Tensile aluminum stranded wire for electric power transmission

A power transmission and tensile technology, applied in the direction of power cables for overhead applications, power cables, power cables with shielding/conducting layers, etc., can solve the problem of low strength of galvanized steel strands and shorten the service life of wires , weak corrosion resistance and other problems, to avoid the freezing of water, improve the ability to prevent ice and snow, and achieve the effect of good fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

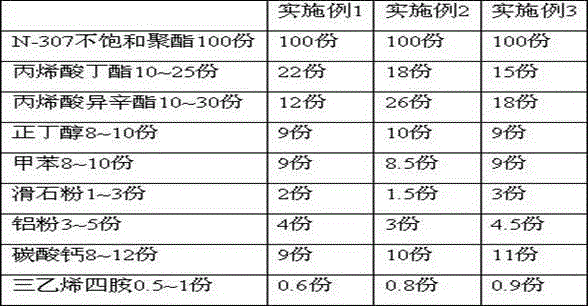

Embodiment 1~3

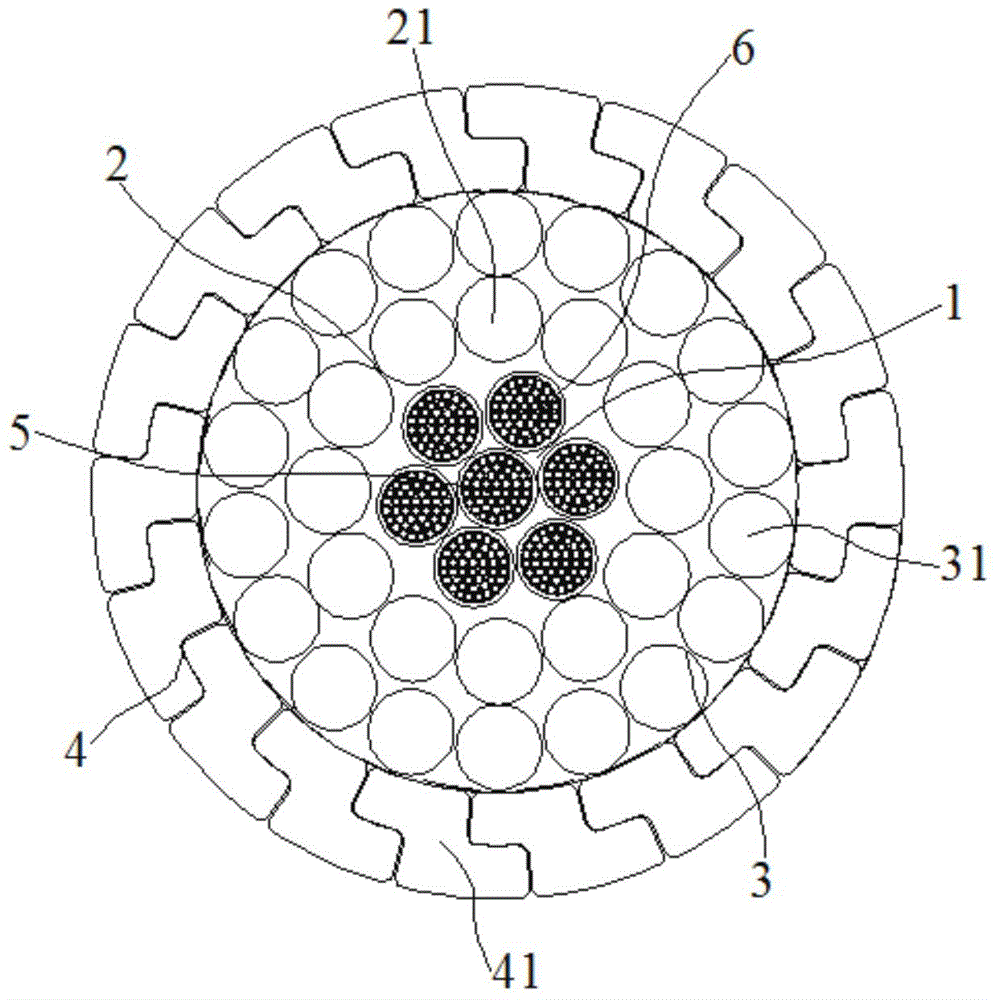

[0050] Embodiments 1 to 3: A tensile aluminum-type stranded wire for power transmission, including a stress unit 1 located in the center and a first aluminum alloy conductive layer 2 and a second aluminum alloy conductive layer twisted on the outer surface of the stress unit 1 in sequence. Aluminum alloy conductive layer 3;

