Power cable

A power cable, semi-conductive technology, used in power cables, power cables with shielding/conducting layers, cables, etc. The flatness of the conductor surface is not high, and the effect of increasing the utilization rate of the conductor cross-section, reducing the amount of partial discharge and easy manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

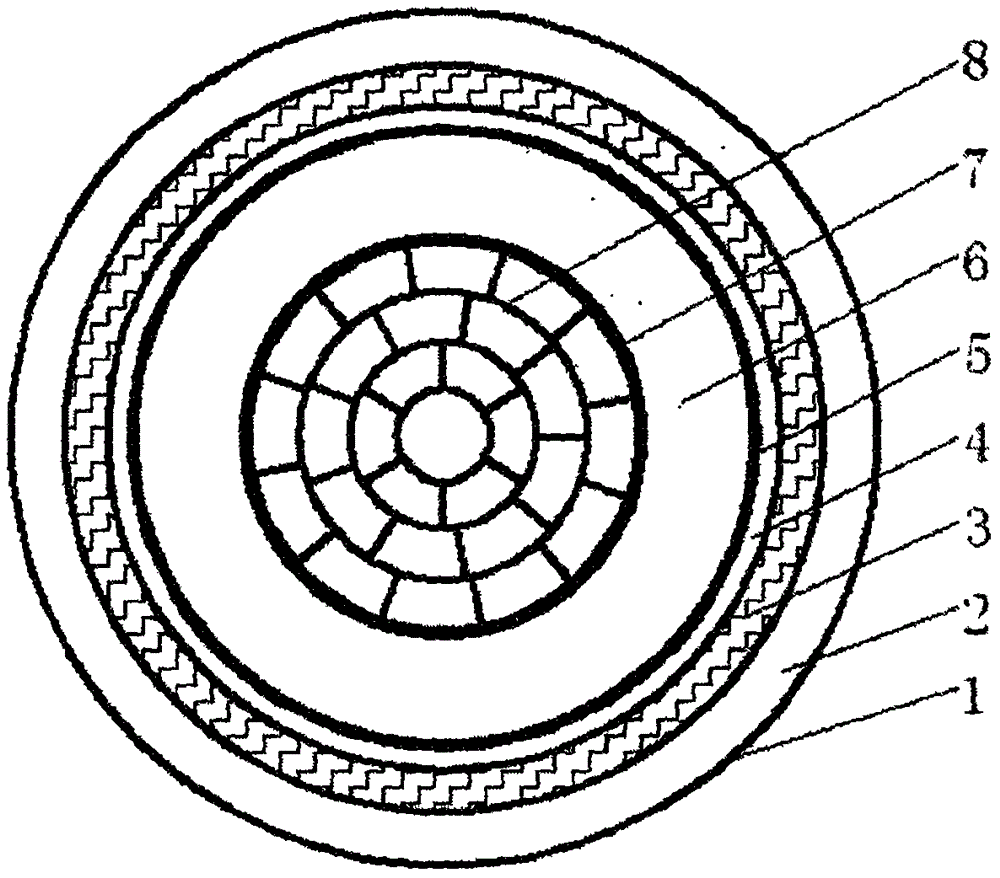

[0018] like figure 1 As shown, this embodiment describes a power cable, and the voltage level of the cable is 127 / 220kV 1×630mm2. The power cable, from outside to inside, is: outer semiconducting layer 1, non-metallic outer protective layer 2, metal protective layer 3, semiconducting resistance water buffer layer 4, insulating shielding layer 5, insulating layer 6, conductor shielding layer 7 , Conductor 8. The conductor 8 is arranged at the most center, the middle of the conductor 8 is a circular conductor, and the surrounding is a trapezoidal single-line conductor that cooperates with each other and surrounds the circular conductor. The conductor 8 is a copper conductor, the conductor shielding layer 7 is composed of a semiconductive wrapping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com