Anti-sliding electric power overhead aluminum stranded wire

一种电力架空、铝绞线的技术,应用在电路、绝缘电缆、电气元件等方向,能够解决镀锌钢绞线强度不高、缩短导线使用寿命、抗腐蚀性不强等问题,达到避免积水结冰、减小安装成本、固定性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

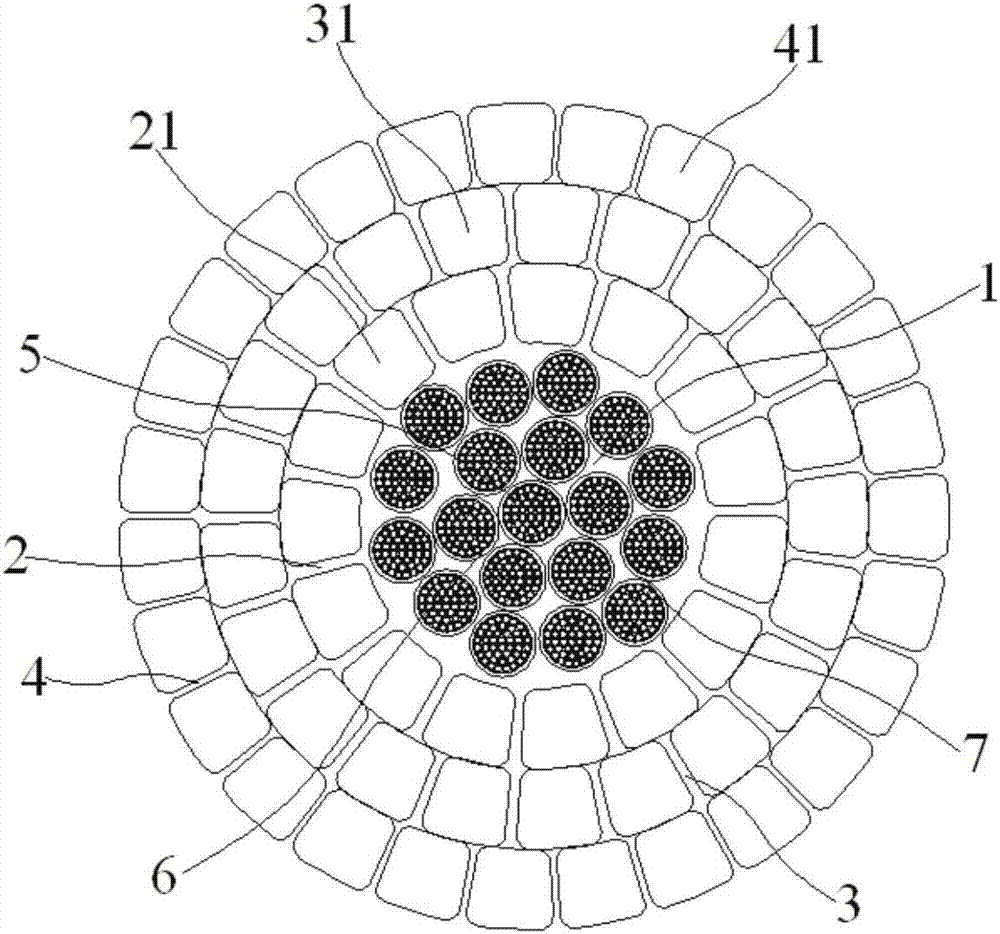

[0032] Embodiments 1 to 3: An anti-slip electric overhead aluminum stranded wire, including a stress unit 1 located in the center and a first aluminum conductive layer 2 and a second aluminum conductive layer 3 twisted on the outer surface of the stress unit 1 in sequence and a third aluminum conductive layer 4;

[0033] The first aluminum conductive layer 2 is formed by twisting 14 first trapezoidal duralumin wires 21, the second aluminum conductive layer 3 is formed by twisting 21 second trapezoidal duralumin wires 31, and the third The aluminum conductive layer 4 is formed by twisting 27 third trapezoidal duralumin wires 41; the cross sections of the first trapezoidal duralumin wire 21, the second trapezoidal duralumin wire 31 and the third trapezoidal duralumin wire 41 are trapezoidal;

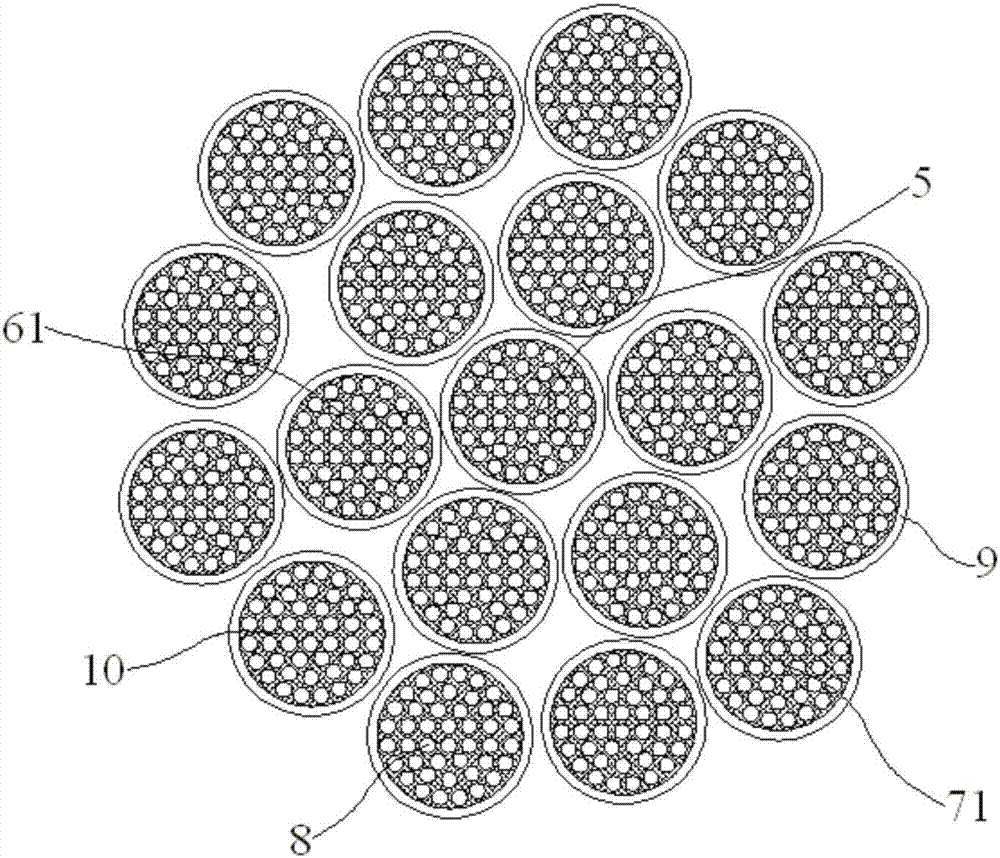

[0034] The stress unit 1 includes a first carbon fiber single wire 5 located in the center and an intermediate stress layer 6 twisted by six second carbon fiber single wires 61 twisted on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com