In-situ synthetic Mo2FeB2 particle reinforced iron-based composite lining plate material and preparation method thereof

A technology of particle reinforcement and in-situ synthesis, which is applied in the field of metal matrix composite materials, can solve the problems of reinforced phase particle deposition and partial agglomeration, easy generation of pores in composite materials, complex powder metallurgy process, etc., to achieve the suppression of secondary grain growth The effect of large size, simple and feasible preparation technology, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

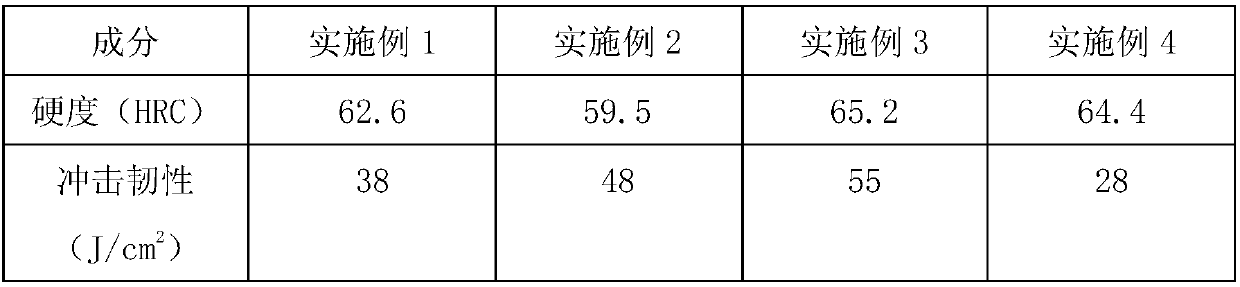

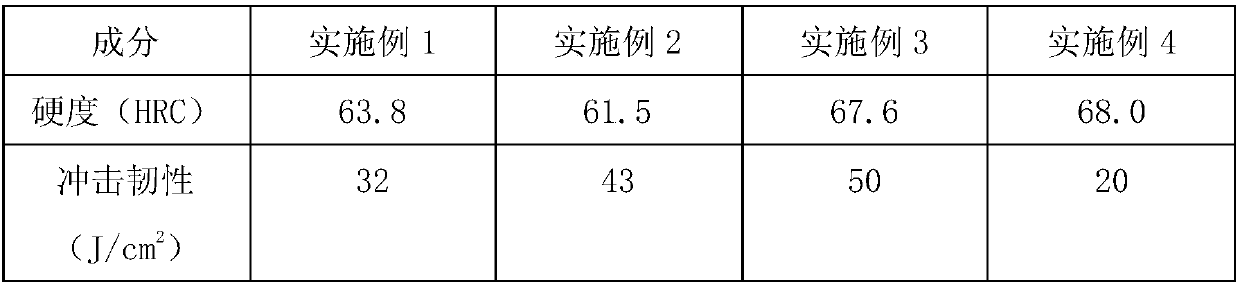

Embodiment 1

[0022] An in-situ synthesized Mo2FeB2 particle-reinforced iron-based composite lining material of the present invention has the following composition in weight percent: C 0.35%, Cr 0.5%, Mn 0.4%, Si 0.3%, FeMo60 15%, FeB 10% , S≤0.025%, P≤0.035%, and the rest is Fe.

Embodiment 2

[0024] An in-situ synthesized Mo2FeB2 particle reinforced iron-based composite liner material of the present invention has the following composition in weight percent: C 0.55%, Cr 0.2%, Mn 0.2%, Si 0.2%, FeMo60 3.7%, FeB 2.5% , S≤0.025%, P≤0.035%, and the rest is Fe.

Embodiment 3

[0026] A kind of in-situ synthesis Mo of the present invention 2 FeB 2 Particle-reinforced iron-based composite lining material, the composition by weight percentage is: C 0.45%, Cr 0.3%, Mn 0.3%, Si 0.25%, FeMo60 9%, FeB 6%, S≤0.025%, P≤0.035 %, the rest is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com