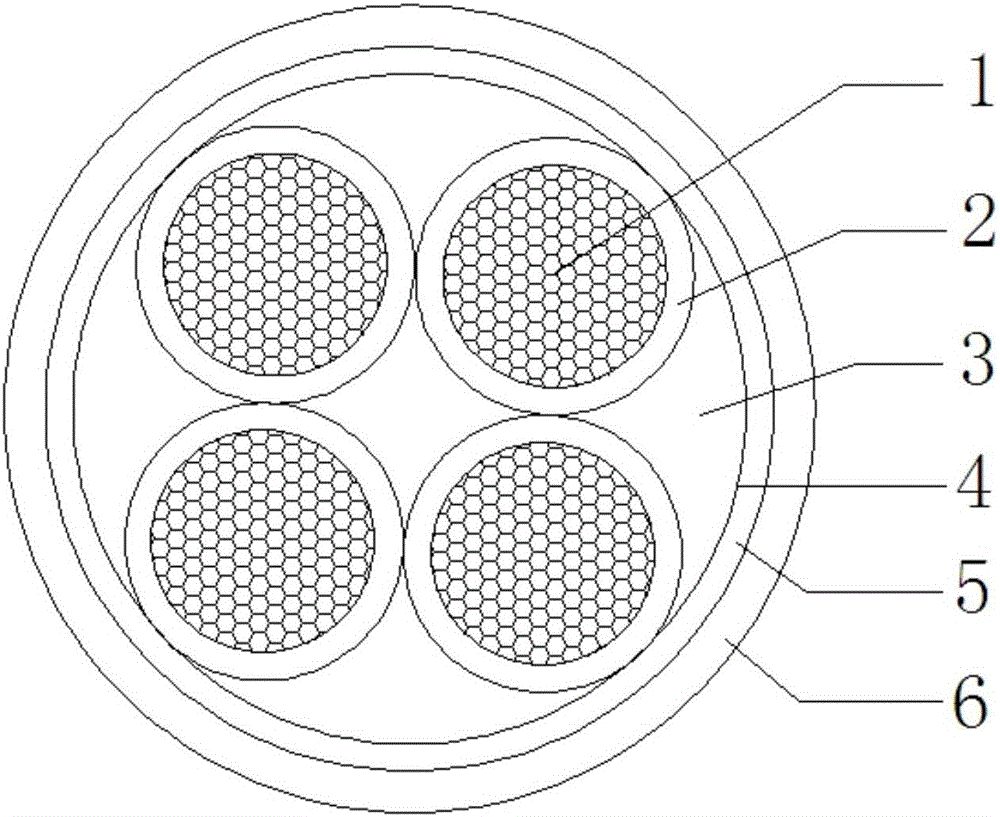

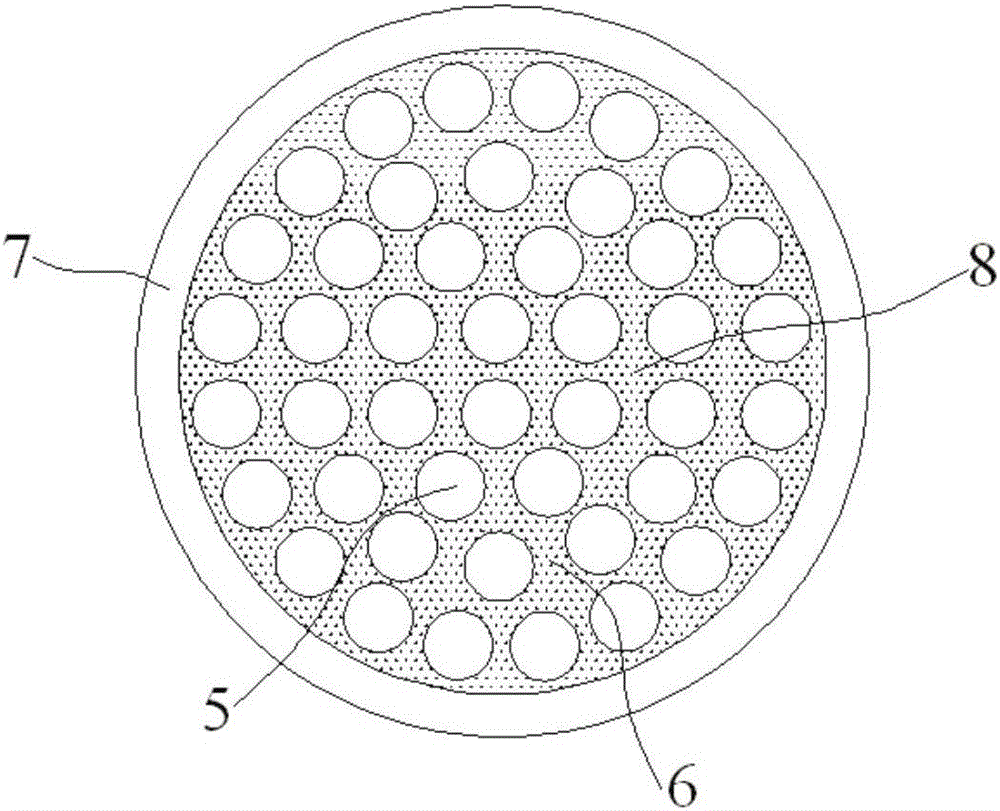

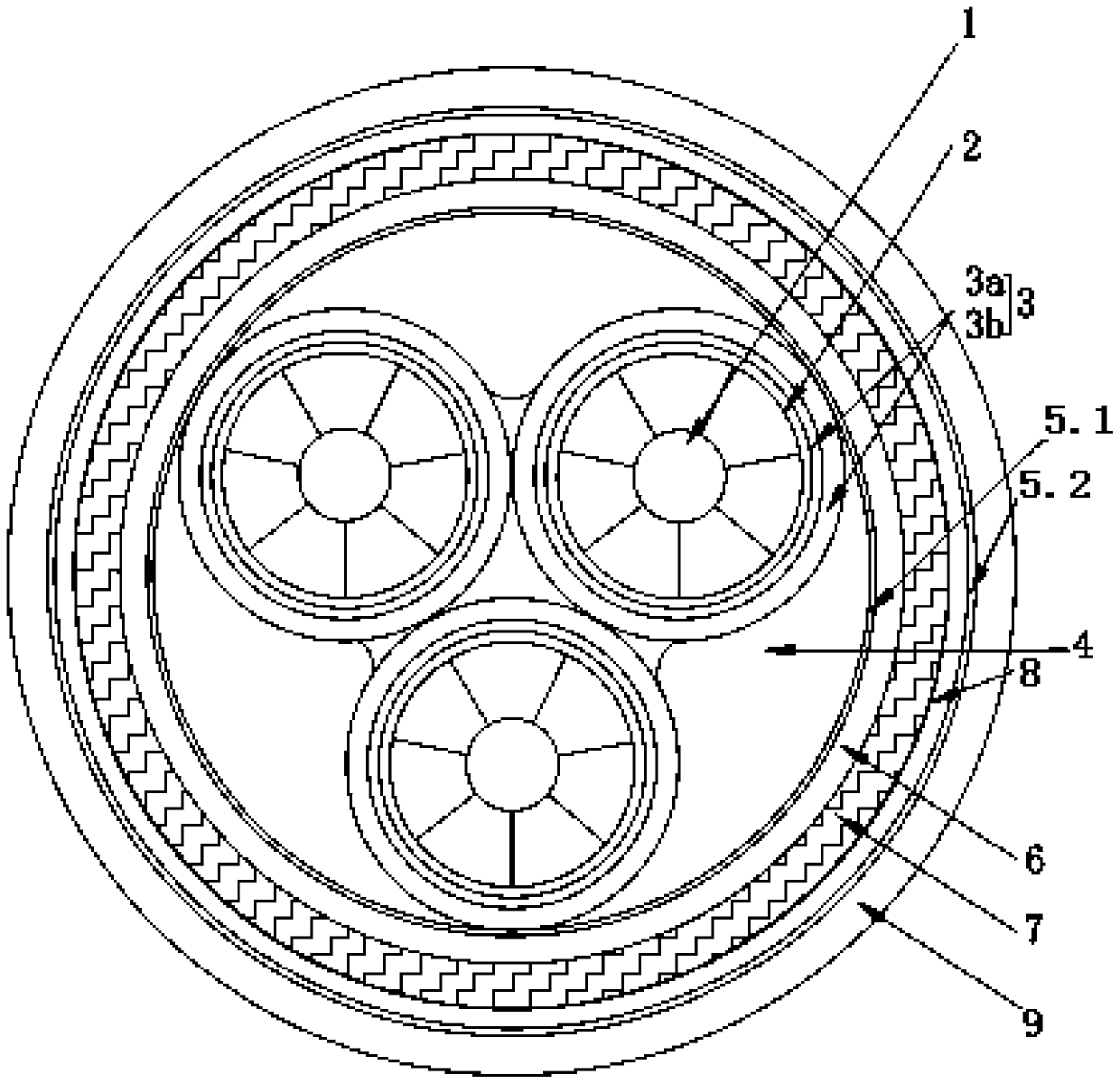

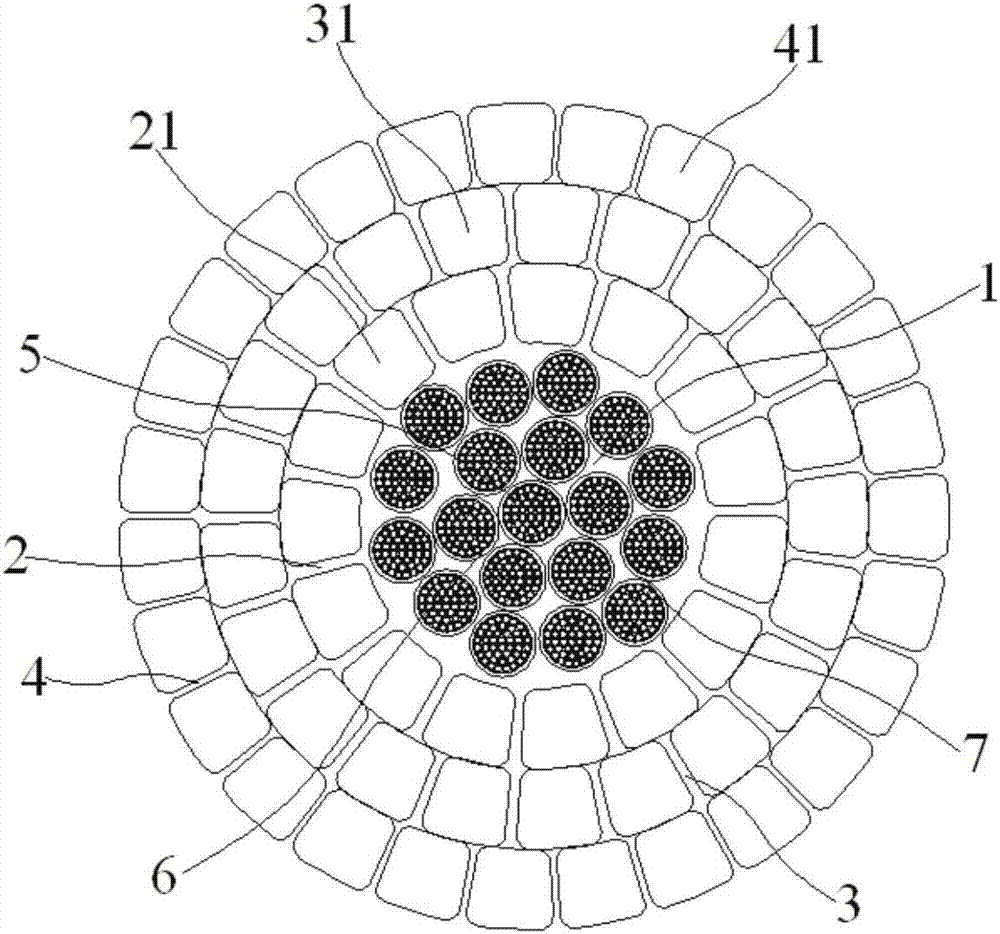

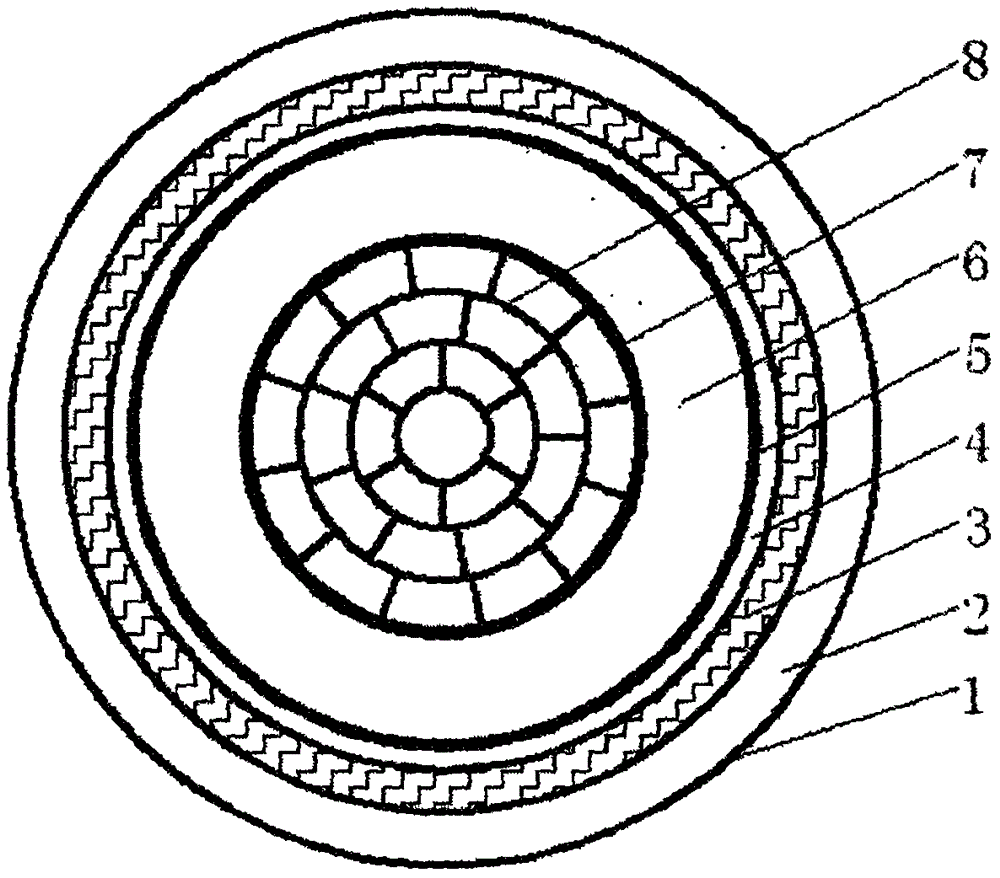

High-compression-coefficient super-smooth corrosion-resistant aluminum alloy conductor medium-voltage cable

InactiveCN102867590AIncrease the compression factorMeet special requirementsPower cables with screens/conductive layersMetal/alloy conductorsElectrical conductorMetallurgy

The invention discloses a high-compression-coefficient super-smooth corrosion-resistant aluminum alloy conductor medium-voltage cable which comprises a cable inner core and a cable outer layer lapped outside the cable inner core, and is characterized in that the cable inner core comprises a high-compression-coefficient super-smooth aluminum alloy conductor, a conductor shielding layer, an insulating layer, an insulation shielding layer and a metal shielding layer successively from inside to outside; and the cable outer layer comprises a lapping strip, a flexible metal tube and a protective sheath successively from inside to outside. According to the invention, the compression coefficient of the high-compression-coefficient super-smooth corrosion-resistant aluminum alloy conductor is up to over 95%, while the compression coefficient of an ordinary cable is only 88%-92%. Compared with a copper core cable, the cable provided by the invention has the advantages that on the basis of realizing equivalent electrical performance, the procurement cost can be reduced by 35%-40%, and the installation cost can be reduced by about 20%.

