Method for extracting grease from schizochytrium

A technology for extracting oil from Schizochytrium algae, applied in the biological field, can solve the problems of difficult ethanol recovery, poor economic results, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

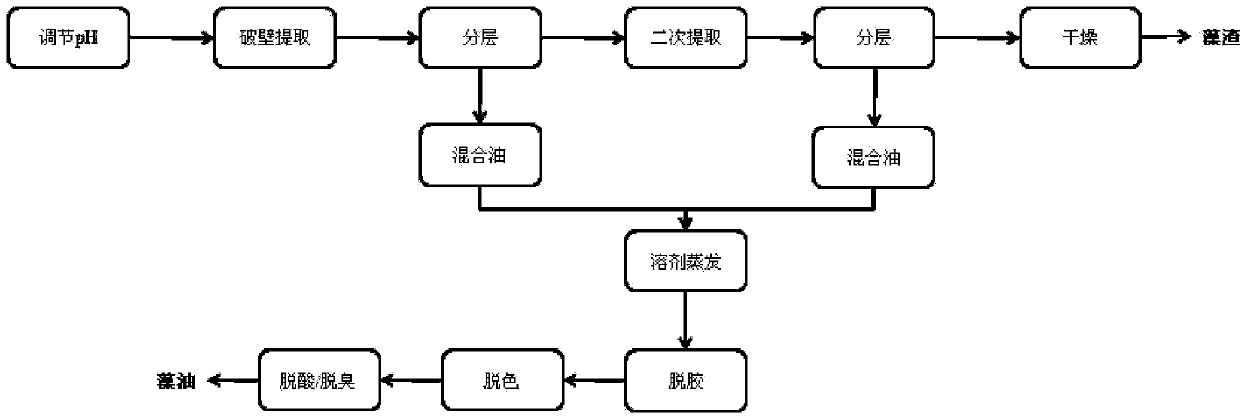

Method used

Image

Examples

Embodiment 1

[0062] After the Schizochytrium ampere tank is used to inoculate the slope, the liquid shake flask culture is carried out, and then it is transferred to 6m 3 Fermentation tank culture, the medium composition of which it belongs is: glucose 100-130g, yeast extract 15-30g, peptone 10-20g, potassium dihydrogen phosphate 2-4g, magnesium sulfate 1-3g, trace element compound liquid 8-11ml, The vitamin complex solution is 4-8ml, and the volume is fixed to 1L with 0.5× sea water; the 0.5× sea water is obtained by mixing 1 volume of sea water with 1 volume of water.

[0063] The preparation method of the trace element composite liquid is as follows: Na2·EDTA 6.0g, FeCl 3 ·6H 2 O 0.29g, H 3 BO 3 6.84g, MnCl 2 ·4H 2 O 0.86g, ZnCl 2 0.06g, CoCl 2 ·6H 2 O 0.026g, NiSO 4 ·6H 2 O0.052g, CuSO 4 ·5H 2 O 0.002g, NaMoO 4 ·2H 2 O 0.005g, dilute to 1L with water.

[0064] The preparation method of the vitamin composite liquid is as follows: 100 mg of vitamin B1, 0.5 mg of vitamin B7, 0.5 mg of vitamin...

Embodiment 2

[0074] After inoculating the sloping surface with a Schizochytrium ampere tank, it is cultured in a liquid shake flask, and then transferred to 6m 3 Fermentation tank culture, its medium composition is: glucose 100-130g, yeast extract 15-30g, peptone 10-20g, potassium dihydrogen phosphate 2-4g, magnesium sulfate 1-3g, trace element compound liquid 8-11ml, The vitamin complex liquid is 4-8ml, and the volume is fixed to 1L with 0.5× sea water; the 0.5× sea water is obtained by mixing 1 volume of sea water with 1 volume of water.

[0075] The preparation method of the trace element composite liquid is as follows: Na2·EDTA 6.0g, FeCl 3 ·6H 2 O0.29g, H 3 BO 3 6.84g, MnCl 2 ·4H 2 O 0.86g, ZnCl 2 0.06g, CoCl 2 ·6H 2 O 0.026g, NiSO 4 ·6H 2 O 0.052g, CuSO 4 ·5H 2 O 0.002g, NaMoO 4 ·2H 2 O 0.005g, dilute to 1L with water.

[0076] The preparation method of the vitamin composite liquid is as follows: 100 mg of vitamin B1, 0.5 mg of vitamin B7, 0.5 mg of vitamin B12, and dilute the volume to ...

Embodiment 3

[0086] After the Schizochytrium ampere tank is used to inoculate the slope, the liquid shake flask culture is carried out, and then it is transferred to 6m 3 Fermentation tank culture, its medium composition is: glucose 100-130g, yeast extract 15-30g, peptone 10-20g, potassium dihydrogen phosphate 2-4g, magnesium sulfate 1-3g, trace element compound liquid 8-11ml, The vitamin complex solution is 4-8ml, and the volume is fixed to 1L with 0.5× sea water; the 0.5× sea water is obtained by mixing 1 volume of sea water with 1 volume of water.

[0087] The preparation method of the trace element composite liquid is as follows: Na2·EDTA 6.0g, FeCl 3 ·6H 2 O 0.29g, H 3 BO 3 6.84g, MnCl 2 ·4H 2 O 0.86g, ZnCl 2 0.06g, CoCl 2 ·6H 2 O 0.026g, NiSO 4 ·6H 2 O0.052g, CuSO 4 ·5H 2 O 0.002g, NaMoO 4 ·2H 2 O 0.005g, dilute to 1L with water;

[0088] The preparation method of the vitamin composite liquid is as follows: 100 mg of vitamin B1, 0.5 mg of vitamin B7, 0.5 mg of vitamin B12, and dilute the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com