Patents

Literature

34results about How to "Save raw and auxiliary materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

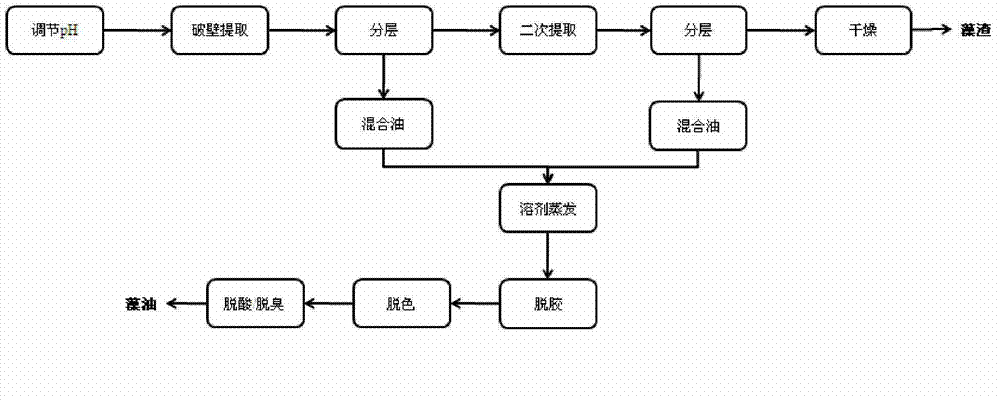

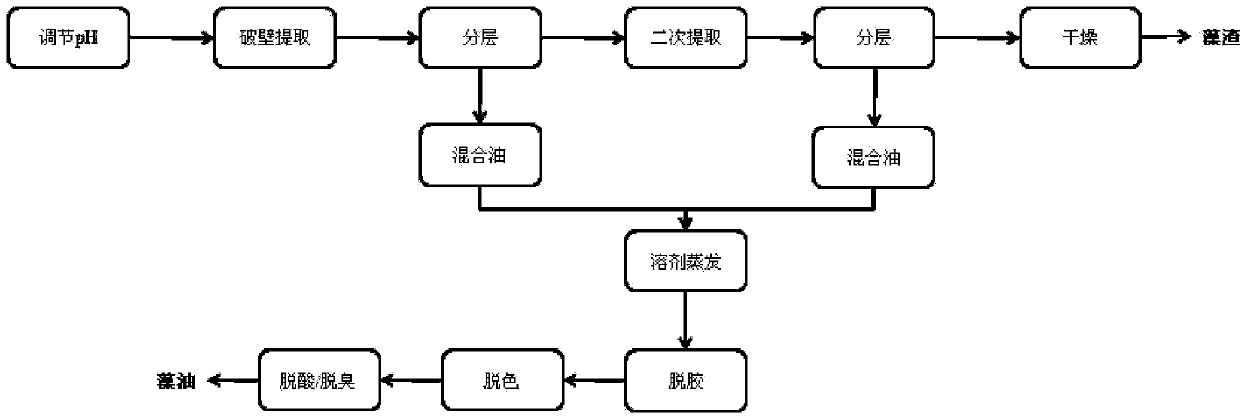

Method for extracting grease from schizochytrium

ActiveCN102965182ASimple processLow costMicroorganism based processesFatty-oils/fats productionFlocculationOil and grease

The invention discloses a method for extracting grease from schizochytrium. The method comprises the following steps: (1) adjusting the pH (Potential of Hydrogen) of the fermentation broth of the schizochytrium until reaching an acid stage, and then adding an organic solvent to stir, so as to realize the wall breaking of schizochytrium cells and extraction of microalgae oil; (2) adding a flocculant to the fermentation broth obtained in step (1) to flocculate, and extracting by the organic solvent to obtain crude algae oil; and (3) treating the crude algae oil by degumming, discoloring, and deacidifying / deodorizing, so as to obtain the microalgae oil rich in DHA (Docosahexaenoic Acid). According to the method disclosed by the invention, autolysis wall-breaking technology is adopted, so that the technological process in wall breaking and extraction of the schizochytrium can be simplified, the operation time in wall breaking can be shortened, the investment on equipment is decreased, and the cost is lowered; and the biological flocculant flocculation technology is carried out, therefore, the demulsification technological process is simplified, the time for layering is shortened, the layering effect is improved, the load due to wastewater discharge and water treatment caused by the demulsification process can be avoided, and the cost of water treatment can be lowered.

Owner:ENN SCI & TECH DEV

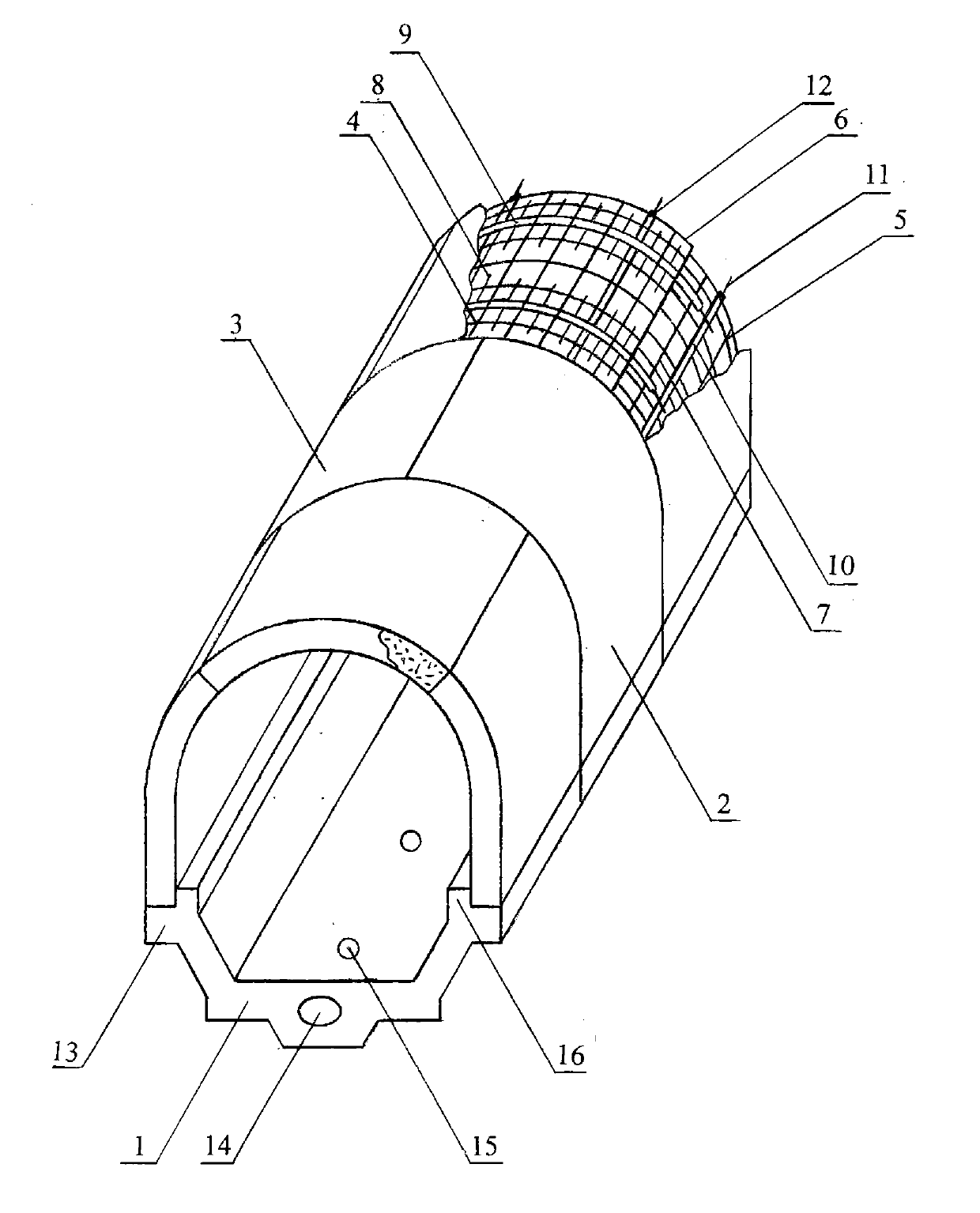

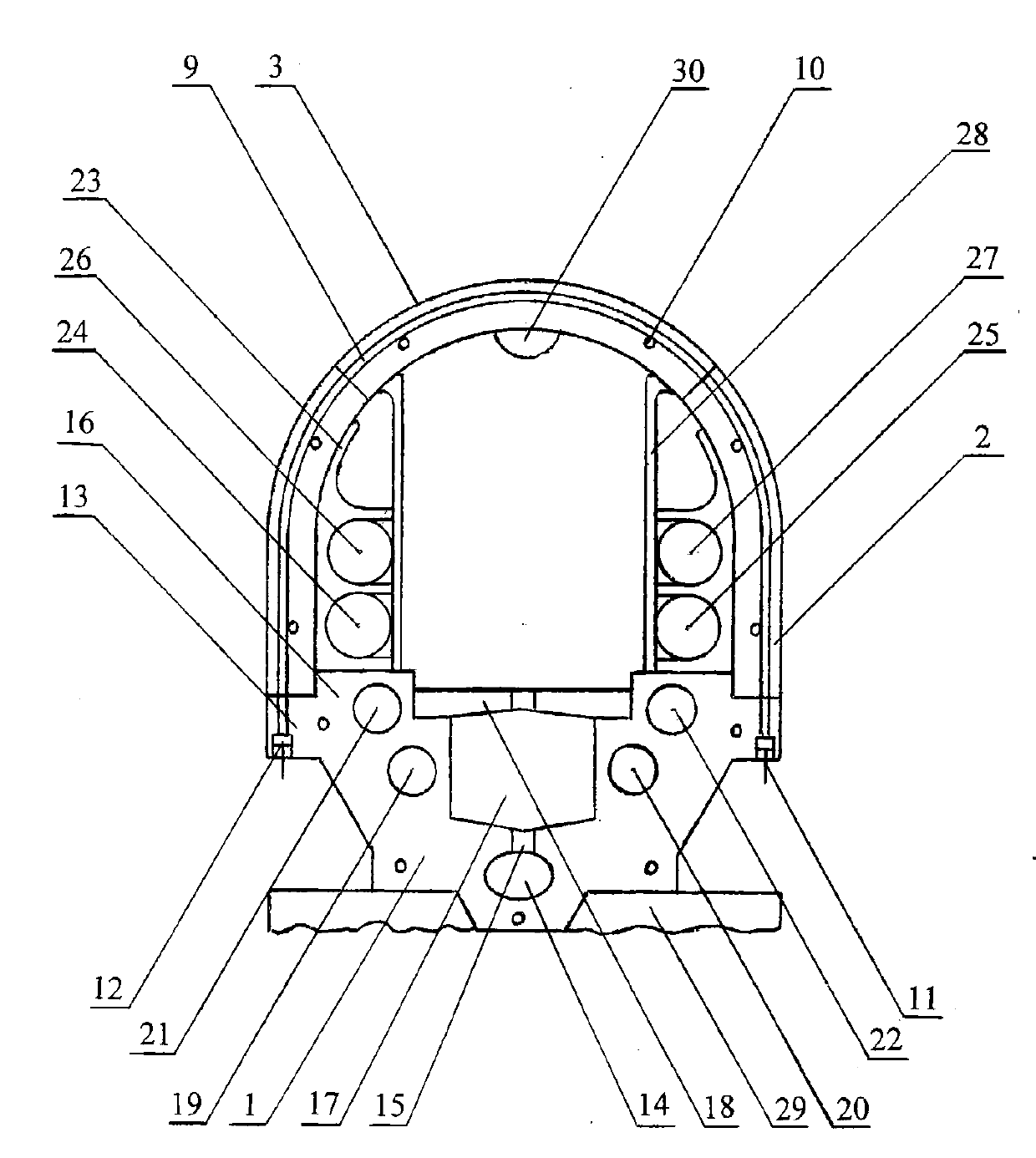

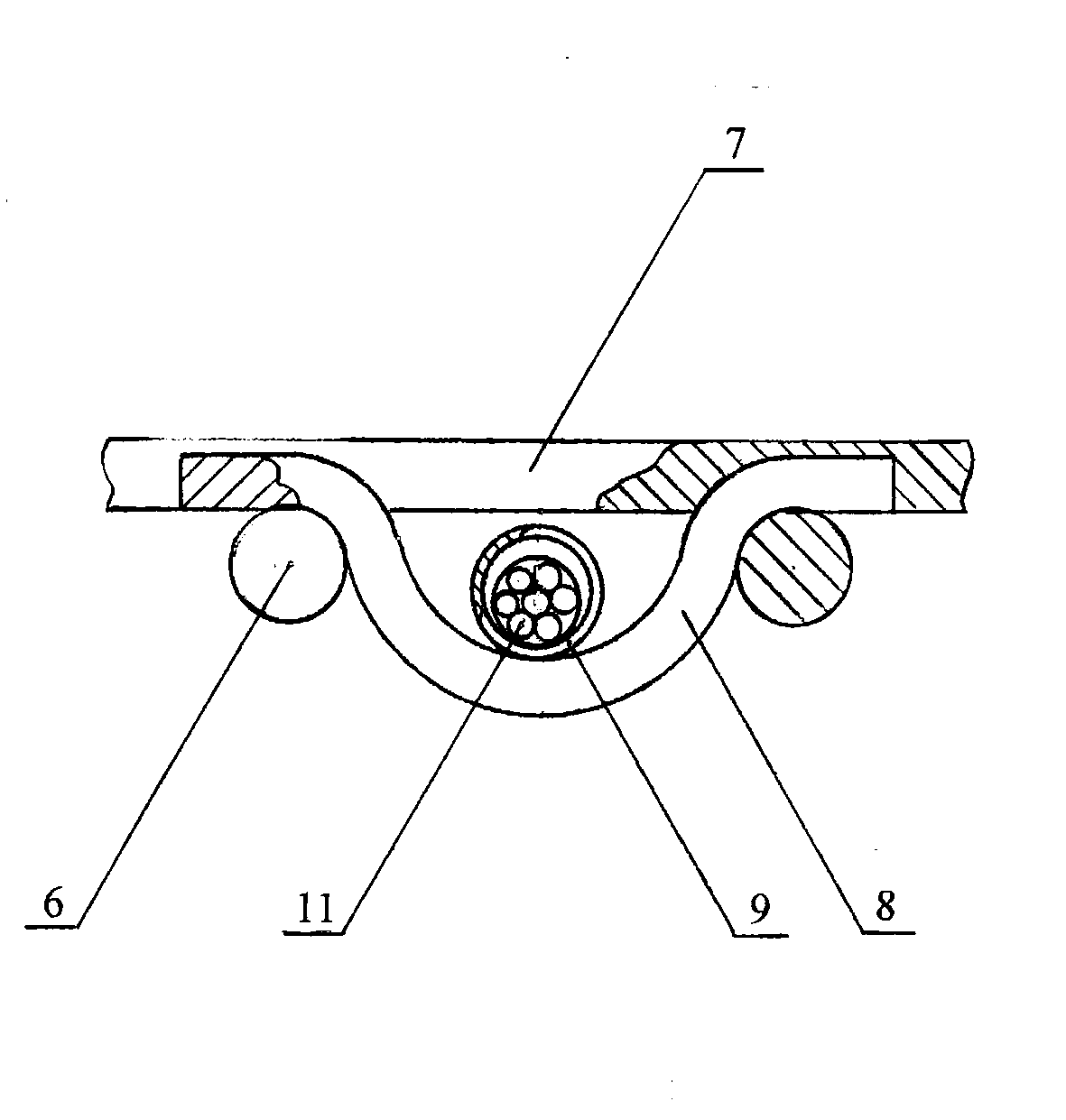

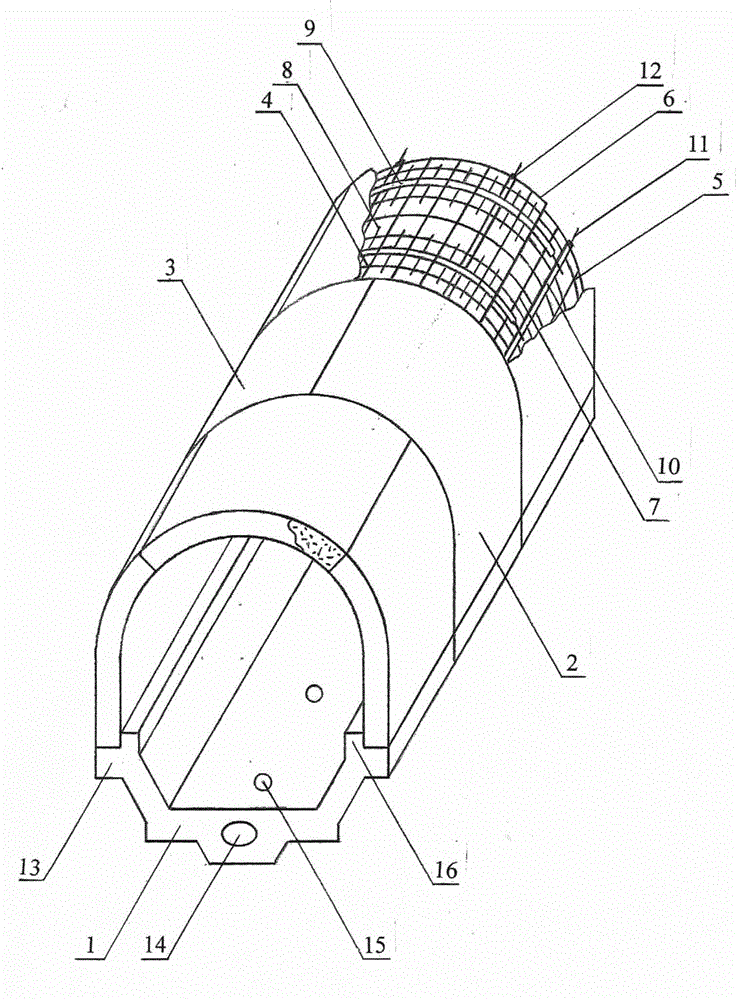

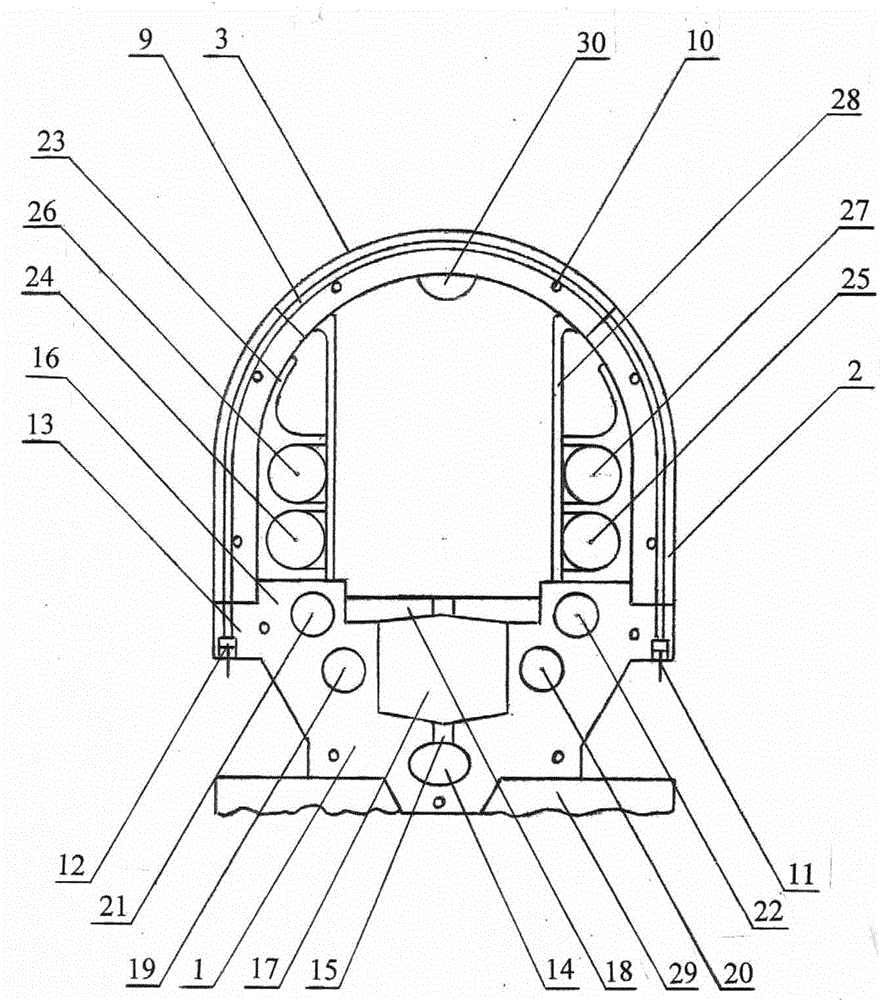

Multifunctional arched combined prestress underground pipe gallery for cisty and preparation process thereof

InactiveCN102995660AImprove shear resistanceImprove high pressure resistanceArtificial islandsUnderwater structuresHigh standardHigh pressure

The invention discloses a multifunctional arched combined prestress underground pipe gallery for a city, and a preparation process thereof. The multifunctional arched combined prestress underground pipe gallery consists of a concrete pipe sheet seat and an arched pipe body, wherein the arched pipe body is arranged on the pipe sheet seat and consists of the tube sheet. The pipe sheet seat and the pipe sheet are utilized, the underground pipe gallery is combined according to a structural mode of the arched pipe body to meet a high standard requirement on high pressure resistance, sedimentation resistance, torsion resistance, displacement resistance and earthquake resistance, so that the construction level of the city is improved. According to the topography of a town, a drainage network with a self-flow function is arranged, so that a design target of the functional pipe gallery and the safe pipe gallery is fulfilled.