Owner:SHANGHAI MORN ELECTRIC EQUIPMENT CO LTD

Thermal insulation bottle type B1-level light fireproof cable

InactiveCN111540525AIncrease the compression factorIncrease profitInsulated cablesInsulated conductorsLow smoke zero halogenInsulation layer

The invention discloses a thermal insulation bottle type B1-level light fireproof cable, which comprises a composite insulation cable core group formed by twisting a plurality of cable cores. Each cable core is formed by twisting a molded line with an aluminum alloy conductor, a mineral insulation layer and a double-insulation irradiation crosslinking composite insulation layer; the whole composite insulated cable core group is wrapped with a first low-smoke halogen-free belt, gaps in the first low-smoke halogen-free belt are filled with inorganic mineral fillers to form a cooling fireproof layer, and a B1-level isolation layer, an armored metal sleeve, a flame-retardant fire-blocking layer, a second low-smoke halogen-free belt and a B1-level sheath are arranged outside the first low-smokehalogen-free belt. The cable provided by the invention has reliable mineral insulated cable fireproof characteristic, B1-level flame retardant property and low-smoke halogen-free environment-friendlycharacteristic.

Owner:ANHUI PACIFIC CABLE CO LTD

Method and device for compressing image data

InactiveCN1319381CSmall sizeAvoid error accumulationTelevision systemsDigital video signal modificationInter frameComputer science

Owner:SAMSUNG ELECTRONICS CO LTD

Acid and alkali resistant duralumin type metal stranded wire

ActiveCN104575703BAvoid damageAvoid defects caused by smoothnessConductive layers on insulating-supportsInsulated cablesYarnFiber

The invention discloses an acid and alkali resistant hard aluminum type metal strand. The acid and alkali resistant hard aluminum type metal strand comprises a stressed unit positioned at the center, and a first aluminum alloy conducting layer and a second aluminum alloy conducting layer which are sequentially stranded on the outer surface of the stressed unit; a first trapezoidal aluminum conductor layer and a second trapezoidal aluminum conductor layer are sequentially stranded on the outer surface of the second aluminum alloy conducting layer; a polyester adhesive filling part is formed by mixing a first component and a second component according to the mass ratio of 1: (2-4); the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, iso-octyl acrylate, normal butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. The aluminum twisted wire not only guarantees the round of a plurality of carbon fiber raw yarns in an aluminum layer, but also avoids the aluminum layer damage during subsequent use, thereby guaranteeing the reliability of electrical property, and the bending radius being reduced to 6 times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Aluminum alloy twisted wire used for ultra-high voltage transmission line

ActiveCN106057330AAvoid defects caused by smoothnessPrevent defects caused by smoothnessNon-insulated conductorsPower cables with screens/conductive layersFiberPolyester

The present invention discloses an aluminum alloy twisted wire used for an ultra-high voltage transmission line. The aluminum alloy twisted wire used for the ultra-high voltage transmission line is characterized in that an aluminum conductor cladding layer is twisted on the outer surface of a second aluminum alloy conductive layer orderly, and the aluminum conductor cladding layer is formed by twisting the Z-shaped aluminum alloy conductors; a first carbon fiber single wire and a second carbon fiber single wire are both formed by twisting a plurality of carbon fiber precursors, the space in an aluminum layer and between the carbon fiber precursors is filled with a polyester adhesive filling part, and the polyester adhesive filling part is formed by mixing a first component and a second component; the second component is formed by the following components of, by weight parts, 100 parts of acrylic acid, 30-35 parts of methyl methacrylate, 20-25 parts of ethanediol, 10-15 parts of toluene diisocynate, 1-2 parts of dibutyltin dilaurate, 0.5-1 parts of benzoyl peroxide and 0.5-0.8 parts of salicylic acid phenyl ester. The aluminum alloy twisted wire used for the ultra-high voltage transmission line of the present invention is tight in structure and high in compression coefficient, enables a bending radius to be reduced to six times of the diameter of a cable, the installation layout space and the installation cost to be reduced and the current-carrying capacity to be improved under an equal cross-section, and is easier to lay.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Anti-sliding electric power overhead aluminum stranded wire

InactiveCN107017039AAvoid damageAvoid defects caused by smoothnessNon-insulated conductorsInsulated cablesFiberPolyester

The invention discloses an anti-sliding electric power overhead aluminum stranded wire. The anti-sliding electric power overhead aluminum stranded wire comprises a stress unit positioned in the center, and a first aluminum conductive layer, a second aluminum conductive layer and a third aluminum conductive layer which are stranded on the outer surface of the stress unit in sequence; a polyester adhesive filling part is prepared from a first component and a second component at a mass ratio of 1 to 2-4 through mixing; the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, 2-ethylhexyl acrylate, n-butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine; and the second component comprises the following components in parts by weight: acrylic acid, methyl methacrylate, ethylene glycol, toluene diisocyanate, dibutyltin dilaurate, benzoyl peroxide and phenyl salicylate. According to the anti-sliding electric power overhead aluminum stranded wire, the smooth and level property of the multiple carbon fiber protofilaments in the aluminum layer is ensured while damage of the aluminum layer in the subsequent use process is also avoided, thereby ensuring reliability of electrical performance.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

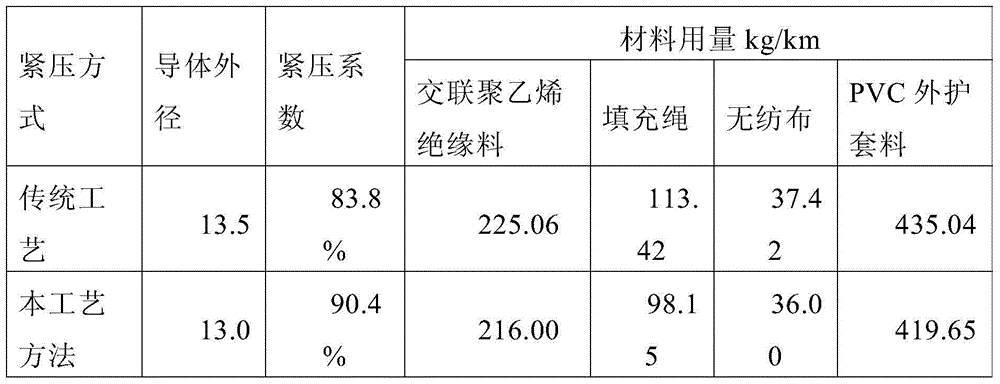

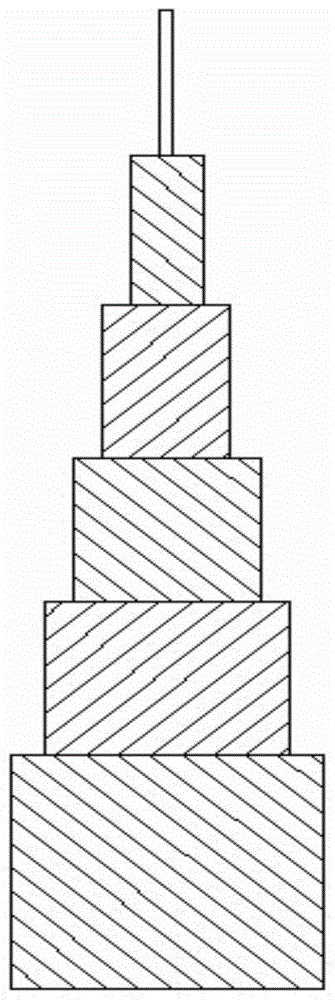

Fabrication method for round pressing of aluminum-alloy conductor

InactiveCN105788755AEasy to manufactureReduce processing costsCable/conductor manufactureState of artInsulation layer

The invention relates to a fabrication method for round pressing of an aluminum-alloy conductor. A round single wire is pressed by a single-way twisting mode. The fabrication method comprises the following steps of 1) winding the round single wire after an intermediate conductor by the single-way twisting mode, and pressing the conductor by a press die; 2) coating the external part of the pressed conductor with an insulation layer; and 3) sleeving the outer layer of the insulation layer with a PVC jacket. Compared with the prior art, the fabrication method has the advantages of low processing cost, material saving, high pressing coefficient and the like, and is convenient to fabricate.

