Hand-hold pliers body structure for mechanical coupling

A hand-held, mechanical technology, used in wire tensioning appliances, metal processing equipment, forming tools, etc., can solve the problems of low construction efficiency, high noise, and large consumption of fasteners, so as to improve work efficiency, The effect of saving raw and auxiliary materials and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

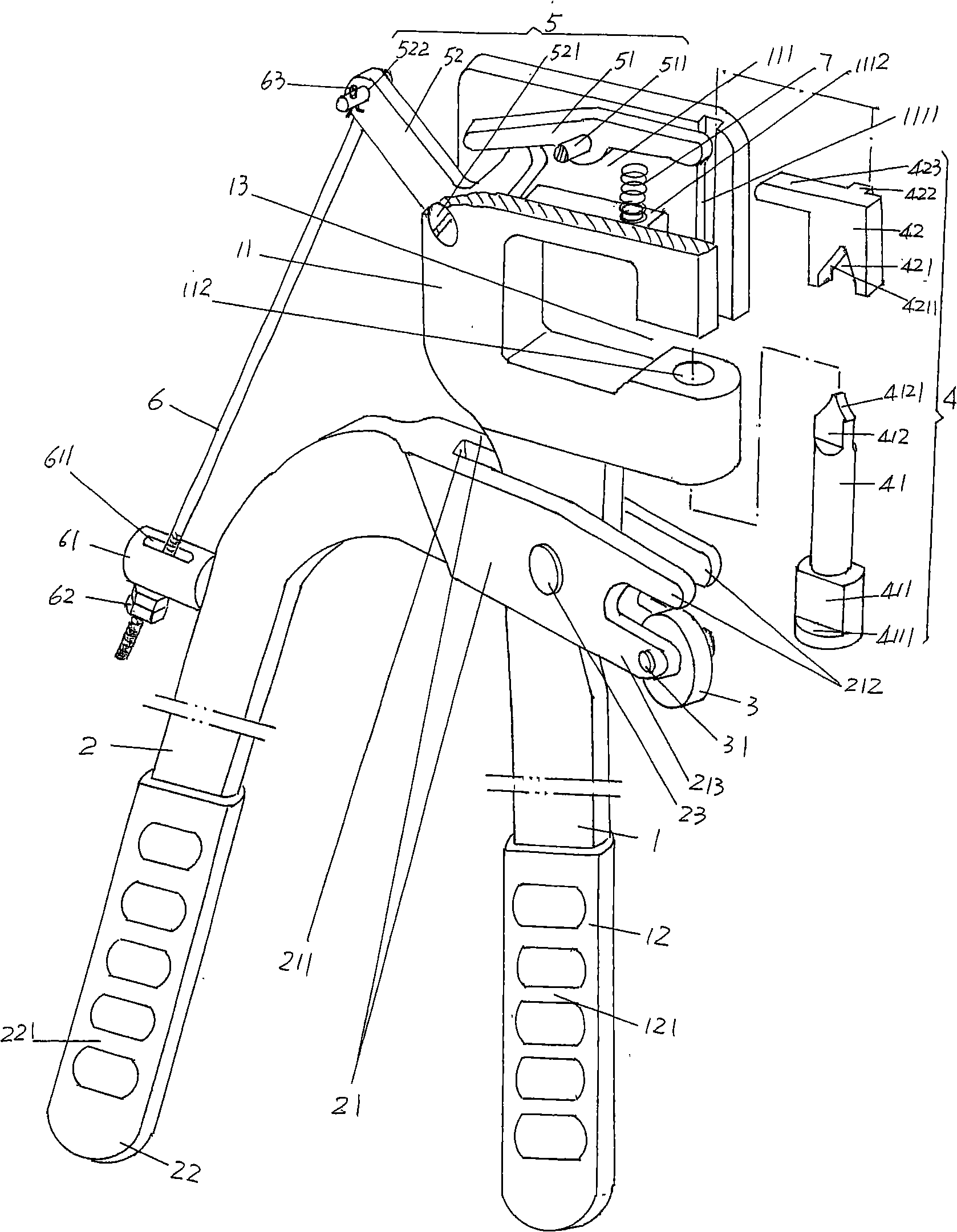

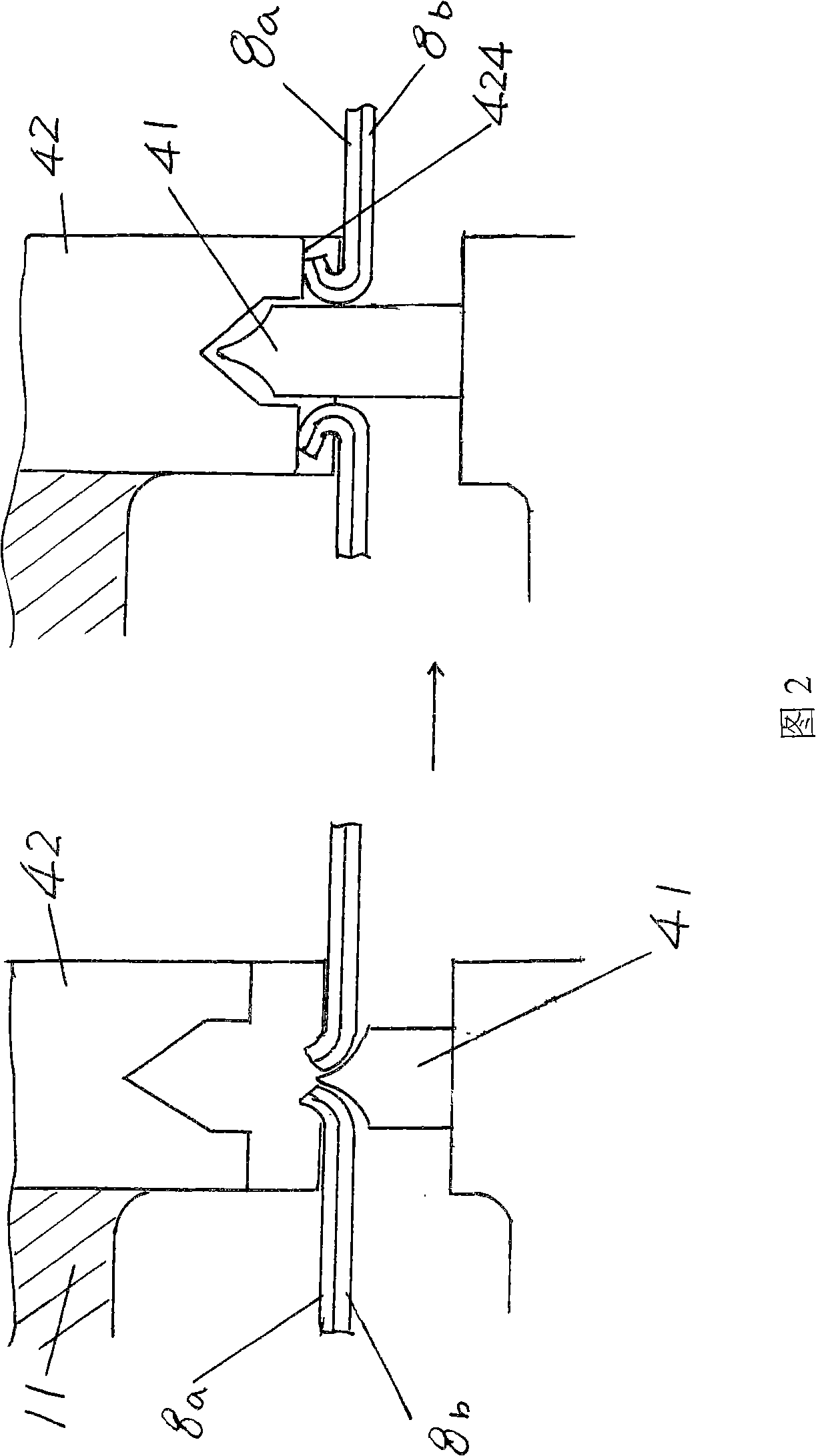

[0018] In order to make the examiners of the Patent Office, especially the public, further understand the structural features and beneficial effects of the present invention, the specific implementation of the present invention is described in detail as follows in conjunction with the accompanying drawings and examples, but the description of the examples does not constitute a review of the present invention. The limitation of the technical solution of the invention, and any form of equivalent replacement that is not substantial shall be regarded as the scope of the technical solution disclosed and claimed in the present invention.

[0019] please see figure 1 , a first handle 1 is given, considering the comfort when gripping in use, a non-metallic first sheath 12 is added to the lower part of the first handle 1, preferably but not limited to The material of the first sheath 12 is plastic or nylon or rubber. In this embodiment, plastic is selected, and a first anti-slip flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com