Owner:张双里

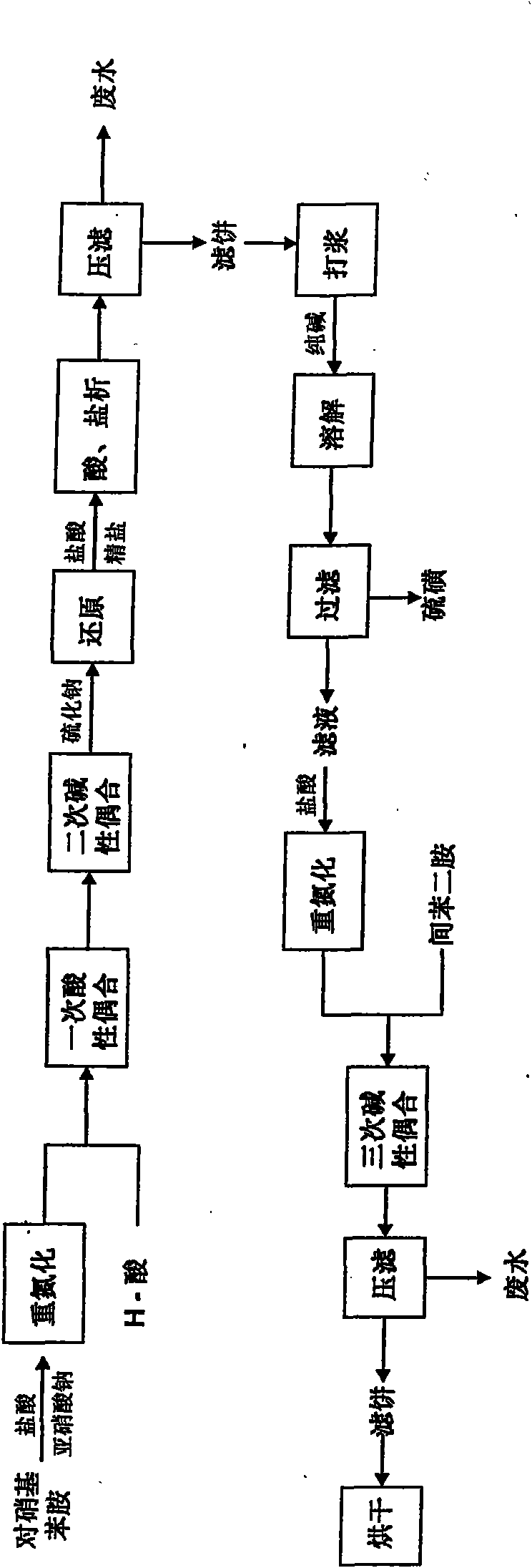

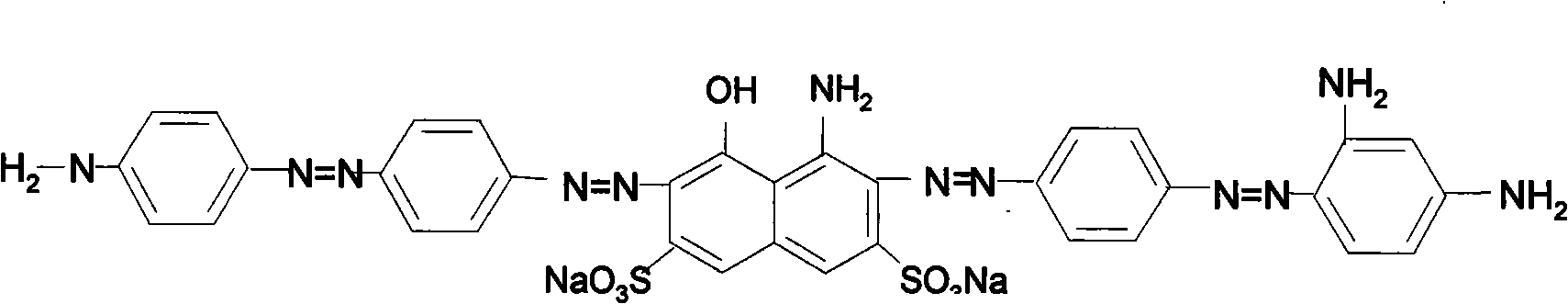

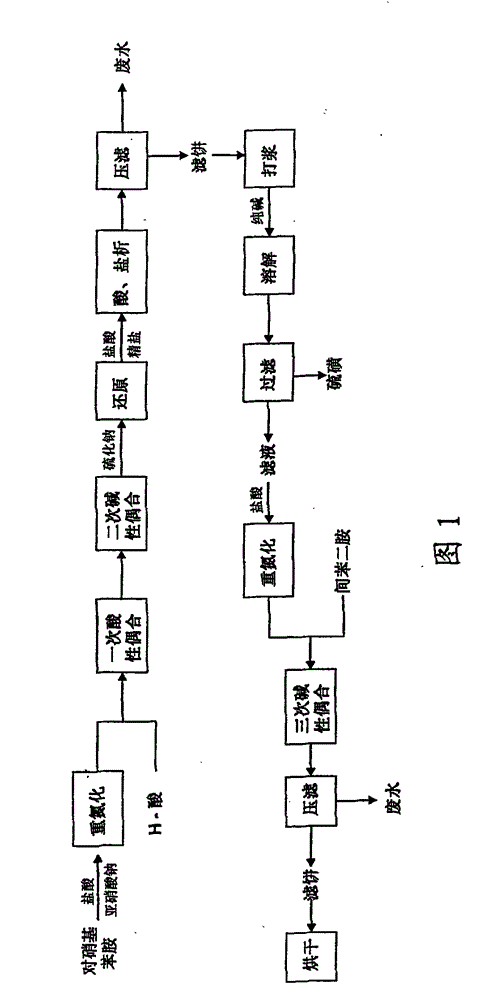

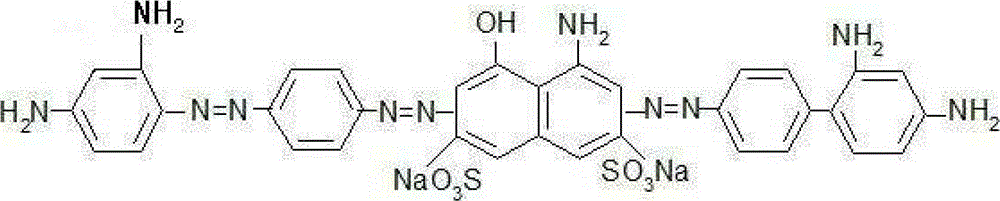

Pollution-free production technology of direct fast black G

The invention relates to a pollution-free production technology of direct fast black G, comprising the following implementation steps: firstly, primary acid coupling is carried out on nitroaniline after diazotization and H-acid; after the full reaction of the H-acid is detected, sodium carbonate is added and pH is adjusted to 8 to 8.2 to carry out secondary basic coupling; the coupling product is added into a sodium sulfide solution for reduction, and the temperature gradually raises to t of 38 DEG C to 40 DEG C in the reaction process; after the sodium carbonate is added into the reduction product after acidification to adjust the pH of a medium to 7.5 to 8, the mixture is adsorbed by activated carbon and filtered, and ternary coupling is carried out on the obtained filter liquor after diazotization and lentine; and after the reaction is detected to be end point, the materials are directly delivered to a drying tower for spray drying. In the invention, the reduced reaction solution does not need the processes of salting out, acidification and filtration, activated carbon adsorption is adopted instead. In the process, no waste liquor is generated, and environment pollution caused in the production process of dye is greatly reduced. Simultaneously, wastewater processing is not needed, and the cost is saved. The optimized technology directly transfers the reaction solution after ternary coupling into the drying tower for spray drying; and the yield and the coloring intensity of the dye are effectively increased, energy is saved, the consumption is reduced, and the effect is obvious.

Owner:INNER MONGOLIA XINYA CHEM

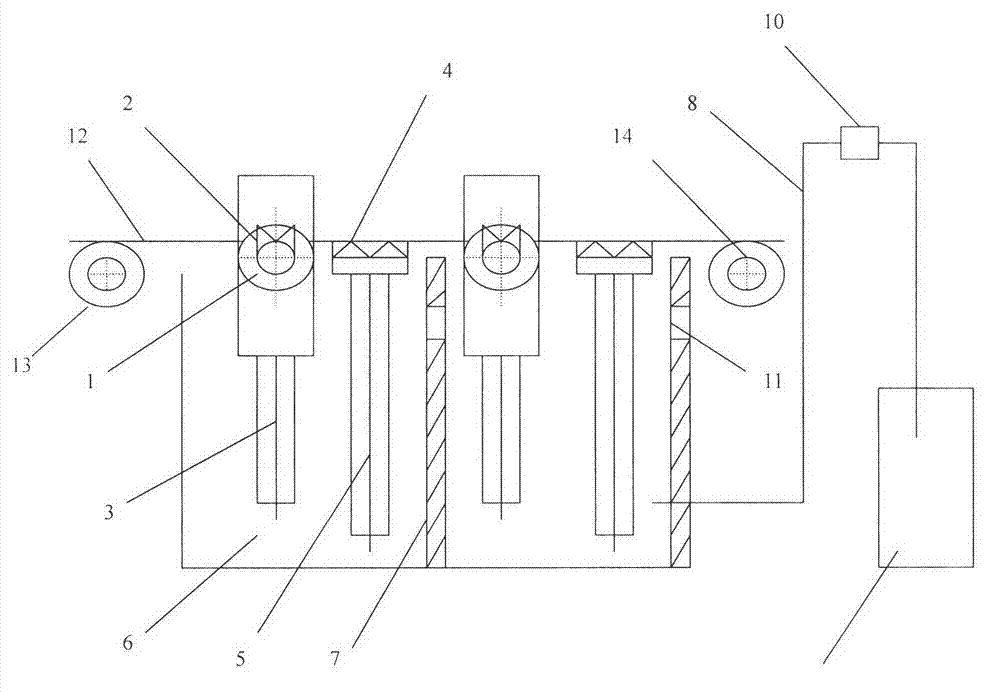

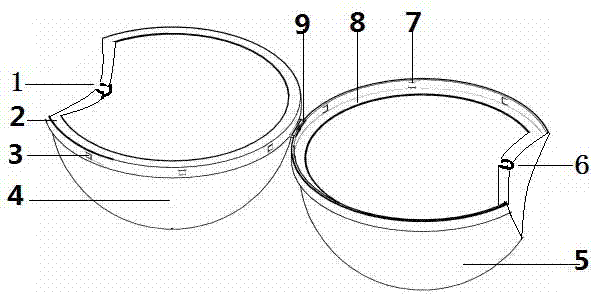

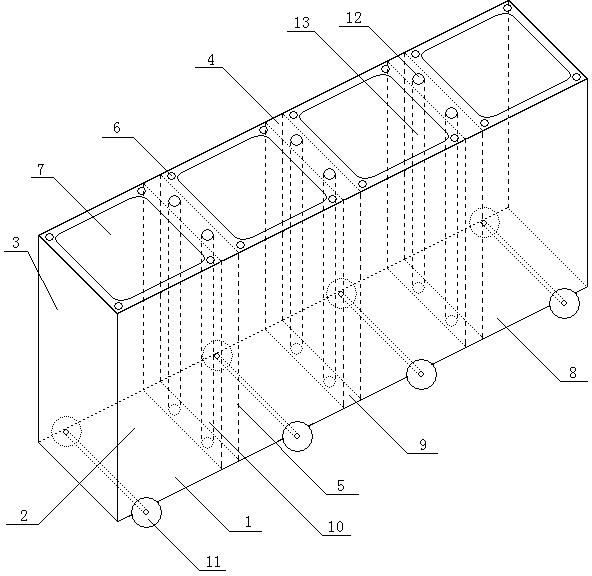

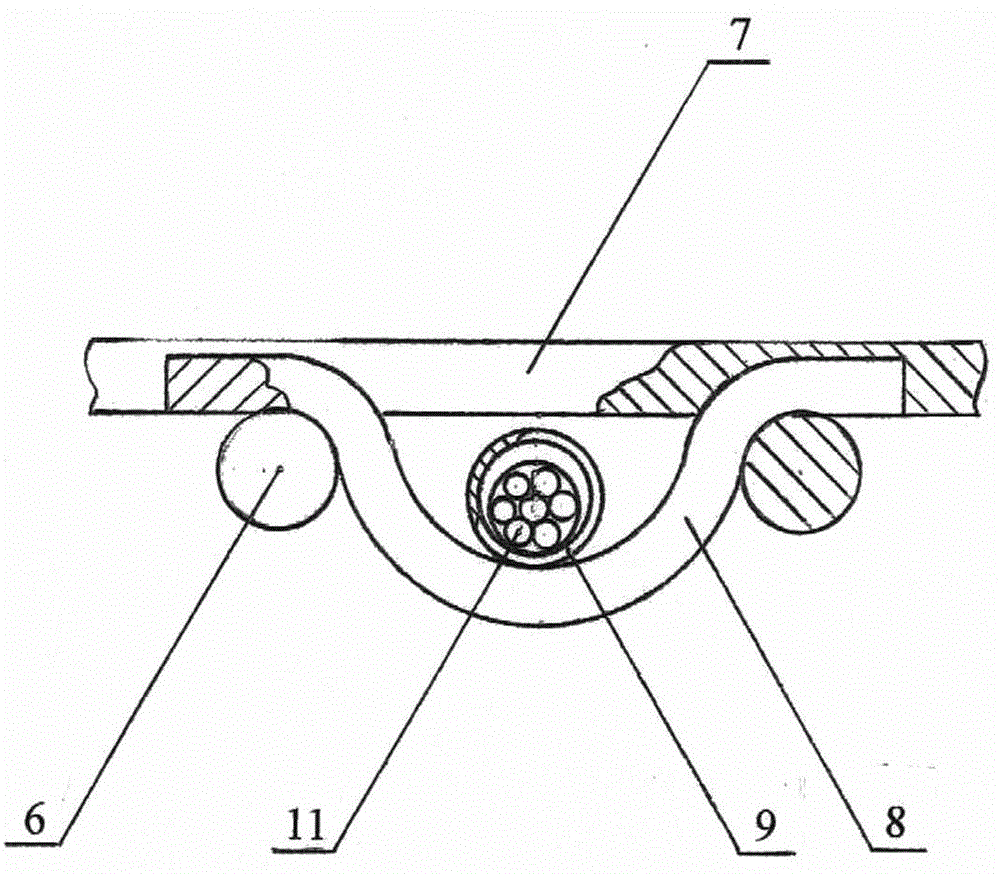

Backflow water washing equipment

The invention provides backflow water washing equipment which is low in cost and has a good using effect. According to the technical scheme, the equipment comprises a water spraying system, an air sucking system, a serial tank body and a circulating system, wherein the water spraying system mainly comprises water spraying plates (1) and lifting pumps (3), and each water spraying plate (1) is provided with a water spraying nozzle (2) of which the water spraying angle can be adjusted; the air sucking system mainly comprises air sucking plates (4) and air channels (5), and each air sucking plate (4) is provided with an air sucking hole; the serial tank body mainly comprises a plurality of washing tanks (6) formed by a plurality of clapboards (7), and water flowing openings (11) at different heights are formed in the clapboards (7); the circulating system mainly comprises a circulating pipe (8), a liquid sucking pump (10) and a plating tank (9); and the air sucking system and the water spraying system are fixed on the edges of the washing tanks (6) respectively. The equipment has a simple structure and is safe and reliable, and the force and the cleanliness of water washing are enhanced; and simultaneously, a serial circulating washing process is realized to achieve the effect of zero emission of washing fluid, so that the environment is greatly protected, and raw and auxiliary materials are greatly saved.

Owner:东营宏源机械设备有限公司

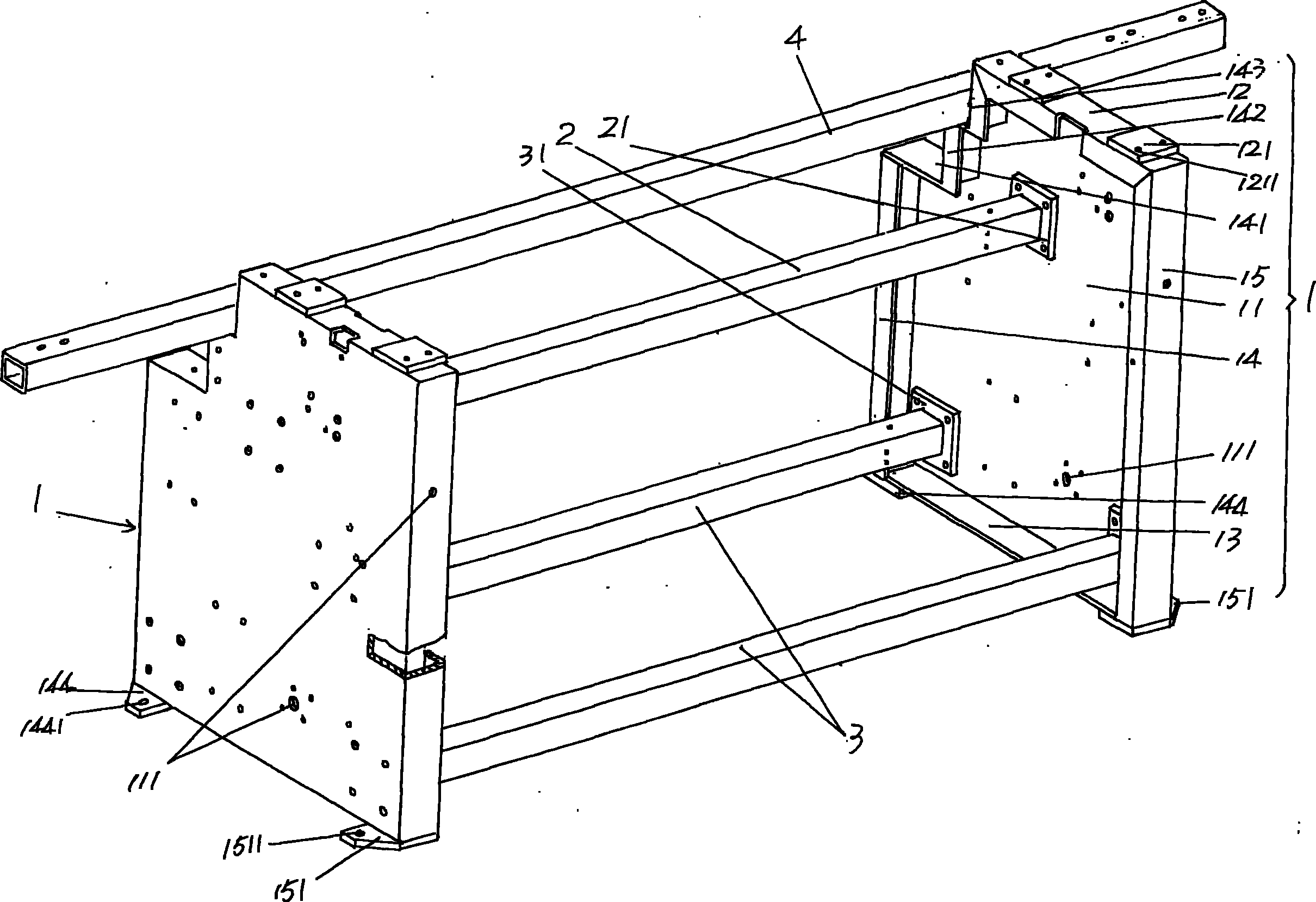

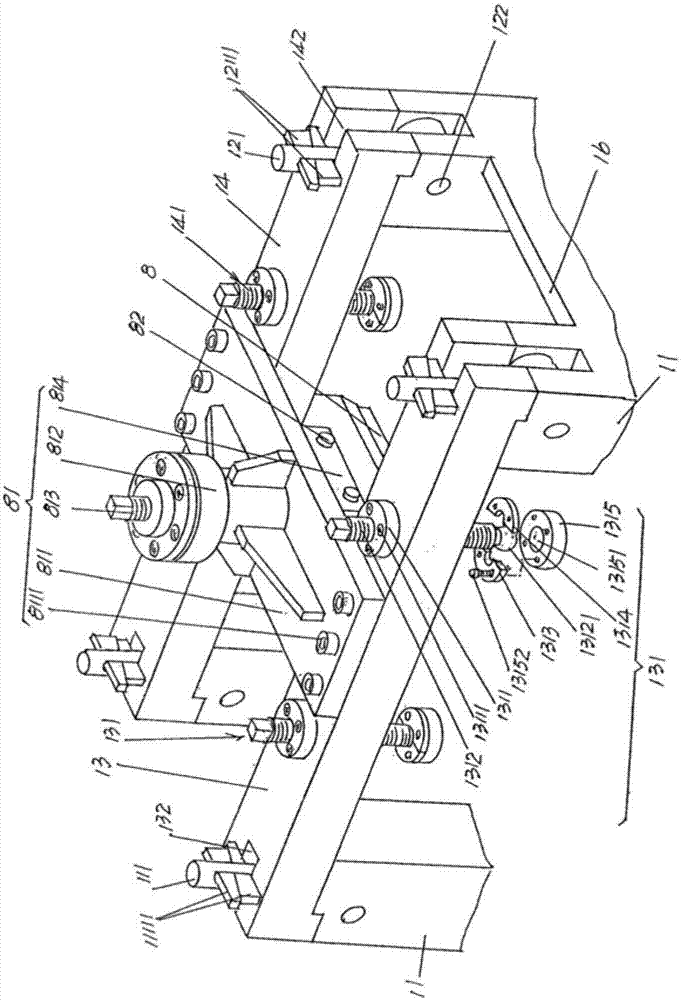

Frame of computer flat knitting machine

InactiveCN102108591AReduce weightReduce labor intensityWeft knittingEngineeringUltimate tensile strength

