Fabrication method for round pressing of aluminum-alloy conductor

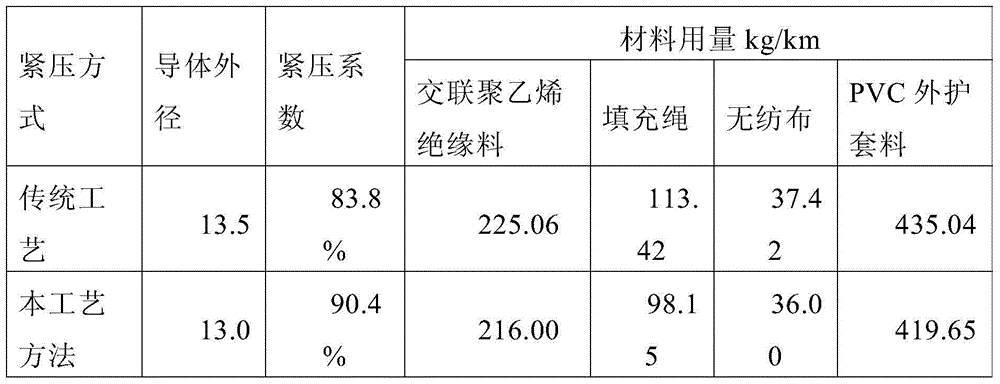

A technology of aluminum alloy conductor and manufacturing method, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of large conductor outer diameter, insulation, filling, large amount of sheath, low compression coefficient, etc., and achieve processing Low cost, easy production, high compression coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The method for manufacturing a circular compacted aluminum alloy conductor of the present invention uses a circular single wire for compaction in a coaxial twisting manner, and the manufacturing method is specifically as follows:

[0025] 1) After the circular single wire is wound in the middle conductor in the same direction, it is pressed by the pressing die;

[0026] 2) Coat the outside of the compressed conductor with an insulating layer;

[0027] 3) Put a PVC jacket on the outer layer of the insulating layer.

[0028] The traditional twisting direction is left-right-left, and the same-direction twisting method of the present invention is the left-left-left twisting method.

[0029] Due to the co-directional stranding, each layer will become tighter and tighter during the stranding process, so when this method is adopted, the pitch diameter ratio of each layer is 1-2 larger than that of the traditional stranding;

[0030] When traditionally stranded aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com