Aluminum or aluminum alloy conductor twisting and compressing process for cables

A kind of aluminum alloy conductor, compression process technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problem of increasing the friction resistance of conductors passing through a circular compression and stretching die, aggravating aluminum wire grain breakage, crystal lattice Distortion, failure to solve the problem of wire breakage from the source, to avoid heating and softening, reduce grain breakage, and reduce sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

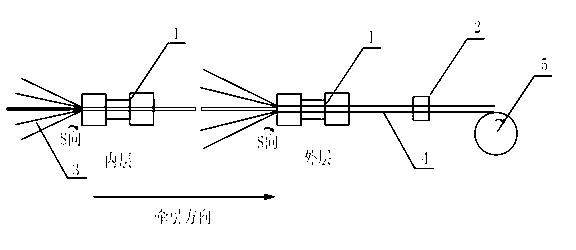

[0027] The stranding and pressing process of aluminum or aluminum alloy conductors for cables includes the steps of stranding the aluminum or aluminum alloy monofilaments 3 along the traction direction of the aluminum or aluminum alloy monofilament 3 and twisting the stranded aluminum or aluminum alloy The monofilament 3 is subjected to the step of pressing by the pressing roller, twisting once and forming a layer of twisted layer after pressing by the pressing roller, the latter twisted layer is formed by twisting on the basis of the previous twisted layer, and the last layer The twisting direction of the twisted layer and the penultimate twisted layer are the same.

[0028] In the present invention, the twisting direction of the twisted layers other than the penultimate twisted layer and the last twisted layer is opposite to the twisting direction of the last twisted layer.

[0029] In the present invention, the step of pressing the pressing roller is to use multiple round pressi...

Embodiment 2

[0036] The difference from Example 1 is that the same stranded wire layer of the penultimate layer of stranded layer is pressed by two round press roll molds 1; the same stranded wire layer of the last layer of stranded layer passes through first 4 round press roll molds 1 are pressed by the press roll, and then press the round mold 2 with a nano-diamond composite coating for compaction; the nano-diamond composite coating presses the round mold 2 from the last one The distance of the circular press roll mold 1 is 1 m.

[0037] When the present invention is in use, the aluminum or aluminum alloy monofilament 3 is twisted into the circular pressing roller mold 1 from left to right under the traction of the traction wheel 5. The aluminum or aluminum alloy conductor 4 needs to be pressed tightly in three layers At the same time, the twisting directions from the inside to the outside are: right-left-left, so that the aluminum or aluminum alloy conductor 4 not only bears the compressiv...

Embodiment 3

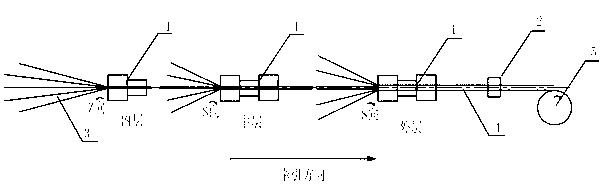

[0039] The difference from Examples 1 and 2 is that the same stranded wire layer of the penultimate layer of stranded layer is pressed by three round press roll molds 1; the same stranded wire layer of the last layer of stranded layer After pressing the rollers with 4 round roller molds 1, then pressing the round mold 2 with a nano-diamond composite coating; the nano-diamond composite coating presses the round mold 2 The distance of the last round press roll mold 1 is 1.5m.

[0040] When the present invention is in use, the aluminum or aluminum alloy monofilament 3 is twisted into the circular pressing roller mold 1 from left to right under the traction of the traction wheel 5. The aluminum or aluminum alloy conductor 4 needs to be pressed tightly in four layers When, the twisting directions from inside to outside are: left-right-left-left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com