The invention provides a frame of a computer flat knitting machine, belonging to the field of knitting machines, comprising a pair of wall plates of same structure and connected by upper and lower beams, wherein each wall plate comprises a plate body, a top folded edge, a bottom folded edge, a left folded edge and a right folded edge, the top folded edge, the bottom folded edge, the left folded edge and the right folded edge are bent in the same direction to form the edge of the plate body, one end of the upper folded edge is connected with the upper end of the left folded edge, the other end of the upper folded edge is connected with the upper end of the right folded edge, one end of the lower folded edge is connected with the lower end of the left folded edge, and the other end of the lower folded edge is connected with the lower end of the right folded edge. The frame can be rapidly manufactured, and raw materials are saved; the wall plates are light and firm so as to save material and be beneficial to packaging and reducing the transportation cost; and the structure of each wall plate can be obtained without welding, so as to reduce the labor strength of workers.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

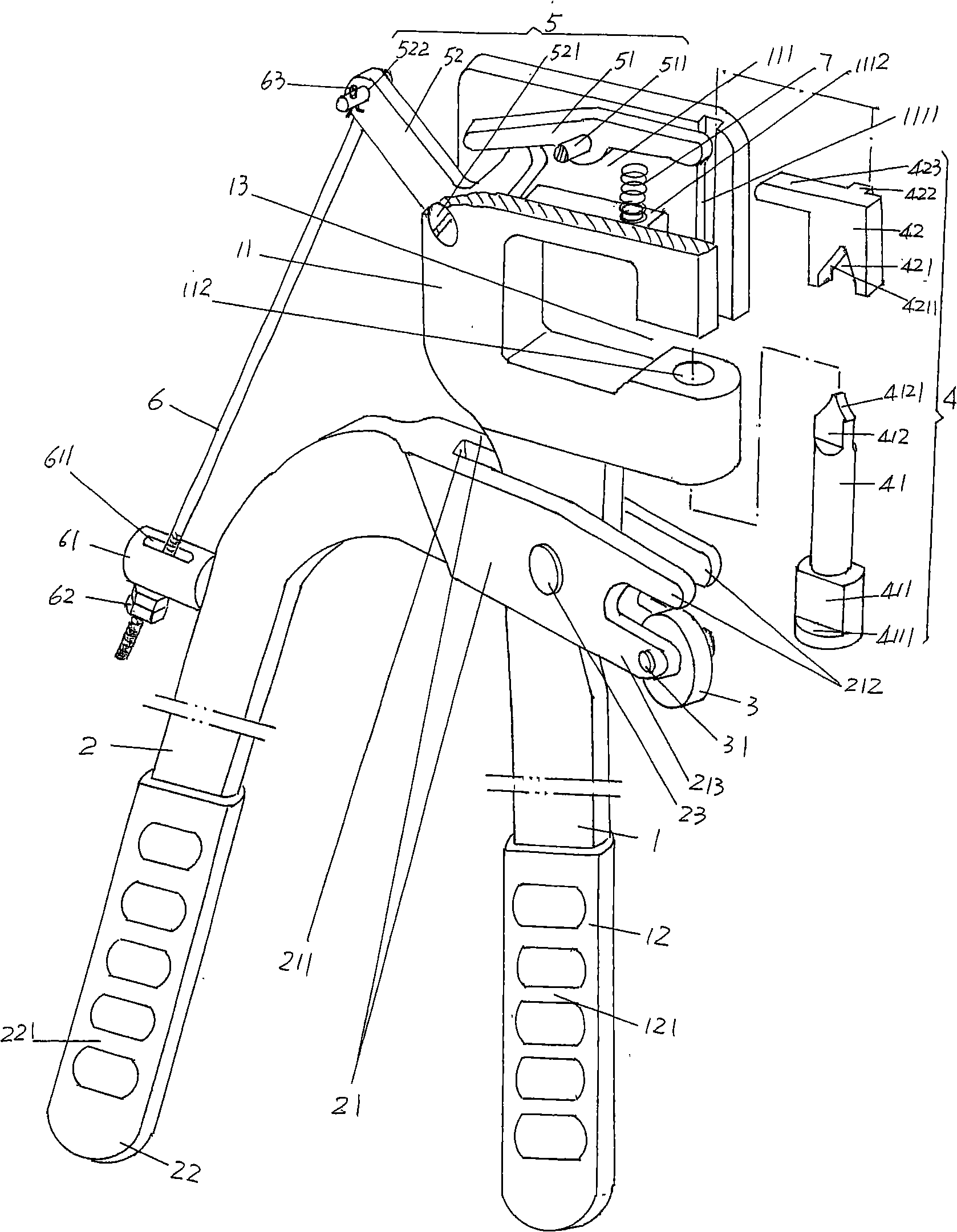

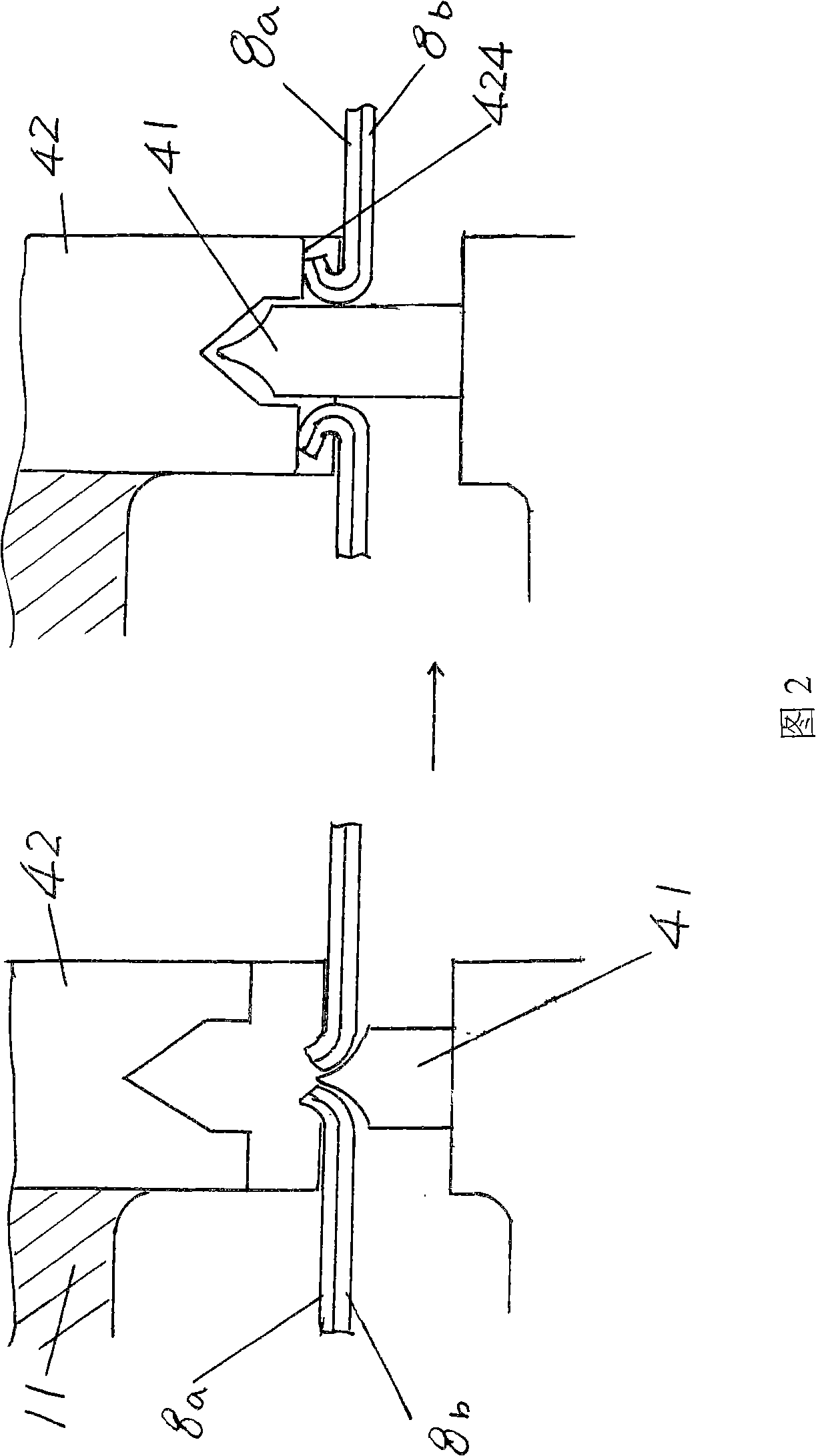

Hand-hold pliers body structure for mechanical coupling

InactiveCN101318316ASave raw and auxiliary materialsReduce construction costsShaping toolsWire toolsHand heldBuilding construction

The invention relates to a hand-held clipper body structure used in mechanical connection, belongs to the technical field of hardware tools and comprises a first handle bar, a second handle bar, a die mechanism, a top part, a female die driving mechanism, a pull rod and an elastic part; wherein, the upper part of the first handle bar forms a clipper head with a clipper head groove; the second handle bar is articulated with the first handle bar; the die mechanism which is formed by matching a female die and a male die is arranged on the clipper head; the top part is positioned at one end of the upper part of the second handle bar in a rotary way; the female die driving mechanism is movably arranged in the clipper head groove; the pull rod is used for driving a bar linkage to move, and one end of the pull rod is connected with the bar linkage while the other end of the pull rod is connected with the second handle bar; the elastic part which is used for ensuring the reset of the female die is positioned in the clipper head groove and is contacted with the female die. The hand-held clipper body structure has the advantages of saving raw and auxiliary materials, embodying the green construction, saving the construction cost and improving the working efficiency as well as ensuring the reliability of the connection.

Owner:JIANGSU JIAYANGHUALIAN BUILDING & DECORATION CO LTD

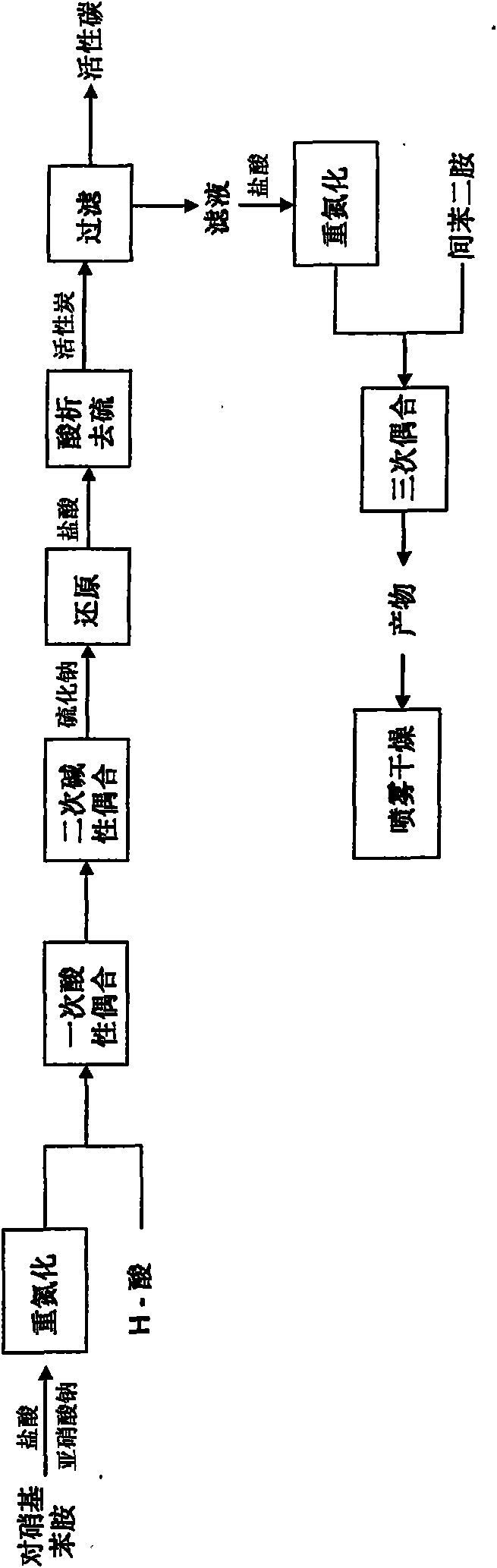

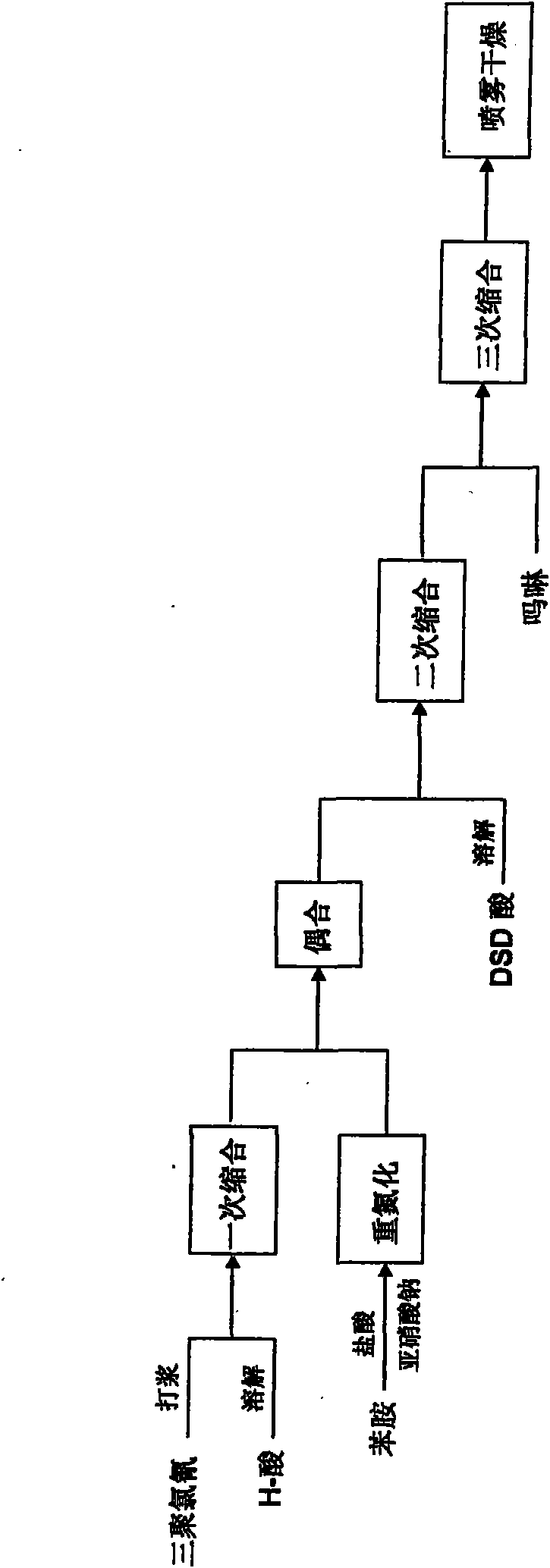

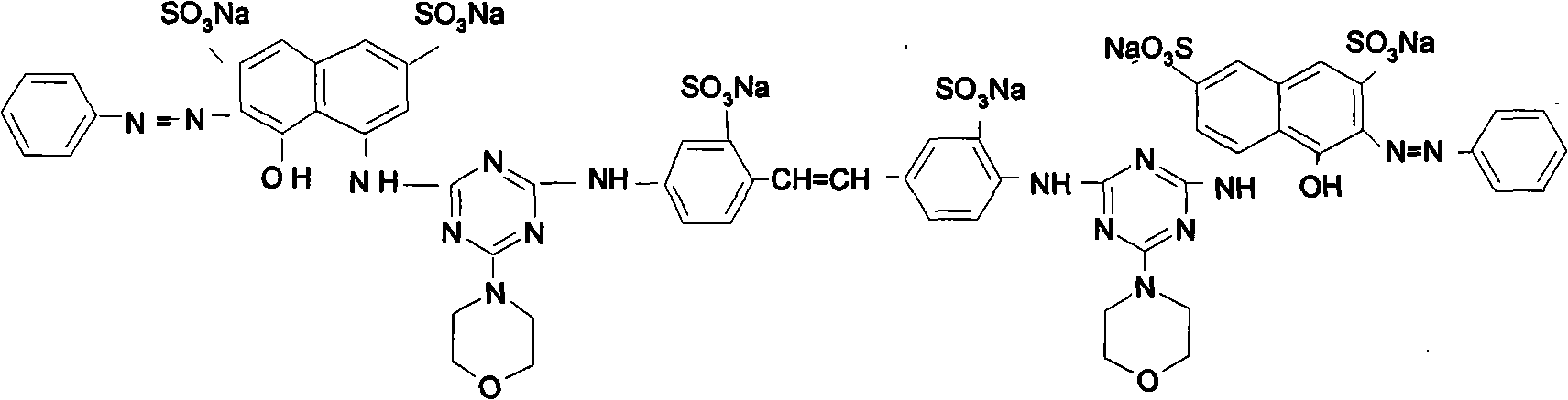

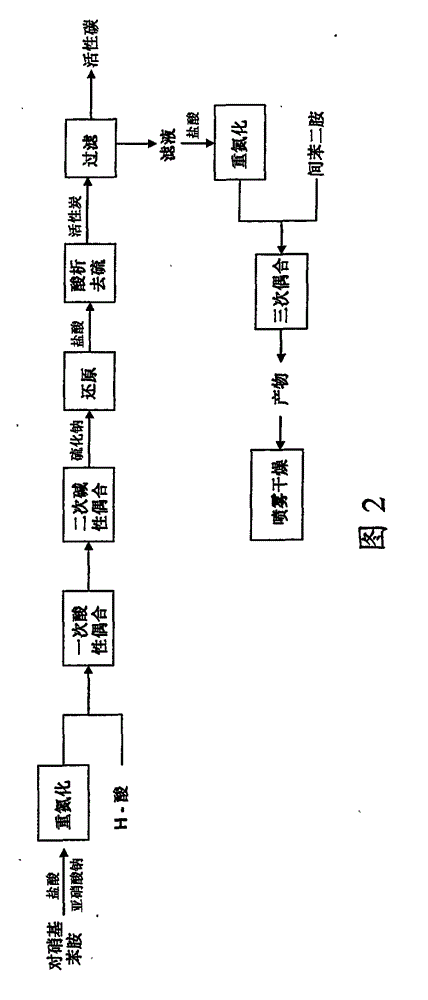

Pollution-free preparation technology of direct rose FR

ActiveCN101580651ASolve the pollution of the environmentReduce consumptionOrganic dyesAnilinePollution

The invention relates to a pollution-free preparation technology of direct rose FR, comprising the following concrete implementation steps: firstly, primary condensation is carried out on pulped cyanuric chloride and H-acid under the pH of 1 to 2 at the temperature t of 0 DEG C to 5 DEG C; then, aniline after diazotization is added into the primary condensation reaction solution for carrying out coupling; a DSD acid solution is added into the coupling product, the pH is adjusted to 8 to 8.5, the temperature t is adjusted to 40 DEG C to 45 DEG C, and secondary condensation is carried out; drewamine is added into the secondary condensation product, the pH are kept at 9 to 9.5 and the temperature t are kept at 95 DEG C to 100 DEG C to carry out ternary condensation; and after the condensation is at end point, direct spray drying is carried out. The technology omits the procedures of salting out, filter pressing and pulping and adopts the direct spray method of primary pulp. Zero discharge of industrial wastewater is achieved. Compared with the traditional technology, the yield is greatly increased. Large numbers of energy sources are saved, and environment pollution is also reduced. The invention effectively increases the yield and the coloring intensity of dye, reduces energy consumption and simplifies the technology; and with steady quality, pollution reduction effect and cheap price, the invention has very strong competitive strength and very extensive market prospect.

