The second type of circular compact conductor structure and its stranding process

A compacted conductor, quasi-circular technology, used in cable/conductor manufacturing, conductors, non-insulated conductors, etc., can solve the problems of destroying metal lattice, increasing damage to metal surface, affecting metal conductivity, etc. coefficient, the effect of reducing the hardening coefficient, and increasing the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

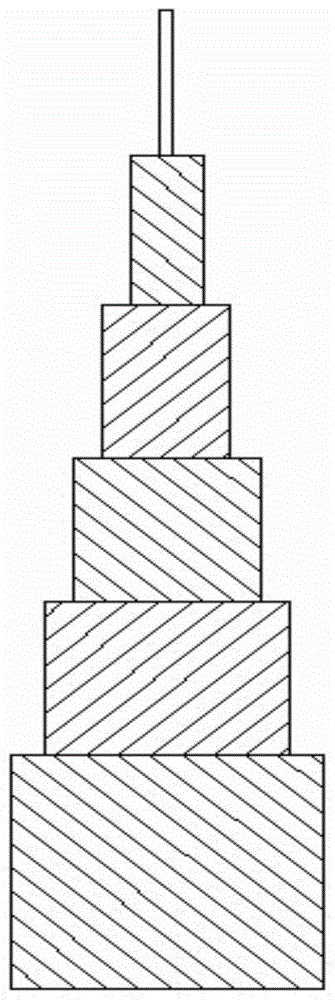

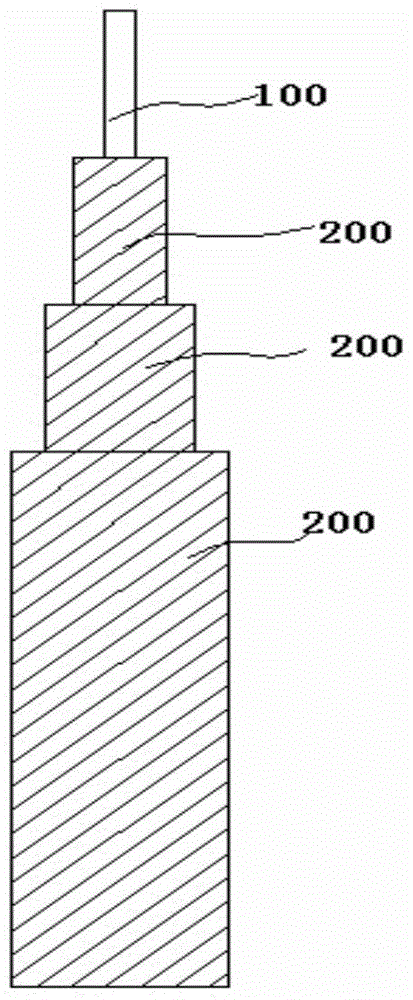

[0030] Reference figure 2 , When the total number of conductors is less than or equal to 19, the second type of circular compact conductor structure includes:

[0031] Several conductors 100 and monofilaments 200. The conductors 100 are normally twisted and divided into several conductor layers, and the conductor layers and the conductor layers are pressed tightly in layers. The monofilaments are arranged between the conductor layers, and all monofilaments 100 Use the same twisting;

[0032] Regular twisting: A twisting method in which the central conductor layer is a conductor. For example: 1+6, 1+6+12, 1+6+12+18, equivalent to core stranding, that is, the number of inner conductors is n, and the number of outer conductors is n+6 of the number of inner strands , And so on.

[0033] For the reason that the outer diameter of the inner conductor is reduced due to compaction, the number of outer conductors can be reduced by 1 to 2 conductors, which should also belong to the category ...

Embodiment 2

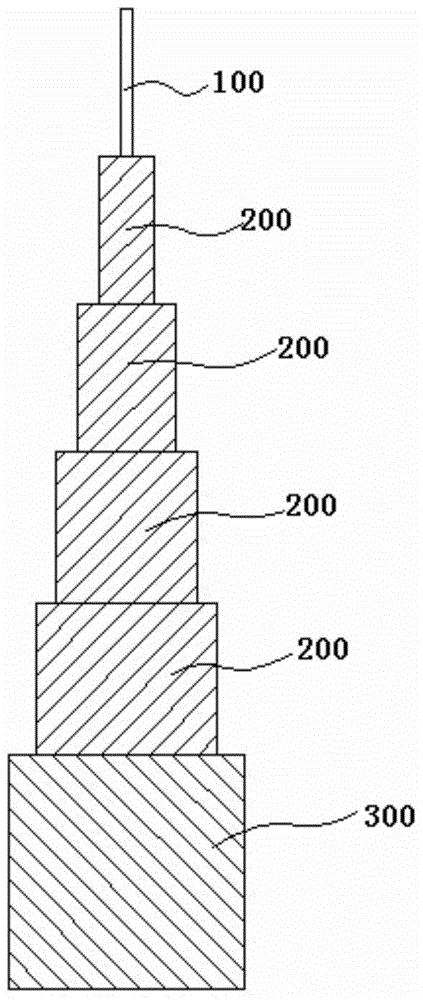

[0036] Reference image 3 , When the total number of conductors is greater than 19, the inner monofilament 200 is twisted in the same direction, the outermost monofilament 300 is twisted in the opposite direction, and the rest of the arrangement is the same as above.

[0037] figure 2 versus image 3 In the second type of circular compacted conductor structure shown, the pitch of each layer of monofilament stranded in the same direction is the same; and the pitch diameter ratio of the outermost layer of monofilament stranding is maintained at 11-13 times.

[0038] Above figure 2 as well as image 3 The disclosed stranding process of the second type of circular compacted conductor structure is as follows, including the following steps:

[0039] 1) Place the intermediate conductor on the rolling equipment, the monofilament winds the intermediate conductor, and the intermediate conductor after the winding is placed in a drawing mold for pressing;

[0040] 2) Place the intermediate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com