CV carton transparent paper packaging machine automatic cigarette filling method and the device used

A technology for transparent paper and tobacco rods, applied in the direction of automatic packaging control, packaging of cigarettes, packaging, etc., can solve the problem of unqualified tobacco rod quality, save raw and auxiliary materials, reduce the cost and difficulty of transformation, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

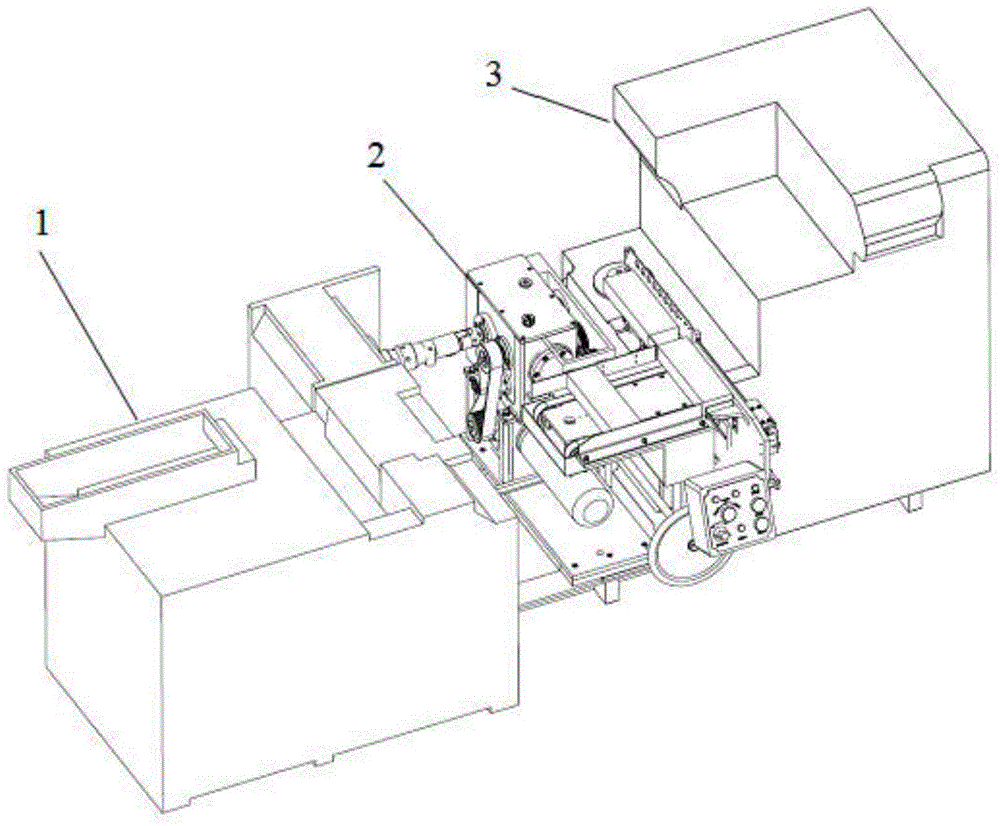

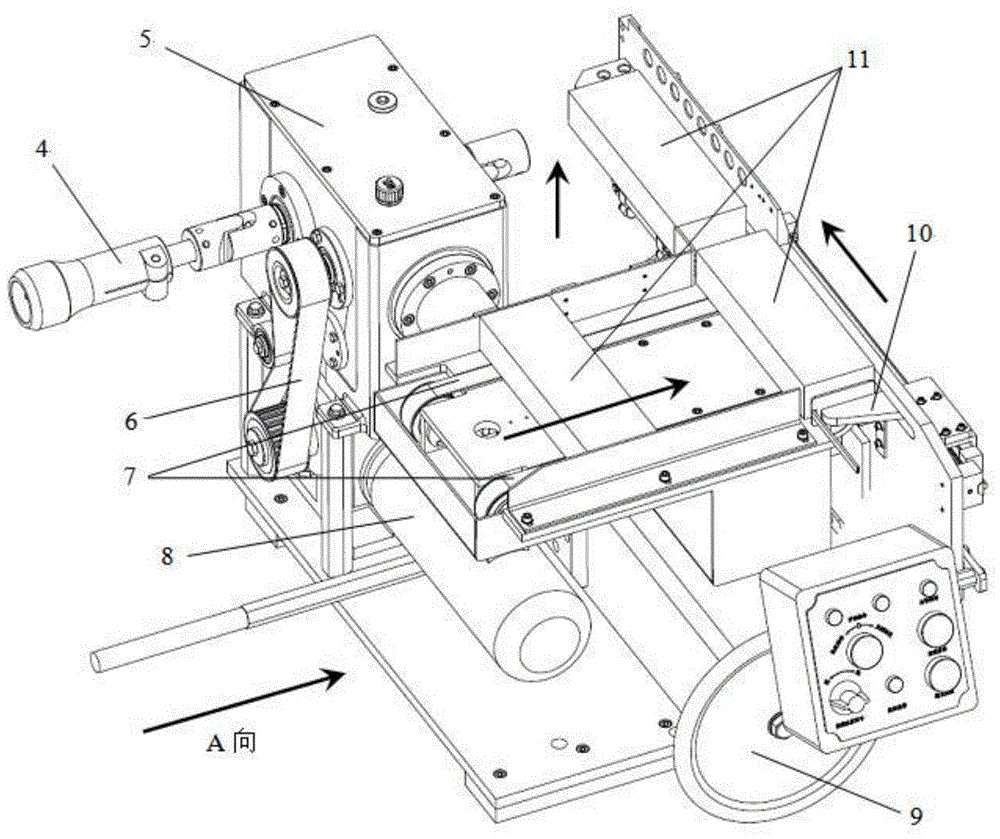

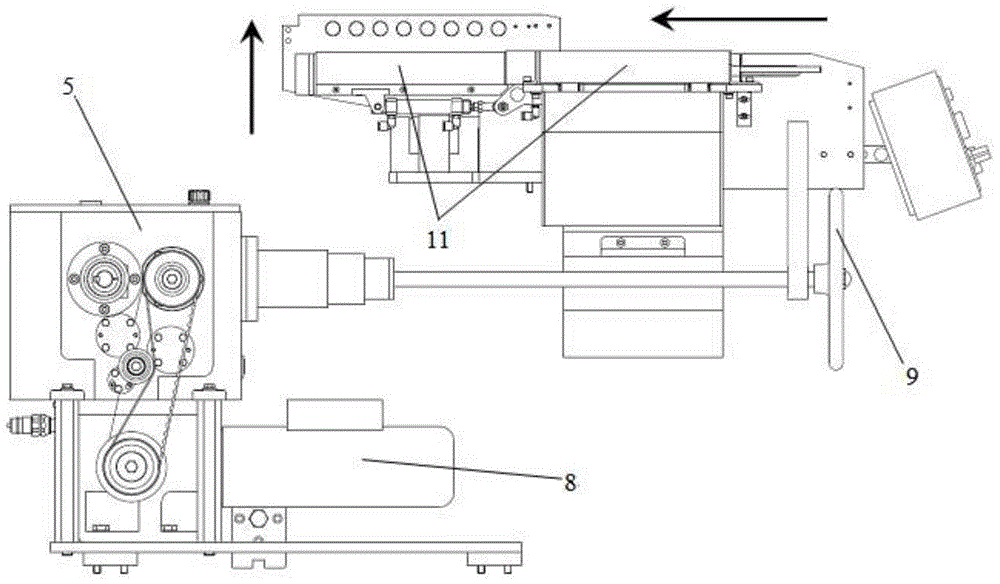

[0037] The following is attached with the manual Figure 1-8 , to introduce in detail the specific implementation of the method for automatically replenishing cigarette sticks of the CV carton transparent paper packaging machine and the device used in the present invention.

[0038] The specific steps of the method for automatically replenishing cigarette bars for the CV carton transparent paper packaging machine of the present invention are:

[0039] Step 1. When the tobacco rod is placed on the tobacco rod replenishing part of the automatic rod filling device, the detection sensor arranged in the detection hole 16 of the tobacco rod will detect the existence of the tobacco rod 11 .

[0040] Step 2. The clutch set between the CT carton packaging machine and the CV carton transparent paper packaging machine will cut off the drive shaft connection between the CT carton packaging machine and the CV carton transparent paper packaging machine, and will fill the strip The device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com