Owner:TIANJIN YADONG CHEM & DYESTUFF FACTORY

Plastic uptake double-layer sleeving bag

InactiveCN104770256AAvoid injuryPrevent and reduce the level of natural hazardsPlant protective coveringsEngineeringDiameter control

The invention relates to the technical field of an apple sleeving bag, in particular to a plastic uptake double-layer sleeving bag. The plastic uptake double-layer sleeving bag is characterized by comprising an inner layer and an outer layer, wherein the outer layer sleeving bag and the inner layer sleeving bag have the similar structures and shapes; during the plastic uptake sleeving bag processing manufacturing, the color of the outer layer sleeving bag is designed into a grey color, the color of the inner layer sleeving bag is designed into a red color, and the double-layer sleeving bags are sleeved together one layer by one layer during the boxing transportation. The wall thickness of the outer layer sleeving bag is generally 1.5mm; the transverse diameter is controlled to be between 10cm and 12cm; the diameter along the longitudinal direction of fruit stems is controlled to be 7cm to 8cm; after apples are ripe, pit shapes are realized at the fruit stem parts; during the sleeving bag manufacturing, a fruit stem A and a fruit stem B are particularly designed to be recessed for 4cm towards the circular center, a gap between a convex groove and a concave groove is a vent hole of the plastic uptake double-layer sleeving bag. During the bag taking, in order to prevent the sun burning phenomenon, the outer layer grey sleeving bag is firstly taken down, the inner layer red sleeving bag is remained, and the inner layer red sleeving bag is taken away after the apples adapt to the external environment for 3 to 5 days.

Owner:苟小平

Primary solution-dyed uvioresistant regenerated polyester fiber and preparation method thereof

InactiveCN111041600AReduce demandRecyclable and reusableMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to primary solution-dyed uvioresistant regenerated polyester fiber and a preparation method thereof. Regenerated polyester powder and environment-friendly toner are blended to prepare color master batches, and antioxidant powder, uvioresistant powder and the regenerated polyester powder are blended to prepare uvioresistant master batches; uvioresistant color master batches are prepared from the color master batches and the uvioresistant master batches according to a ratio of 1: 1, the uvioresistant color master batches and regenerated polyester chips are uniformly mixed according to a ratio of 35-45 wt% to 55-65 wt%, the mixture is extruded and molten by a screw extruder to form a melt, the temperature of the melt is controlled to be 285 + / - 2 DEG C, primary solution-dyed uvioresistant regenerated fiber protofilaments are prepared through spinning, cooling by circular air blow, winding and molding; and then the protofilaments are subjected to post-spinning bundling, primary drawing, secondary drawing, filament stacking, curling, drying, cooling and cutting to obtain the primary solution-dyed uvioresistant regenerated polyester staple fibers.

Owner:SHANGHAI DEFULUN CHEM FIBER

Method for extracting grease from schizochytrium

ActiveCN102965182BSimple processLow costMicroorganism based processesFermentationOil and greaseFlocculation

The invention discloses a method for extracting grease from schizochytrium. The method comprises the following steps: (1) adjusting the pH (Potential of Hydrogen) of the fermentation broth of the schizochytrium until reaching an acid stage, and then adding an organic solvent to stir, so as to realize the wall breaking of schizochytrium cells and extraction of microalgae oil; (2) adding a flocculant to the fermentation broth obtained in step (1) to flocculate, and extracting by the organic solvent to obtain crude algae oil; and (3) treating the crude algae oil by degumming, discoloring, and deacidifying / deodorizing, so as to obtain the microalgae oil rich in DHA (Docosahexaenoic Acid). According to the method disclosed by the invention, autolysis wall-breaking technology is adopted, so that the technological process in wall breaking and extraction of the schizochytrium can be simplified, the operation time in wall breaking can be shortened, the investment on equipment is decreased, and the cost is lowered; and the biological flocculant flocculation technology is carried out, therefore, the demulsification technological process is simplified, the time for layering is shortened, the layering effect is improved, the load due to wastewater discharge and water treatment caused by the demulsification process can be avoided, and the cost of water treatment can be lowered.

