Tunnel geotextile, waterproof cloth and secondary lining steel bar laying process

A technology of geotextile and waterproof cloth, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of low strength of the secondary lining, and achieve the effects of high strength, convenient retraction, and prevention of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

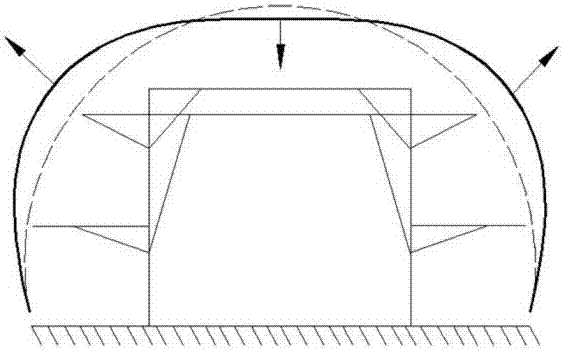

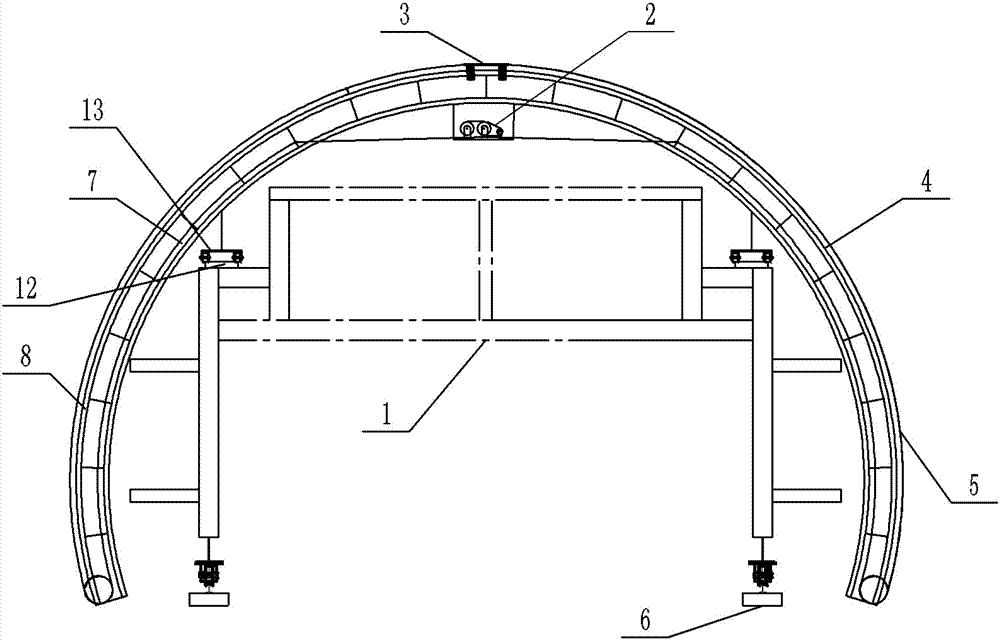

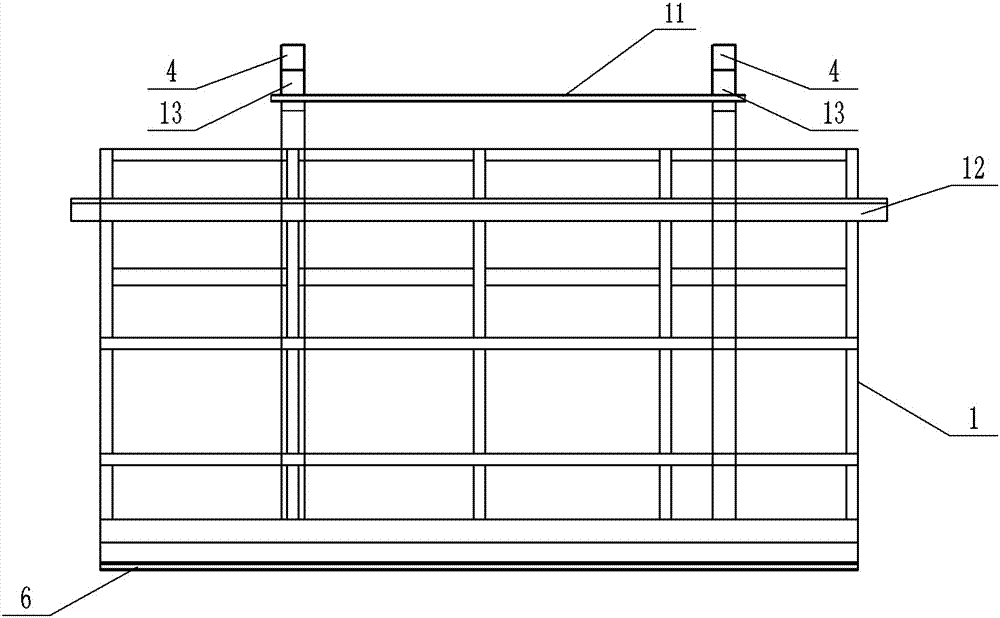

[0056] Embodiment: The paving process of the tunnel 27 geotextile waterproof cloth and the second lining steel bar 26 in this plan uses the geotextile waterproof cloth and the second lining steel bar 26 to lay the integrated platform 1, including the platform 1, which is used for hoisting and laying The arc-shaped container mechanism of the hoop steel bar 26, the arc-shaped slide rail 8 mechanism 4 for hoisting the longitudinal steel bar and laying waterproof cloth and geotextile, and the ejection mechanism for ejecting the hoop-to-steel bar 26.

[0057] The bottom of the stand 1 is equipped with a traveling mechanism 6, and track steel is installed under the traveling mechanism 6. The traveling mechanism 6 is driven by the motor 23 to realize the walking of the stand 1 on the track. A first hinge is welded on the excavation side of the platform 1 near the tunnel 27 , and the first hinge is located at the bottom of the platform 1 . The platform of platform 1 is longitudinally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com