Owner:SHANGHAI XINYI ELECTRICAL CIRCUIT EQUIP

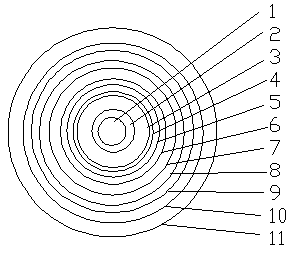

Power cable

InactiveCN106158128ASimple manufacturing techniqueManufacturing technology realizationPower cables with screens/conductive layersEngineeringElectrical conductor

The invention relates to a power cable, which comprises an outer semiconductive layer, an outer nonmetal protective layer, a metal sheath layer, a semiconductive water-stop buffer layer, an insulated shield layer, an insulated layer, a conductor shield layer and conductors. The conductors are disposed in the innermost center, and the conductor shield layer, the insulated layer, the insulated shield layer, the semiconductive water-stop buffer layer, the metal sheath layer, the outer nonmetal protective layer and the outer semiconductive layer are arranged outside sequentially layer by layer. The conductors include a middle round conductor, and trapezoidal or Z-shaped single conductors mutually matching to surround the round conductor.

Owner:DATANG SANMENXIA POWER GENERATION

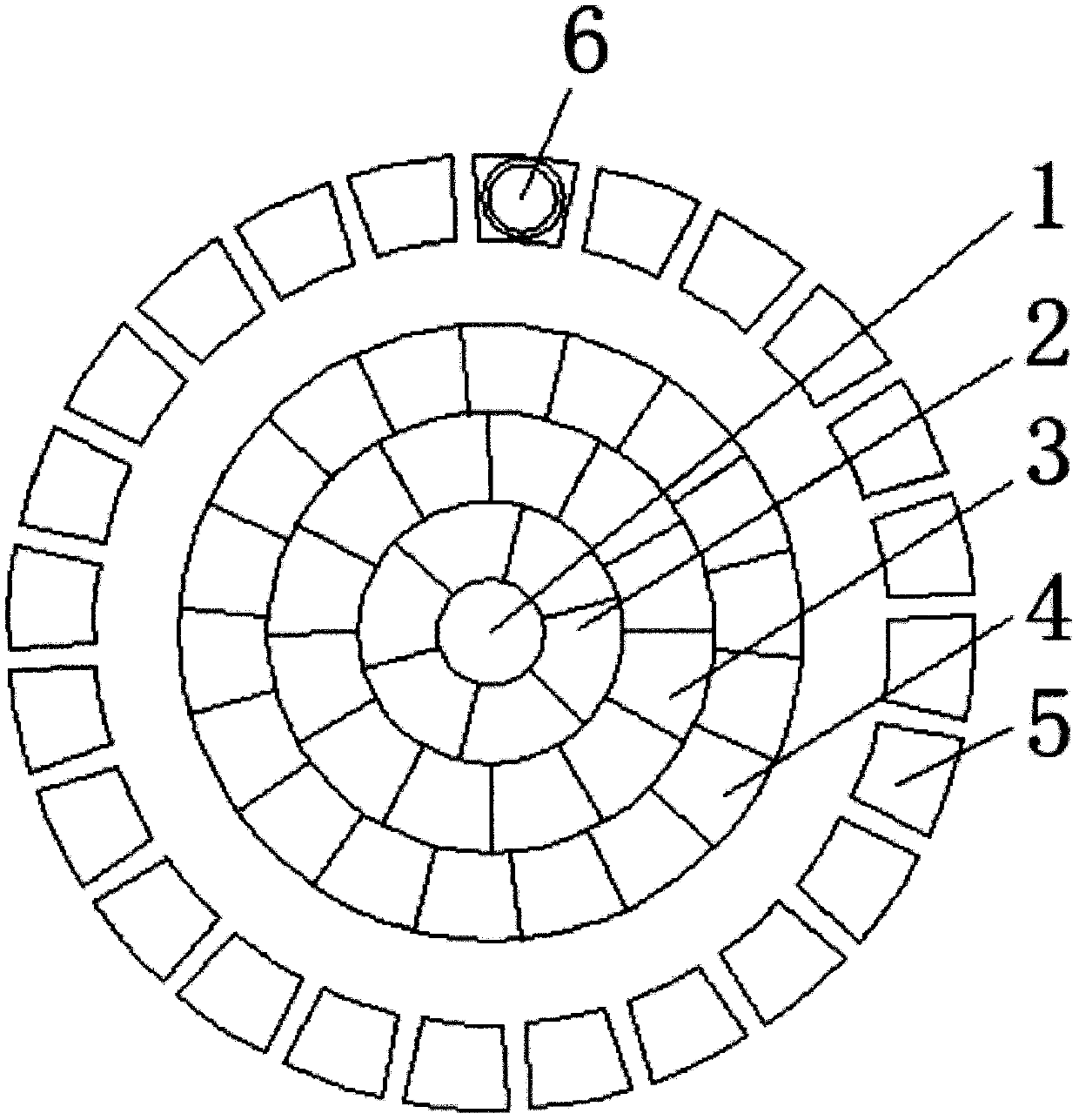

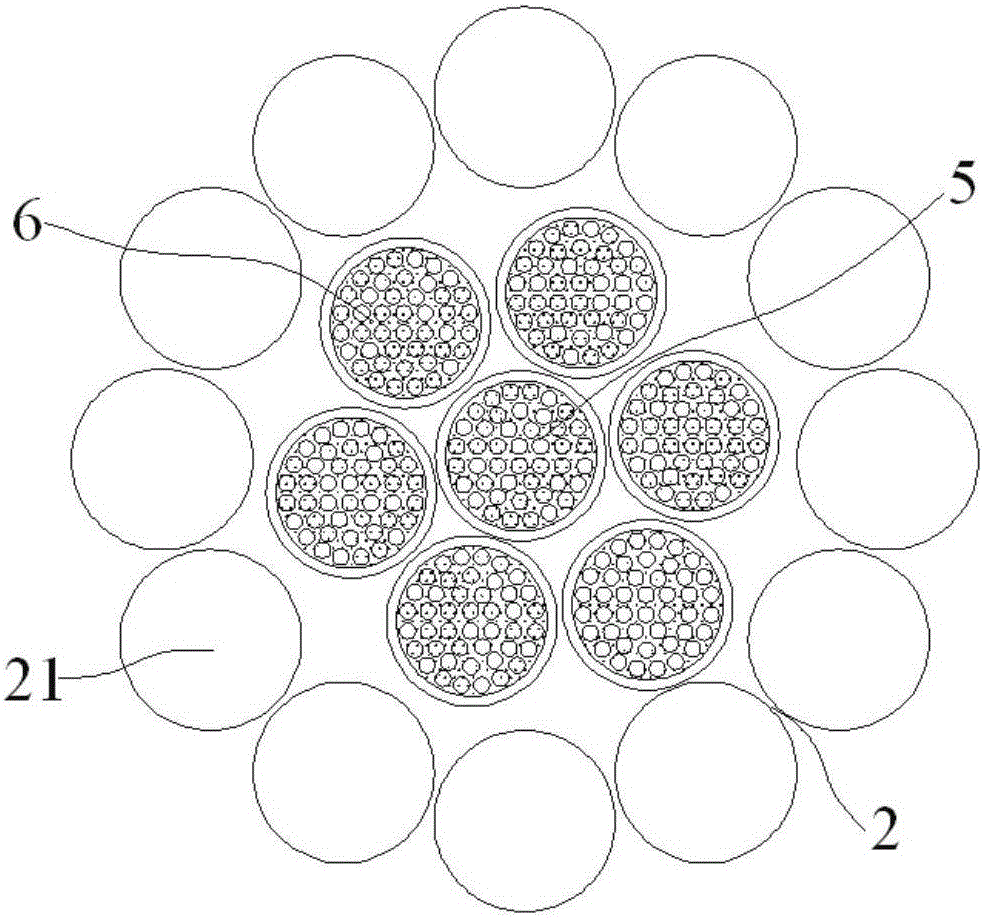

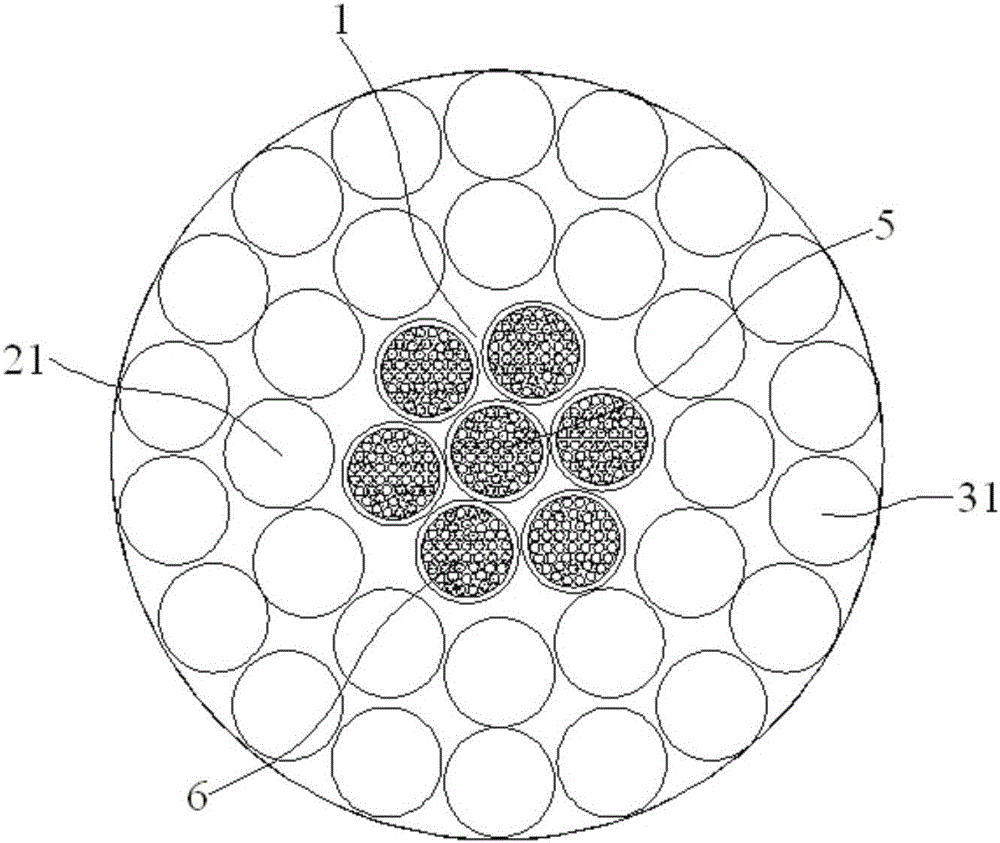

The second type of circular compact conductor structure and its stranding process

InactiveCN103559954BFill the voidSmall outer diameterNon-insulated conductorsPower cablesElectrical conductorFill factor

The invention discloses a second type of circular compacted conductor structure, including: several conductors and monofilaments, the conductors are normally twisted and divided into several conductor layers, and the conductor layers and conductor layers are layered and compacted, and the monofilaments are arranged Between the conductor layers, when the total number of conductors is less than or equal to 19, all monofilaments are twisted in the same direction; when the total number of conductors is more than 19, the outermost monofilaments are twisted in reverse, and the inner monofilaments are twisted in the same direction. To twist. It solves the problem of increasing the filling factor of the conductor and improving the conductivity of the conductor. The flexibility is better than that of the traditional second-class round compact conductor. It has the characteristics of stable structure, simple processing and easy operation.