Owner:ENN SCI & TECH DEV

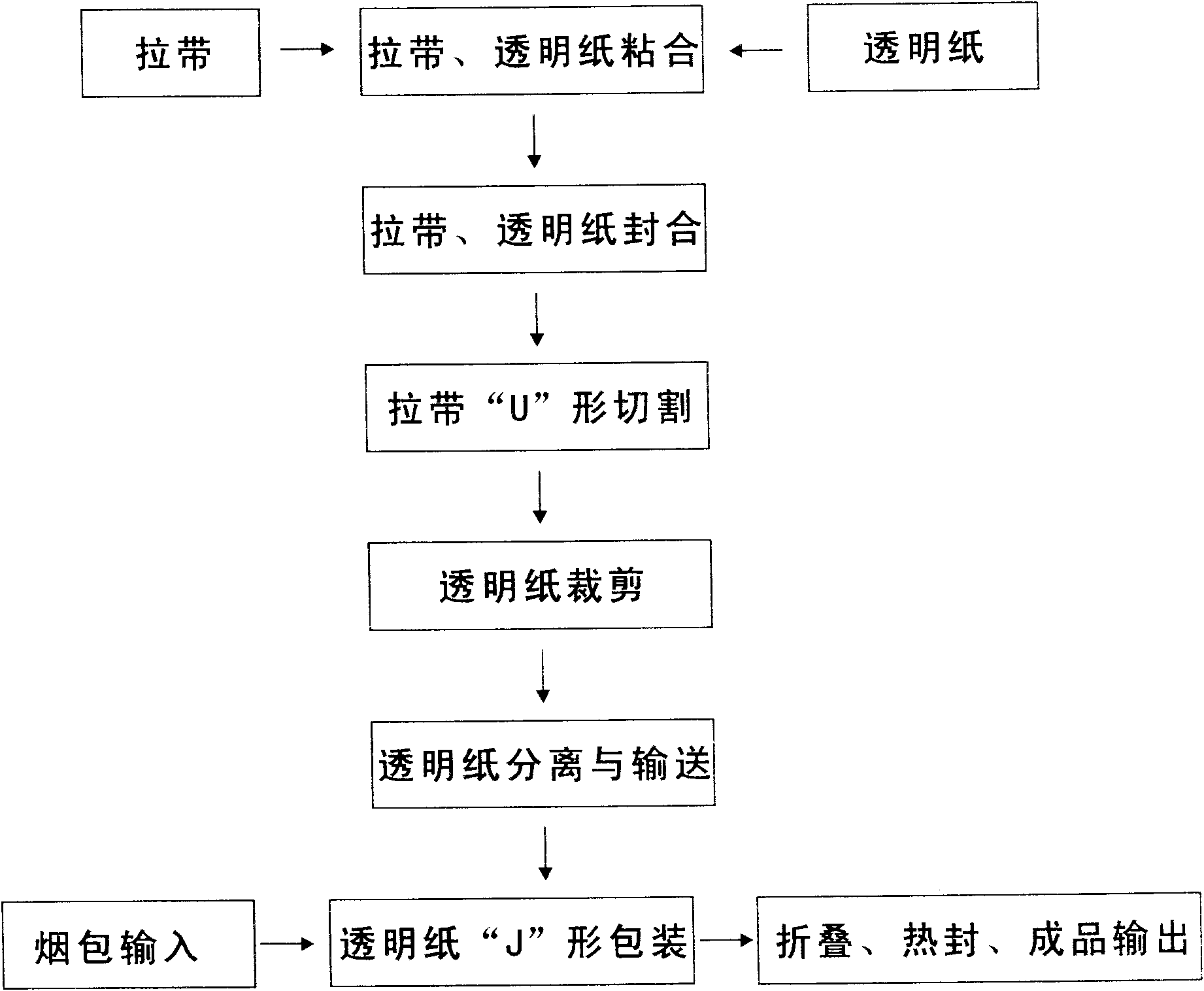

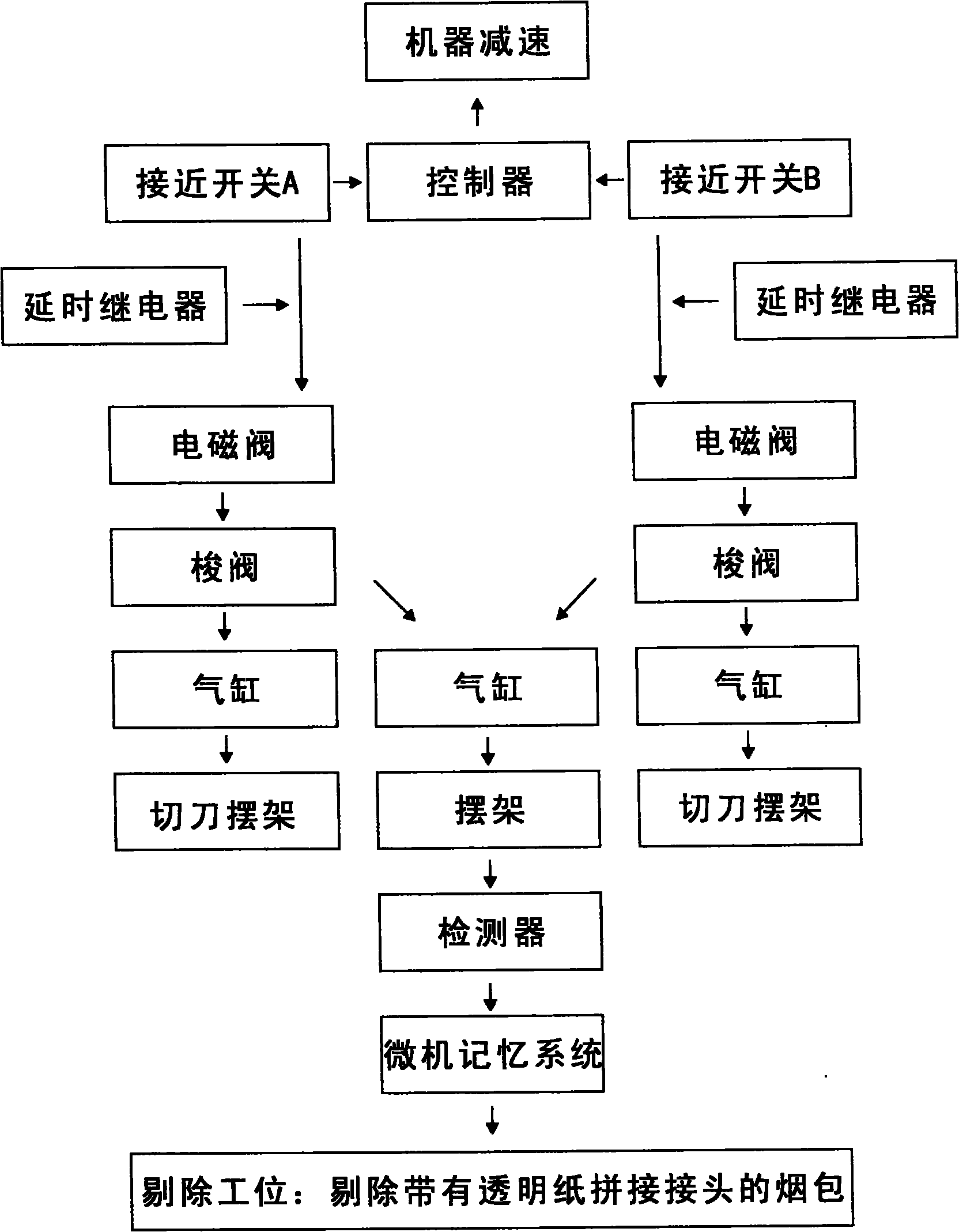

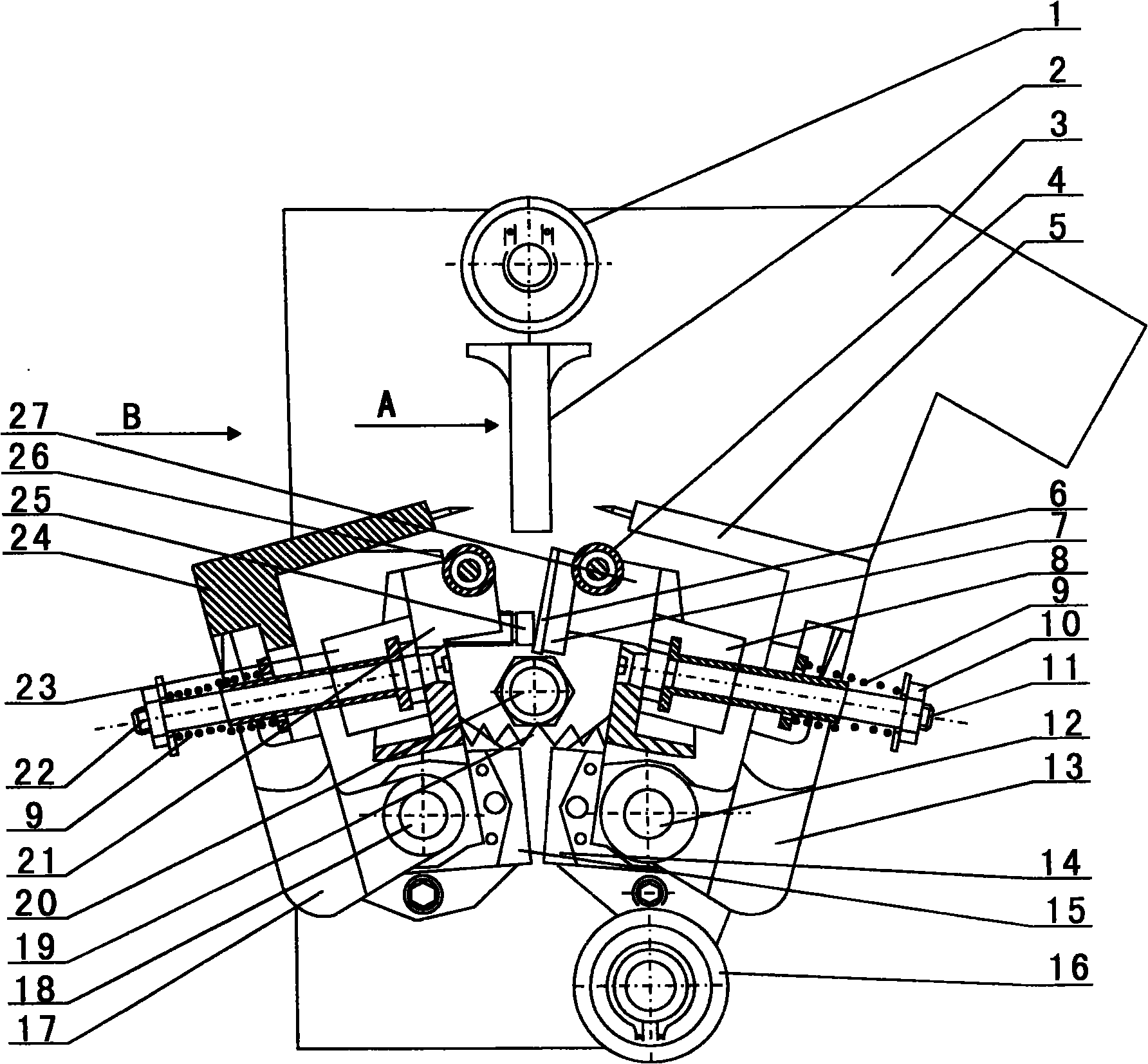

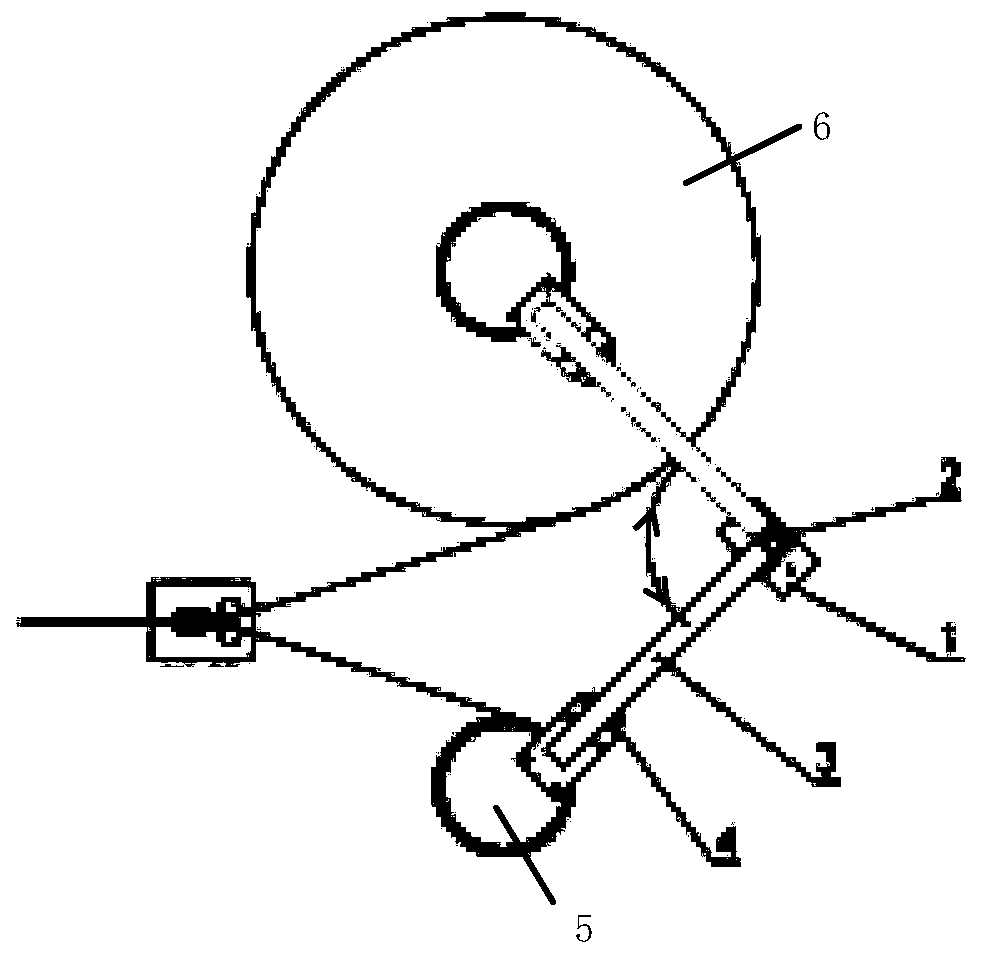

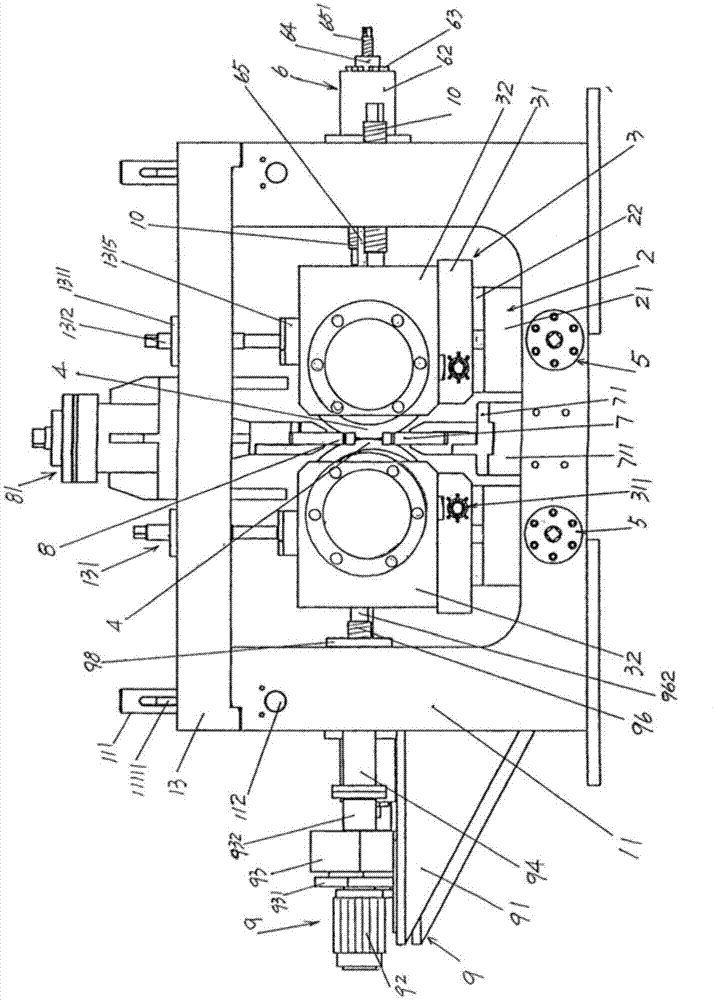

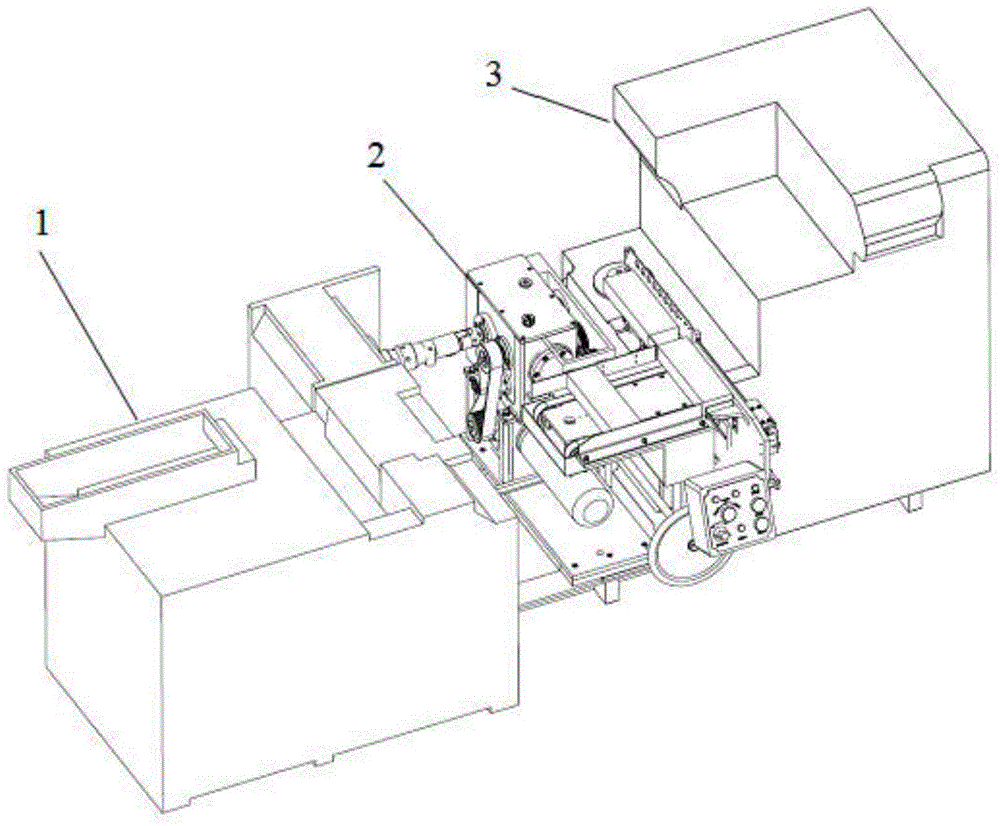

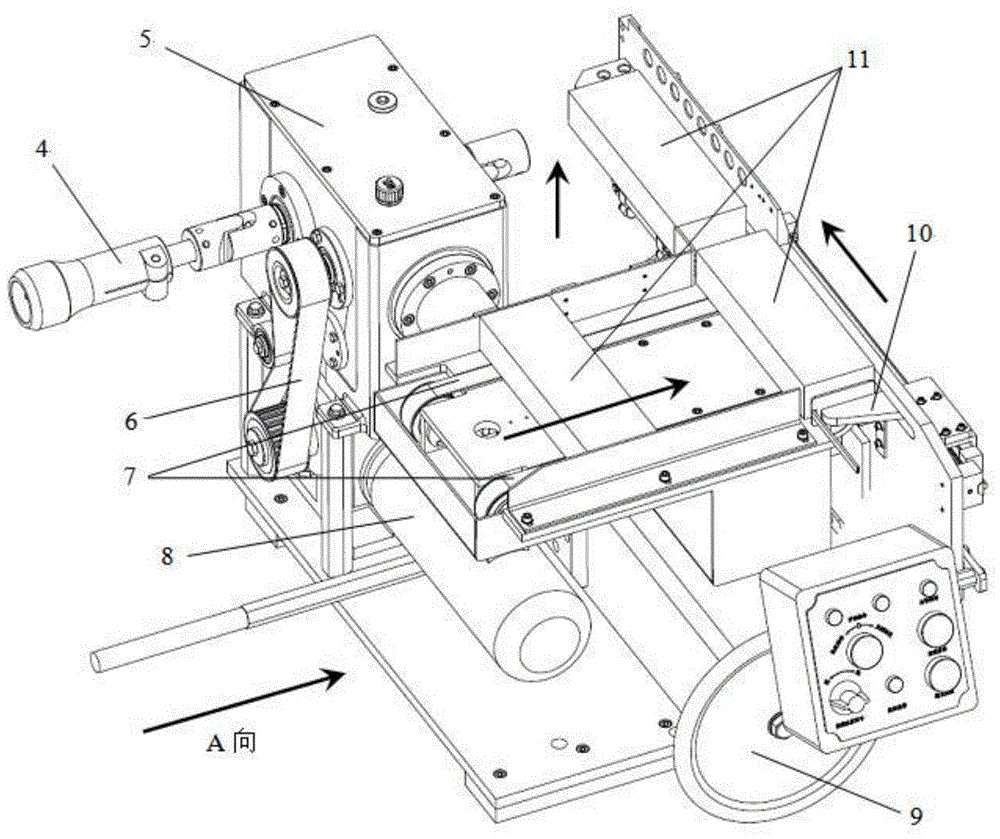

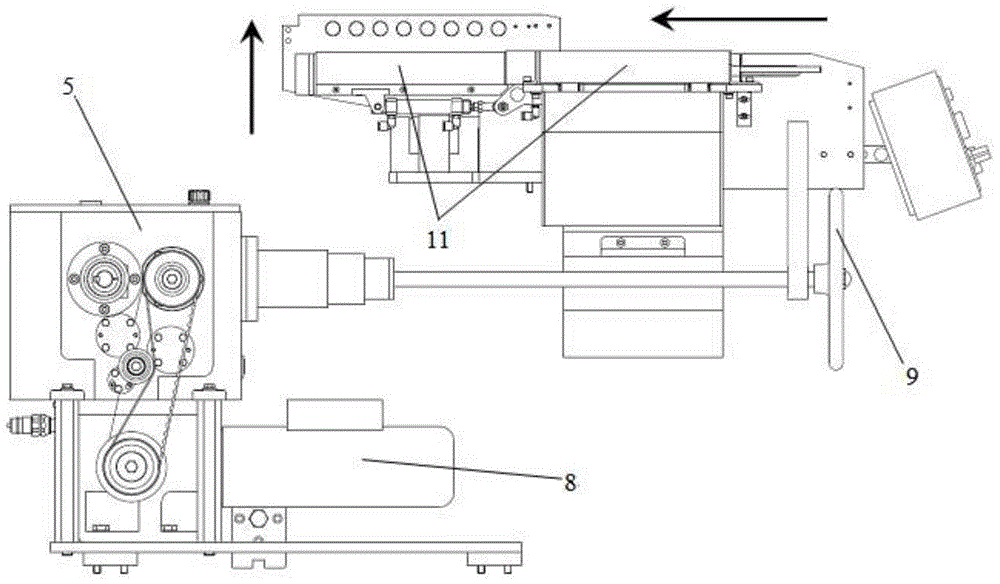

Cigarette case packaging transparent paper automatic jointing device

InactiveCN101927914AReduce downtimeSave raw and auxiliary materialsWrapping material feeding apparatusWebs handlingControl systemPulp and paper industry

The invention discloses a cigarette case packaging transparent paper automatic jointing device, which relates to a jointing device of cigarette transparent paper and which comprises a GDX2 cigarette case packaging machine body and a device control system, wherein one side of a paper feeding roller (16) of the packaging machine body is fixedly connected with the lower part of a bracket (3) of the cigarette case packaging transparent paper automatic jointing device; the upper part of the bracket is provided with a transparent paper guide wheel (1), an upper part bonding swing frame (2) is arranged on the bracket corresponding to the lower part of the transparent paper guide wheel; the lower part of the upper part adhesive swing frame is corresponding to a triggering detector (20) between a one-side swing bonding mechanism and an other-side bonding mechanism at the other side; and two ends of a tension spring (19) are respectively connected with a one-side bonding swing frame (27) of the one-side swing bonding mechanism and an other-side bonding swing frame (21) of the other-side bonding mechanism at the other side. In case of normal operation of original equipment, the device realizes automatic turnover of operating paper scroll and backup paper scroll, thereby reducing shutdown frequency and effectively enhancing unit efficiency.

Owner:CHINA TOBACCO HENAN IND

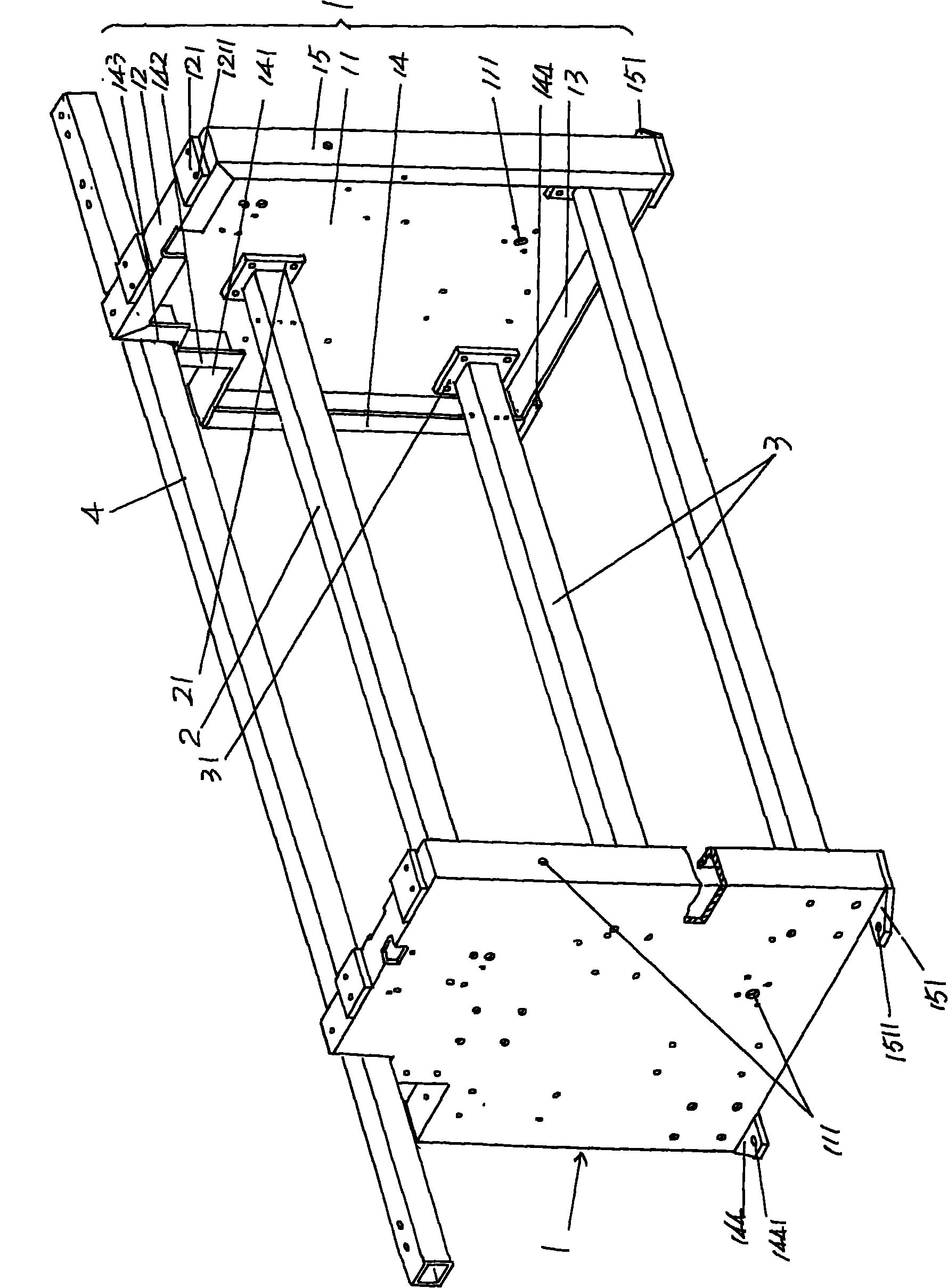

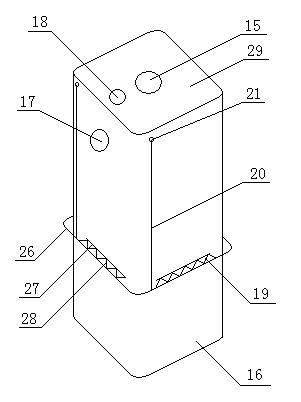

Vertical grouting flue manufacturing equipment

The invention discloses vertical grouting flue manufacturing equipment. The equipment comprises a movable die group, inner cavity dies and a grouting platform, wherein separating plates are arranged in the die group and separate the die group into a plurality of die cavities; an inner cavity die hole and four grouting holes are formed on the top of each die cavity; a separating cavity is formed between every two adjacent die cavities and comprises a separating plate adjusting device for adjusting the sizes of the die cavities; each inner cavity die comprises a vibrating motor, a punching device and a mesh fixing device; the grouting platform comprises a grouting vehicle; and a slurry outlet is formed at the bottom of the grouting vehicle and connected with a grouting hose. The vibrating motor, the punching device and the mesh fixing device are arranged in each inner cavity die, so that flues are simply manufactured, and the operation intensity and labor intensity of workers are greatly reduced; and the flues are formed at one time when produced, a plurality of flues can be produced in each batch, yield is improved, production efficiency is greatly improved, raw and auxiliary materials can be saved, wastes are reduced, and production land is saved.

