Bobbin splicing method and system

A technology of coiling paper and splicing device, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of increasing production cost, waste of raw and auxiliary materials, etc., so as to improve accuracy, reduce production cost and save money. The effect of raw and auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

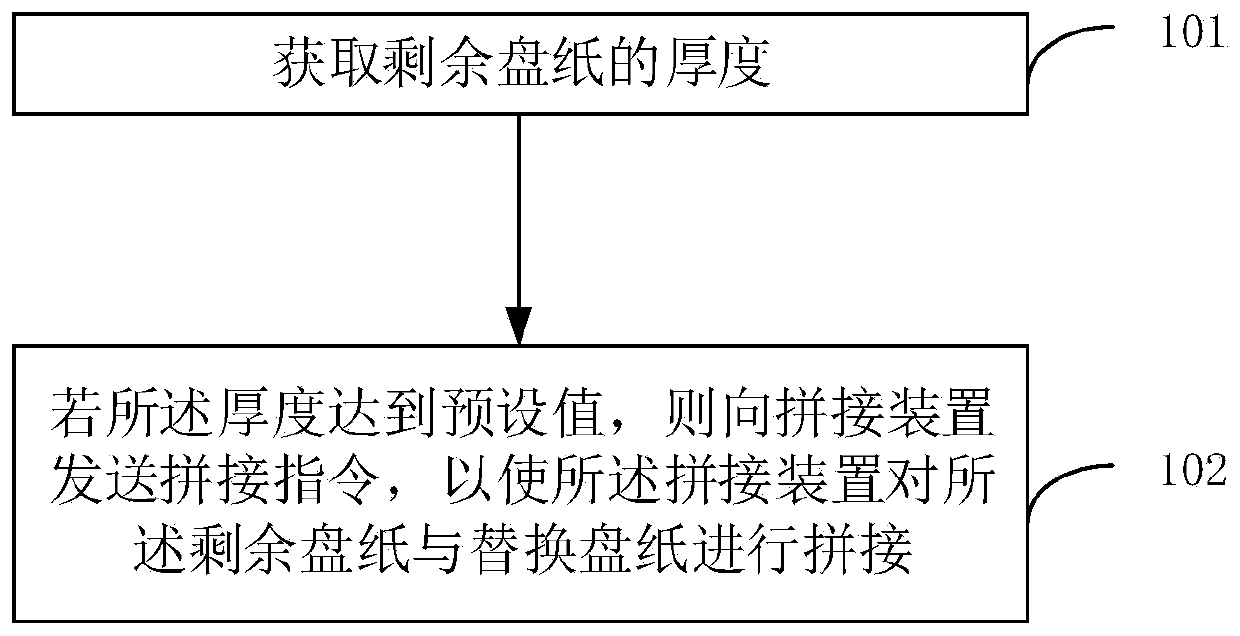

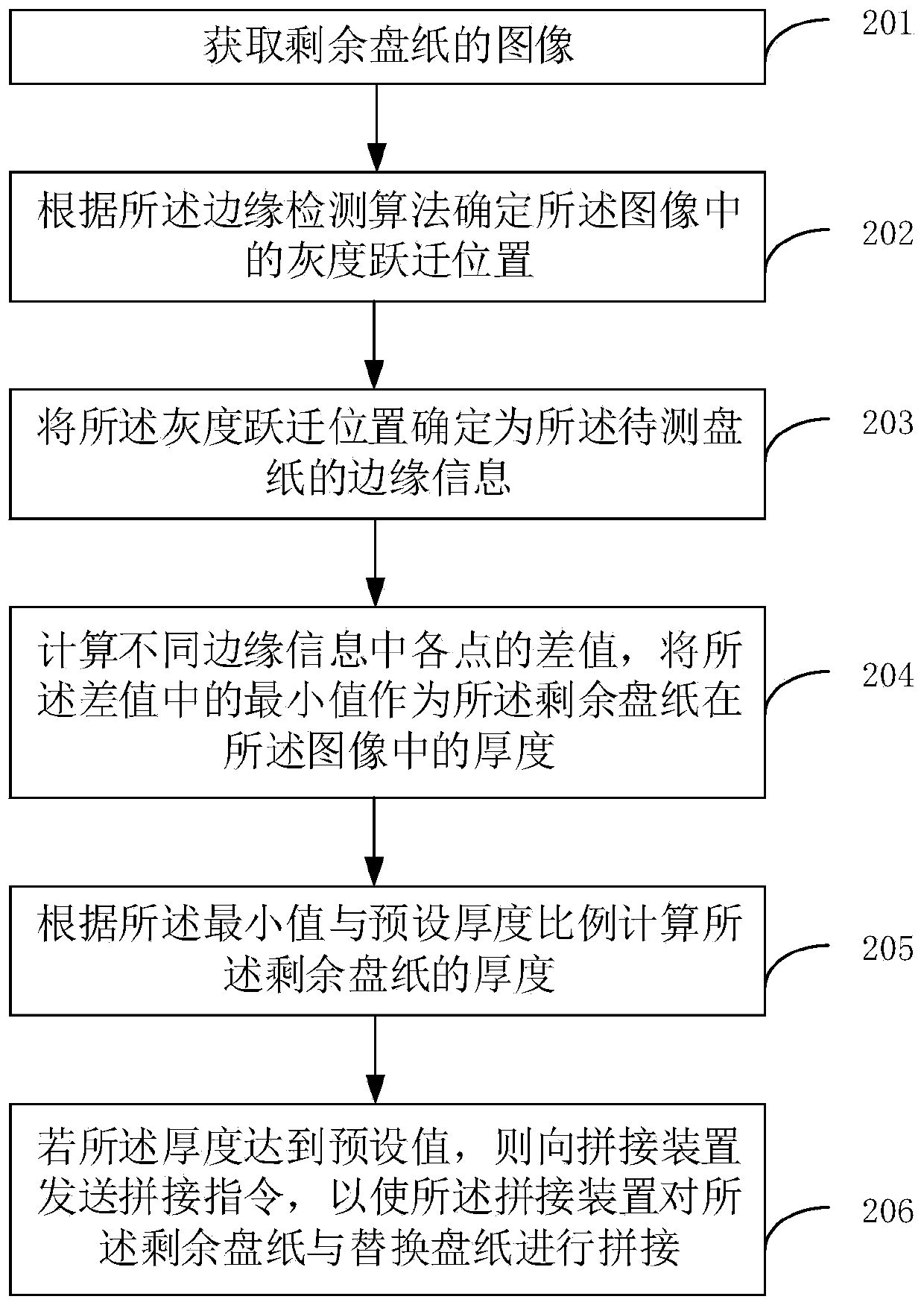

[0047] figure 1 It is a schematic flowchart of a splicing method for paper trays provided by an embodiment of the present invention. like figure 1 As shown, this embodiment provides a method for splicing paper trays, including:

[0048] Step 101, acquiring the thickness of the remaining paper tray.

[0049] In some embodiments, the thickness of the remaining coil can be obtained in various ways, for example, by acquiring an image of the remaining coil, determining the edge information of the remaining coil in the image according to an edge detection algorithm, and determining the edge information of the remaining coil according to the edge The information determines the thickness of the remaining paper coil; the thickness of the remaining paper coil can also be detected in real time by setting a thickness detection device.

[0050] Step 102: If the thickness reaches a preset value, send a splicing instruction to the splicing device, so that the splicing device splices the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com