[0051] The first aluminum alloy conductive layer 2 is formed by twisting 11 first aluminum single wires 21, and the second aluminum alloy conductive layer 3 is formed by twisting 18 second aluminum single wires 31;

[0052] The outer surface of the second aluminum alloy conductive layer 3 is successively twisted with an aluminum conductor cladding layer 4, and the aluminum conductor cladding layer 4 is formed by twisting 21 "Z" aluminum alloy conductors 41 with a "Z" cross section. ;

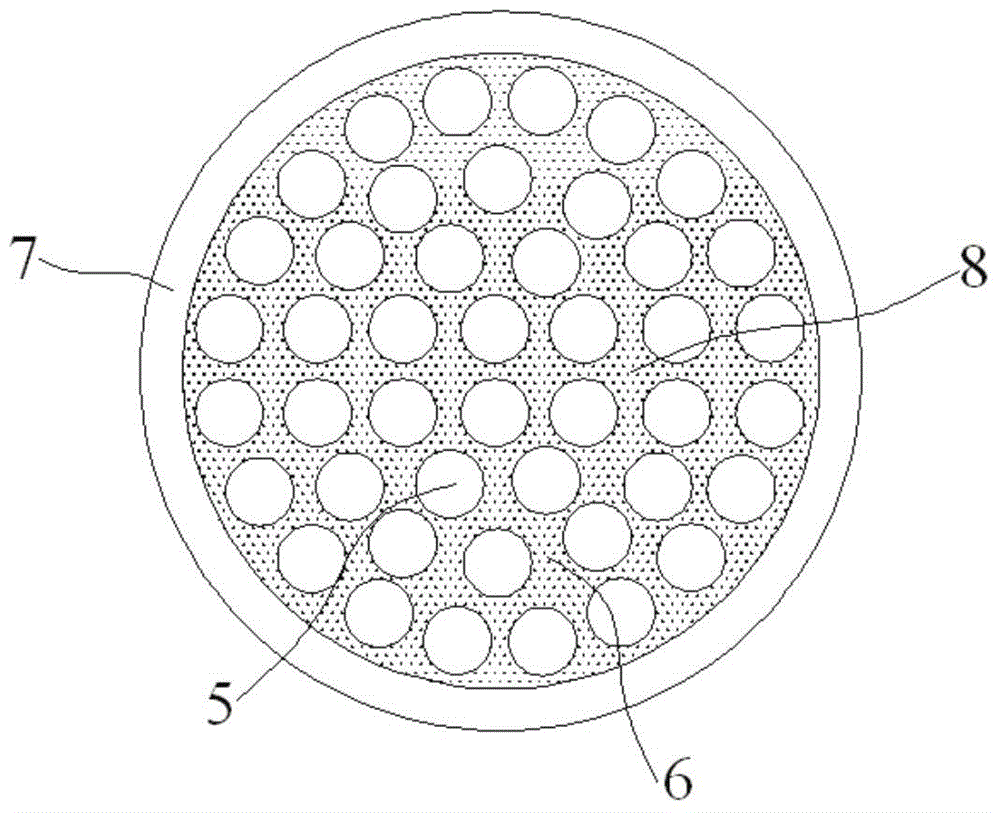

[0053] The stress unit 1 includes a first carbon fiber single wire 5 at the center and 6 second carbon fiber single wires 6 twisted on the outer surface of the first carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com