Owner:JIANGSU HEXIN PETROLEUM MACHINERY

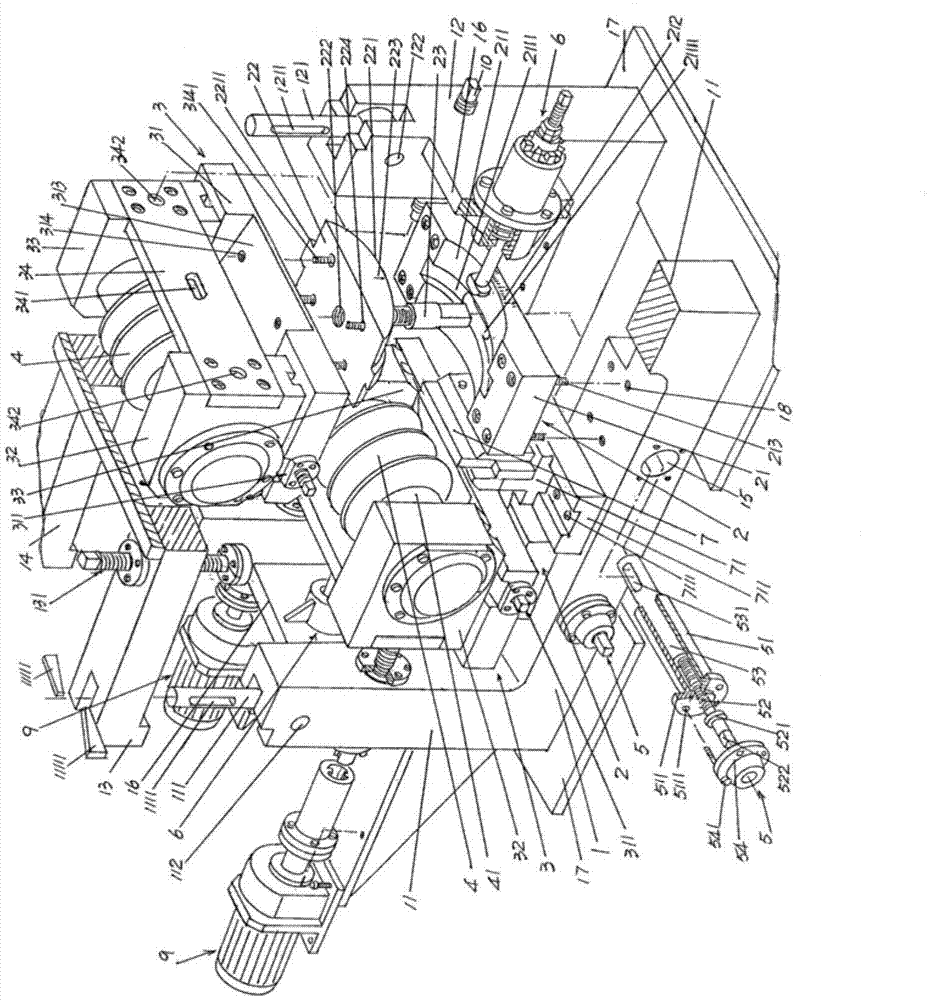

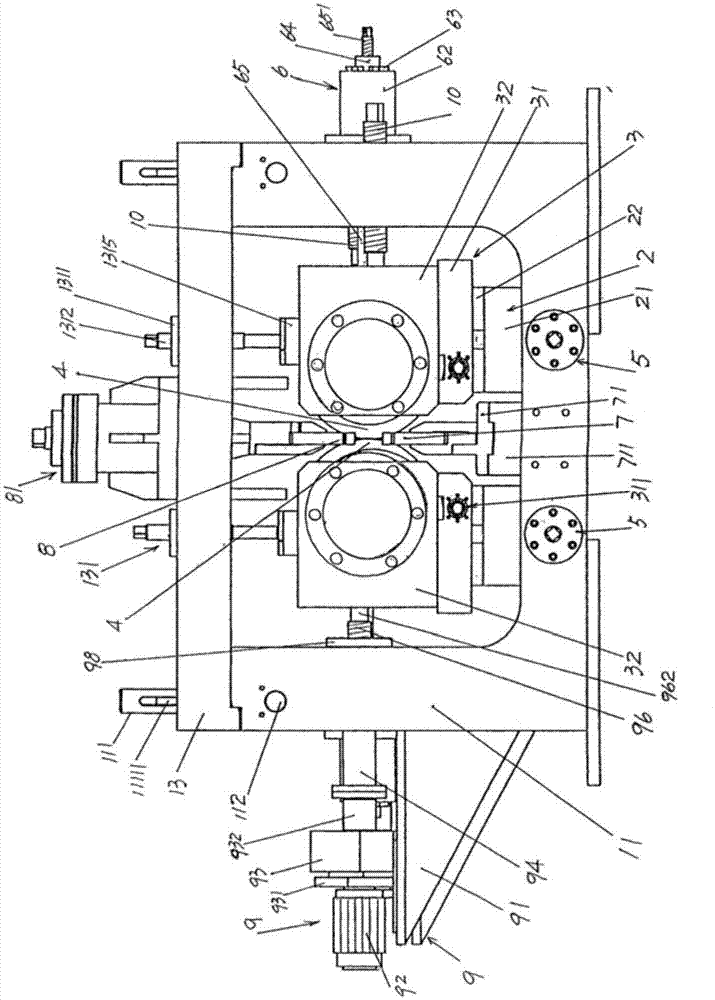

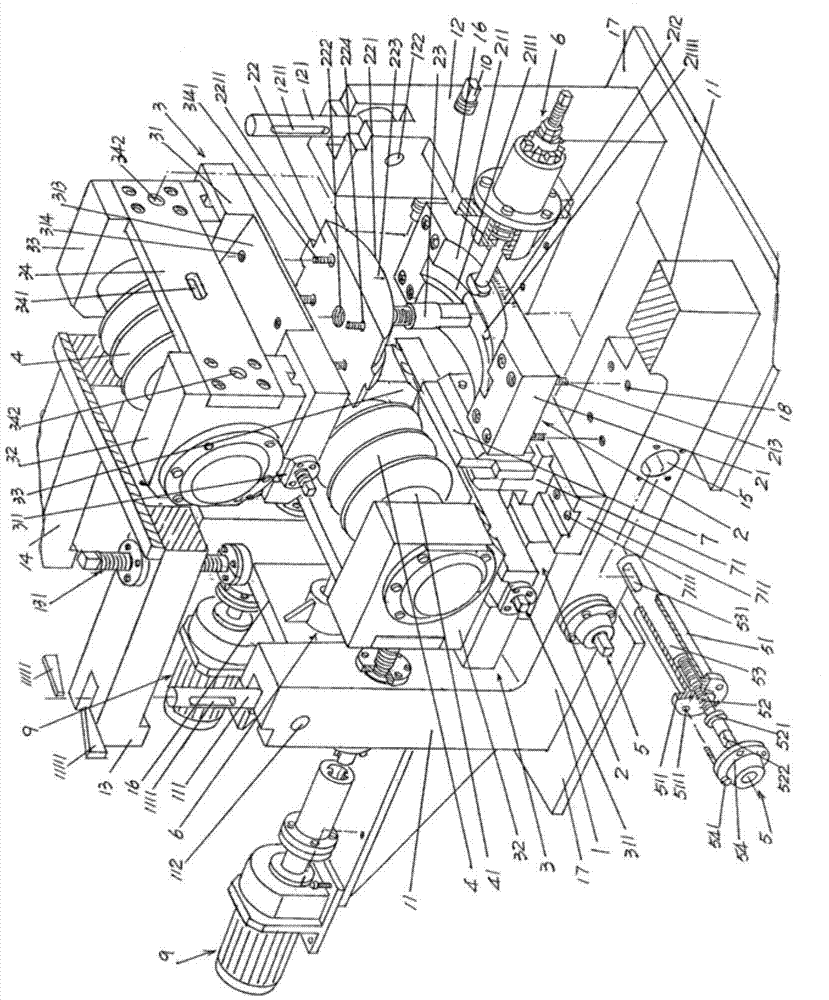

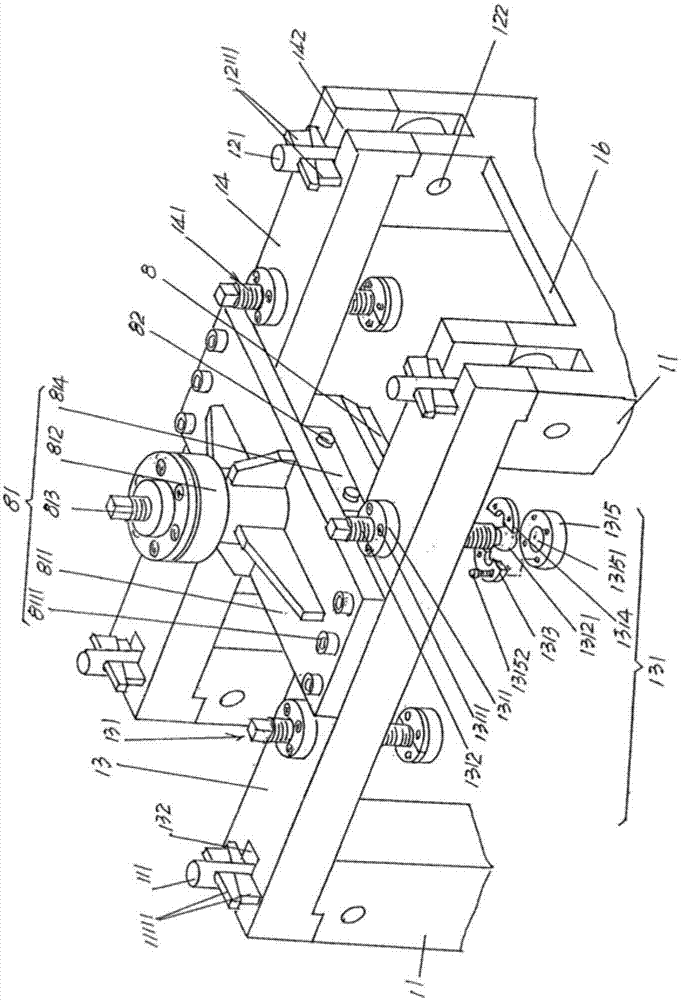

Drum adjustable ball forming device of steel ball rolling machine

ActiveCN103480781AImprove regulation efficiencyNo wear and tearBearing componentsEngineeringSteel ball

The invention relates to a drum adjustable ball forming device of a steel ball rolling machine and belongs to the technical field of steel ball machining machinery. The drum adjustable ball forming device comprises a supporting frame, a pair of drum mechanisms, a pair of drum inclination angle adjusting mechanisms, a pair of ball forming roller pivotal supporting frame adjusting mechanisms, a lower ball baffle and an upper ball baffle. The supporting frame is provided with a front side pillar, a rear side pillar, a front beam, a rear beam and a pair of supporting frame connection seat plates. A pair of top limitation mechanisms of a front bearing seat and a rear bearing seat are arranged on the front beam and the rear beam. Ball forming roller pivotal supporting frames are connected to the drum mechanisms. Ball forming rollers are arranged on the ball forming roller pivotal supporting frames. The drum inclination angle adjusting mechanisms are connected with the drum mechanisms. The ball forming roller pivotal supporting frame adjusting mechanisms are connected with the ball forming roller pivotal supporting frames. The lower ball baffle is arranged on the lower portion of the supporting frame and the upper ball baffle is arranged between the front beam and the rear beam. Each drum mechanism comprises a drum seat, a drum and a poking rod. The middle transitional links are reduced, operation is capable of saving labor, and the drum adjusting efficiency is improved. A drum support positioning plate is removed and the poking rod is not subjected to abrasion. When the drum is adjusted, the blindness can be avoided, adjustment precision is ensured, the drum adjustable ball forming device is convenient to manufacture and assemble and materials are saved.

Owner:山东招金新型耐磨材料有限公司

Cottage method for borneol camphor oil camphor tree

InactiveCN106258741AImprove survival rateImprove land utilizationCultivating equipmentsShootObserved Survival

The invention relates to the technical field of borneol camphor tree cottage, and in particular to a cottage method for a borneol camphor oil camphor tree. The cottage method specifically comprises the following steps: (I), selecting an area, namely, selecting sandy soil at the altitude of 700-800m with the average temperature of 16 DEG C or greater, the average sunshine duration of 1200 hours and the mean annual precipitation of 11600mm, wherein the pH value of the sandy soil is 5.5-7.0, and the sandy soil is deep, fertile and wet; (II), setting the cottage time, namely, performing cottage after spring shoots grow out and before summer shoots grow out, or after the summer shoots grow out and before autumn shoots grow out; (III), selecting a medium, namely, selecting a medium which is good in water retention, air permeability and hydrophobicity, and controlling the temperature to be 25-30 DEG C; and (IV), collecting cutting slips, namely, 1) collecting the cutting slips which are good in vitality and high in cottage survival rate from stock plants of 1-5 years. By adopting the cottage method, the survival rate of cottage seedlings can be increased, the rented cottage land area can be reduced, raw and auxiliary materials can be saved, the land utilization rate can be increased, the seedling breeding cost can be lowered, and practices show that the seedling emergence rate can be about 70%, and the growth amount is effectively increased.

Owner:HUNAN LYUBO AGRI & FORESTRY DEV CO LTD

Large sculpture loop lofting technological method

InactiveCN109050136AGuaranteed original effectStaking data is scientifically accurateOrnamental structuresParallel computingBuilding construction

The invention discloses a large sculpture loop lofting technological method. The method comprises the following two ways including manual loop lofting and computer-assisted manual loop lofting. The manual loop lofting way comprises the following specific steps that firstly, a plaster model draft is designed; secondly, loops are prepared; thirdly, plywood loops which are ten times bigger are obtained; fourthly, the outline loops are assembled; and fifthly, a plaster sculpture is prepared. The computer-assisted manual loop lofting way comprises the steps that firstly, data of the outline loops are acquired; secondly, the outline data are processed; thirdly, the outline loops are assembled; and fourthly, the plaster sculpture is prepared. According to the large sculpture loop lofting technological method, lofting data are scientific and accurate, and the original effect of the sculpture art can be better guaranteed; and the construction period can be shortened, and raw and auxiliary materials can be saved. The large sculpture loop lofting technological method is reasonable in design and has quite good practical application and popularization value.

Owner:SHANXI YUDA GRP

Primary liquid coloring sheath-core regenerated polyester fiber and preparation method thereof

InactiveCN110983485ASave raw and auxiliary materialsLow costConjugated synthetic polymer artificial filamentsPigment addition to spinning solutionPolyesterYarn

The invention relates to a primary liquid coloring sheath-core regenerated polyester fiber and a preparation method thereof. The preparation method comprises the following steps of S1, preparing a primary liquid coloring sheath layer component, namely, mixing pretreated environment-friendly toner and regenerated polyester powder according to a weight ratio of 20-26 to 74-80 to prepare a primary liquid coloring regenerated polyester master batch; and then, carrying out mixing on the primary liquid coloring regenerated polyester master batch and a regenerated polyester slice at a ratio of 4-15 to 85-96 in a vacuum state, and carrying out continuous drying at 120-130 DEG C to prepare the primary liquid coloring sheath layer component; S2, preparation of a sheath-core type regenerated composite fiber raw yarn, namely, extruding and melting the primary liquid coloring sheath layer component and the regenerated polyester slice serving as a core layer component into a melt in respective screwextruders to prepare the sheath-core type regenerated composite fiber raw yarn, and controlling the melt temperature to be 282-290 DEG C, controlling the weight ratio of the primary liquid coloring sheath layer component to the core layer component to be 15-25 to 85-75, and controlling the spinning speed to be 650-1000m / min; and S3, preparing the primary liquid coloring sheath-core regenerated polyester fiber, namely, carrying out drying, cooling and cutting off on tows through a raw yarn first-break-draft process to prepare the primary liquid coloring regenerated polyester fiber with the sheath-core structure.

Owner:SHANGHAI DEFULUN CHEM FIBER

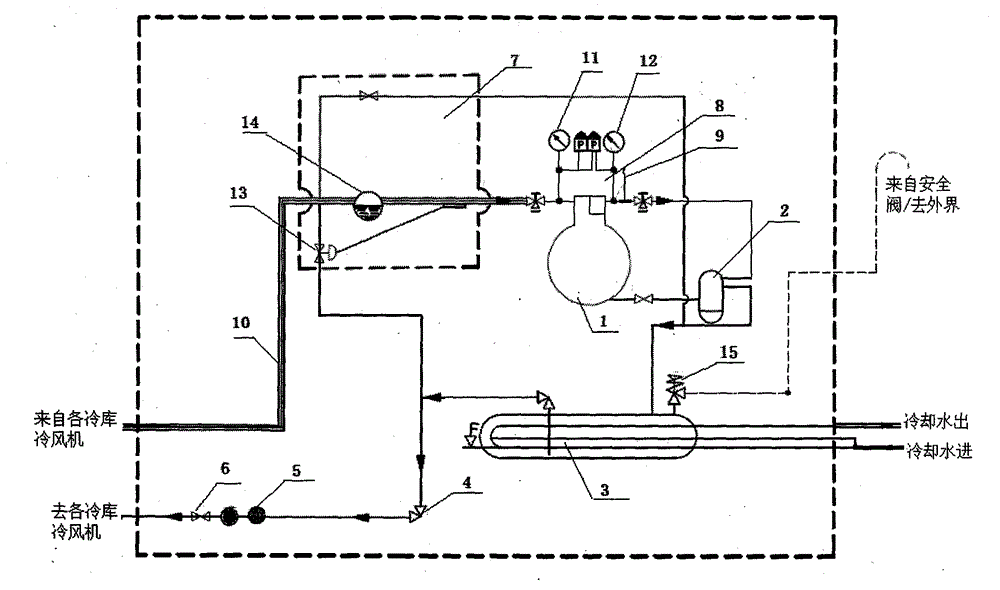

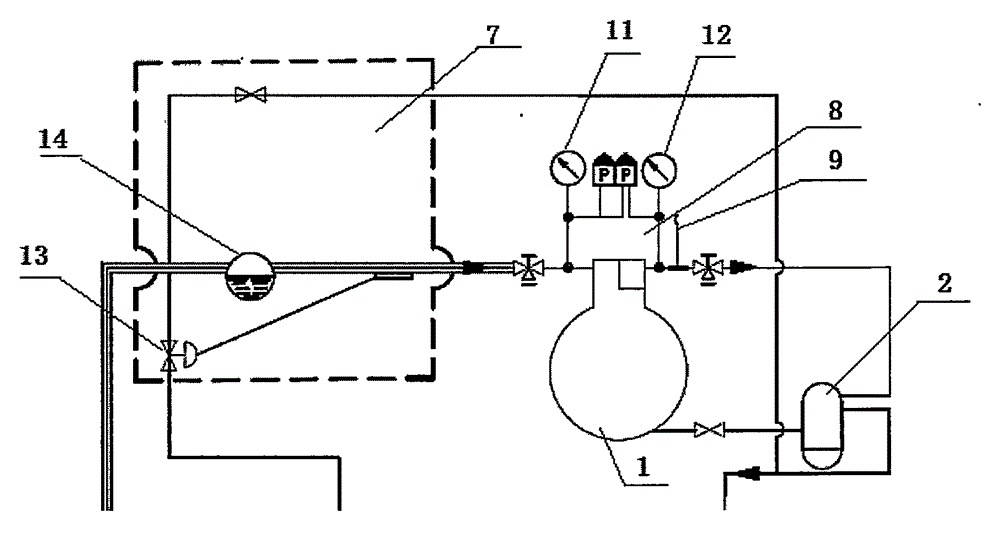

Refrigerating unit of ship refrigeratory

InactiveCN105091381ALightweightSave raw and auxiliary materialsCompressorCompression machines with non-reversible cycleInput/outputMarine engineering

The invention relates to a refrigerating unit for a ship, and belongs to the field of ship equipment. The refrigerating unit of a ship refrigeratory is characterized by comprising a ship scroll compressor, wherein exhaust air from an air cooler of the refrigeratory is communicated to the ship scroll compressor through an air and liquid inlet pipe; a hot spraying device is arranged on the air and liquid inlet pipe, and is connected with the ship scroll compressor; a sucking port of the ship scroll compressor is provided with a pressure control device; a discharge port of the ship scroll compressor is provided with a temperature control device; gas or liquid discharged from the discharge port of the ship scroll compressor passes through an oil separator and a condenser, and is fed to the air cooler of the refrigeratory after being filtered; the pressure control device induces the air sucking pressure of the compressor, and outputs signals to the hot spraying device; the temperature control device induces the exhaust temperature of the compressor, and outputs signals to the hot spraying device; and the hot spraying device adjusts the input / output air quantity of the ship scroll compressor according to the pressure signals, and adjusts the refrigerating capacity of the ship scroll compressor according to the temperature signals.

Owner:丹华海洋工程装备(上海)有限公司

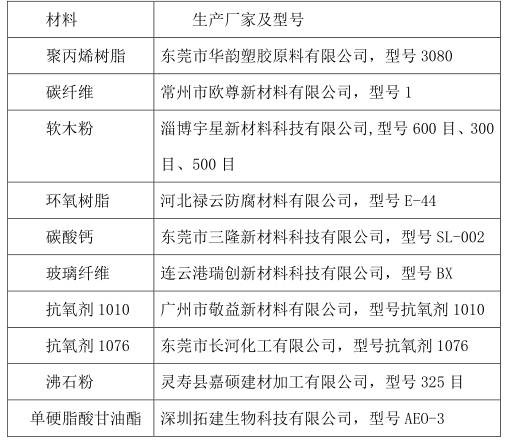

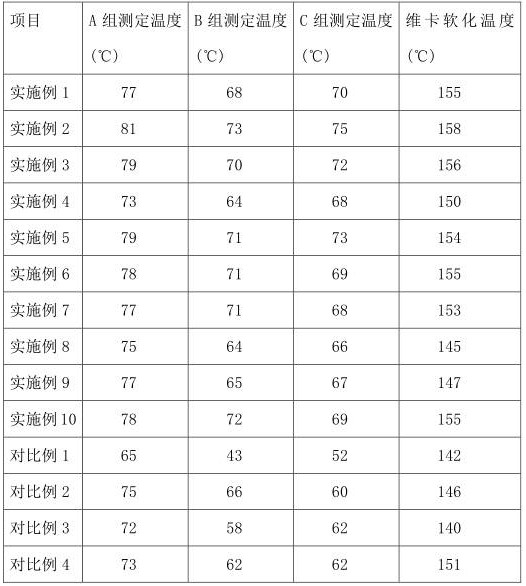

Thermal insulation plastic meal box and preparation method thereof

The invention relates to the technical field of plastic manufacturing processes, and particularly discloses a thermal insulation plastic meal box and a preparation method thereof. The thermal insulation plastic meal box is prepared from the following raw materials in parts by weight: 90-100 parts of polypropylene resin; 5-10 parts of a heat preservation agent; 10-15 parts of a filling agent; 0.2-0.6 part of an antioxidant; 2-3 parts of an adhesive; the preparation method comprises the following steps: S1, mixing and blending the polypropylene resin, the heat preservation agent and the filling agent according to the ratio, and stirring at the rotating speed of 20-30r / min for 10-20min to obtain a primary mixture; s2, adding an antioxidant and an adhesive into the first-stage mixture according to the proportion, and stirring for 30-60 minutes at the rotating speed of 30-50 r / min to obtain a secondary mixture; S3, adding the secondary mixture into a double-screw extruder for melt extrusion, and calendering the extruded material to obtain the thermal insulation polypropylene sheet; and S4, carrying out plastic suction molding on the polypropylene sheet by using a plastic suction machine to obtain the molded thermal insulation plastic meal box. The composition provided by the invention has the advantage of good thermal insulation effect; in addition, the preparation method has the advantage of being simple in preparation mode.

