Sizing sleeve of vacuum sizing die applied to billet tube

A technology of vacuum setting and sizing sleeve, applied in application, household appliances, other household appliances, etc., can solve the problems of uneven surface of winding pipe, affecting construction quality, waste of raw and auxiliary materials, etc., to achieve smooth surface and reliable construction quality. , the effect of reducing the wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

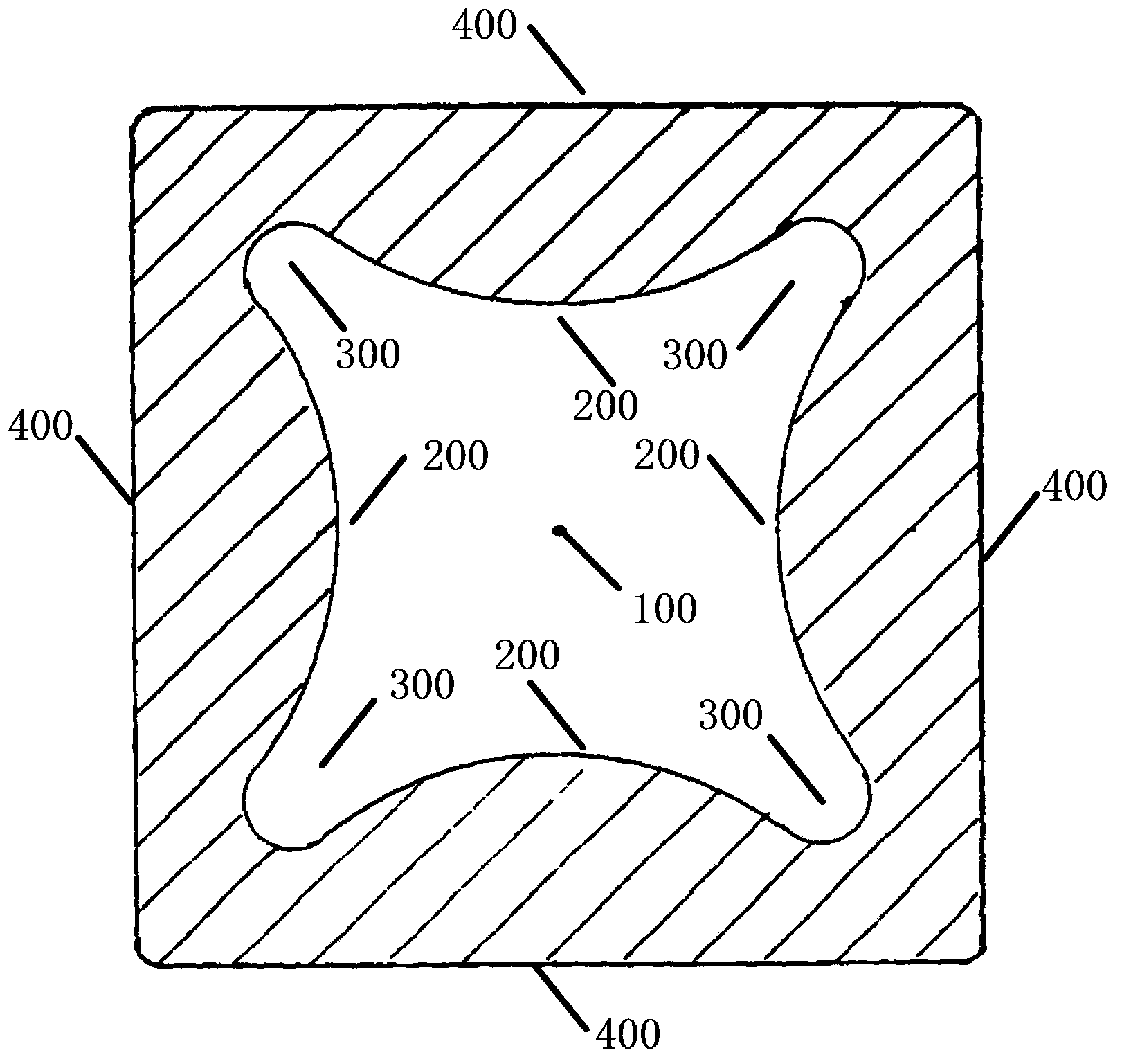

[0013] Such as figure 1 As shown, the sizing sleeve of the vacuum sizing mold applied to the billet tube according to the present invention has a sizing sleeve with four sides forming a rectangular shape, and the inner sides of the four sides facing the center 100 of the sizing cavity protrude to form an arc surface Protrusions 200, the inner sides of two adjacent protrusions are recessed toward the opposite direction of the shaping cavity center 100 at four corners to form an arc groove 300, and the arc surface protrusions 200 of the inner sides reach the shaping cavity center 100 The distance is greater than or equal to the distance from the arcuate protrusion 200 to the outer edge 400 . In addition, the connection between the arcuate protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com