led rotary built-in power fluorescent lamp

A fluorescent lamp, rotating technology, applied in the field of fluorescent lamps, can solve problems such as broken wires, unstable connection between the power board and the lamp board, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

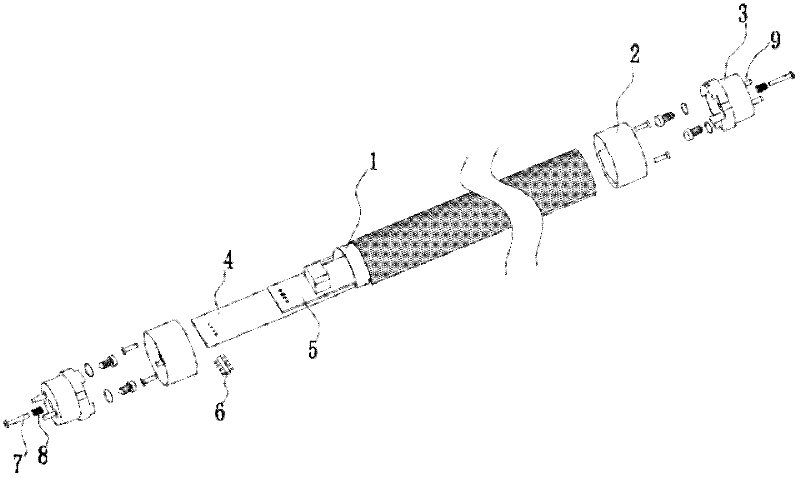

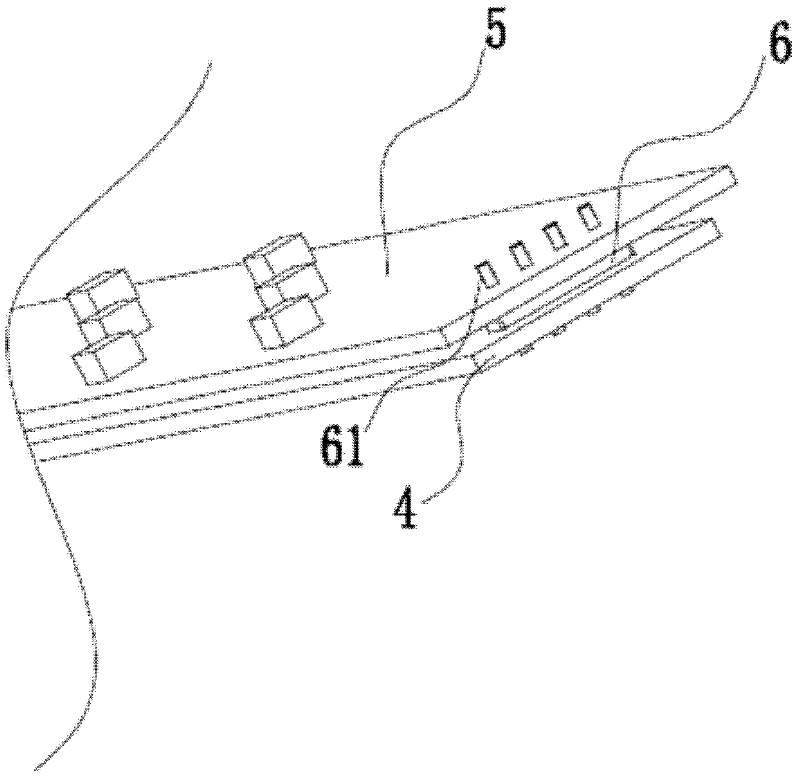

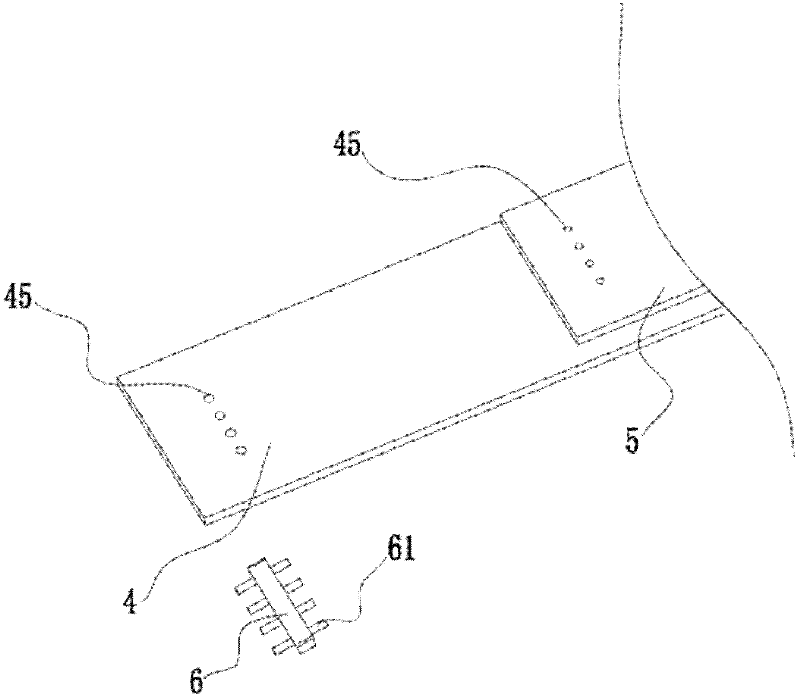

[0026] Such as figure 1 As shown, the LED rotary fluorescent lamp with built-in power supply provided by the present invention includes a lamp tube 1, a power supply assembly 5, a lamp panel assembly 4, two upper tube heads 3 and two lower tube heads 2, and each upper tube head 3 has a The lamp pins 9 are arranged symmetrically, the power supply assembly 5 and the lamp panel assembly 4 are located in the lamp tube 1, the power supply assembly 5 is located at the upper end of the lamp panel assembly 4, and the two lower tube heads 2 are respectively socketed at both ends of the lamp tube 1, each lower An upper pipe head 3 is nested outside the pipe head 2, such as figure 2 , image 3 As shown, between the power supply assembly 5 and the lamp panel assembly 4, a pin header 6 is installed to realize the electrical connection between the power supply assembly 5 and the lamp panel assembly 4. The pin header 6 is provided with four sets of pins 61 corresponding to conduction on bo...

Embodiment 2

[0032] Such as Figure 9 , Figure 10 , Figure 11 As shown, the general structure of the LED rotary fluorescent lamp with built-in power supply provided by this embodiment is consistent with that of Embodiment 1, but in order to further improve the safety of use, an insulating plate 14 is provided between the power supply assembly 5 and the lamp panel assembly 4, The lower end of the lamp panel assembly 4 is provided with a lampshade 10, and the lampshade 10 is fixed on the lamp tube 1; in order to improve the installation strength, a reinforcing rib 13 is provided on the partition 24 between the fixing hole 23 and the inner wall of the lower tube head 2; and In order to prolong the service life, the upper tube head 3 is provided with a tube head protective cover 12 that matches the lamp pin 9; a tube plug 11 is provided in the step mounting hole 33 of the upper tube head 3, and the tube plug 11 is located at the fastening position. outside of element 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com