Owner:昆山傲毅包装制品有限公司

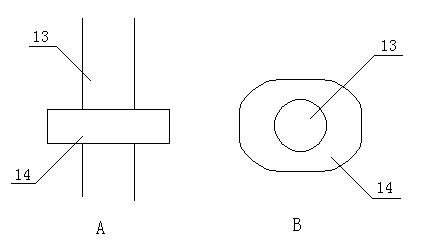

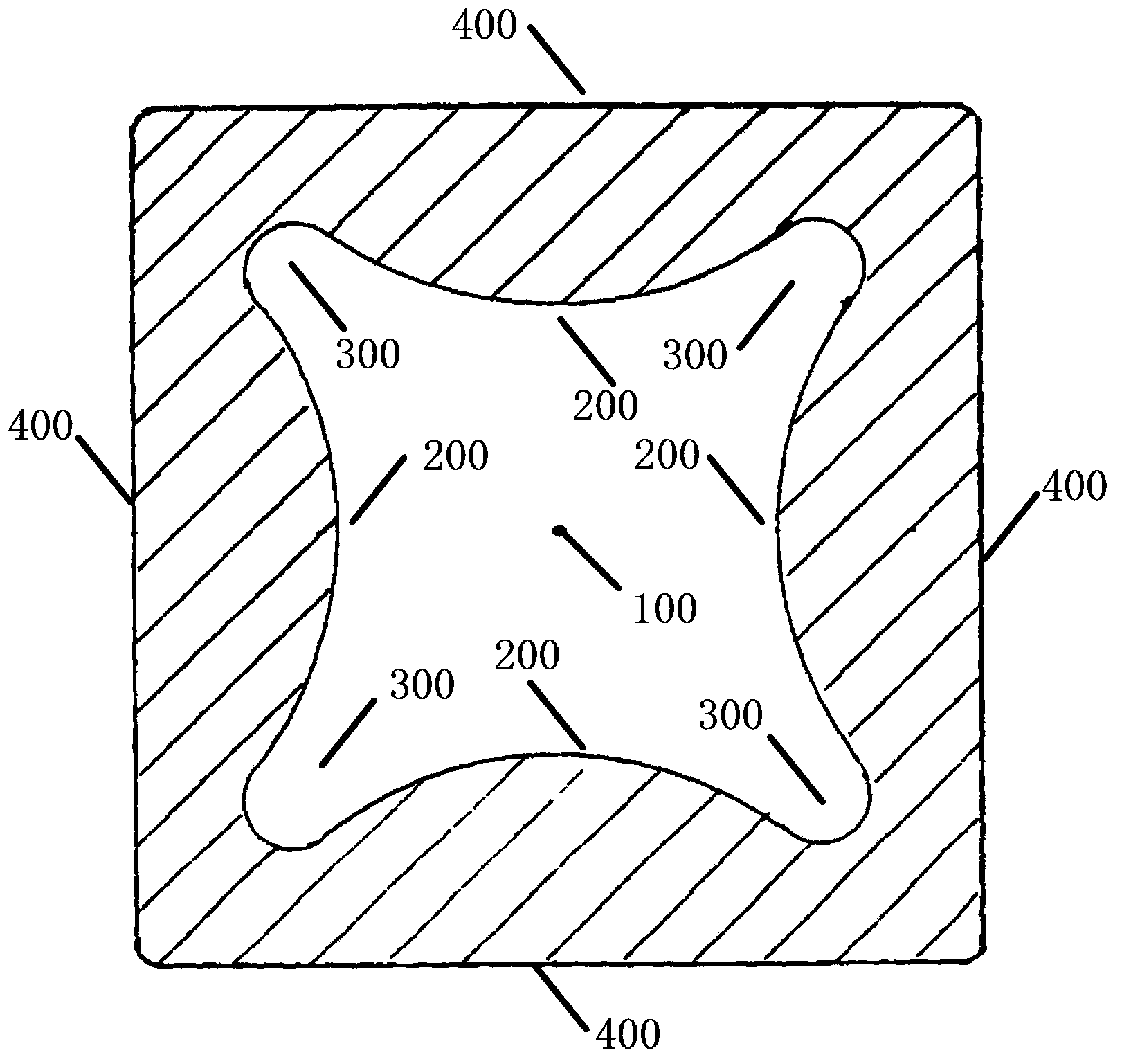

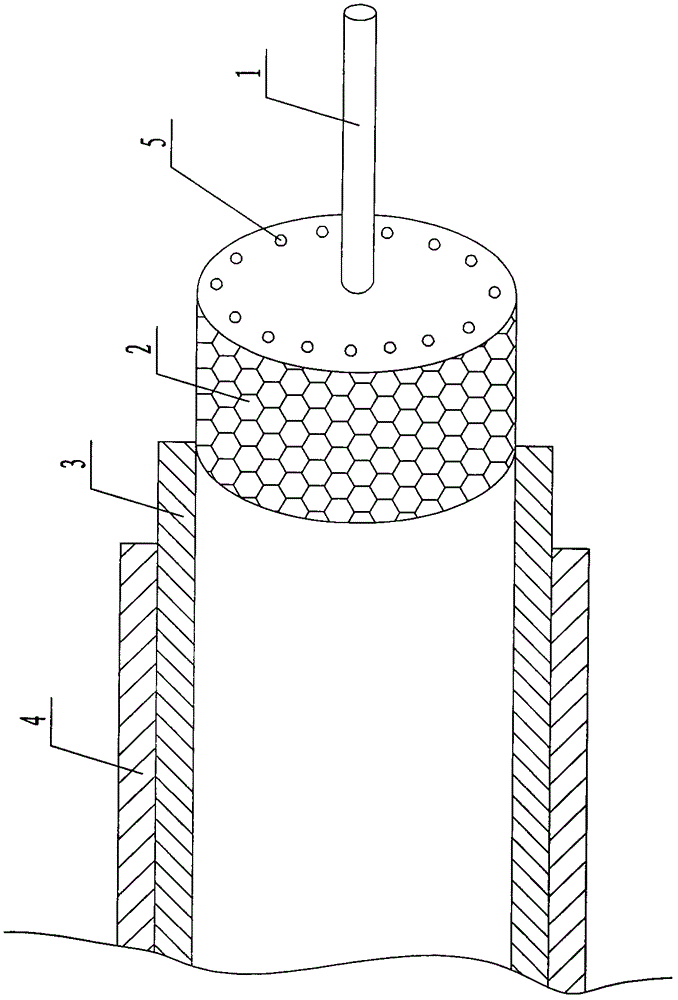

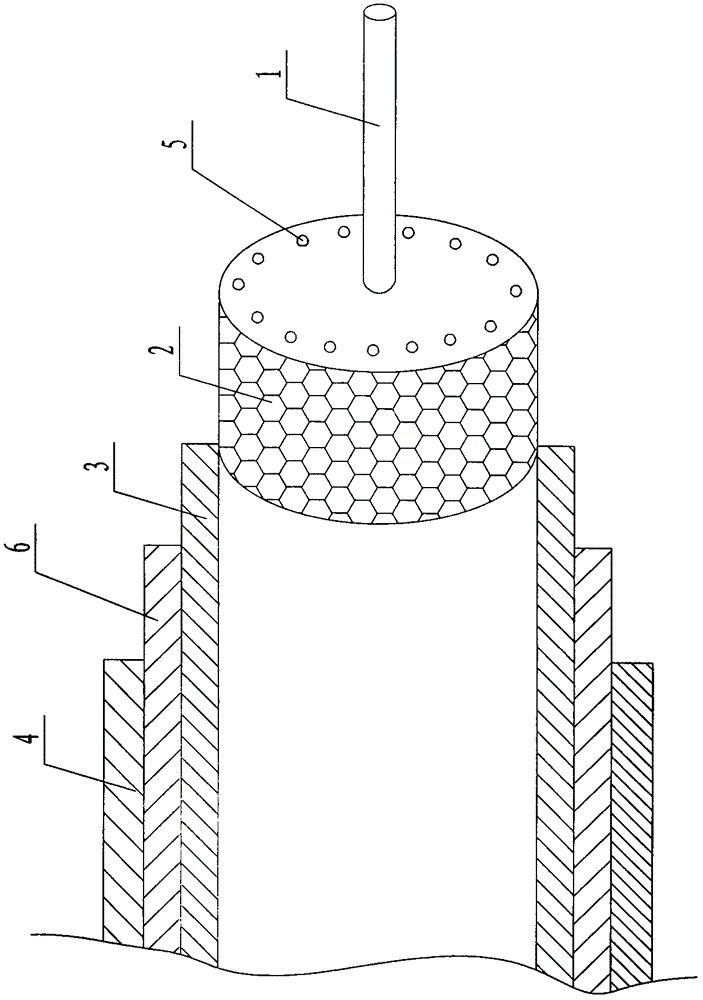

Sizing sleeve of vacuum sizing die applied to billet tube

InactiveCN103568286AReduce wall thicknessSave raw and auxiliary materialsTubular articlesEngineeringSizing

The invention discloses a sizing sleeve of a vacuum sizing die applied to a billet tube. The sizing sleeve of the vacuum sizing die applied to the billet tube is characterized in that the sizing sleeve is a sizing cavity of which four sides form a rectangle; an inner side, which faces the center of the sizing cavity, of the four sides protrudes to form an arc bulge; inner sides of two adjacent bulges are recessed to the opposite direction of the center of the sizing cavity to form an arc groove at four corners; the distance from the arc bulge part of the inner side to the center of the sizing cavity is larger than or equal to the distance from the arc bulge to an outer side. The wall thickness of the billet tube can be reduced under the same ring stiffness condition, and original auxiliary materials are saved. Meanwhile, the surface of a winding pipe is smooth, and the construction quality is reliable.

Owner:NINGBO KANGRUN MACHINERY TECH

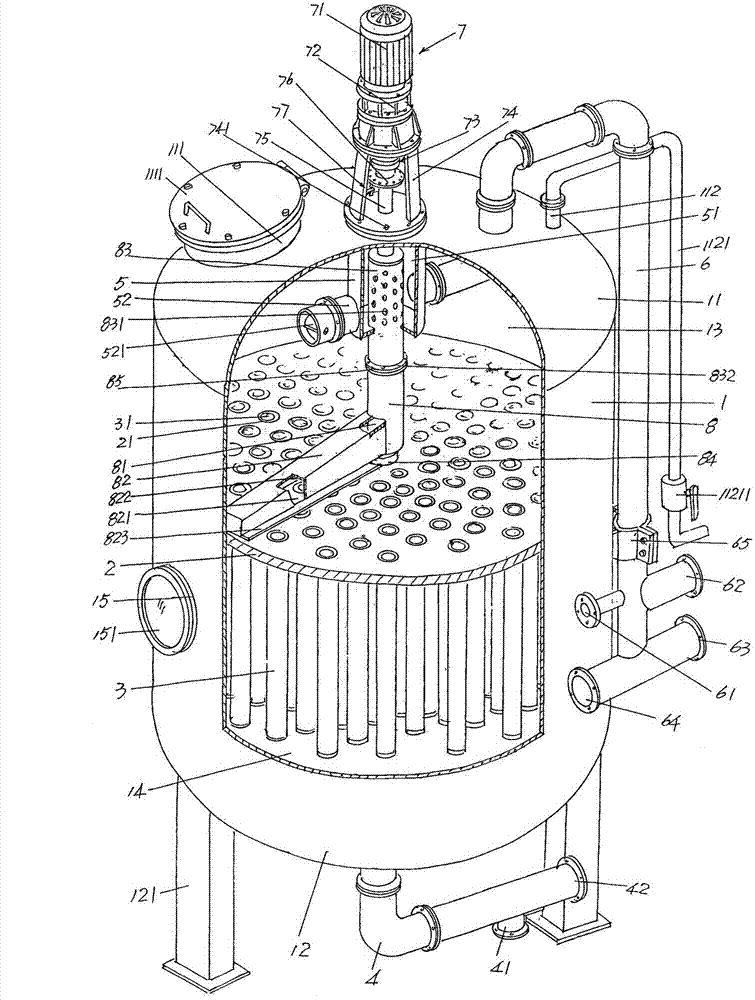

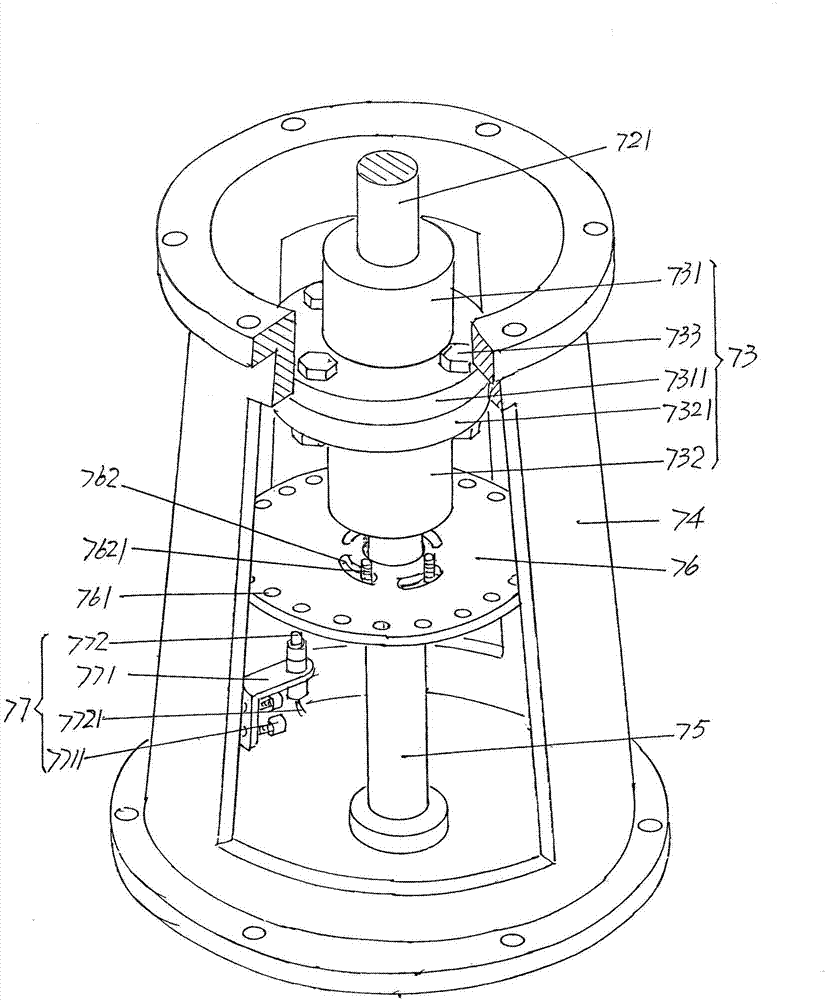

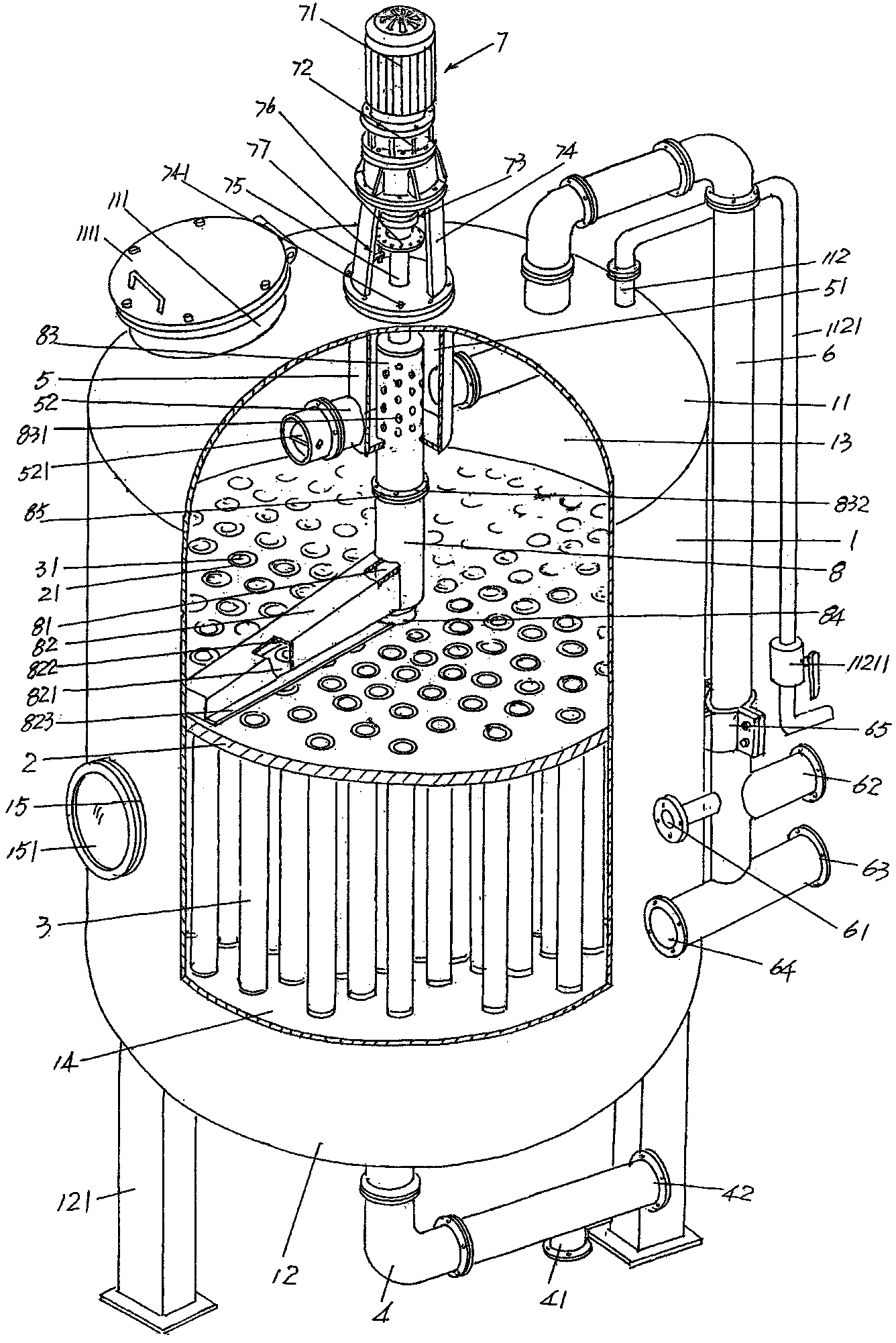

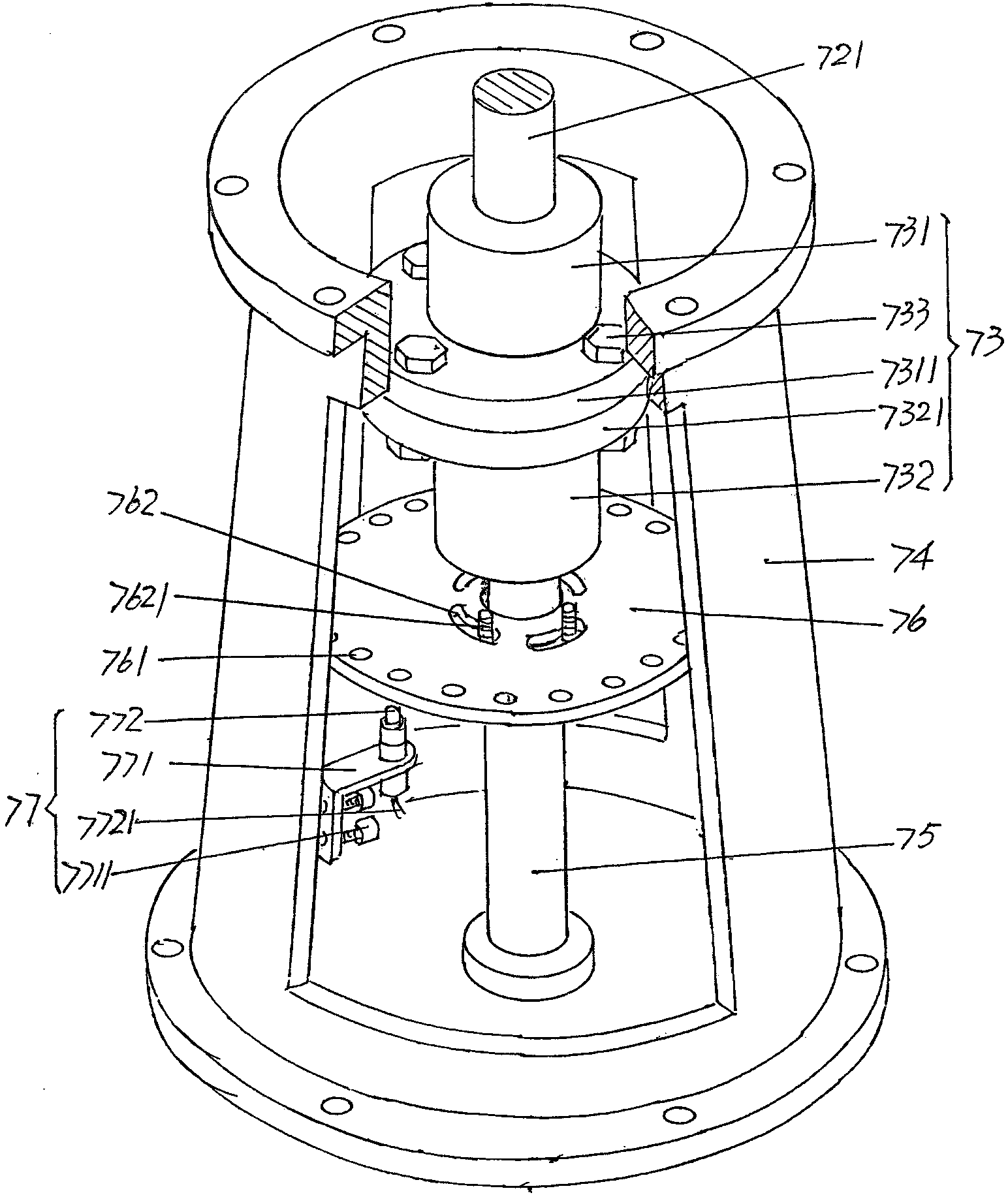

Precision treater for condensed water

ActiveCN103480193AGood backwash effectShort backwash timeStationary filtering element filtersEngineeringMechanical engineering

A precision treater for condensed water belongs to the technical field of water treatment equipment, and comprises a barrel, a barrel cavity partition plate, a group of lower cavity filter elements, a condensed water leading-in pipe, a spacer sleeve, a return water pipe, a back-wash pipe drive mechanism and a back-wash pipe, wherein the barrel is provided with an upper seal head and a lower seal head; the barrel cavity partition plate is arranged in a barrel cavity; a group of lower cavity filter element liquid outlet matching holes are formed in the barrel cavity partition plate; the lower cavity filter elements are arranged in the lower cavity of the barrel; the condensed water leading-in pipe is fixed with the bottom of the lower seal head; the spacer sleeve is fixed on one side of the upper seal head; a spacer sleeve water inlet connector extends from one side of the spacer sleeve; a one-way valve is arranged on the water inlet connector; one end of the return water pipe extends into the cavity of the spacer sleeve, and the other end thereof extends out of the barrel cavity; the back-wash pipe drive mechanism is arranged on the upper seal head; the upper end of the back-wash pipe extends into the cavity of the spacer sleeve, and the lower end thereof is supported in the center of the barrel cavity partition plate. The precision treater has the characteristics that a back-wash liquid spray arm is fixed at the lower end of the back-wash pipe, a spray arm opening is formed in the bottom of the back-wash liquid spray arm, the back-wash effect is ideal, the back-wash time is shortened, energy is saved, the outage time of the equipment is shortened, the structure is simplified, and the material is saved.

