Novel fireproof cable

A fireproof cable, a new type of technology, applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of low electrical conductivity, large creep deformation, and increased contact resistance of hard pure aluminum wire materials for electrical purposes, and achieve energy saving Good effect, excellent fire performance, and the effect of reducing the diameter of the conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

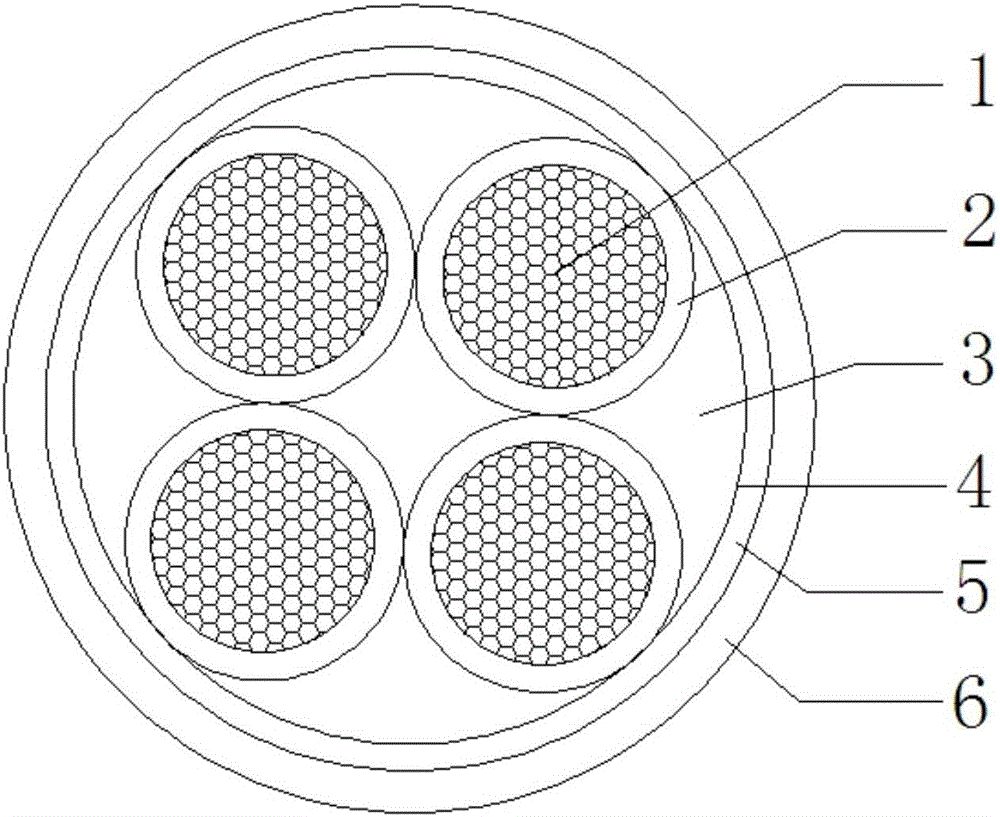

[0024] Such as figure 1 As shown, this embodiment includes a cable core, and the cable core is made by twisting several wire cores, and the wire core includes an aluminum alloy conductor 1. Preferably, the conductor 1 uses an aluminum alloy material instead of a copper conductor cable, which solves the problem of Electrically pure aluminum conductors are prone to oxidation, poor creep resistance, etc., and the material cost is low, and the economic performance is excellent; at the same time, conductor 1 adopts a stranded conductor structure with a high conductor compression coefficient, which can reduce the conductor diameter by 5%. Save more than 10% of raw material consumption in each process; aluminum alloy conductor 1 is extruded with ceramic low-smoke halogen-free polyolefin refractory insulating layer 2, which can effectively avoid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com