Battery for an electric drive of a motor vehicle

A motor vehicle and electric drive technology, which is applied in the direction of power devices, electric power devices, batteries, etc., can solve the problems of large structure and cost of battery casings, and achieve the effect of simplifying manufacturing technology and improving driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Examples described below are preferred embodiments of the present invention. In this exemplary embodiment, the individual components described of the embodiment are each individual features of the invention which can be regarded as independent of one another, which in each case also improve the invention independently of each other and which can then also be individually or independently Other combinations than those shown are considered to be part of the present invention. Furthermore, the described embodiments can also be supplemented by other described features of the invention.

[0033] In the figures, functionally identical elements are provided with the same reference symbols.

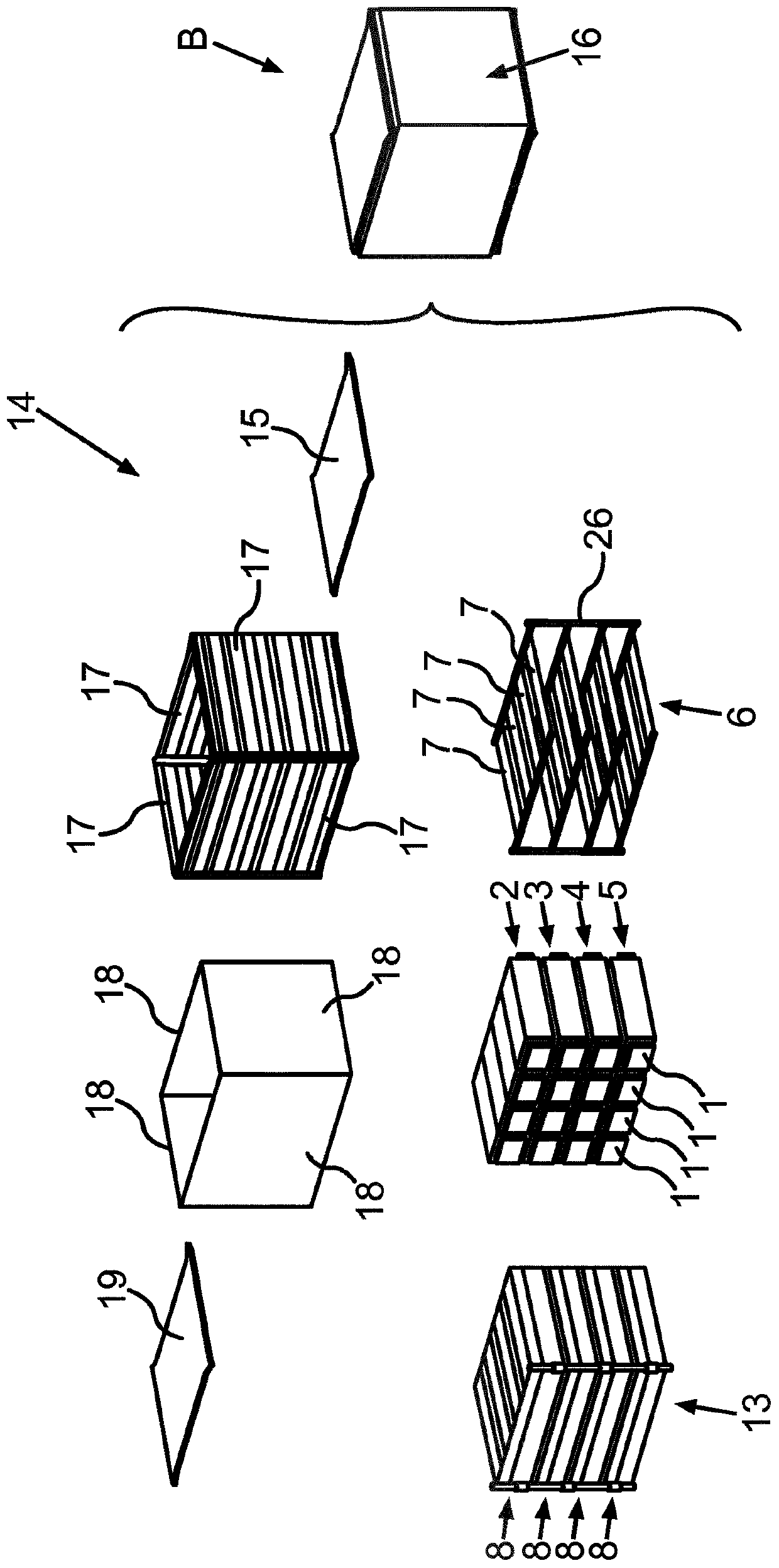

[0034] exist figure 1 , the main components of battery B, which are also shown assembled in the schematic perspective view on the right, can be seen in a perspective exploded view. The battery B here essentially comprises a plurality of battery modules 1 , of which in the present case, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com