Owner:常熟市华能水处理设备有限责任公司

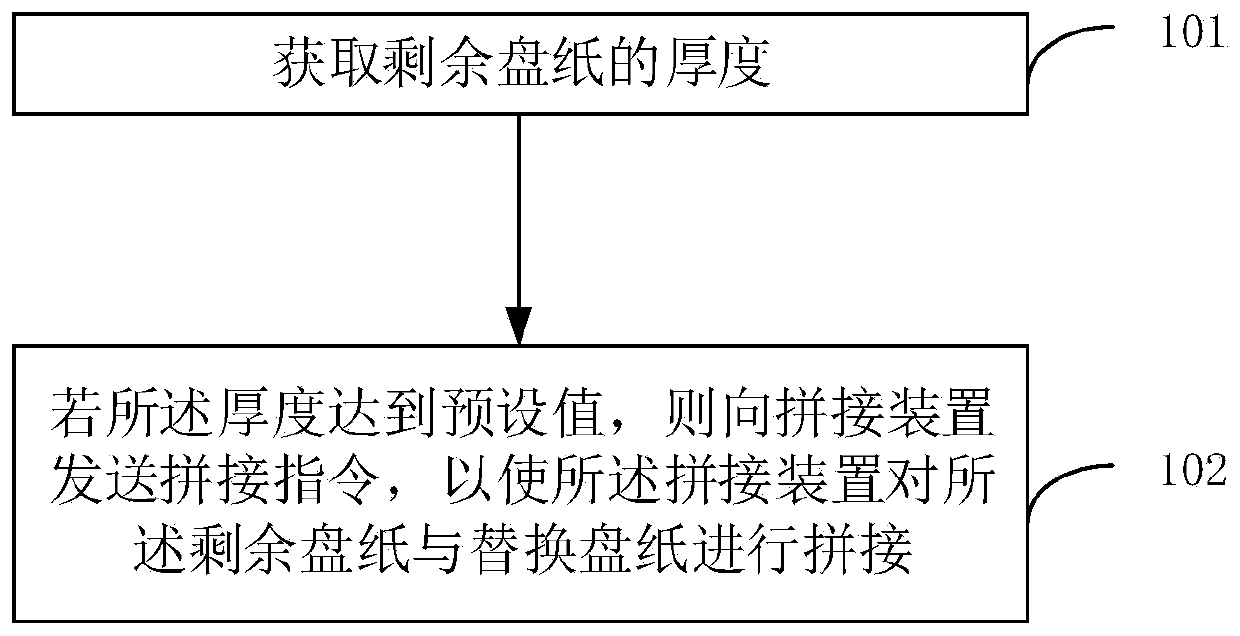

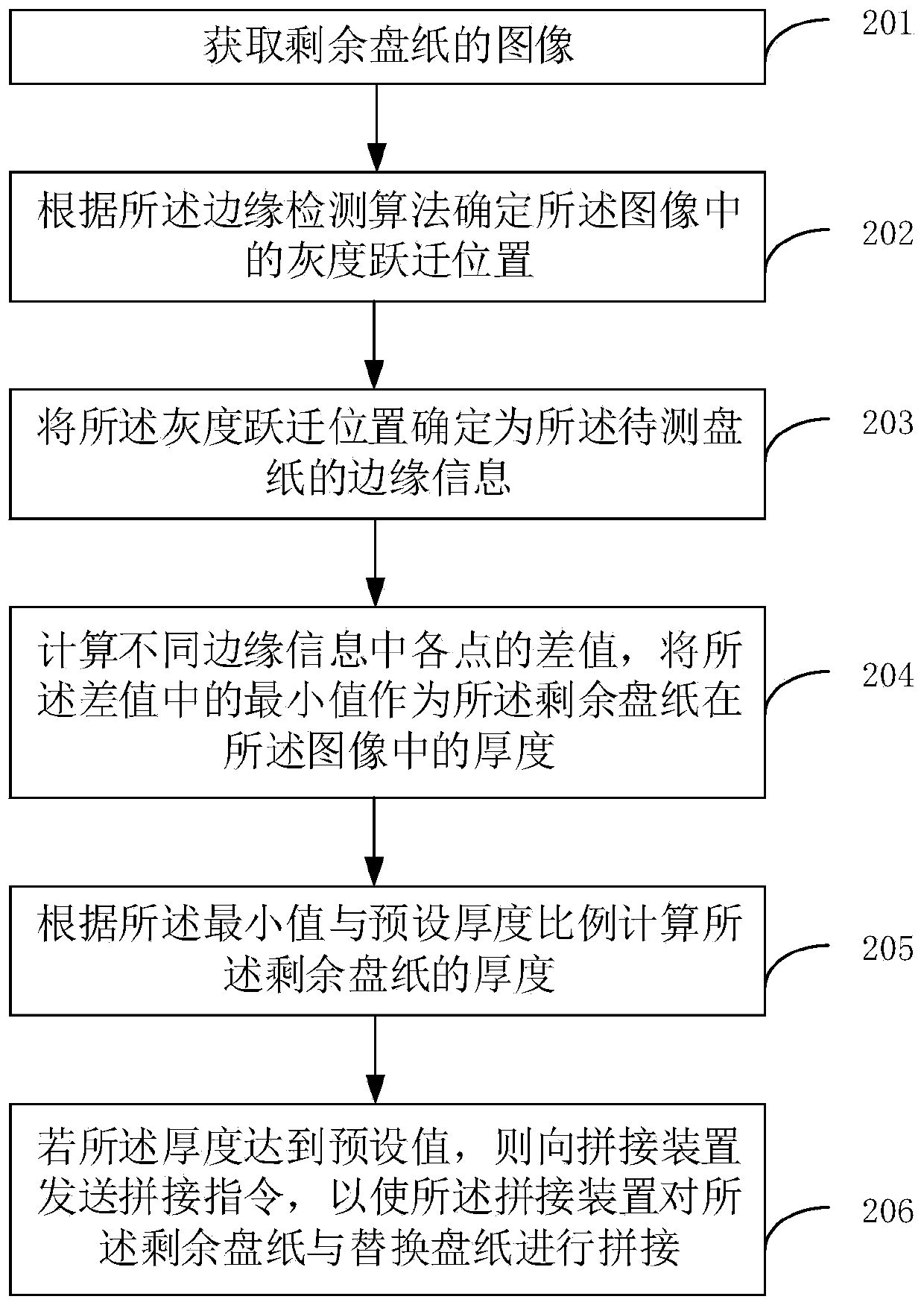

Bobbin splicing method and system

InactiveCN110834981AImprove accuracySave raw and auxiliary materialsWebs handlingBobbinSoftware engineering

The invention relates to a bobbin splicing method and system, and are applied to the technical field of splicing. The bobbin splicing method comprises the steps that the thickness of remaining bobbinis obtained, wherein the thickness reaches a preset value, and the first sending module sends a splicing instruction to a splicing device, so that the splicing device splicing the remaining bobbin andthe replacement bobbin.

Owner:成都忠信机电技术有限公司

Drum adjustable ball forming device of steel ball rolling machine

ActiveCN103480781BImprove regulation efficiencyNo wear and tearBearing componentsEngineeringSteel ball

The invention relates to a drum adjustable ball forming device of a steel ball rolling machine and belongs to the technical field of steel ball machining machinery. The drum adjustable ball forming device comprises a supporting frame, a pair of drum mechanisms, a pair of drum inclination angle adjusting mechanisms, a pair of ball forming roller pivotal supporting frame adjusting mechanisms, a lower ball baffle and an upper ball baffle. The supporting frame is provided with a front side pillar, a rear side pillar, a front beam, a rear beam and a pair of supporting frame connection seat plates. A pair of top limitation mechanisms of a front bearing seat and a rear bearing seat are arranged on the front beam and the rear beam. Ball forming roller pivotal supporting frames are connected to the drum mechanisms. Ball forming rollers are arranged on the ball forming roller pivotal supporting frames. The drum inclination angle adjusting mechanisms are connected with the drum mechanisms. The ball forming roller pivotal supporting frame adjusting mechanisms are connected with the ball forming roller pivotal supporting frames. The lower ball baffle is arranged on the lower portion of the supporting frame and the upper ball baffle is arranged between the front beam and the rear beam. Each drum mechanism comprises a drum seat, a drum and a poking rod. The middle transitional links are reduced, operation is capable of saving labor, and the drum adjusting efficiency is improved. A drum support positioning plate is removed and the poking rod is not subjected to abrasion. When the drum is adjusted, the blindness can be avoided, adjustment precision is ensured, the drum adjustable ball forming device is convenient to manufacture and assemble and materials are saved.

Owner:山东招金新型耐磨材料有限公司

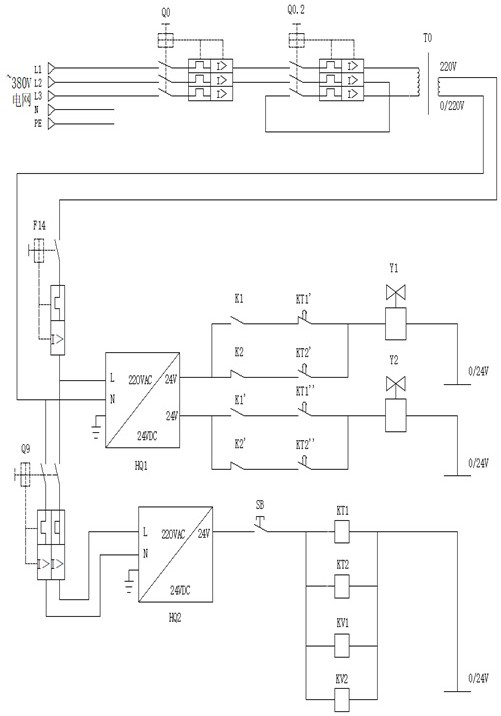

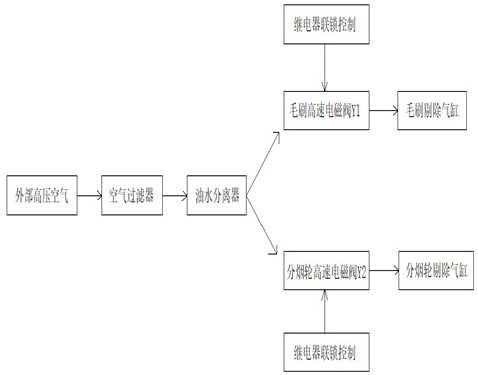

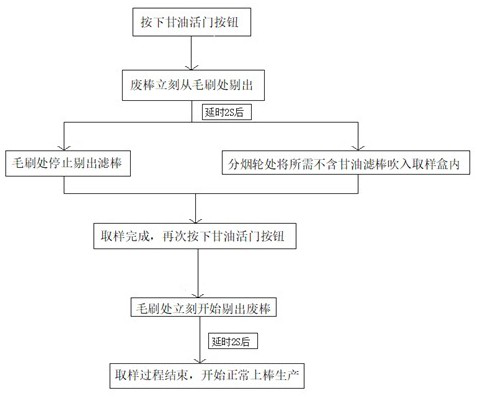

Online filter stick sampling device

ActiveCN112578746ARealize online sampling functionEasy to operateWithdrawing sample devicesSortingAir filterControl engineering

The invention relates to the field of filter stick processing, and provides an online filter stick sampling device which comprises an electric control system, an air filter, an oil-water separator, astatic eliminator and a sample collection box, and through the control of an electrical system, the sampling function of the filter stick can be completed in the normal operation process of the equipment. Through interlocking and timing control of a glycerol valve switch, the filter stick lacking or not lacking glycerol in the sampling process falls into a garbage can, and meanwhile, the requiredfilter stick sample is collected into a special sampling box. The device disclosed by the invention does not need to be repeatedly opened, closed and debugged, so that raw and auxiliary materials andtime are greatly saved, the production efficiency is improved, the device can ensure that unqualified filter rods generated in the sampling process are completely removed through accurate control of an electrical system, and the product quality is improved.

Owner:HUBEI CHINA TOBACCO IND +1

Single-core semi-foaming type monitoring coaxial cable

InactiveCN106328300AControl signal attenuationSave raw and auxiliary materialsInsulated cablesInsulated conductorsUltrasound attenuationElectrical conductor

The invention discloses a single-core semi-foaming type monitoring coaxial cable which is low in material consumption. The cable comprises a single-core inner conductor, a semi-foaming insulator arranged on the outer side of the single-core inner conductor, a shielding layer arranged on the outer side of the semi-foaming insulator and a protection sleeve arranged on the outer side of the shielding layer. The cable is advantageous in that in a production process, semi-foaming processing is performed on the insulator; by use of the semi-foaming technology, raw and auxiliary materials can be greatly reduced; resources are saved; the call of the country for energy conservation and emission reduction is responded to; signal attenuation in the cable can be effectively controlled; signal transmission performance is good; whether the insulator is damaged can be detected; maintenance can be performed timely; and occurrence of accidents can be reduced.

Owner:JIANGSU BAOHUA WIRE CABLE

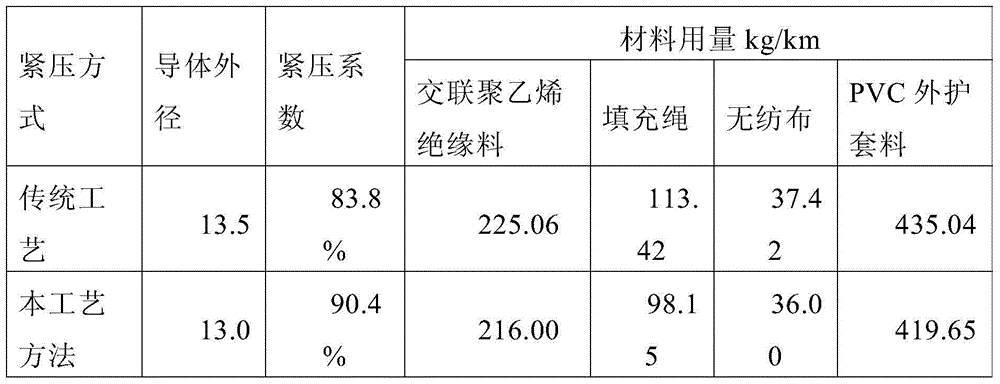

Fabrication method for round pressing of aluminum-alloy conductor

InactiveCN105788755AEasy to manufactureReduce processing costsCable/conductor manufactureState of artInsulation layer

The invention relates to a fabrication method for round pressing of an aluminum-alloy conductor. A round single wire is pressed by a single-way twisting mode. The fabrication method comprises the following steps of 1) winding the round single wire after an intermediate conductor by the single-way twisting mode, and pressing the conductor by a press die; 2) coating the external part of the pressed conductor with an insulation layer; and 3) sleeving the outer layer of the insulation layer with a PVC jacket. Compared with the prior art, the fabrication method has the advantages of low processing cost, material saving, high pressing coefficient and the like, and is convenient to fabricate.

Owner:SHANGHAI XINYI ELECTRICAL CIRCUIT EQUIP

Multifunctional arched combined prestress underground pipe gallery for cisty and preparation process thereof

InactiveCN102995660BImprove high pressure resistanceSave energyArtificial islandsUnderwater structuresEarthquake resistanceHigh pressure

The invention discloses a multifunctional arched combined prestress underground pipe gallery for a city, and a preparation process thereof. The multifunctional arched combined prestress underground pipe gallery consists of a concrete pipe sheet seat and an arched pipe body, wherein the arched pipe body is arranged on the pipe sheet seat and consists of the tube sheet. The pipe sheet seat and the pipe sheet are utilized, the underground pipe gallery is combined according to a structural mode of the arched pipe body to meet a high standard requirement on high pressure resistance, sedimentation resistance, torsion resistance, displacement resistance and earthquake resistance, so that the construction level of the city is improved. According to the topography of a town, a drainage network with a self-flow function is arranged, so that a design target of the functional pipe gallery and the safe pipe gallery is fulfilled.

Owner:张双里

Pollution-free production technology of direct fast black G

ActiveCN101580643BSolve the pollution of the environmentReduce pollutionPolyazo dyesFiltrationP-Nitroaniline

The invention relates to a pollution-free production technology of direct fast black G, comprising the following implementation steps: firstly, primary acid coupling is carried out on nitroaniline after diazotization and H-acid; after the full reaction of the H-acid is detected, sodium carbonate is added and pH is adjusted to 8 to 8.2 to carry out secondary basic coupling; the coupling product isadded into a sodium sulfide solution for reduction, and the temperature gradually raises to t of 38 DEG C to 40 DEG C in the reaction process; after the sodium carbonate is added into the reduction product after acidification to adjust the pH of a medium to 7.5 to 8, the mixture is adsorbed by activated carbon and filtered, and ternary coupling is carried out on the obtained filter liquor after diazotization and lentine; and after the reaction is detected to be end point, the materials are directly delivered to a drying tower for spray drying. In the invention, the reduced reaction solution does not need the processes of salting out, acidification and filtration, activated carbon adsorption is adopted instead. In the process, no waste liquor is generated, and environment pollution caused in the production process of dye is greatly reduced. Simultaneously, wastewater processing is not needed, and the cost is saved. The optimized technology directly transfers the reaction solution afterternary coupling into the drying tower for spray drying; and the yield and the coloring intensity of the dye are effectively increased, energy is saved, the consumption is reduced, and the effect is obvious.

Owner:INNER MONGOLIA XINYA CHEM

CV carton transparent paper packaging machine automatic cigarette filling method and the device used

ActiveCN104085555BReduce labor intensityReduce manufacturing costPackaging cigarettePackaging automatic controlProcess engineeringPaper sheet

The invention relates to an automatic cigarette strip supplement method and device for a CV strip box transparent paper packaging machine. The method mainly comprises the steps that cigarette strips are sequentially placed in from a cigarette strip supplement component, and two synchronous belts on the cigarette strip supplement device drive the cigarette strips on the synchronous belts to be conveyed to a cigarette strip transverse conveying component and a cigarette strip lifting component for transparent paper packaging. The automatic cigarette strip supplement device mainly comprises a transmission gear box, the cigarette strip supplement component, the cigarette strip transverse conveying component, the cigarette strip lifting component and the like. The automatic cigarette strip supplement method and device have the advantages that automatic strip supplement is achieved on the condition that the CV strip box transparent paper packaging machine works independently, the labor intensity of operators is reduced, a large number of raw and auxiliary materials are saved, and the production cost of the cigarette industry is reduced.

Owner:BEIJING TIANSHEN ZHENGXIANG TECH

Precision treater for condensed water

ActiveCN103480193BImprove backwashing effectShort backwash timeStationary filtering element filtersEngineeringMechanical engineering

A precision treater for condensed water belongs to the technical field of water treatment equipment, and comprises a barrel, a barrel cavity partition plate, a group of lower cavity filter elements, a condensed water leading-in pipe, a spacer sleeve, a return water pipe, a back-wash pipe drive mechanism and a back-wash pipe, wherein the barrel is provided with an upper seal head and a lower seal head; the barrel cavity partition plate is arranged in a barrel cavity; a group of lower cavity filter element liquid outlet matching holes are formed in the barrel cavity partition plate; the lower cavity filter elements are arranged in the lower cavity of the barrel; the condensed water leading-in pipe is fixed with the bottom of the lower seal head; the spacer sleeve is fixed on one side of the upper seal head; a spacer sleeve water inlet connector extends from one side of the spacer sleeve; a one-way valve is arranged on the water inlet connector; one end of the return water pipe extends into the cavity of the spacer sleeve, and the other end thereof extends out of the barrel cavity; the back-wash pipe drive mechanism is arranged on the upper seal head; the upper end of the back-wash pipe extends into the cavity of the spacer sleeve, and the lower end thereof is supported in the center of the barrel cavity partition plate. The precision treater has the characteristics that a back-wash liquid spray arm is fixed at the lower end of the back-wash pipe, a spray arm opening is formed in the bottom of the back-wash liquid spray arm, the back-wash effect is ideal, the back-wash time is shortened, energy is saved, the outage time of the equipment is shortened, the structure is simplified, and the material is saved.

Owner:常熟市华能水处理设备有限责任公司

Multi-stranded semi-foamed monitoring coaxial cable

InactiveCN106328302AControl signal attenuationSave raw and auxiliary materialsCoaxial cables/analogue cablesInsulated cablesUltrasound attenuationCoaxial cable

The invention discloses a multi-stranded semi-foamed monitoring coaxial cable with small consumable usage. The multi-stranded semi-foamed monitoring coaxial cable comprises a multi-stranded inner conductor, a semi-foamed insulator arranged at the outer side of the multi-stranded inner conductor, a shielding layer arranged at the outer side of the semi-foamed insulator and a protective sleeve arranged at the outer side of the shielding layer. The multi-stranded semi-foamed monitoring coaxial cable has the advantages that semi-foaming treatment is carried out on the insulator in the production process; the raw and auxiliary materials can be greatly reduced by using a semi-foaming technology; resources are saved; the multi-stranded semi-foamed monitoring coaxial cable responds to the national call of energy conservation and emissions reduction; signal attenuation in the cable can be effectively controlled; the signal transmission performance is good; the flame retarding effect is good; and whether the insulator is damaged or not can be detected and the insulator can be timely repaired, so that an accident is reduced.

Owner:JIANGSU BAOHUA WIRE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com