Owner:SHANGHAI NANDA GROUP

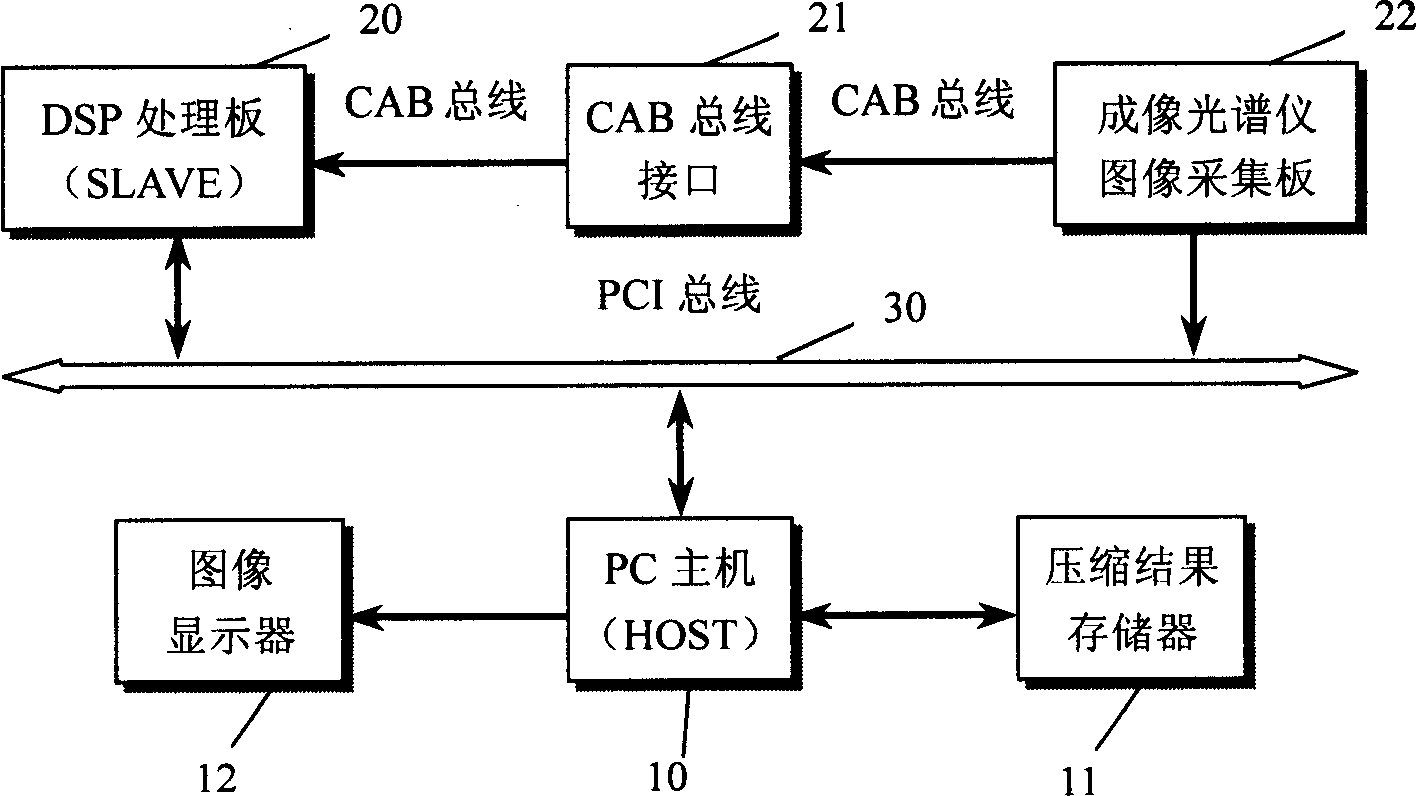

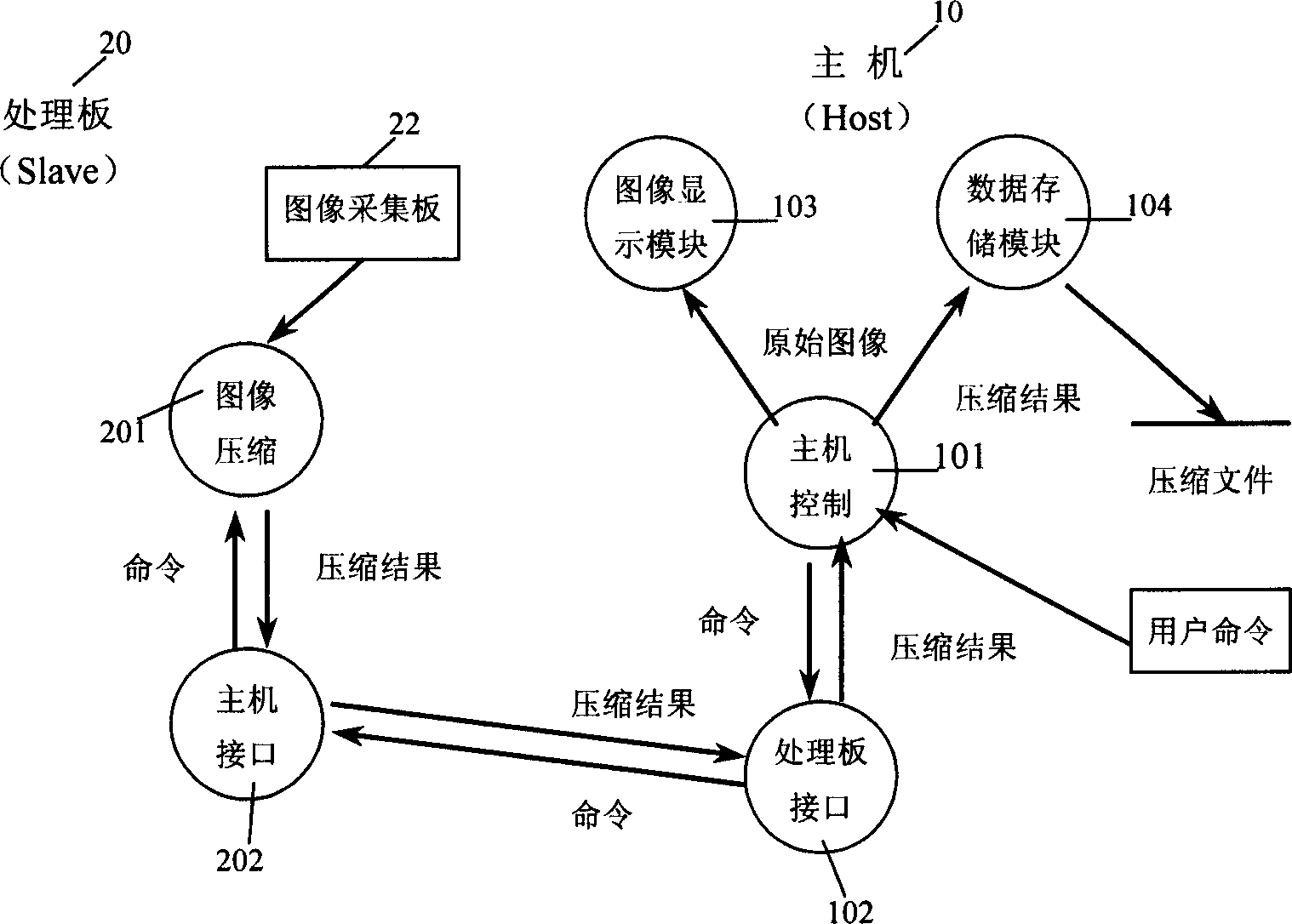

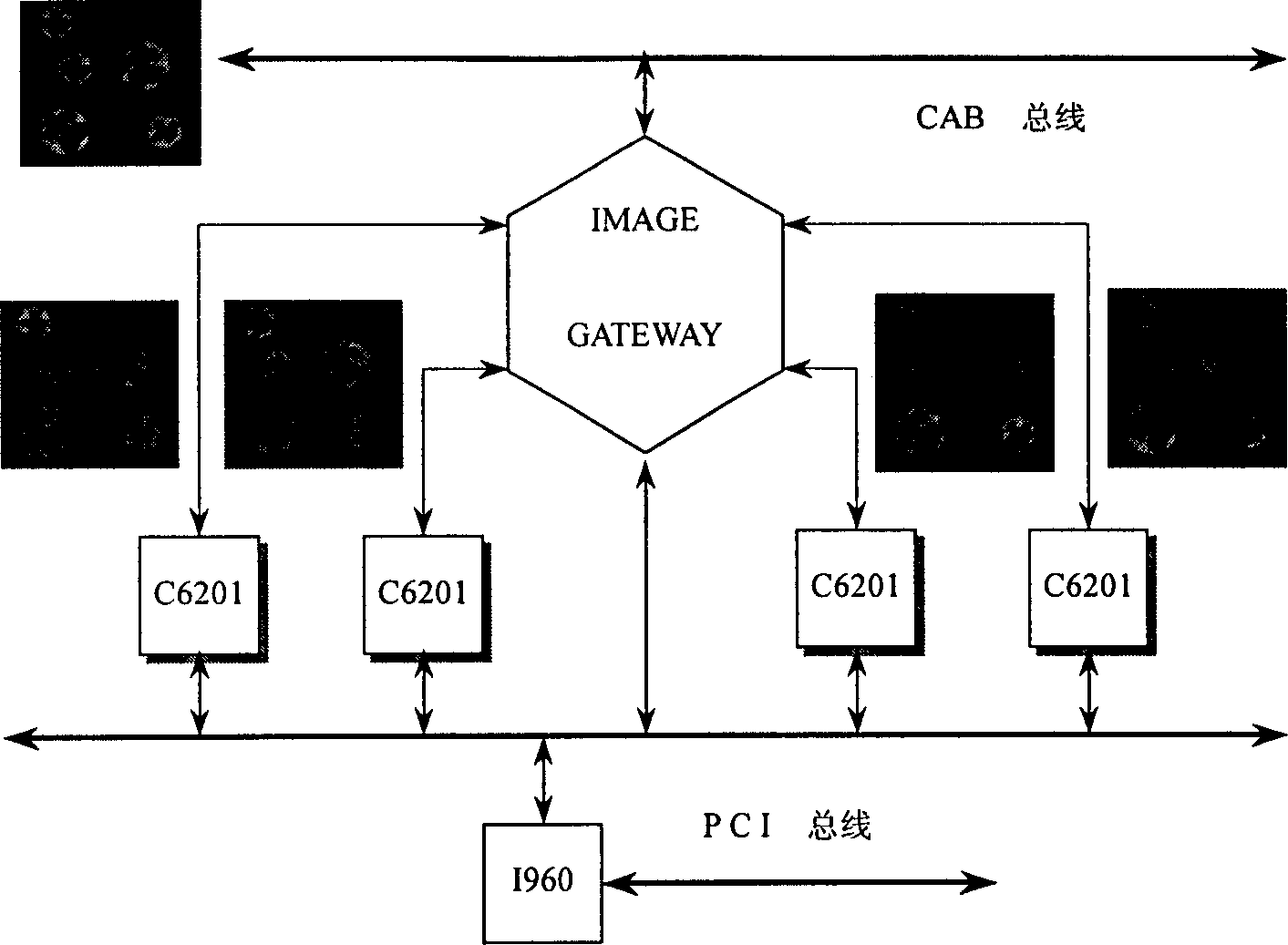

Ultra-spectrum image real-time compression system based on noise masking

InactiveCN1290056CReduce workloadEasy and convenientImage codingImage data processing detailsDisplay deviceImage compression

