Pollution-free production technology of direct fast black G

A production process, non-polluting technology, applied in the direction of polyazo dyes, etc., can solve the problems of increasing product cost, environmental pollution, etc., and achieve the effect of reducing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

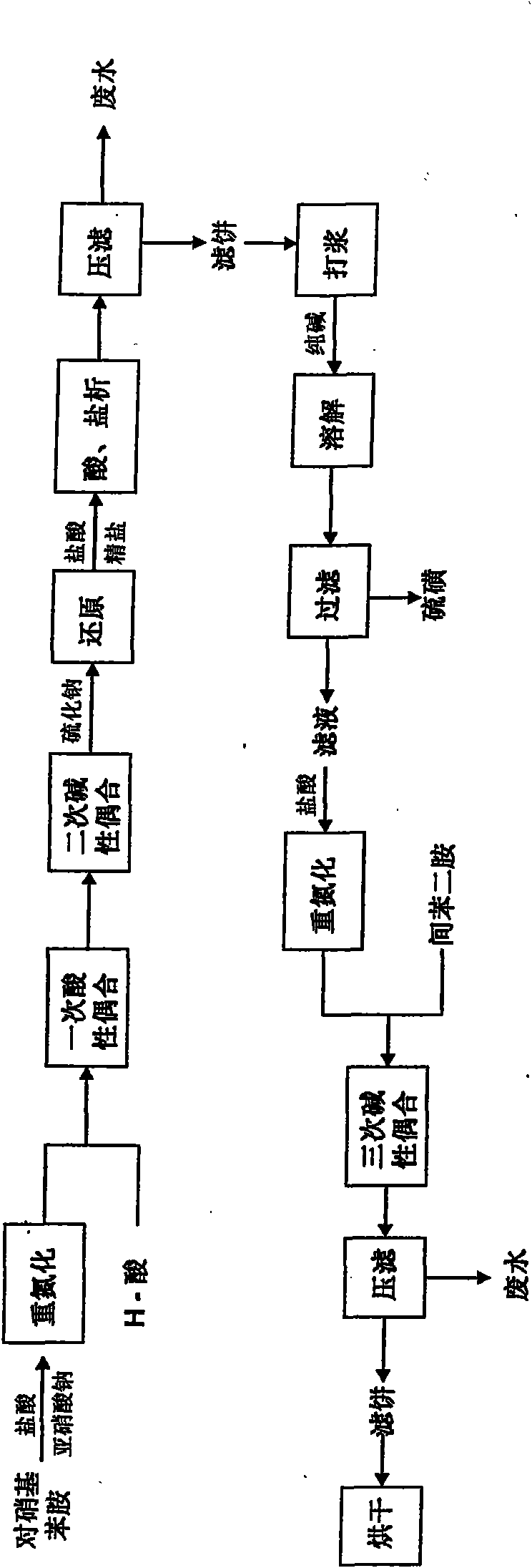

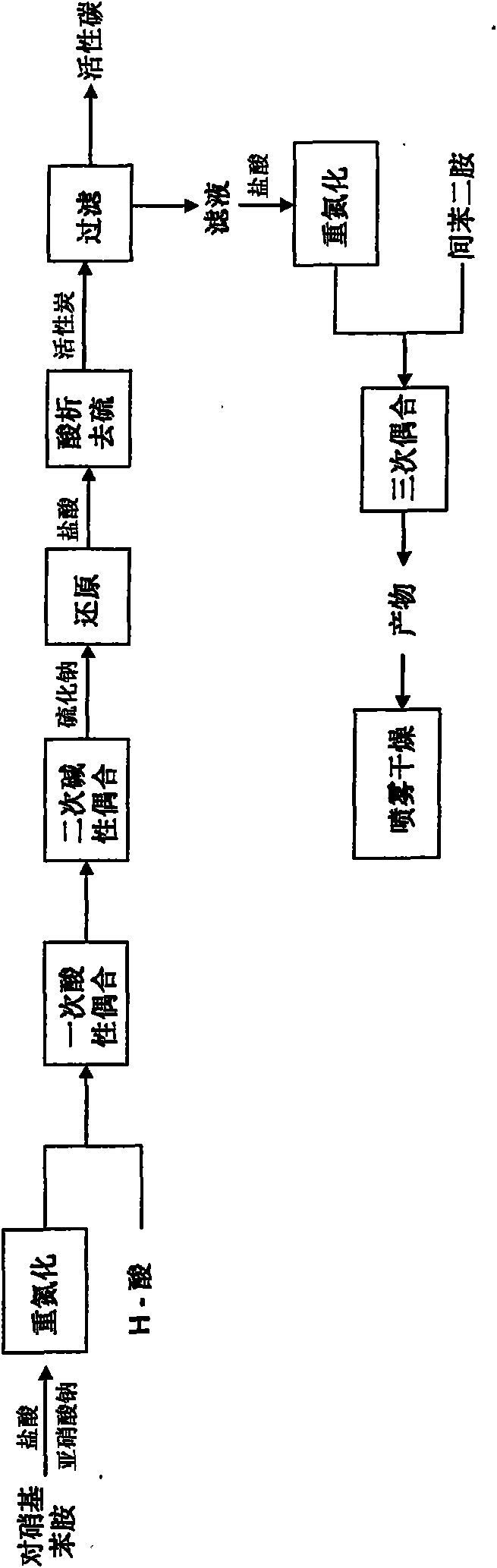

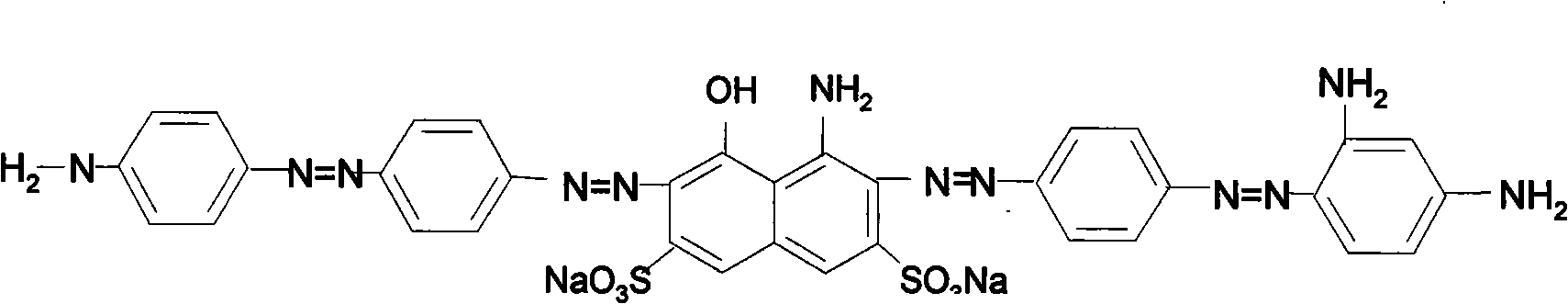

[0030] Below in conjunction with accompanying drawing and preferred embodiment, the specific implementation mode that provides according to the present invention is described in detail as follows:

[0031] like figure 2 Shown, a kind of pollution-free production technology of direct sunfast black G is characterized in that the implementation steps are as follows:

[0032] (1) Diazotization of p-nitroaniline:

[0033] Drain 50-55ml of water, add 13g of p-nitroaniline and 28g of 30% hydrochloric acid, stir for 2 hours, add ice cubes and cool down to t=0-5°C; quickly add 3.7g of sodium nitrite, and then spend 10-30 minutes on the liquid surface Then add 3.7g of sodium nitrite; after the addition, the temperature t=5~10°C, and it is detected as blue with Congo red test paper and starch potassium iodide test paper; continue to stir for 2~2.5 hours until all p-nitroaniline is dissolved as the reaction end point, Then add sulfamic acid to neutralize excess nitrous acid;

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com