Backflow water washing equipment

A technology of flowing water and equipment, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of environmental pollution, large water consumption, etc., and achieve the effect of protecting the environment, enhancing strength and cleanliness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

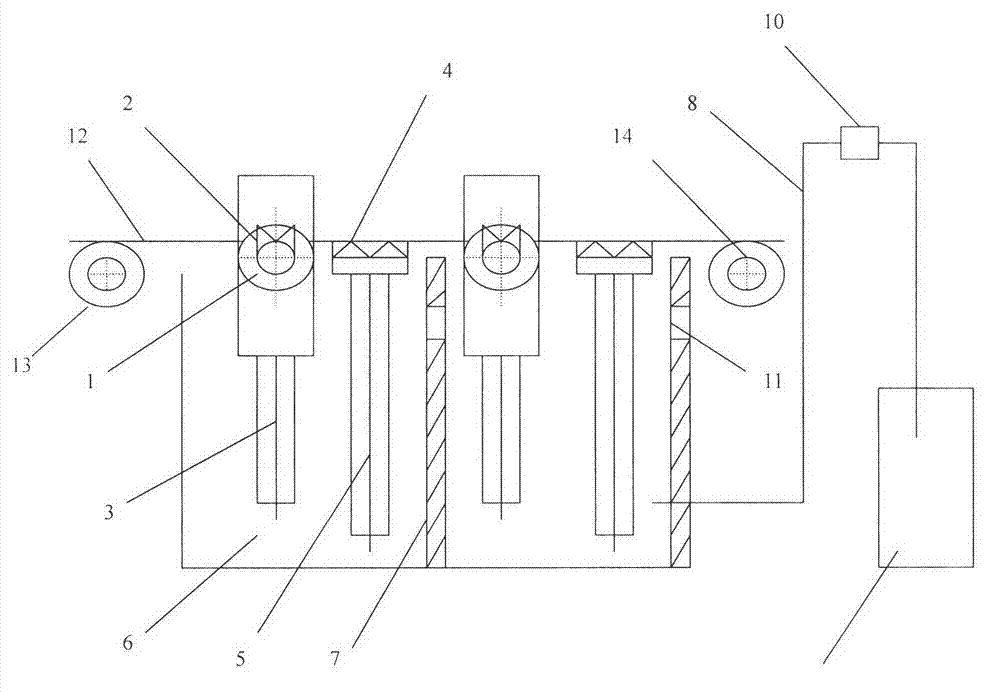

[0005] As shown in the figure, a countercurrent water flushing equipment includes a water spray system, an air suction system, a series tank body and a circulation system. The water spray system is mainly composed of a water spray plate 1 and a lift pump 3. The water spray plate 1 is equipped with Water spray port 2 with adjustable water spray angle; the air suction system is mainly composed of air suction plate 4 and air channel 5, and air suction holes are arranged on the air suction plate 4; the series tank body is mainly composed of several partition plates 7 The flushing tank 6 and the divider 7 are designed with water outlets 11 of different heights; the circulation system mainly consists of a circulation pipe 8, a liquid pump 10 and a plating tank 9, and the suction system and the water spray system are respectively fixed on the edge of the flushing tank 6 .

[0006] When working, the high-carbon steel wire 12 is washed by the guide wheel 14 and then reaches the guide w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com