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Al-Fe-Cu alloy material and preparation method thereof

The invention particularly relates to an Al-Fe-Cu alloy material and a preparation method thereof. The Al-Fe-Cu alloy material comprises the following components in percentage by weight: 0.20-1.30 wt% of Fe, 0.01-0.08 wt% of Cu, 0.06-0.15 wt% of Si, 0.02-0.10 wt% of rare-earth element and the balance of Al and unavoidable impurities. The aluminum alloy is prepared by casting and semi-annealing raw materials. When the aluminum alloy is prepared, the alloy material is semi-annealed, and thus, the adverse effects of stress on a conductor structure in the process of drawing and twisting are reduced, the electric conductivity reaches and even exceeds 61% of IACS (International Annealed Copper Standard) (the electric conductivity standard of an aluminum conductor for a general electrician is 61% of IACS), and the performances of elongation and the flexibility of the aluminum alloy are improved greatly by annealing. The performances of the elongation of a cable made of the aluminum alloy wire can reach 30%, the flexibility is 25% higher than that of a copper cable, and the resistivity maintains in a lower level.

Owner:安徽省惠尔电气有限公司

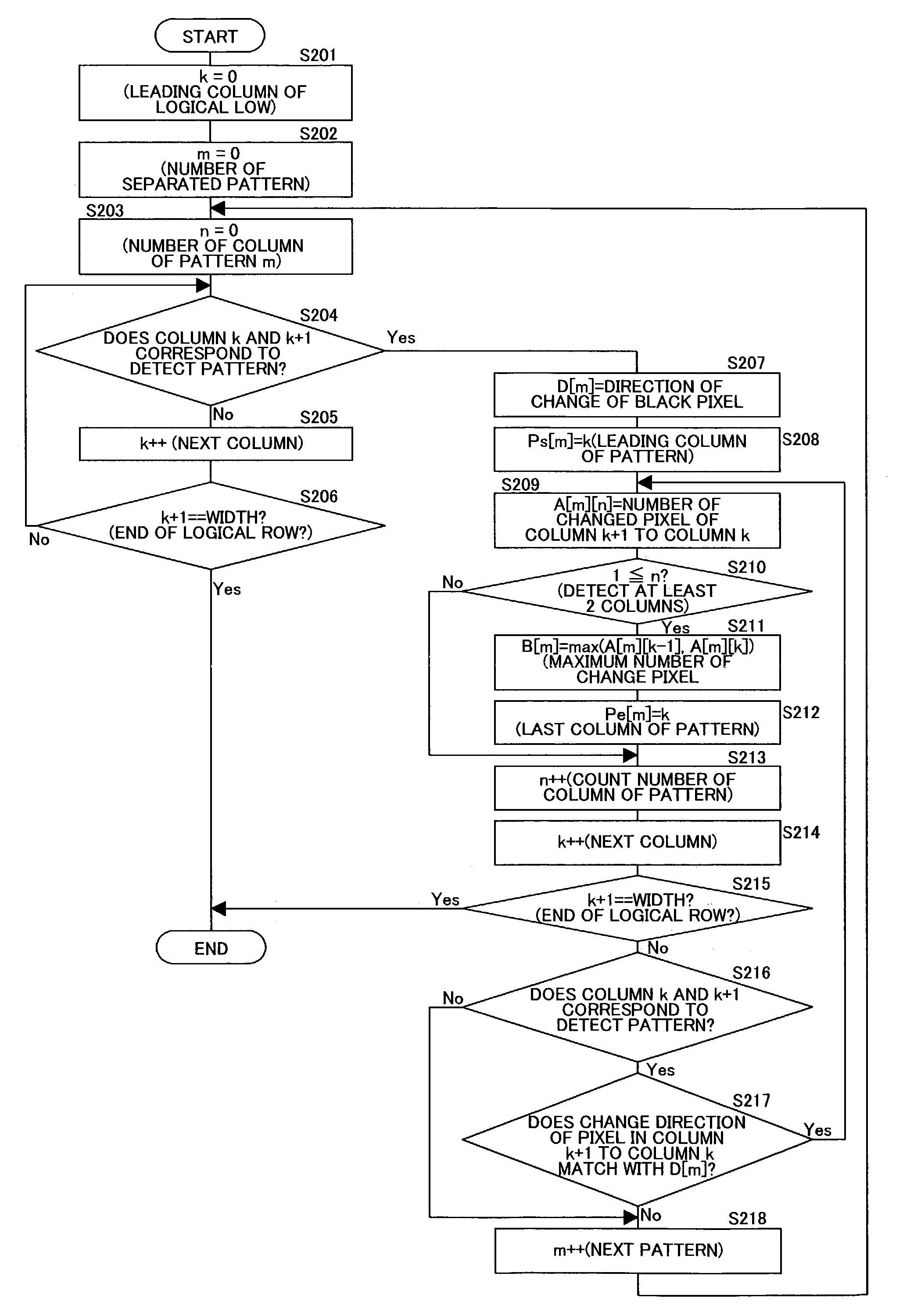

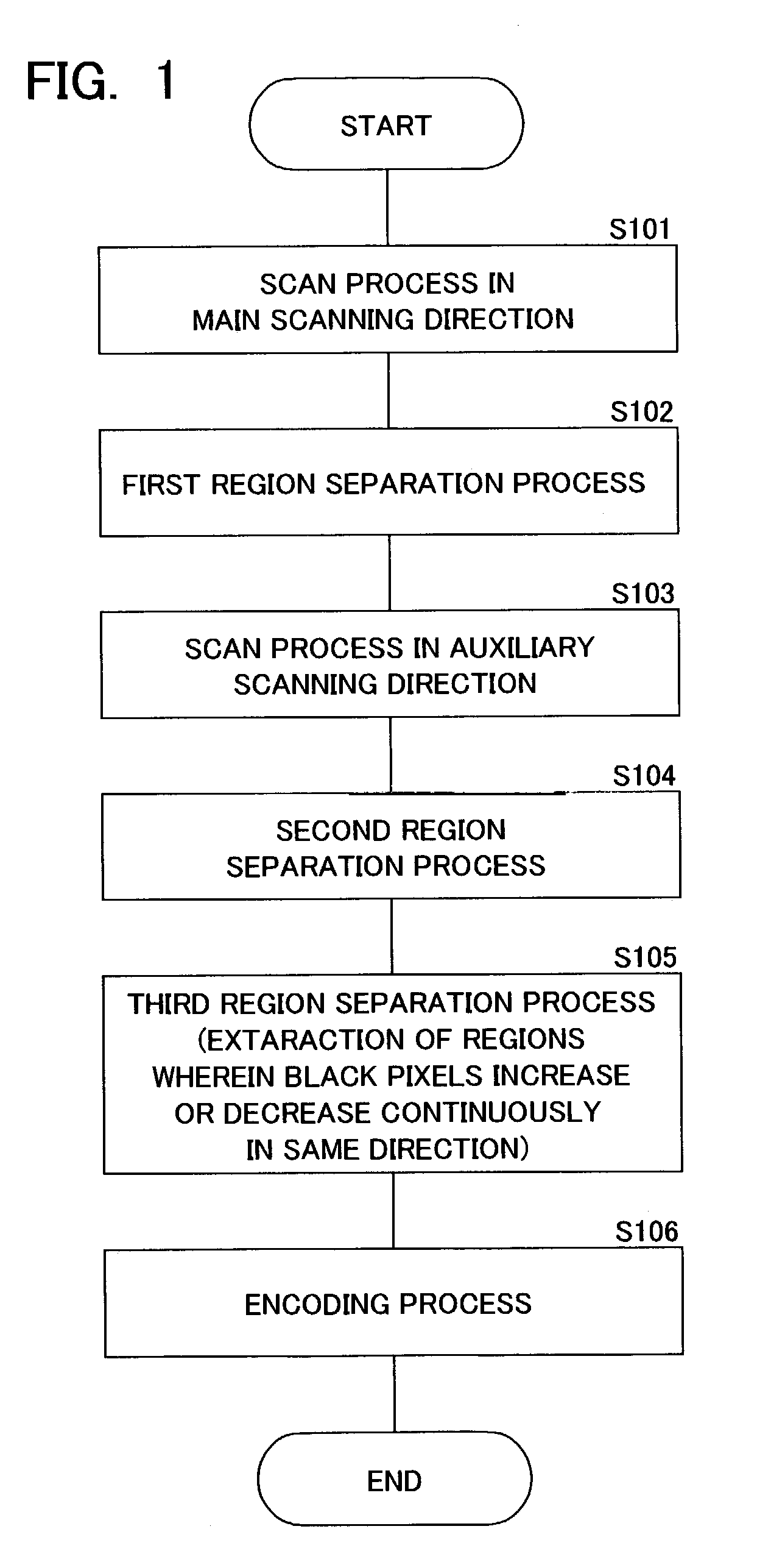

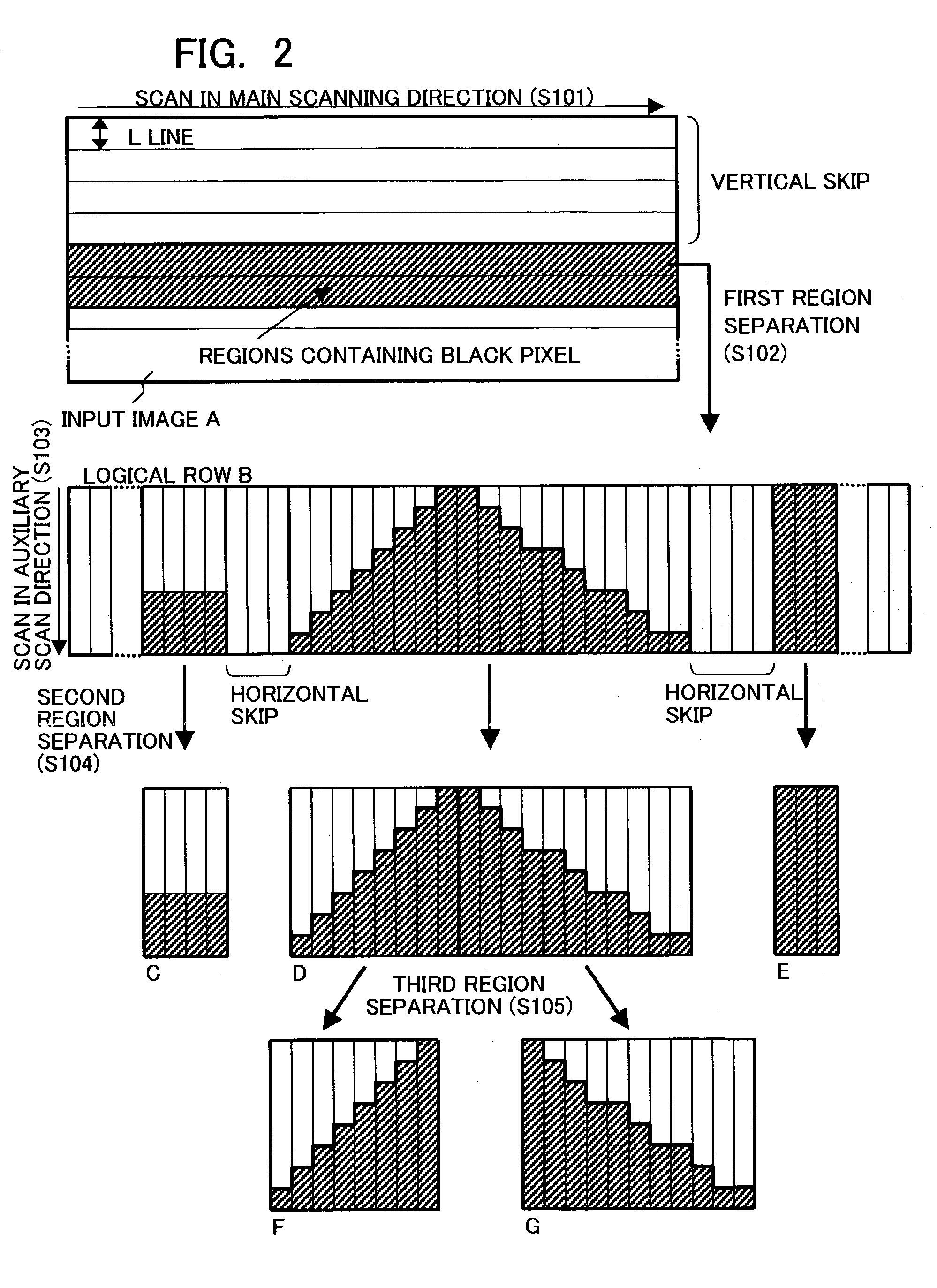

Image compression method, decompression method thereof and program therefor

InactiveUS7259891B2Increase the compression factorEasy to compressDigitally marking record carriersDigital computer detailsMethod of imagesImage compression

In a method of image compression in which vertical and horizontal white skipping are performed, data compression is performed in the regions containing black pixels other than the skipped regions. While vertical and horizontal white skipping being performed, in the other regions, regions are detected in which pixel values change in smooth fashion, such as the outlines of letters and encoding is performed using the pixel value of the leading column of the region, number of columns and amount of change of the pixel values. As a result, the compression factor of the image can be increased and a considerable contribution made to reduce the storage capacity for storage of data and reduce the time required for data transmission.

Owner:FUJITSU CLIENT COMPUTING LTD

Novel energy-saving water-blocking cable

InactiveCN106128605ALow costImprove economyInsulated cablesMetal/alloy conductorsYarnElectrical conductor

The invention relates to a novel energy-saving water-blocking cable. The novel energy-saving water-blocking cable comprises a cable core formed by twisting a plurality of insulated wire cores, wherein each insulated wire core consists of a water-blocking conductor and a water-tree-resistant insulating layer extruded outside the corresponding water-blocking conductor; a water-blocking wrapping belt, a metal sheath water-blocking layer and a composite water-blocking sheath layer wraps the outside of the cable core in sequence; and the water-blocking wrapping belt is filled with water-blocking filling yarns. The novel energy-saving water-blocking cable is compact and reasonable in structure and convenient to manufacture, and is good in energy-saving effect, high in water-blocking performance, long in service life and environmentally-friendly.

Owner:JIANGSU CHANGFENG CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com